Control Technology of Soft Rock Floor in Mining Roadway with Coal Pillar Protection: A case study

Abstract

:1. Introduction

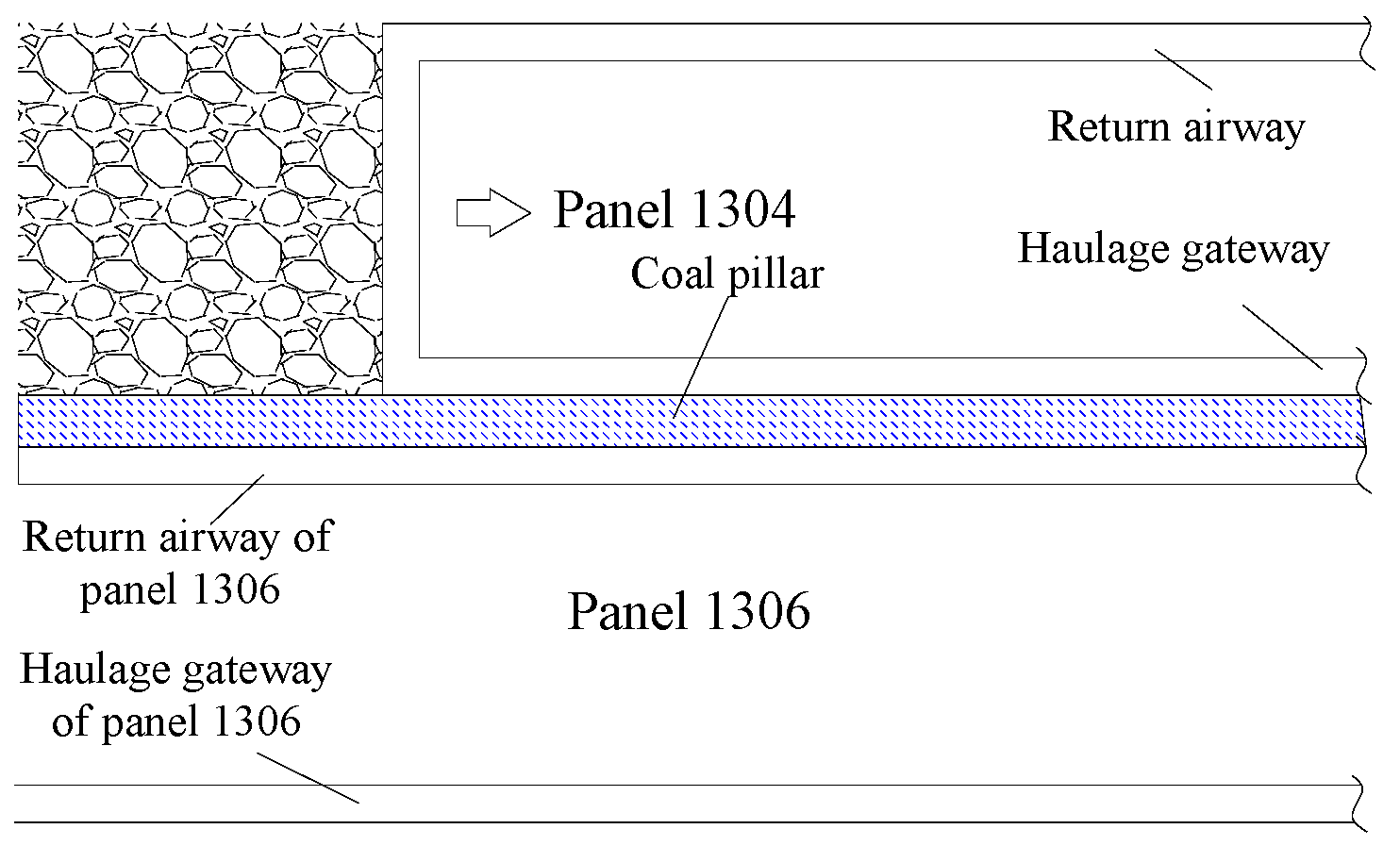

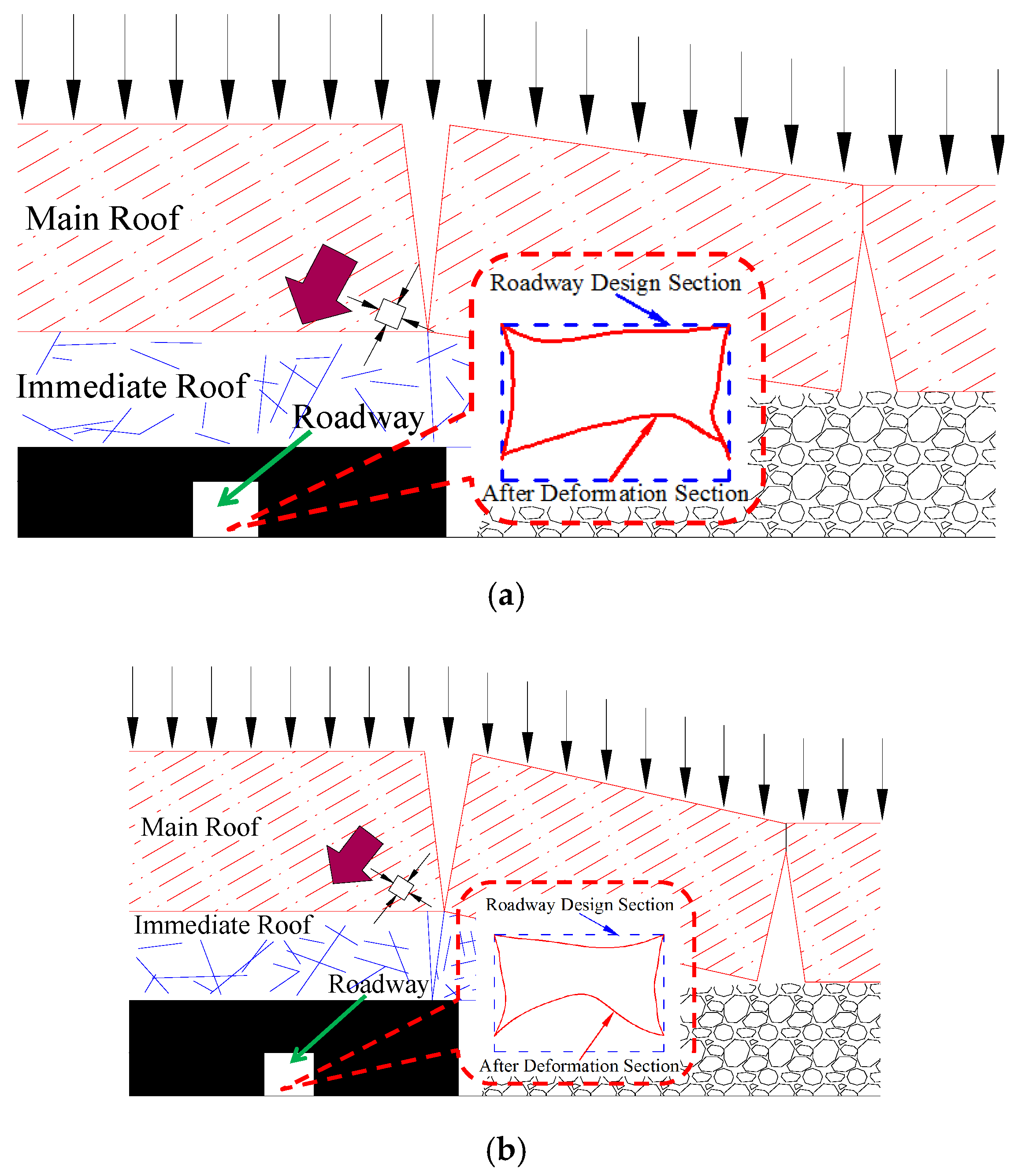

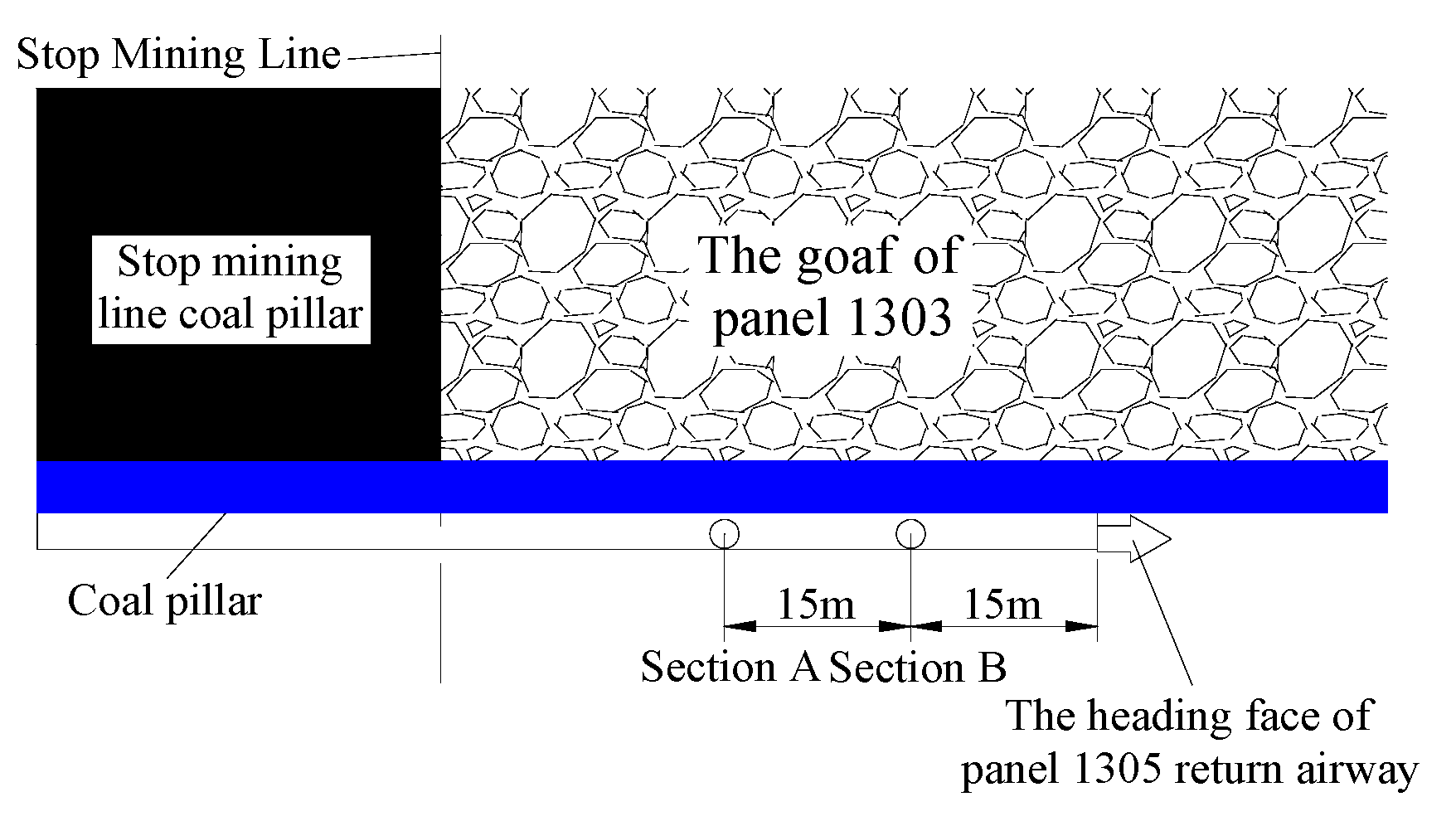

2. Deformation Characteristics and Stress Environment Analysis of Rock Surrounding Roadway

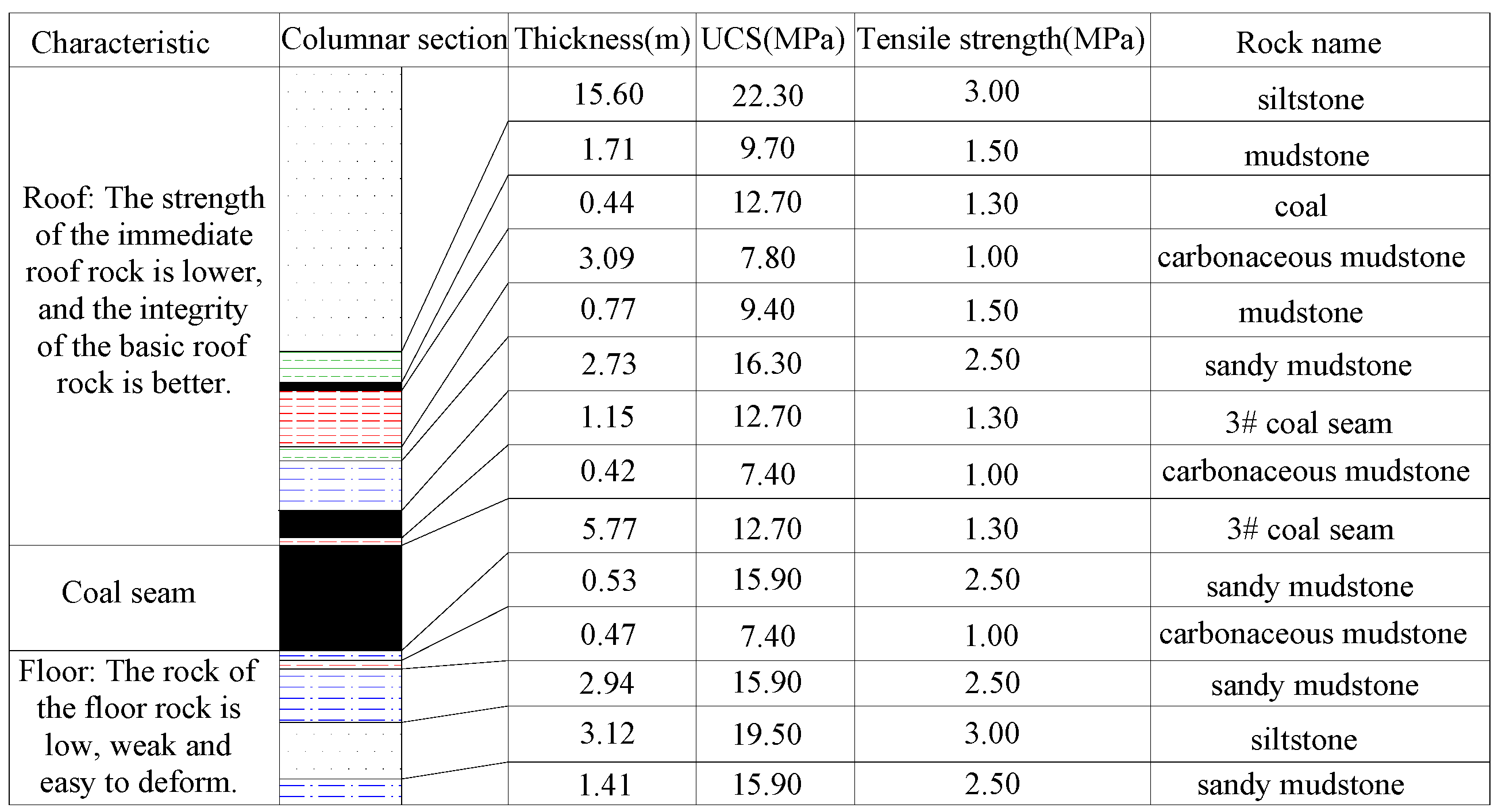

2.1. Structural Characteristics of Rock Surrounding Roadway

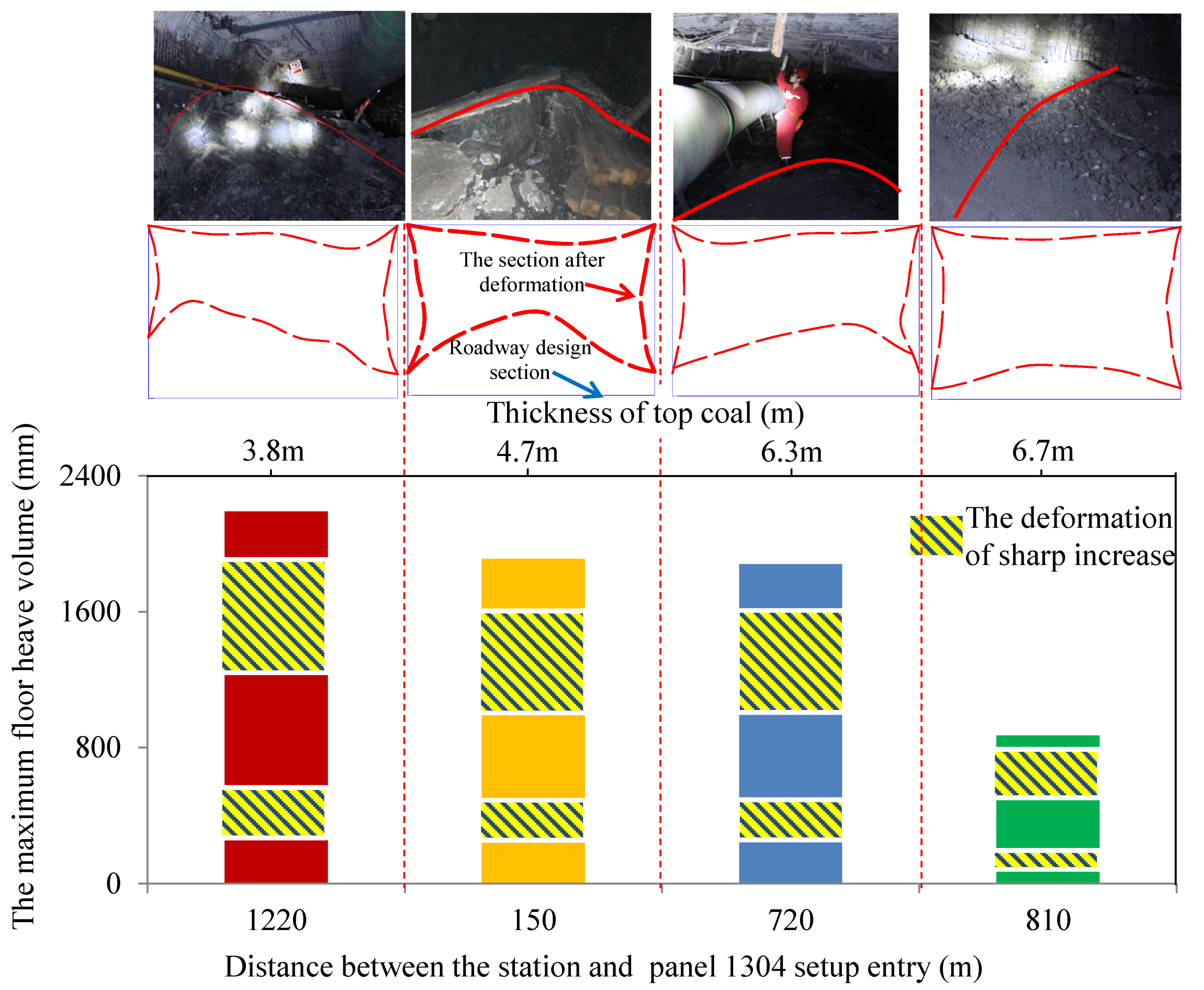

