Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Developed and Built Front-Mounted Beet Topper Machine

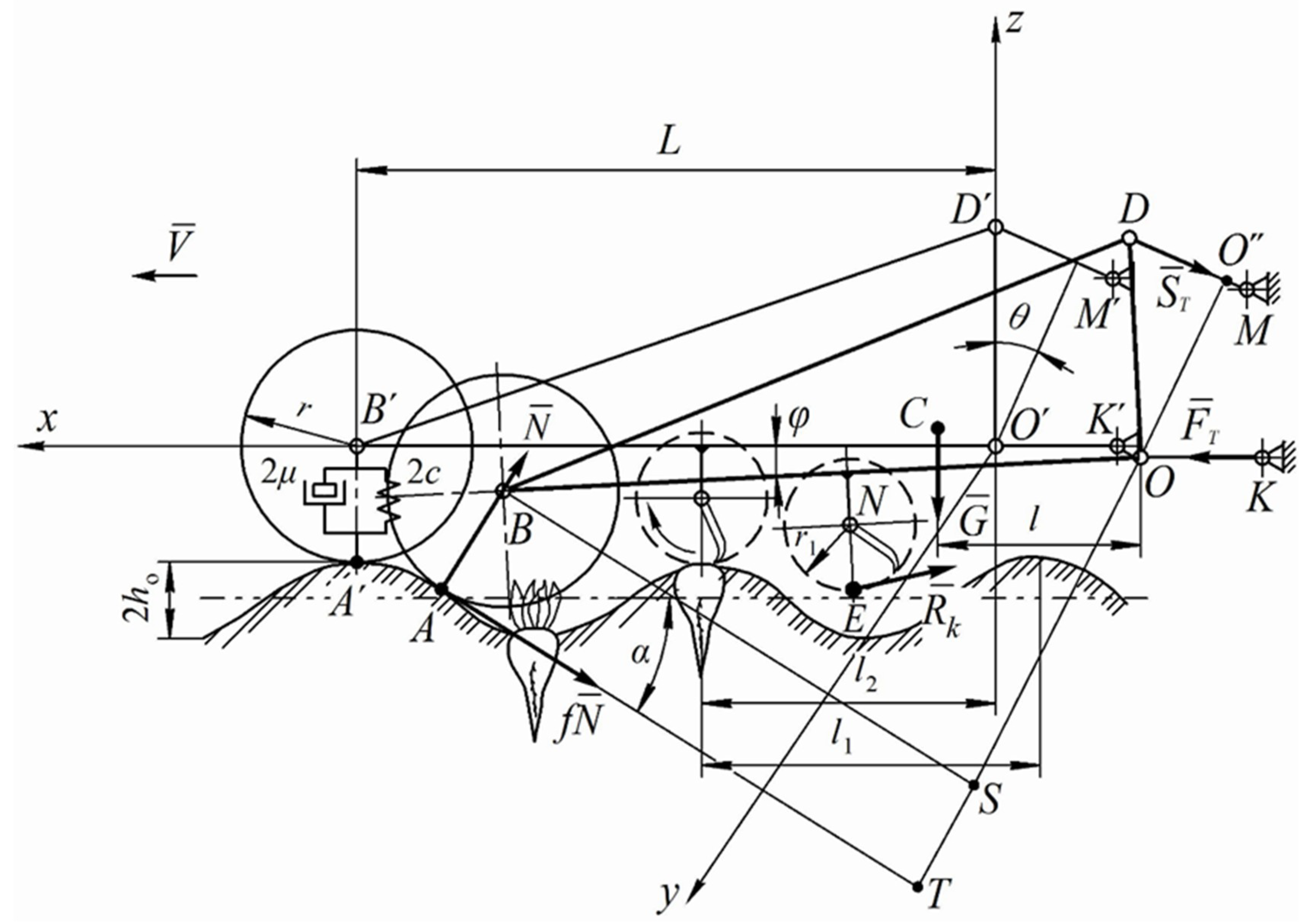

2.2. Theoretical Study of the Oscillations of the Front-Mounted Beet Topper Machine

- [m]: Soil surface height irregularity;

- [m]: Half of the maximum soil roughness;

- [m]: Horizontal distance between two consecutives soil points having the same characteristics;

- [m]: Is the current coordinate with [m s−1] forward speed of the front-mounted beet topper machine.

