Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications: Design, Major Elements, and Scalability

Abstract

:1. Introduction

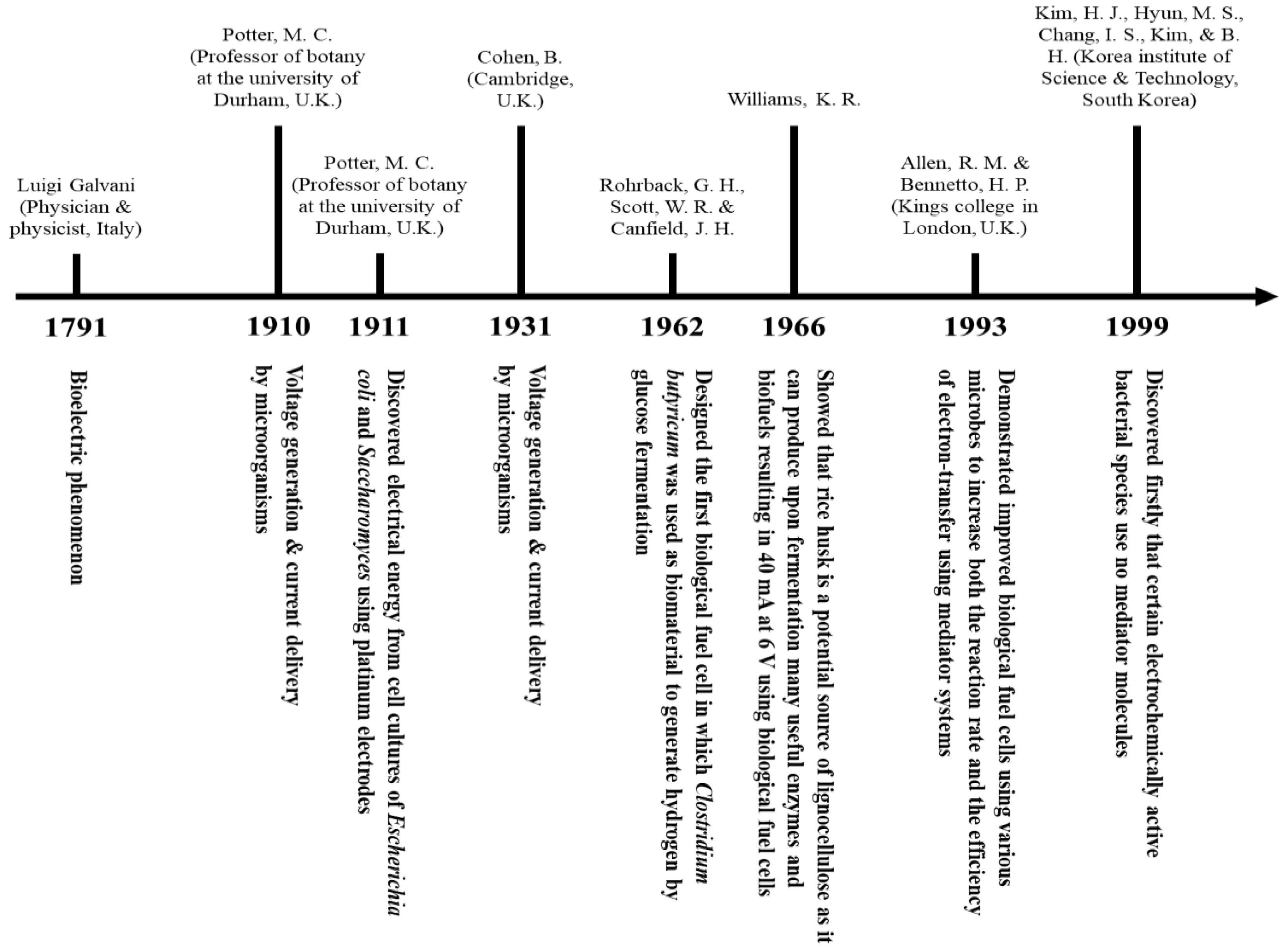

2. Microbial Fuel Cell Evolution

3. MFC Elements, Electron Transfer, and Principles of Working Machinery

3.1. MFC Elements and Setup

3.2. MFC Electron Transfer

3.3. MFC Working Principles

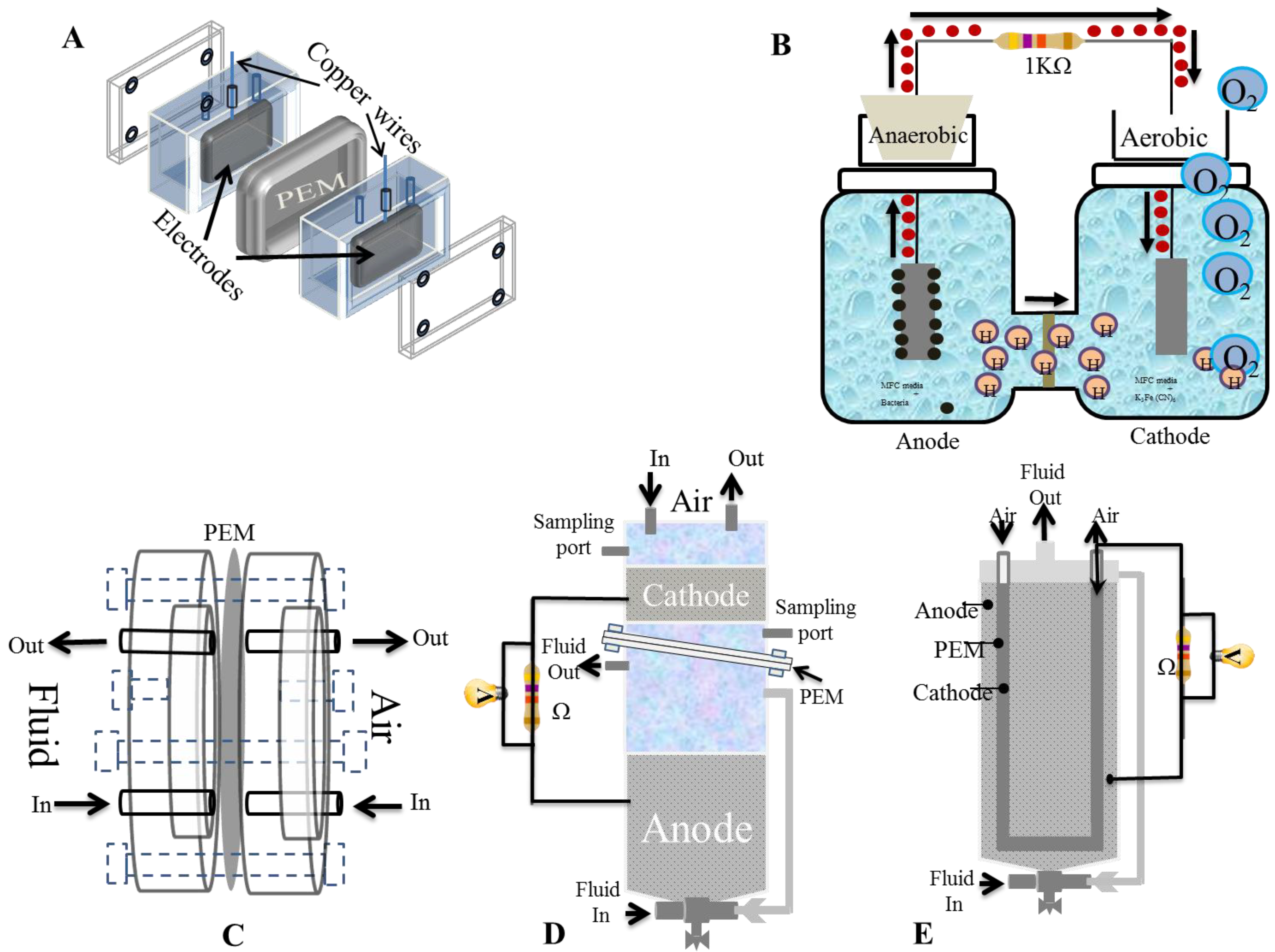

4. Design of MFCs

4.1. Double-Chambered Fuel Cells

4.2. Single-Chambered Fuel Cells

4.3. Stacked MFC

4.3.1. Bipolar Electrode Stack

4.3.2. Horizontal MFC Stack

4.3.3. Vertical MFC Stack

5. Scalability of MFC

5.1. Modular MFC Stack Systems with Multiple Electrodes

5.2. Outlook for MFC Scale-Up

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bishoge, O.; Zhang, L.; Mushi, W. The Potential Renewable Energy for Sustainable Development in Tanzania: A Review. Clean Technol. 2018, 1, 70–88. [Google Scholar] [CrossRef] [Green Version]