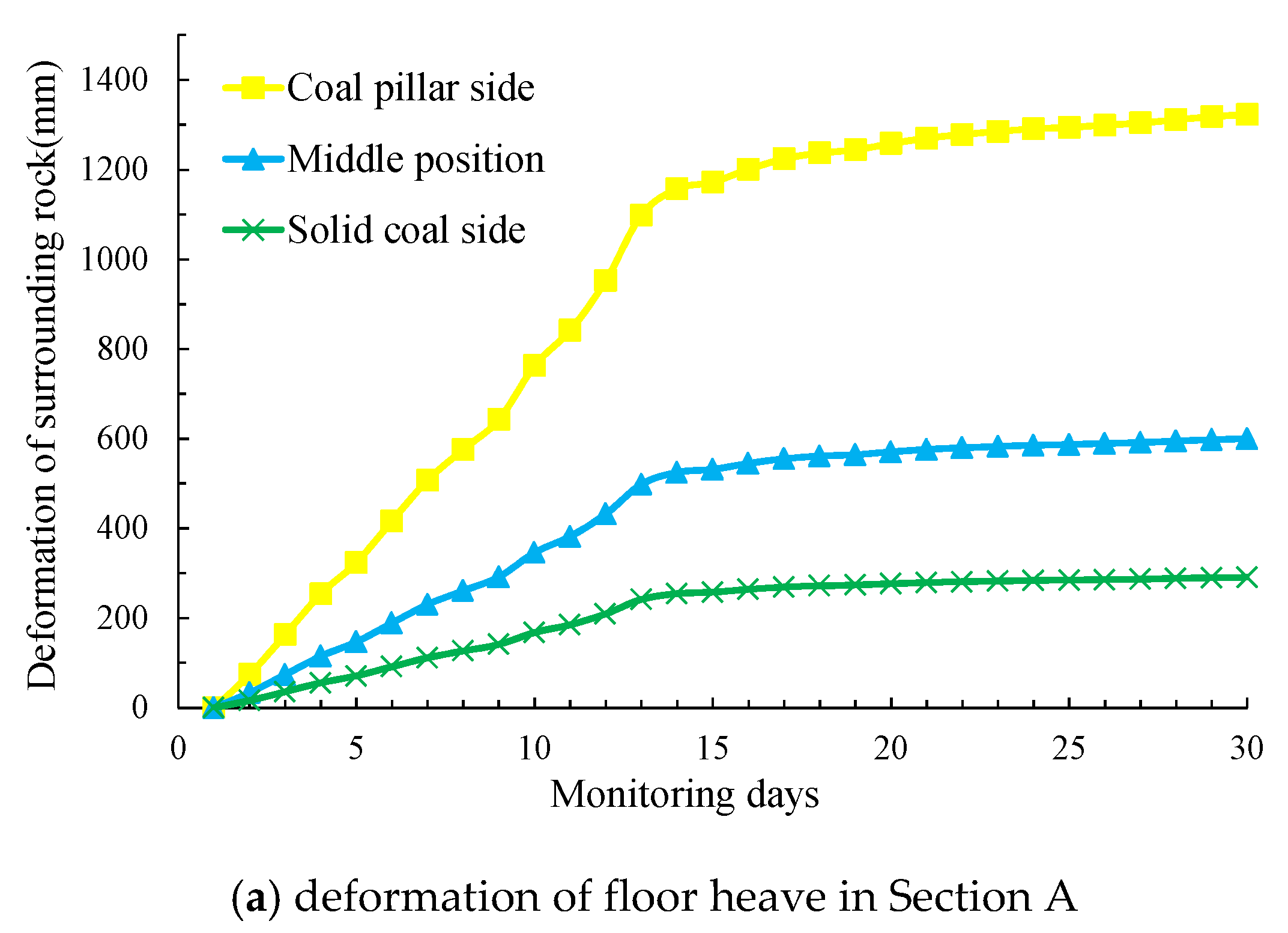

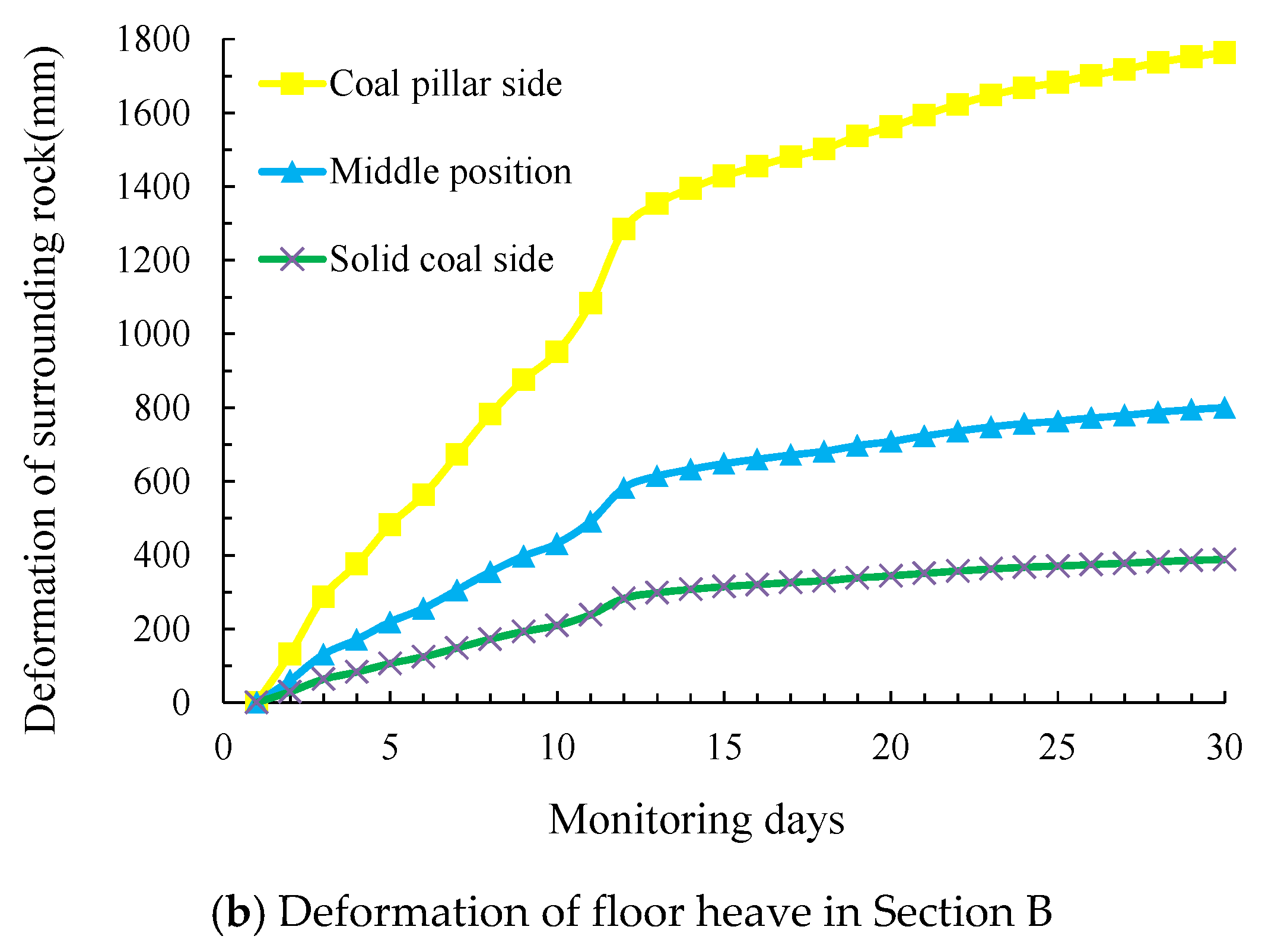

2.2. Monitoring of Law Governing Floor Heave in Mining Roadway

2.3. Analysis of Stress Environment of Surrounding Rock in Mining Roadway

3. Numerical Analysis of Roadway’s Floor Heave Mechanism

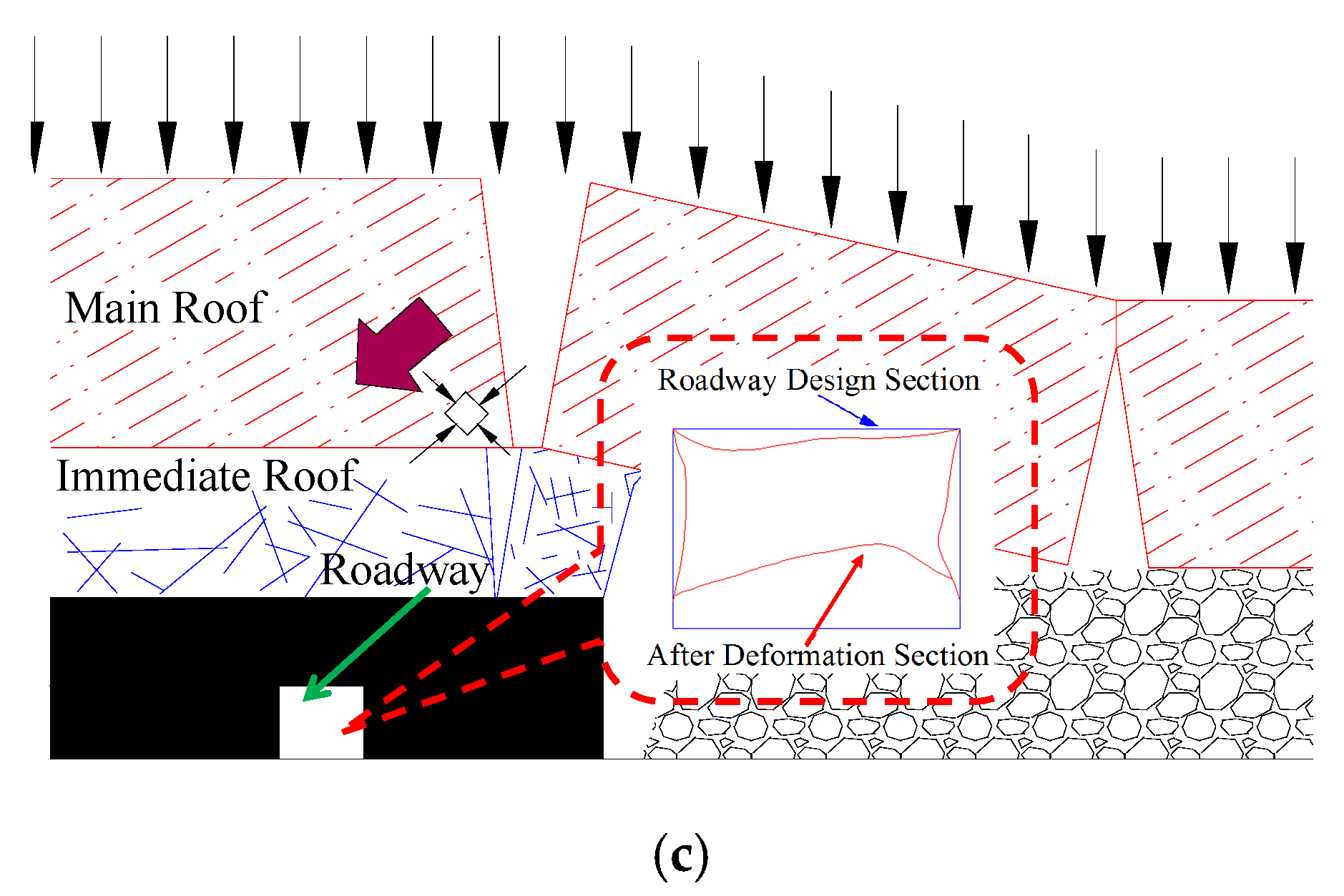

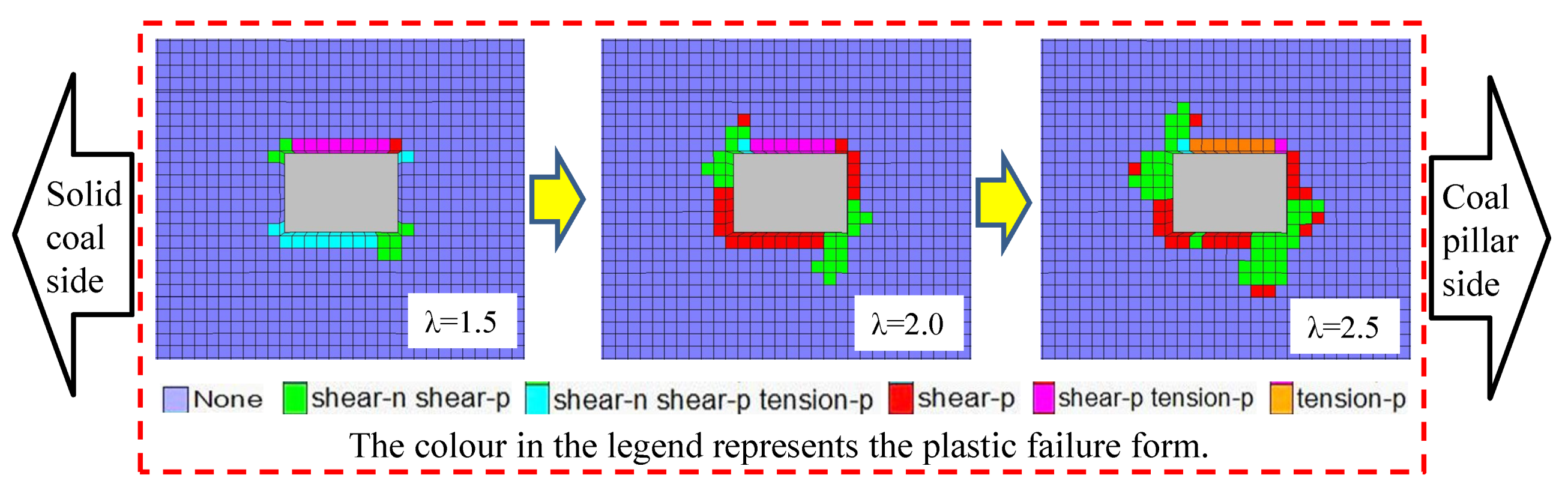

3.1. Modelling

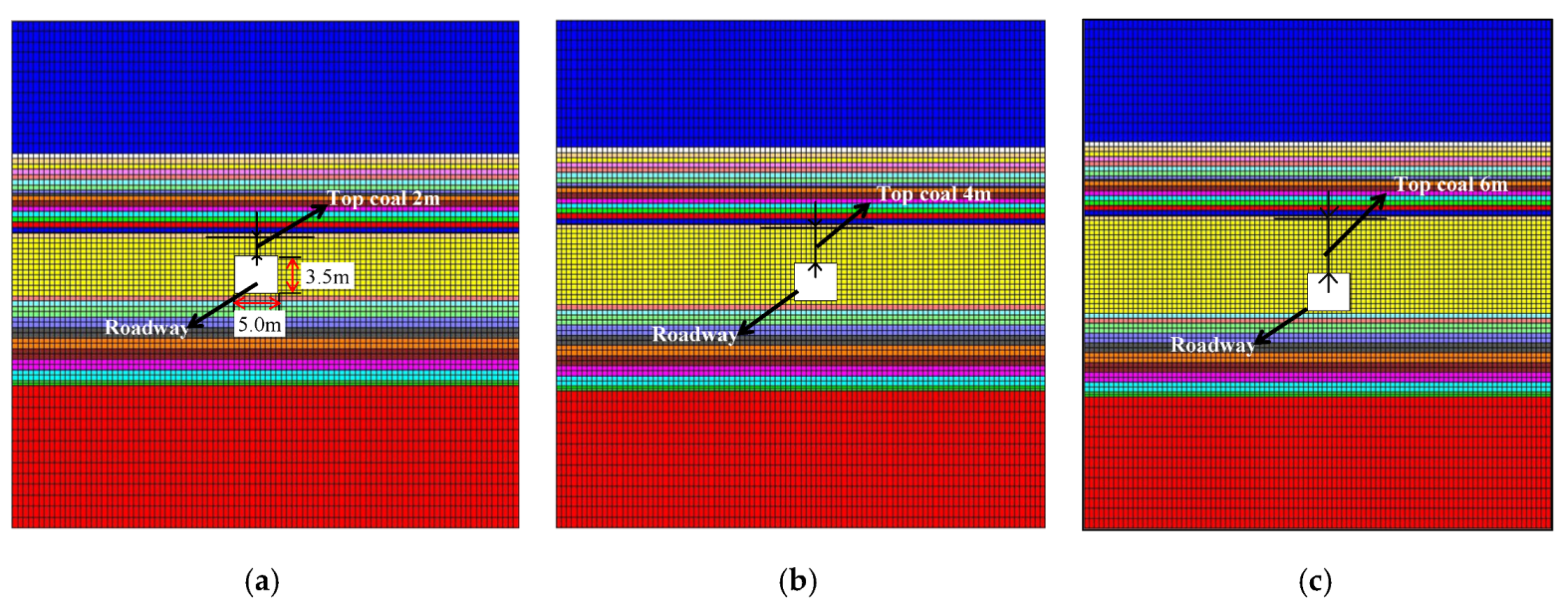

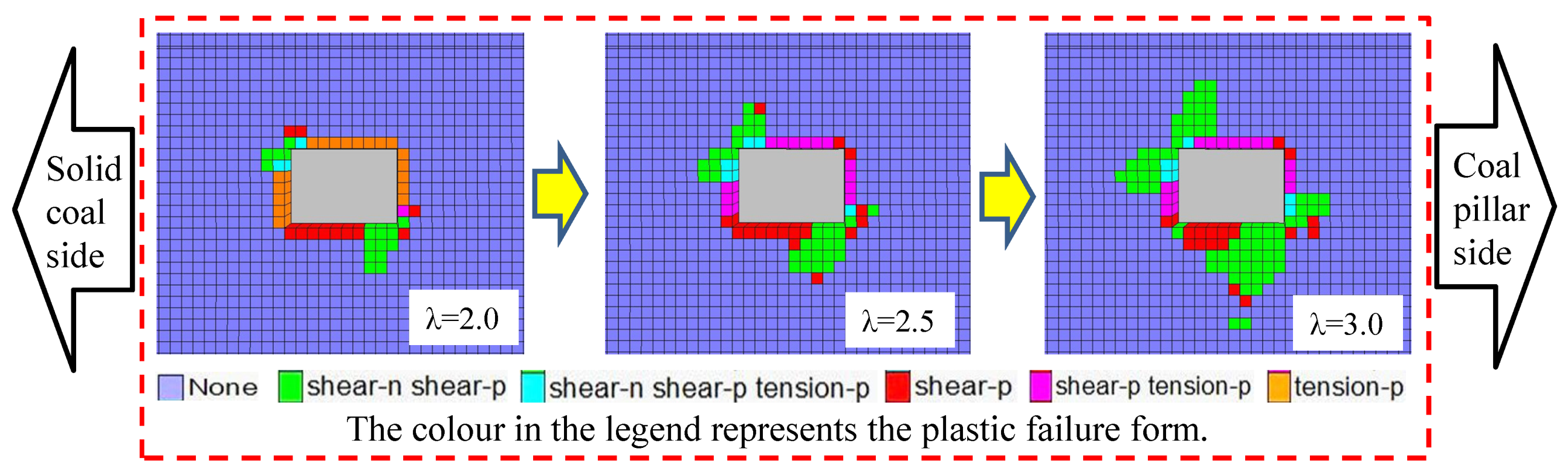

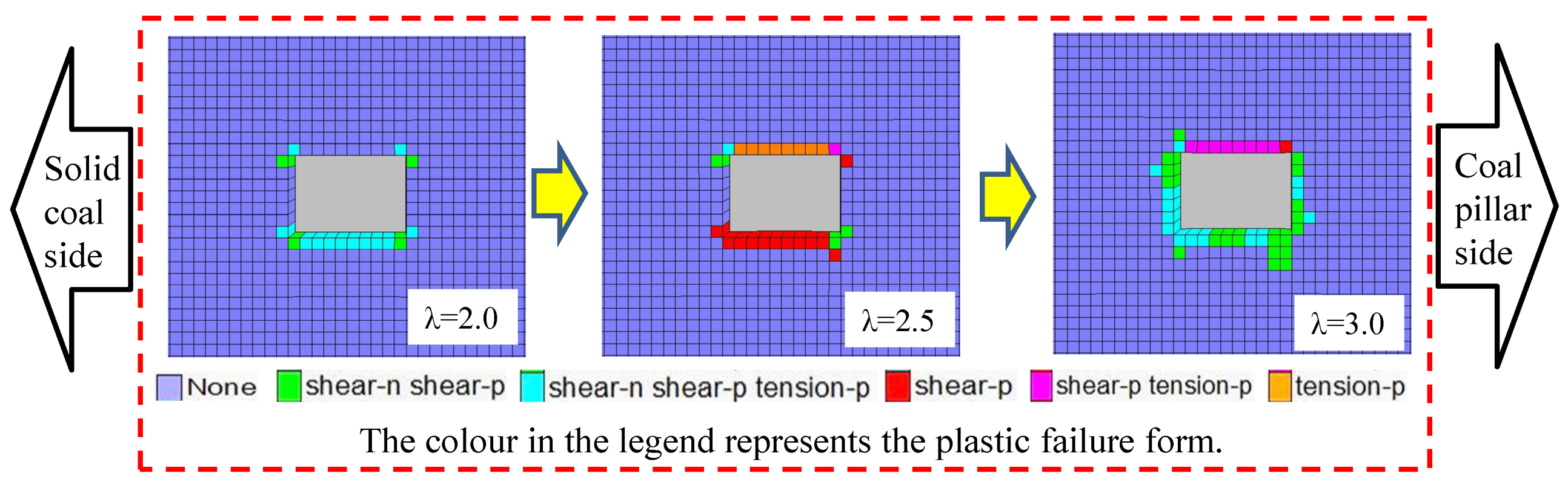