- (a)

- the normal soil reactions applied at point of contact between the feeler wheels and the soil;

- (b)

- the tangential soil reactions applied at point of contact between the feeler wheels and the soil (where is the rolling friction coefficient related to the relative movement between the feeler wheels and the soil surface);

- (c)

- the weight of the front-mounted beet topper machine applied in its center of gravity;

- (d)

- the cutting resistance reaction of beet tops applied at point ;

- (e)

- the traction tension in the upper beam of the mounting frame between the front-mounted beet topper machine and the tractor in the direction from point to point .

3. Results and Discussion

3.1. Mathematical Model

- : kinetic energy;

- : generalized force;

- : potential energy;

- : dissipative function (Rayleigh function);

- : generalized coordinate;

- : generalized speed.

- : horizontal distance between the front-mounted beet topper machine rotation axis and cutting device rotation axis;

- : horizontal distance between the front-mounted beet topper machine rotation axis and its center of mass.

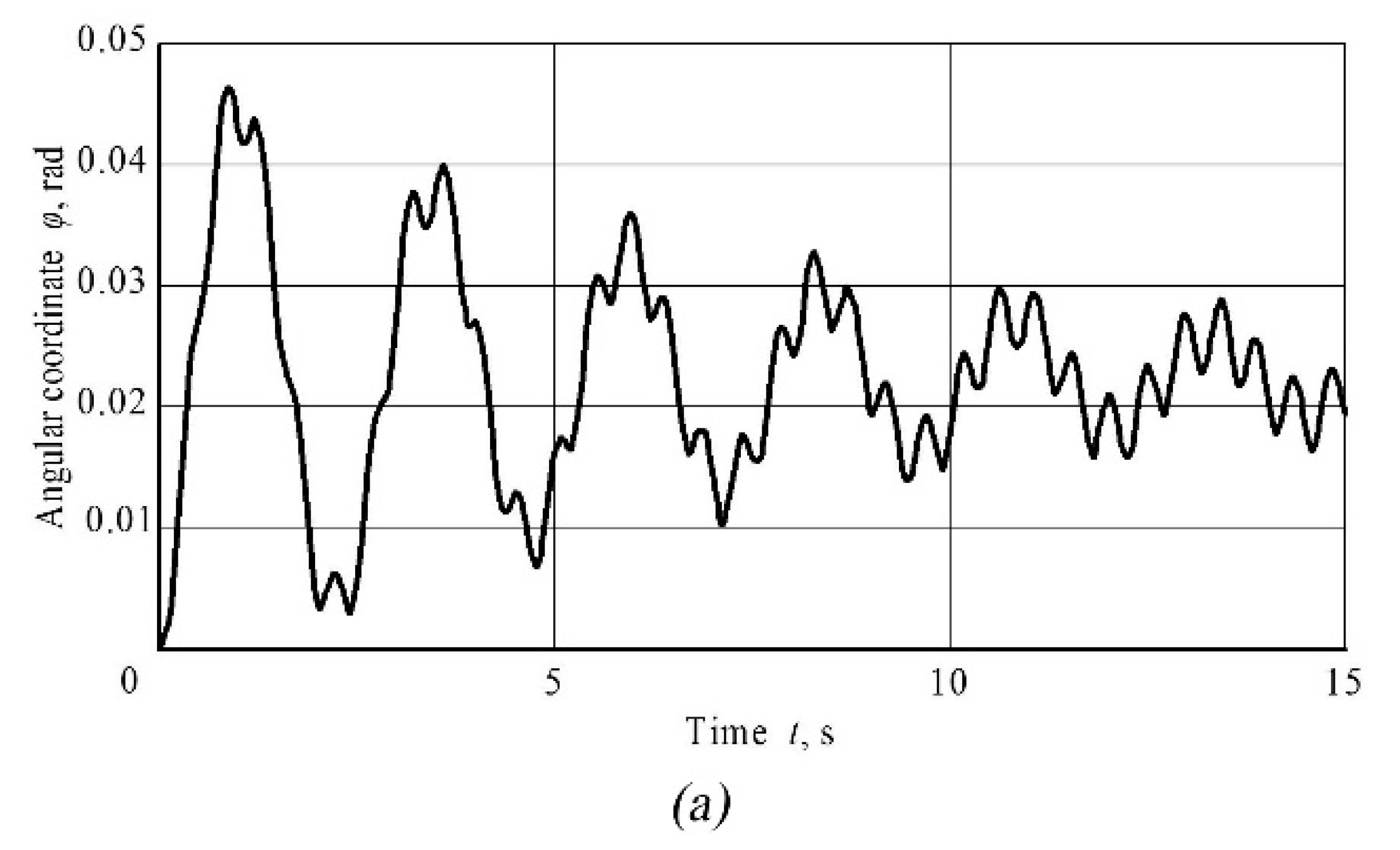