- Bond, D.R.; Lovley, D.R. Electricity Production by Geobacter sulfurreducens Attached to Electrodes. Appl. Environ. Microbiol. 2003, 69, 1548–1555. [Google Scholar] [CrossRef] [PubMed]

- Bose, D.; Kandpal, V.; Dhawan, H.; Vijay, P.; Gopinath, M. Energy Recovery with Microbial Fuel Cells: Bioremediation and Bioelectricity. In Waste Bioremediation; Varjani, S.J., Gnansounou, E., Gurunathan, B., Pant, D., Zakaria, Z.A., Eds.; Springer: Singapore, 2018; pp. 7–33. [Google Scholar]

- Aghababaie, M.; Farhadian, M.; Jeihanipour, A.; Biria, D. Effective factors on the performance of microbial fuel cells in wastewater treatment—A review. Environ. Technol. Rev. 2015, 4, 71–89. [Google Scholar] [CrossRef]

- Galvani, L. De viribus electricitatis in motu musculari. Commentarius. Bonoiensi Sci. Artium Intituo Acad. Comment. 1791, 7, 363–418. [Google Scholar]

- Grove, W.R. LVI. On a new voltaic combination: To the editors of the Philosophical Magazine and Journal. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1838, 13, 430–431. [Google Scholar] [CrossRef]

- Potter, M.C. Bacteria as Agents in the Oxidation of Amorphous Carbon. Proc. R. Soc. Lond. Ser. B Contain. Papers Biol. Character 1908, 80, 239–259. [Google Scholar] [CrossRef]

- Potter, M.C. Electrical effects accompanying the decomposition of organic compounds. Proc. R. Soc. Lond. B Biol. Sci. 1911, 84, 260–276. [Google Scholar] [CrossRef]

- Cohen, B. The bacterial culture as an electrical half-cellJournal of Bacteriology. J. Bacteriol. 1931, 21, 18–19. [Google Scholar]

- Rohrback, G.H.; Scott, W.R.; Canfield, J.H. Biochemical fuel cells. Biol. Fuel Cells Appl. 1962, 19, 18. [Google Scholar]

- Williams, K.R. An Introduction to Fuel Cells; Elsevier: Amsterdam, The Netherlands, 1966. [Google Scholar]

- Allen, R.M.; Bennetto, H.P. Microbial Fuel-Cells: Electricity production from carbohydrates. Appl. Biochem. Biotechnol. 1993, 39, 27–40. [Google Scholar] [CrossRef]

- Kim, B.H.; Kim, H.J.; Hyun, M.S.; Park, D.H. Direct electrode reaction of Fe(III)-reducing bacterium, Shewanella putrefaciens. J. Microbiol. Biotechnol. 1999, 9, 127–131. [Google Scholar]

- Du, Z.; Li, H.; Gu, T. A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bioenergy. Biotechnol. Adv. 2007, 25, 464–482. [Google Scholar] [CrossRef] [PubMed]

- Ucar, D.; Zhang, Y.; Angelidaki, I. An Overview of Electron Acceptors in Microbial Fuel Cells. Front. Microbiol. 2017, 8, 643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Katz, E.; Shipway, A.N.; Willner, I. Biochemical fuel cells. In Handbook of Fuel Cells; John Wiley & Sons, Ltd.: Chichester, West Sussex, UK, 2010. [Google Scholar]

- Rahimnejad, M.; Adhami, A.; Darvari, S.; Zirepour, A.; Oh, S.-E. Microbial fuel cell as new technology for bioelectricity generation: A review. Alex. Eng. J. 2015, 54, 745–756. [Google Scholar] [CrossRef] [Green Version]

- Bennetto, H.P.; Stirling, J.L.; Tanaka, K.; Vega, C.A. Anodic reactions in microbial fuel cells. Biotechnol. Bioeng. 1983, 25, 559–568. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, H.S.; Hyun, M.S.; Chang, I.S.; Kim, M.; Kim, B.H. A mediator-less microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens. Enzyme Microb. Technol. 2002, 30, 145–152. [Google Scholar] [CrossRef]