3.2. Analysis of Numerical Simulation Results

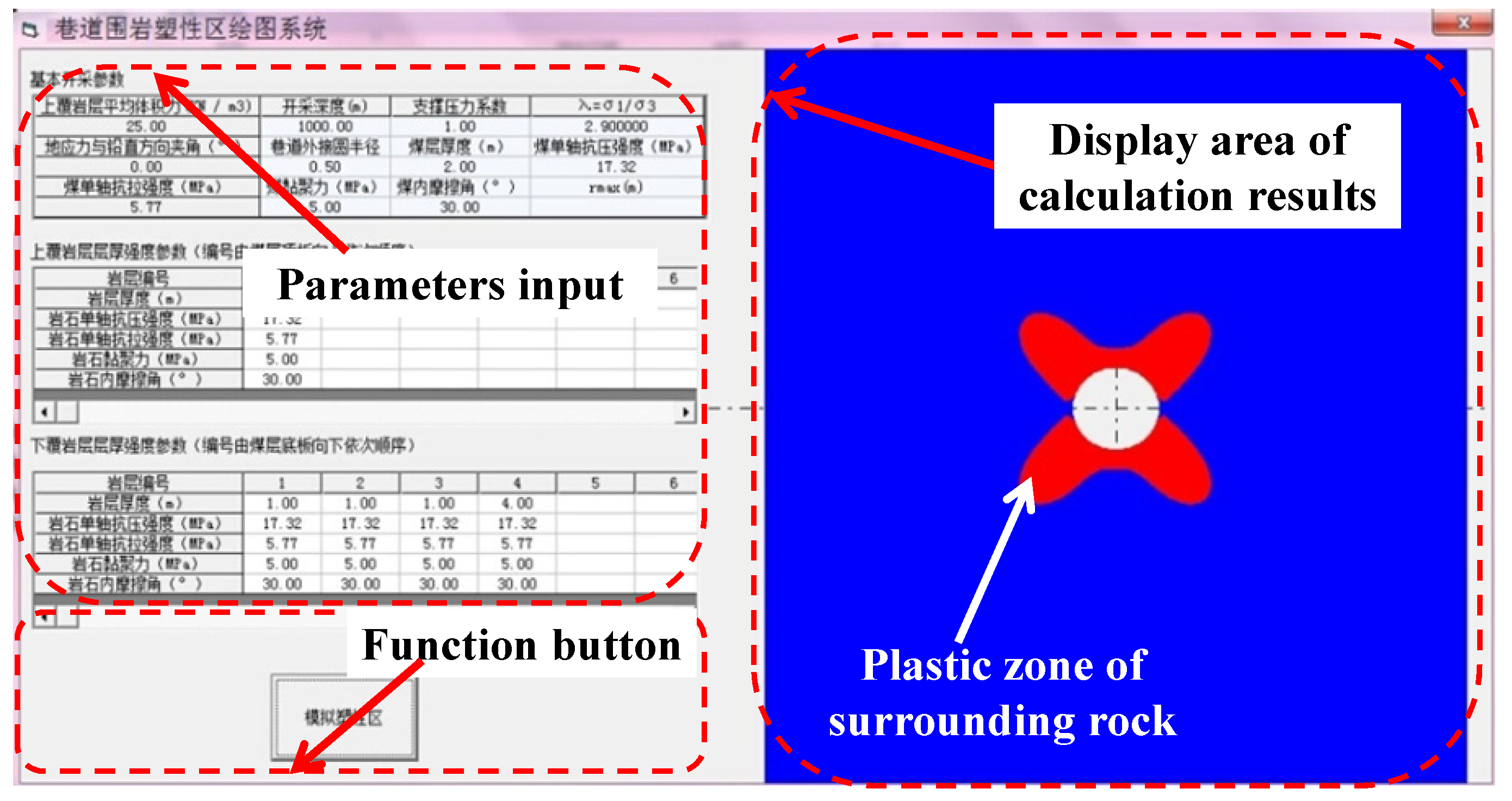

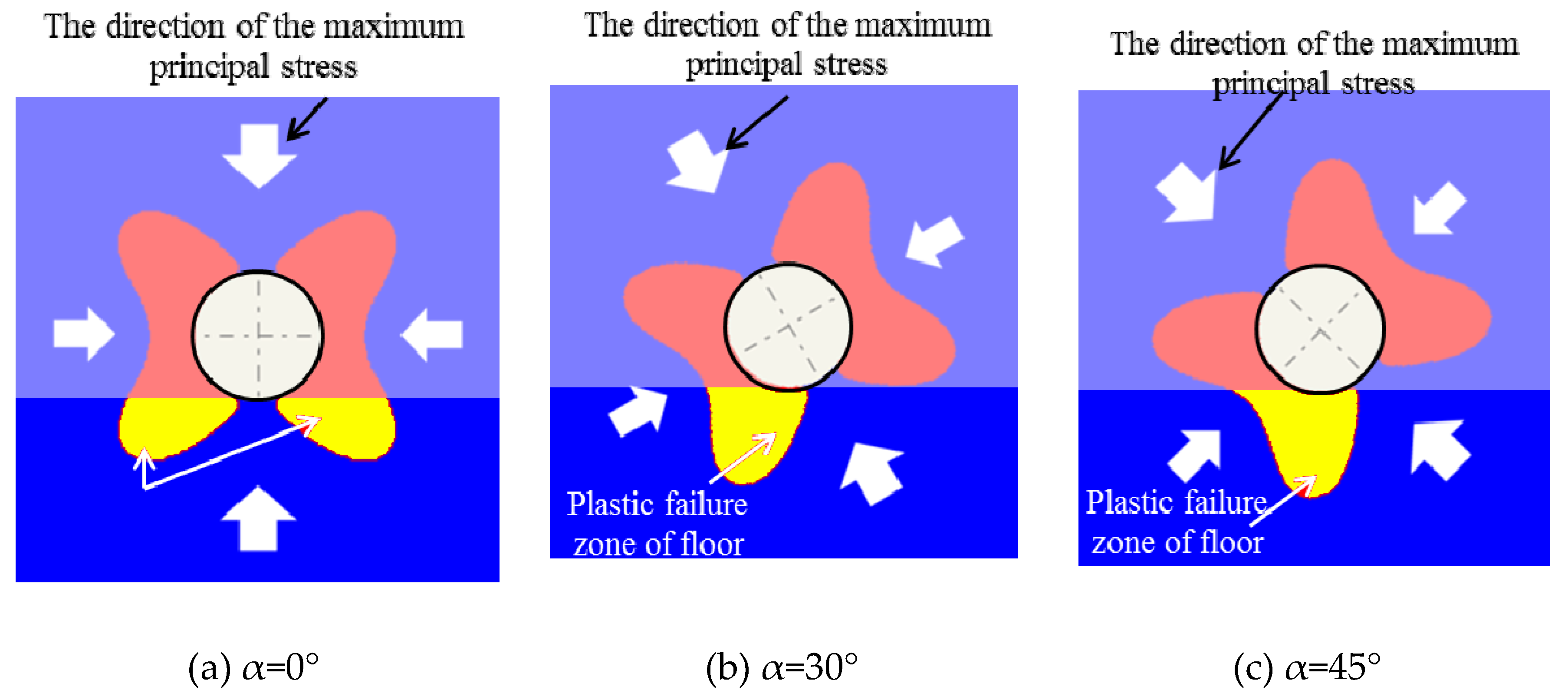

3.3. Theoretical Analysis of Mining Roadway’s Floor Heave Mechanism

4. Control Measures for Roadway’s Floor Heave and Field Test

4.1. Adjusting Relationship Between Mining and Tunneling to Improve Stress Environment of Rock Surrounding Roadway

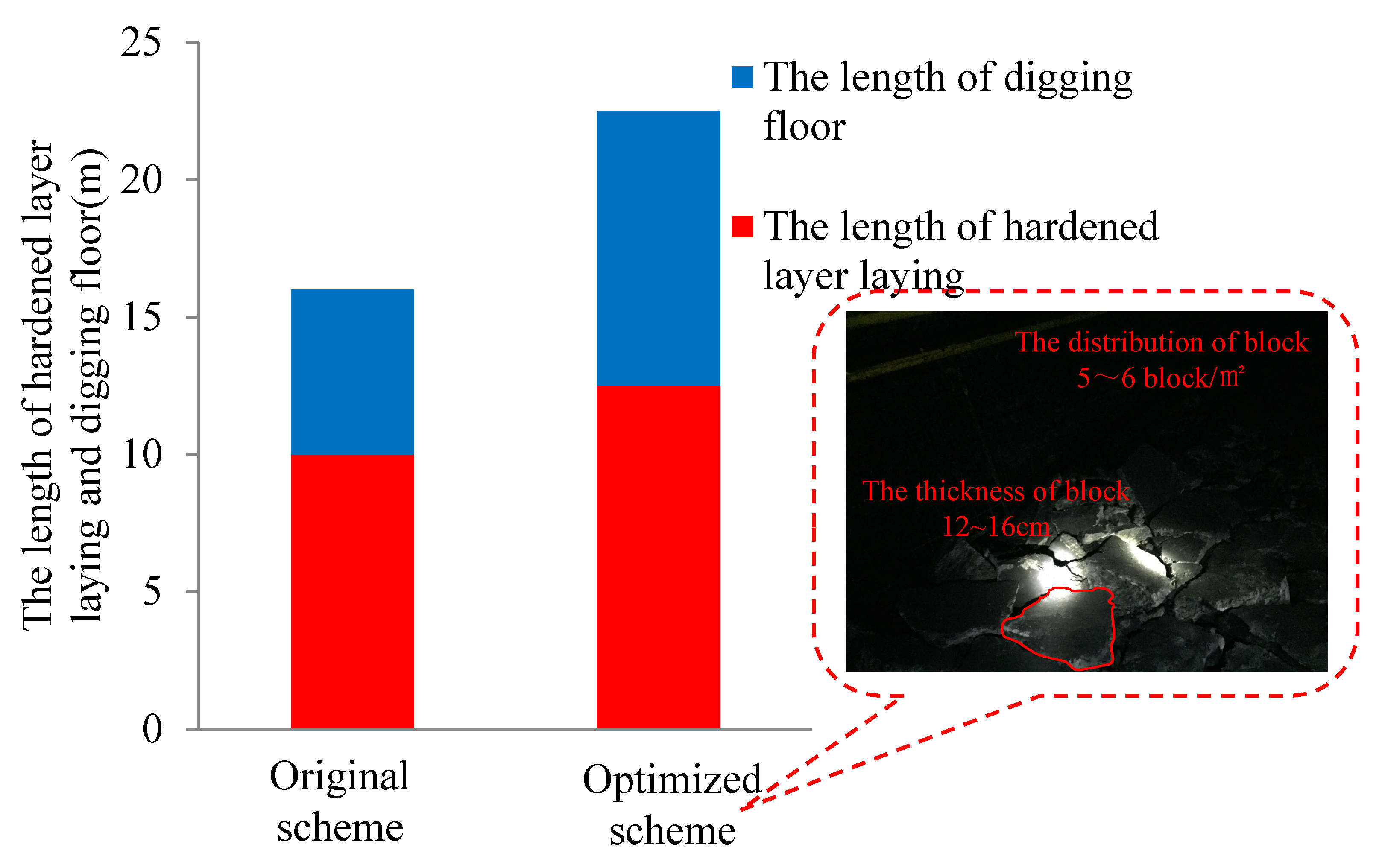

4.2. Optimization of Floor’s Hardening Thickness to Reduce Amount of Floor Digging

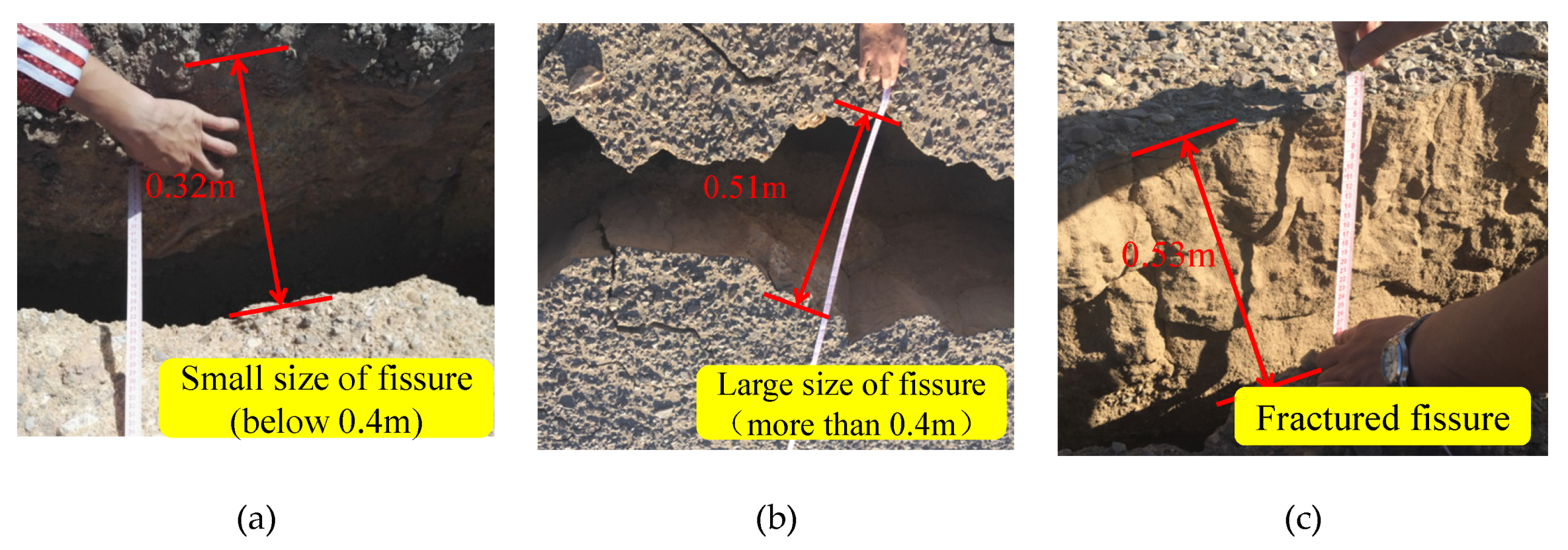