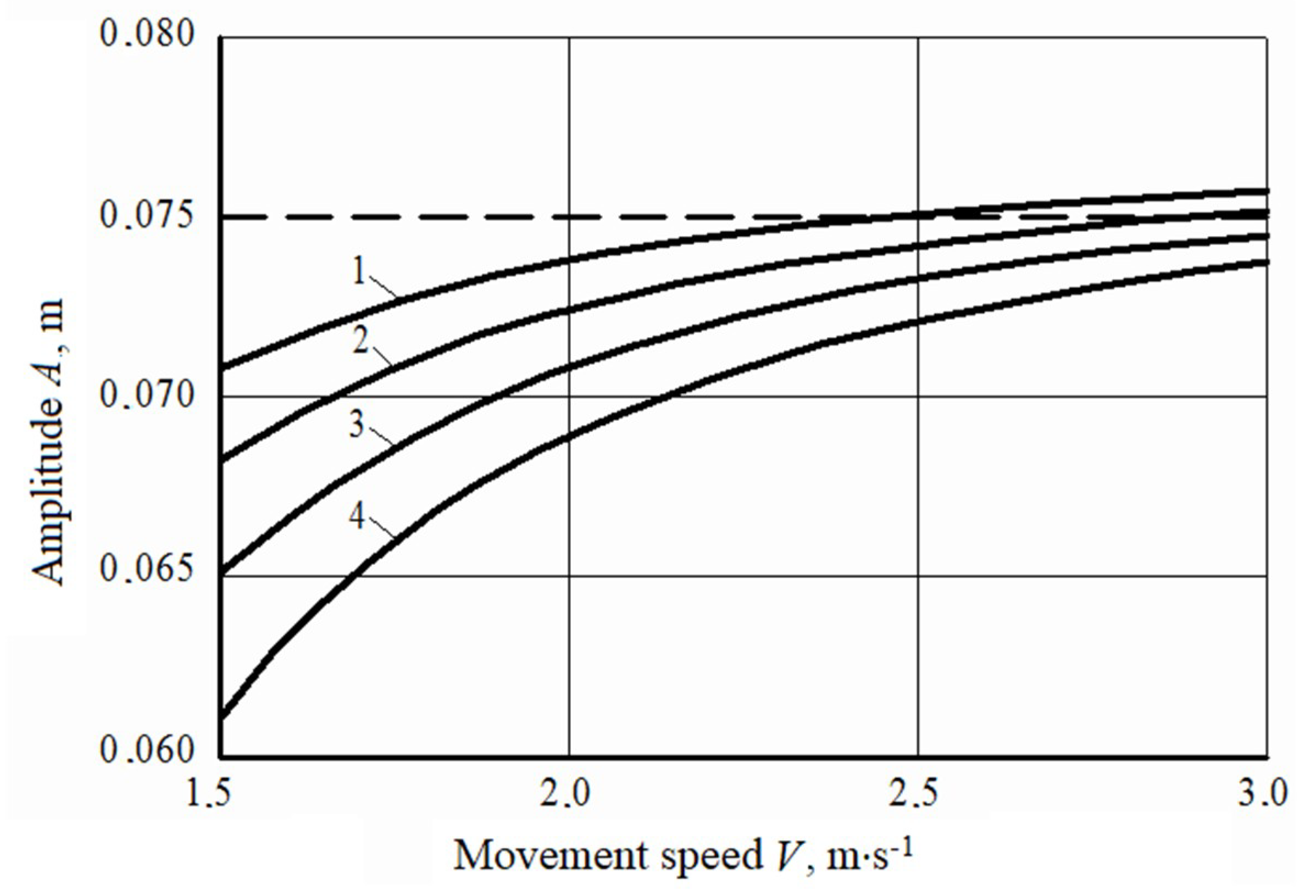

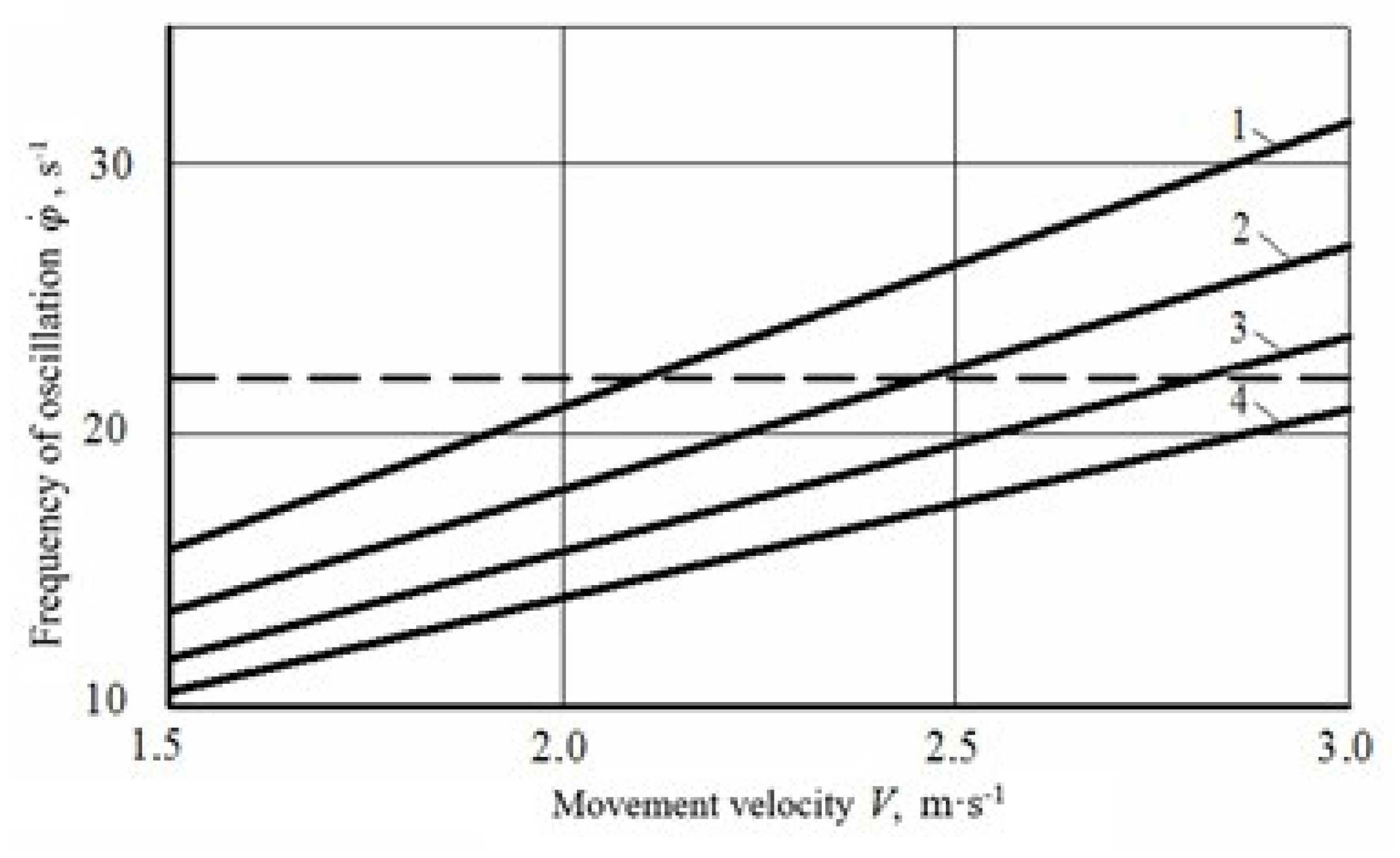

3.2. Numerical Simulation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

- : kinetic energy;

- : generalized force;

- : potential energy;

- : dissipative function (Rayleigh function);

- : generalized coordinate;

- : generalized speed.

- : kinetic energy of the translational motion;

- : kinetic energy of the rotational motion of machine frame around a point O;

- : kinetic energy of the vertical oscillations of the feeler wheels;

- : kinetic energy of rotational motion feeler wheels around their axes.