- Ringeisen, B.R.; Henderson, E.; Wu, P.K.; Pietron, J.; Ray, R.; Little, B.; Biffinger, J.C.; Jones-Meehan, J.M. High Power Density from a Miniature Microbial Fuel Cell Using Shewanella oneidensis DSP10. Environ. Sci. Technol. 2006, 40, 2629–2634. [Google Scholar] [CrossRef]

- Kim, B.; Ikeda, T.; Park, H.; Kim, H.; Hyun, M.; Kano, K.; Takagi, K.; Tatsumi, H. Electrochemical activity of an Fe(III)-reducing bacterium, Shewanella putrefaciens IR-1, in the presence of alternative electron acceptors. Biotechnol. Tech. 1999, 13, 475–478. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, L.; Wahid, Z.A.; Din, M.F.M. Exoelectrogens in microbial fuel cells toward bioelectricity generation: A review. Int. J. Energy Res. 2015, 39, 1048–1067. [Google Scholar] [CrossRef]

- Chaudhuri, S.K.; Lovley, D.R. Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat. Biotechnol. 2003, 21, 1229–1232. [Google Scholar] [CrossRef]

- Pham, C.A.; Jung, S.J.; Phung, N.T.; Lee, J.; Chang, I.S.; Kim, B.H.; Yi, H.; Chun, J. A novel electrochemically active and Fe(III)-reducing bacterium phylogenetically related to Aeromonas hydrophila, isolated from a microbial fuel cell. FEMS Microbiol. Lett. 2003, 223, 129–134. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, S.; Zhuang, L.; Li, W.; Zhang, J.; Lu, N.; Deng, L. Microbial fuel cell based on Klebsiella pneumoniae biofilm. Electrochem. Commun. 2008, 10, 1641–1643. [Google Scholar] [CrossRef]

- Fan, L.P.; Xue, S. Overview on Electricigens for Microbial Fuel Cell. Open Biotechnol. J. 2016, 10, 398–406. [Google Scholar] [CrossRef] [Green Version]

- Gil, G.-C.; Chang, I.-S.; Kim, B.H.; Kim, M.; Jang, J.-K.; Park, H.S.; Kim, H.J. Operational parameters affecting the performannce of a mediator-less microbial fuel cell. Biosens. Bioelectron. 2003, 18, 327–334. [Google Scholar] [CrossRef]

- Barua, P.K.; Deka, D. Electricity Generation from Biowaste Based Microbial Fuel Cells. Int. J. Energy 2010, 1, 77–92. [Google Scholar]

- Hamelers, H.M.; Ter Heijne, A.; Sleutels, T.J.A.; Jeremiasse, A.; Strik, D.B.T.B.; Buisman, C.N. New applications and performance of bioelectrochemical systems. Appl. Microbiol. Biotechnol. 2010, 85, 1673–1685. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Liu, H.; Logan, B.E. Power Densities Using Different Cathode Catalysts (Pt and CoTMPP) and Polymer Binders (Nafion and PTFE) in Single Chamber Microbial Fuel Cells. Environ. Sci. Technol. 2006, 40, 364–369. [Google Scholar] [CrossRef]

- Dombrovskis, J.K.; Palmqvist, A.E.C. Recent Progress in Synthesis, Characterization and Evaluation of Non-Precious Metal Catalysts for the Oxygen Reduction Reaction. Fuel Cells 2016, 16, 4–22. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Jafary, T.; Najafpour, G.; Ghoreyshi, A.A. Effect of Glucose Concentration on Performance of Microbial Fuel Cell. In Proceedings of the International Conference on Environmental Research and Technology, Penang, Malaysia, 2–4 June 2010; pp. 236–240. [Google Scholar]

- Khater, D.Z.; El-Khatib, K.M.; Hassan, H.M. Microbial diversity structure in acetate single chamber microbial fuel cell for electricity generation. J. Genet. Eng. Biotechnol. 2017, 15, 127–137. [Google Scholar] [CrossRef]