4.3. Determine Digging Floor Scheme According to Law of Asymmetric Floor Heave

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hou, C. Ground Control of Roadways; China University of Mining and Technology Press: Xuzhou, China, 2013. [Google Scholar]

- Zhao, Z.; Ma, N.; Jia, H. Partitioning characteristics of gas channel of coal-rock mass in mining space and gas orientation method. Int. J. Min. Sci. Technol. 2013, 23, 873–877. [Google Scholar] [CrossRef]

- Zhong, Z.; Tu, Y.; Liu, X. Occurrence mechanism and control technology of the floor heave disaster for soft-rock tunnel. Disaster Adv. 2012, 5, 987–992. [Google Scholar]

- Wang, M.; Zhegn, D.; Wang, K. Strain energy analysis of floor heave in longwall gateroads. R. Soc. Open Sci. 2018, 5, 180691. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, M.; Liu, S.; Su, F. An experimental study of the vibration of a drill rod during roof bolt installation. Int. J. Rock Mech. Min. Sci. 2018, 104, 20–26. [Google Scholar] [CrossRef]

- Gong, P.; Ma, Z.; Ni, X.; Zhang, R. Floor heave mechanism of gob-side entry retaining with fully-mechanized backfilling mining. Energies 2017, 10, 2085. [Google Scholar] [CrossRef]

- Zheng, W.; Zhao, Y.; Bu, Q. The coupled control of floor heave based on a composite structure consisting of bolts and concrete antiarches. Math. Probl. Eng. 2018, 2018, 14. [Google Scholar] [CrossRef]

- Hou, C.; Ma, N. Stress in in-seam roadway sides and limlt equillbrlum zone. J. China Coal Soc. 1989, 4, 21–29. [Google Scholar]

- Hou, C. Key technologies for surrounding rock control in deep roadway. J. China Univ. Min. Technol. 2017, 46, 970–978. [Google Scholar]

- Hou, C. Effective approach for surrounding rock control in deep roadway. J. China Univ. Min. Technol. 2017, 46, 467–473. [Google Scholar]

- He, M.C.; Zhang, G.F.; Wang, G.L.; Xu, Y.L.; Wu, C.Z.; Tang, Q.D. Research on mechanism and application to floor heave control of deep gateway. Chin. J. Rock Mech. Eng. 2009, 28, 2593–2598. [Google Scholar]