- [kg]: mass of the front-mounted beet topper machine;

- [m s−1]: forward speed of the center of mass of the machine;

- [kg m2]: moment of inertia of the frame the front-mounted beet topper machine relative to the axis (perpendicular to the longitudinal-vertical plane and passing through the point );

- [s−1]: angular speed of the frame of the machine;

- [kg]: mass of the feeler wheels;

- [m s−1]: speed of vertical oscillations of the feeler wheels;

- [s−1]: angular speed of the rotation of the frame of the machine;

- [kg m2]: moment of inertia of the two feelers wheels relative to their axis of rotation;

- [s−1]: angular speed of the feeler wheels.

- [m]: radius of the feeler wheels.

- [N m−1]: stiffness coefficient of the pneumatic tires of the feeler wheels;

- [m]: distance between the axis of suspension of the front-mounted beet topper machine (point ) and the axis of the feeler wheels (point ).

- [N s m−1]: damping coefficient of the pneumatic tires of the feeler wheels;

- [m]: distance between the axis of suspension of the front-mounted beet topper machine (point ) and the axis of the feeler wheels (point ).

- [N]: modulus of normal soil reactions of feeler wheels with the soil;

- [m]: arm of ;

- [N]: modulus of tangential soil reactions of feeler wheels with the soil;

- [m]: arm of ;

- [N]: modulus of cutting resistance reaction of beet tops;

- [m]: arm of ;

- [N]: modulus of weight of the front-mounted beet topper machine;

- [m]: arm of ;

- [N]: modulus of traction tension in the upper connection beam ;

- [m]: arm of ;

- Calling the slope of the tangent to the profile representing the soil roughness: ;

- calling the angle between the vertical part of the front-mounted beet topper machine frame and the normal to the upper connection beam

- remembering that [m] is the length of the frame of the machine;

- remembering that [m] is the height of the frame of the machine;

- remembering that = [m] is the radius of the beet top cutting device in (A13), considering Figure 2;

- ;

- ;

Appendix B

References

- Bulgakov, V.M. Beet Harvesting Machines; Agrarian Science: Kiev, Ukraine, 2011; 351p. [Google Scholar]

- Khvostov, V.A.; Reingart, E.S. Machines for Harvesting Root Crops and Onions (Theory, Design, Calculation); VISHOM: Moscow, Russia, 1995; 391p. [Google Scholar]

- Cerruto, E.; Manetto, G.; Santoro, F.; Pascuzzi, S. Operator Dermal Exposure to Pesticides in Tomato and Strawberry Greenhouses from Hand-Held Sprayers. Sustainability 2018, 10, 2273. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop Prot. 2017, 91, 34–48. [Google Scholar] [CrossRef]

- Manetto, G.; Cerruto, E.; Pascuzzi, S.; Santoro, F. Improvements in citrus packing lines to reduce the mechanical damage to fruit. Chem. Eng. Trans. 2017, 58, 391–396. [Google Scholar]

- Pascuzzi, S.; Cerruto, E. An innovative pneumatic electrostatic sprayer useful for tendone vineyards. J. Agric. Eng. 2015, XLVI:458, 123–127. [Google Scholar] [CrossRef]

- Bulgakov, V.; Adamchuk, V.; Ivanovs, S.; Ihnatiev, Y. Theoretical investigation of aggregation of top removal machine frontally mounted on wheeled tractor. Eng. Rural Dev. Jelgava 2017, 16, 273–280. [Google Scholar]

- Bulgakov, V.; Adamchuk, V.; Nozdrovický, L.; Ihnatiev, Y. Theory of Vibrations of Sugar Beet Leaf Harvester Front-Mounted on Universal Tractor. In Acta Technologica Agriculturae; Slovaca Universitas Agriculturae Nitriae: Nitra, Slovakia, 2017; Volume 20, pp. 96–103. [Google Scholar]

- Vasilenko, P.M. Introduction to Agricultural Mechanics; Agriculture: Kiev, Ukraine, 1996; 252p. [Google Scholar]

- Vasilenko, I.F. Theory of Cutting Machines Reaping Machines; Works of the VISHOM: Moscow, Russia, 1937; Volume 5, pp. 7–14. [Google Scholar]