- Kim, J.R.; Jung, S.H.; Regan, J.M.; Logan, B.E. Electricity generation and microbial community analysis of alcohol powered microbial fuel cells. Bioresour. Technol. 2007, 98, 2568–2577. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, S. A biofuel cell with enhanced power output by grape juice. Electrochem. Commun. 2007, 9, 1423–1427. [Google Scholar] [CrossRef]

- Tatinclaux, M.; Gregoire, K.; Leininger, A.; Biffinger, J.C.; Tender, L.; Ramirez, M.; Torrents, A.; Kjellerup, B.V. Electricity generation from wastewater using a floating air cathode microbial fuel cell. Water Energy Nexus 2018, 1, 97–103. [Google Scholar] [CrossRef]

- Patil, S.A.; Surakasi, V.P.; Koul, S.; Ijmulwar, S.; Vivek, A.; Shouche, Y.S.; Kapadnis, B.P. Electricity generation using chocolate industry wastewater and its treatment in activated sludge based microbial fuel cell and analysis of developed microbial community in the anode chamber. Bioresour. Technol. 2009, 100, 5132–5139. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Logan, B.E. Hydrogen and electricity production from a food processing wastewater using fermentation and microbial fuel cell technologies. Water Res. 2005, 39, 4673–4682. [Google Scholar] [CrossRef] [PubMed]

- Wen, Q.; Wu, Y.; Cao, D.; Zhao, L.; Sun, Q. Electricity generation and modeling of microbial fuel cell from continuous beer brewery wastewater. Bioresour. Technol. 2009, 100, 4171–4175. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Zhao, Q.; Zhang, J.; Zhang, G.; Lee, D.-J. Electricity generation from bio-treatment of sewage sludge with microbial fuel cell. Bioresour. Technol. 2009, 100, 5808–5812. [Google Scholar] [CrossRef] [PubMed]

- Cercado-Quezada, B.; Delia, M.-L.; Bergel, A. Testing various food-industry wastes for electricity production in microbial fuel cell. Bioresour. Technol. 2010, 101, 2748–2754. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flimban, S.G.A.; Hassan, S.H.A.; Rahman, M.M.; Oh, S.-E. The effect of Nafion membrane fouling on the power generation of a microbial fuel cell. Int. J. Hydrogen Energy 2018. [Google Scholar] [CrossRef]

- Kondaveeti, S.; Lee, J.; Kakarla, R.; Kim, H.S.; Min, B. Low-cost separators for enhanced power production and field application of MFCs (MFCs). Electrochim. Acta 2014, 132, 434–440. [Google Scholar] [CrossRef]

- Call, D.; Logan, B.E. Hydrogen Production in a Single Chamber Microbial Electrolysis Cell Lacking a Membrane. Environ. Sci. Technol. 2008, 42, 3401–3406. [Google Scholar] [CrossRef]

- Pant, D.; Bogaert, G.V.; Diels, L.; Vanbroekhoven, K. A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioressour. Technol. 2010, 101, 1533–1543. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.; Cheng, S.; Watson, V.; Estadt, G. Graphite Fiber Brush Anodes for Increased Power Production in Air-Cathode Microbial Fuel Cells. Environ. Sci. Technol. 2007, 41, 3341–3346. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Zhang, X.; Liu, J.; Zhu, X.; Feng, Y.; Logan, B.E. Microbial fuel cells with an integrated spacer and separate anode and cathode modules. Environ. Sci. 2016, 2, 186–195. [Google Scholar] [CrossRef]

- You, S.; Zhao, Q.; Zhang, J.; Jiang, J.; Zhao, S. A microbial fuel cell using permanganate as the cathodic electron acceptor. J. Power Sources 2006, 162, 1409–1415. [Google Scholar] [CrossRef]

- Rabaey, K.; Boon, N.; Siciliano, S.D.; Verhaege, M.; Verstraete, W. Biofuel Cells Select for Microbial Consortia That Self-Mediate Electron Transfer. Appl. Environ. Microbiol. 2004, 70, 5373–5382. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.; Li, H.; Zhou, X.; Liang, P.; Zhang, X.; Jiang, Y.; Huang, X. A novel pilot-scale stacked microbial fuel cell for efficient electricity generation and wastewater treatment. Water Res. 2016, 98, 396–403. [Google Scholar] [CrossRef] [PubMed]