- Sun, X.M.; Chen, F.; He, M.C.; Gong, W.L.; Xu, H.C.; Lu, H. Physical modeling of floor heave for the deep-buried roadway excavated in ten degree inclined strata using infrared thermal imaging technology. Tunn. Undergr. Space Technol. 2017, 63, 228–243. [Google Scholar] [CrossRef]

- Guofeng, L.I.; Manchao, H.E.; Zhang, G.; Zhigang, T. Deformation mechanism and excavation process of large span intersection within deep soft rock roadway. Min. Sci. Technol. 2010, 20, 28–34. [Google Scholar]

- Kang, H.; Lu, S. An analysis on the mechanism of roadway floor heave. Chin. J. Rock Mech. Eng. 1991, 10, 362–373. [Google Scholar]

- Guo, G.; Kang, H.; Qian, D.; Gao, F.; Wang, Y. Mechanism for controlling floor heave of mining roadways using reinforcing roof and sidewalls in underground coal mine. Sustainability 2018, 10, 1413. [Google Scholar] [CrossRef]

- Kang, H. Studies of stress state and rock properties on floor heave. Ground Press. Strat. Control 1994, 11, 43–46. [Google Scholar]

- Kang, H.; Li, J.; Yang, J.; Gao, F. Investigation on the Influence of Abutment Pressure on the Stability of Rock Bolt Reinforced Roof Strata Through Physical and Numerical Modeling. Rock Mech. Rock Eng. 2017, 50, 387–401. [Google Scholar] [CrossRef]

- Kang, H.; Lou, J.; Gao, F.; Yang, J.; Li, J. A physical and numerical investigation of sudden massive roof collapse during longwall coal retreat mining. Int. J. Coal Geol. 2018, 188, 25–36. [Google Scholar] [CrossRef]

- Bai, J.B.; Li, W.F.; Wang, X.Y.; Xu, Y.; Huo, L.J. Mechanism of Floor Heave and Control Technology of Roadway Induced by Mining. J. Min. Saf. Eng. 2011, 28, 1–5. [Google Scholar]

- Zhang, Z.; Bai, J.; Chen, Y.; Yan, S. An innovative approach for gob-side entry retaining in highly gassy fully-mechanized longwall top-coal caving. Int. J. Rock Mech. Min. Sci. 2015, 80, 1–11. [Google Scholar] [CrossRef]

- Yang, B.S.; Geng, X.L.; Sun, L.H.; Song, X.Z.; Zhang, L. Research on floor heave mechanism of thick seam roadway in Wuyang coal mine and its control. J. Min. Saf. Eng. 2012, 29, 8–13. [Google Scholar]

- Yang, B.S.; Jia, Y.F.; Sun, L.H.; Li, X.; Gao, B. Experimental research on the continuous “double shell” har-nessing floor heave in high horizontal stress roadway. J. China Coal Soc. 2014, 39, 1504–1510. [Google Scholar]

- Sun, L.; Yang, B.; Yang, W. Reinforcement mechanism and experimental study on con-tinuous double shell of deep roadway. J. Min. Saf. Eng. 2013, 30, 687–691. [Google Scholar]

- Ma, N.J.; Guo, X.F.; Zhao, Z.Q.; Zhao, X.D.; Liu, H.T. Occurrence mechanisms and judging criterion on circular tunnel butterfly rock burst in homogeneous medium. J. China Coal Soc. 2016, 41, 2679–2688. [Google Scholar]

- Jiang, L.; Wu, Q.; Wu, Q.; Wang, P.; Xue, Y.; Kong, P.; Gong, B. Fracture failure analysis of hard and thick key layer and its dynamic response characteristics. Eng. Fail. Anal. 2019, 98, 118–130. [Google Scholar] [CrossRef]

- Jiang, L.; Sainoki, A.; Mitri, H.S.; Ma, N.; Liu, H.; Hao, Z. Influence of fracture-induced weakening on coal mine gateroad stability. Int. J. Rock Mech. Min. Sci. 2016, 88, 307–317. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Li, S.; Zhu, Y. Failure Mechanism for Surrounding Rock of Deep Circular Roadway in Coal Mine Based on Min-ing-Induced Plastic Zone. Adv. Civ. Eng. 2018, 2018, 14. [Google Scholar]

- Wang, W.; Yuan, C.; Guo, G.; Yu, W.J. Control of malignant expansion of plastic zone in surrounding rock of rock roadway under the conditions of violent mining. J. Min. Saf. Eng. 2016, 33, 957–964. [Google Scholar]

- Yu, W.; Wang, W.; Chen, X. Field investigations of high stress soft surrounding rocks and deformation control. J. Rock Mech. Geotech. Eng. 2015, 7, 421–433. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.Q.; Ma, N.J.; Guo, X.F. Falling principle and support design of butterfly-failure roof in large deformation mining roadways. J. China Coal Soc. 2016, 41, 2932–2939. [Google Scholar]

- Jia, H.; Ma, N.; Zhu, Q. Mechanism and control method of roof fall resulted from butterfly plastic zone penetration. J. China Coal Soc. 2016, 41, 1384–1392. [Google Scholar]

- Qian, M.; Shi, P.; Xu, J. Ground Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Cheng, L.; Zhang, Y. A New Closed-Form Solution of the Side Abutment Pressure Distribution of Roadway. Adv. Civ. Eng. 2018, 2018, 10. [Google Scholar] [CrossRef]

| Simulation Scheme | Thickness of Roadway Caving Coal | Deflection Direction of Principal Stress (°) | Principal Stress Ratio | Principal Stress (MPa) | ||

|---|---|---|---|---|---|---|

| σ1 | σ2 | σ3 | ||||

| Scheme 1 | 2 m | 30° | 1.5 | 9.75 | 7.50 | 6.50 |

| 2.0 | 13.00 | 9.00 | 6.50 | |||

| 2.5 | 16.25 | 10.00 | 6.50 | |||

| Scheme 2 | 4 m | 45° | 2.0 | 13.00 | 9.00 | 6.50 |

| 2.5 | 16.25 | 10.00 | 6.50 | |||

| 3.0 | 19.50 | 12.00 | 6.50 | |||

| 60° | 2.0 | 13.00 | 9.00 | 6.50 | ||

| 2.5 | 16.25 | 10.00 | 6.50 | |||

| 3.0 | 19.50 | 12.00 | 6.50 | |||

| Scheme 3 | 6 m | 10° | 1.0 | 6.50 | 6.50 | 6.50 |

| 1.5 | 9.75 | 7.50 | 6.50 | |||

| 2.0 | 13.00 | 9.00 | 6.50 | |||

| Lithology | Bulk Density (Kg/m3) | K (GPa) | G (GPa) | C (MPa) | Φ (°) | |

|---|---|---|---|---|---|---|

| Carbonaceous mudstone | 2250 | 6.0 | 3.5 | 2.5 | 25 | 1.0 |

| Mudstone | 2300 | 6.0 | 3.5 | 3.0 | 27 | 1.5 |

| Sandy mudstone | 2420 | 8.0 | 5.0 | 5.0 | 29 | 2.5 |

| 3# coal seam | 1500 | 7.0 | 4.5 | 4.0 | 28 | 1.5 |

| Siltstone | 2700 | 14.3 | 9.0 | 6.0 | 30 | 3.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Wang, L.; Fan, K.; Peng, B.; Pan, K. Control Technology of Soft Rock Floor in Mining Roadway with Coal Pillar Protection: A case study. Energies 2019, 12, 3009. https://doi.org/10.3390/en12153009

Jia H, Wang L, Fan K, Peng B, Pan K. Control Technology of Soft Rock Floor in Mining Roadway with Coal Pillar Protection: A case study. Energies. 2019; 12(15):3009. https://doi.org/10.3390/en12153009

Chicago/Turabian StyleJia, Housheng, Luyao Wang, Kai Fan, Bo Peng, and Kun Pan. 2019. "Control Technology of Soft Rock Floor in Mining Roadway with Coal Pillar Protection: A case study" Energies 12, no. 15: 3009. https://doi.org/10.3390/en12153009

APA StyleJia, H., Wang, L., Fan, K., Peng, B., & Pan, K. (2019). Control Technology of Soft Rock Floor in Mining Roadway with Coal Pillar Protection: A case study. Energies, 12(15), 3009. https://doi.org/10.3390/en12153009