- Reznik, N.E. The Theory of Cutting with a Blade and the Basics of Calculating the Cutting Apparatus; Mechanical Engineering: Moscow, Russia, 1975; 311p. [Google Scholar]

- Bosoy, E.S. Cutting Apparatus of the Harvesting Machines. Theory and Calculation; Mechanical Engineering: Moscow, Russia, 1967; 167p. [Google Scholar]

- Tatyanko, N.V. The calculation of the working bodies for cutting machines of sugar beet tops. Tract. Agric. Mach. 1962, 11, 18–21. [Google Scholar]

- Kolychev, E.I. On the choice of the design impact case in the study of the smoothness of the movement of tractors and agricultural machinery. Tract. Agric. Mach. 1976, 3, 9–11. [Google Scholar]

- Anifantis, A.S.; Pascuzzi, S.; Scarascia Mugnozza, G. Geothermal source heat pump performance for a greenhouse heating system. An experimental study. J. Agric. Eng. 2016, 47, 167–173. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Nadykto, V.; Ivanovs, S. A mathematical model of the plane-parallel movement of an asymmetric machine-and-tractor aggregate. Agriculture 2018, 8, 151. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Santoro, F.; Anifantis, A.S. Mathematical Model of the Plane-Parallel Movement of the Self-Propelled Root-Harvesting Machine. Sustainability 2018, 10, 3614. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The Effects of Pressure and Temperature on the Process of Auto-Ignition and Combustion of Rape Oil and Its Mixtures. Sustinability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Ivanovs, S.; Kaletnik, G.; Yanovich, V. Angular oscillation model to predict the performance of a vibratory ball mill for the fine grinding of grain. Biosyst. Eng. 2018, 171, 155–164. [Google Scholar] [CrossRef]

- Anifantis, A.S.; Colantoni, A.; Pascuzzi, S.; Santoro, F. Photovoltaic and Hydrogen Plant Integrated with a Gas Heat Pump for Greenhouse Heating: A Mathematical Study. Sustainability 2018, 10, 378. [Google Scholar] [CrossRef]

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Machine weight | N | 9480.0 | |

| Feeler wheels weight | N | 48.9 | |

| Machine moment of inertia relative to its rotation axis | Kg m2 | 60.0 | |

| Machine rotation axis-feeler wheels axis distance Machine frame length | m | 1.800 | |

| Machine frame height | OD | m | 0.580 |

| Angle between the vertical frame beam and the perpendicular to the upper suspension beam | rad | 0.087 | |

| Machine rotation axis-cutting device axis horizontal distance | m | 1.100 | |

| Machine rotation axis-center of mass horizontal distance | m | 0.800 | |

| Forward speed of the tractor | V | m s−1 | 1.5–3.0 |

| Cutting device radius | m | 0.365 | |

| Feeler wheels radius | m | 0.300 | |

| Feeler wheels pneumatic tires stiffness coefficient | N m−1 | 4000 | |

| Feeler wheels pneumatic tires damping coefficient | N s m−1 | 150 | |

| Half of the maximum soil roughness | m | 0.040 | |

| Horizontal distance between two consecutives soil irregularities | m | 0.700 | |

| Soil-feeler wheels friction coefficient | - | 0.30 | |

| Cutting resistance reaction of three beet tops | N | 300 | |

| Normal reaction component between feeler wheels and soil | N | 4117 | |

| Tangential reaction component between feeler wheels and soil | N | 1235 | |

| Traction tension in the upper beam of the mounting frame | N | 209 | |

| Traction tension in the lower beam of the mounting frame | N | 1750 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulgakov, V.; Pascuzzi, S.; Anifantis, A.S.; Santoro, F. Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting. Energies 2019, 12, 2774. https://doi.org/10.3390/en12142774

Bulgakov V, Pascuzzi S, Anifantis AS, Santoro F. Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting. Energies. 2019; 12(14):2774. https://doi.org/10.3390/en12142774

Chicago/Turabian StyleBulgakov, Volodymyr, Simone Pascuzzi, Alexandros Sotirios Anifantis, and Francesco Santoro. 2019. "Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting" Energies 12, no. 14: 2774. https://doi.org/10.3390/en12142774

APA StyleBulgakov, V., Pascuzzi, S., Anifantis, A. S., & Santoro, F. (2019). Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting. Energies, 12(14), 2774. https://doi.org/10.3390/en12142774