- Tremouli, A.; Greenman, J.; Ieropoulos, I. Investigation of ceramic MFC stacks for urine energy extraction. Bioelectrochemistry 2018, 123, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Asensio, Y.; Montes, I.B.; Fernandez-Marchante, C.M.; Lobato, J.; Cañizares, P.; Rodrigo, M.A. Selection of cheap electrodes for two-compartment microbial fuel cells. J. Electroanal. Chem. 2017, 785 (Suppl. C), 235–240. [Google Scholar] [CrossRef]

- Sun, J.; Hu, Y.; Bi, Z.; Cao, Y. Improved performance of air-cathode single-chamber MFC for wastewater treatment using microfiltration membranes and multiple sludge inoculation. J. Power Sources 2009, 187, 471–479. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.R.; Cha, J.; Kim, Y.; Premier, G.C.; Kim, C. Enhanced power production of a membrane electrode assembly MFC (MFC) using a cost effective poly[2,5-benzimidazole] (ABPBI) impregnated non-woven fabric filter. Bioresour. Technol. 2013, 128, 14–21. [Google Scholar] [CrossRef]

- Min, B.; Logan, B.E. Continuous Electricity Generation from Domestic Wastewater and Organic Substrates in a Flat Plate Microbial Fuel Cell. Environ. Sci. Technol. 2004, 38, 5809–5814. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.R.; Cheng, S.; Oh, S.-E.; Logan, B.E. Power generation using different cation, anion, and ultrafiltration membranes in MFCs. Environ. Sci. Technol. 2007, 41, 1004–1009. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Minteer, S.D.; Angenent, L.T. Electricity Generation from Artificial Wastewater Using an Upflow Microbial Fuel Cell. Environ. Sci. Technol. 2005, 39, 5262–5267. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Wagner, N.; Minteer, S.D.; Angenent, L.T. An Upflow Microbial Fuel Cell with an Interior Cathode: Assessment of the Internal Resistance by Impedance Spectroscopy. Environ. Sci. Technol. 2006, 40, 5212–5217. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Logan, B.E. Electricity Generation Using an Air-Cathode Single Chamber Microbial Fuel Cell in the Presence and Absence of a Proton Exchange Membrane. Environ. Sci. Technol. 2004, 38, 4040–4046. [Google Scholar] [CrossRef] [PubMed]

- Eom, H.; Chung, K.; Kim, I.; Han, J.I. Development of a hybrid microbial fuel cell (MFC) and fuel cell (FC) system for improved cathodic efficiency and sustainability: The M2FC reactor. Chemosphere 2011, 85, 672–676. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Liu, H.; Logan, B.E. Increased performance of single-chamber MFCs using an improved cathode structure. Electrochem. Commun. 2006, 8, 489–494. [Google Scholar] [CrossRef]

- Shin, S.H.; Choi, Y.J.; Na, S.H.; Jung, S.H.; Kim, S.H. Development of bipolar plate stack type microbial fuel cells. Bull. Korean Chem. Soc. 2006, 27, 281–285. [Google Scholar]

- Dekker, A.; Heijne, A.T.; Saakes, M.; Hamelers, H.V.; Buisman, C.J. Analysis and improvement of a scaled-up and stacked microbial fuel cell. Environ. Sci. Technol. 2009, 43, 9038–9042. [Google Scholar] [CrossRef]

- Aelterman, P.; Rabaey, K.; Pham, H.T.; Boon, N.; Verstraete, W. Continuous electricity generation at high voltages and currents using stacked microbial fuel cells. Environ. Sci. Technol. 2006, 40, 3388–3394. [Google Scholar] [CrossRef]

- An, J.; Kim, B.; Jang, J.K.; Lee, H.-S.; Chang, I.S. New architecture for modulization of membraneless and single-chambered microbial fuel cell using a bipolar plate-electrode assembly (BEA). Biosens. Bioelectron. 2014, 59, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, H.; Fu, Q.; Liao, Q.; Zhu, X.; Kobayashi, H.; Ye, D. Voltage reversal causes bioanode corrosion in microbial fuel cell stacks. Int. J. Hydrogen Energy 2017, 42, 27649–27656. [Google Scholar] [CrossRef]

- Vilajeliu-Pons, A.; Puig, S.; Salcedo-Dávila, I.; Balaguer, M.; Colprim, J. Long-term assessment of six-stacked scaled-up MFCs treating swine manure with different electrode materials. Environ. Sci. 2017, 3, 947–959. [Google Scholar] [CrossRef] [Green Version]

- Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Younesi, H.; Shakeri, M. A novel microbial fuel cell stack for continuous production of clean energy. Int. J. Hydrogen Energy 2012, 37, 5992–6000. [Google Scholar] [CrossRef]

- Jafary, T.; Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Hghparast, F.; Daud, W.R.W. Assessment of bioelectricity production in microbial fuel cells through series and parallel connections. Energy Convers. Manag. 2013, 75, 256–262. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Zhu, X.; Ye, D.-d.; Fu, Q.; Liao, Q. Response of stacked microbial fuel cells with serpentine flow fields to variable operating conditions. Int. J. Hydrogen Energy 2017, 42, 27641–27648. [Google Scholar] [CrossRef]

- Zhuang, L.; Zhou, S. Substrate cross-conduction effect on the performance of serially connected microbial fuel cell stack. Electrochem. Commun. 2009, 11, 937–940. [Google Scholar] [CrossRef]

- Zhuang, L.; Yuan, Y.; Wang, Y.; Zhou, S. Long-term evaluation of a 10-liter serpentine-type microbial fuel cell stack treating brewery wastewater. Bioresour. Technol. 2012, 123, 406–412. [Google Scholar] [CrossRef]

- Gurung, A.; Kim, J.; Jung, S.; Jeon, B.-H.; Yang, J.E.; Oh, S.-E. Effects of substrate concentrations on performance of serially connected microbial fuel cells (MFCs) operated in a continuous mode. Biotechnol. Lett. 2012, 34, 1833–1839. [Google Scholar] [CrossRef]

- An, J.; Sim, J.; Lee, H.-S. Control of voltage reversal in serially stacked microbial fuel cells through manipulating current: Significance of critical current density. J. Power Sources 2015, 283, 19–23. [Google Scholar] [CrossRef]

- Ledezma, P.; Stinchcombe, A.; Greenman, J.; Ieropoulos, I. The first self-sustainable microbial fuel cell stack. Phys. Chem. Chem. Phys. 2013, 15, 2278–2281. [Google Scholar] [CrossRef] [PubMed]

- Ledezma, P.; Greenman, J.; Ieropoulos, I. MFC-cascade stacks maximise COD reduction and avoid voltage reversal under adverse conditions. Bioresour. Technol. 2013, 134, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Walter, X.A.; Stinchcombe, A.; Greenman, J.; Ieropoulos, I. Urine transduction to usable energy: A modular MFC approach for smartphone and remote system charging. Appl. Energy 2017, 192, 575–581. [Google Scholar] [CrossRef]

- Ieropoulos, I.; Greenman, J.; Melhuish, C. Microbial fuel cells based on carbon veil electrodes: Stack configuration and scalability. Int. J. Energy Res. 2008, 32, 1228–1240. [Google Scholar] [CrossRef]

- Zhuang, L.; Zheng, Y.; Zhou, S.; Yuan, Y.; Yuan, H.; Chen, Y. Scalable microbial fuel cell (MFC) stack for continuous real wastewater treatment. Bioresour. Technol. 2012, 106, 82–88. [Google Scholar] [CrossRef]

- Feng, Y.; He, W.; Liu, J.; Wang, X.; Qu, Y.; Ren, N. A horizontal plug flow and stackable pilot microbial fuel cell for municipal wastewater treatment. Bioresour. Technol. 2014, 156, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Mateo, S.; Cantone, A.; Cañizares, P.; Fernández-Morales, F.J.; Scialdone, O.; Rodrigo, M.A. On the staking of miniaturized air-breathing microbial fuel cells. Appl. Energy 2018, 232, 1–8. [Google Scholar] [CrossRef]

- He, W.; Wallack, M.J.; Kim, K.-Y.; Zhang, X.; Yang, W.; Zhu, X.; Feng, Y.; Logan, B.E. The effect of flow modes and electrode combinations on the performance of a multiple module microbial fuel cell installed at wastewater treatment plant. Water Res. 2016, 105, 351–360. [Google Scholar] [CrossRef]

- Ge, Z.; He, Z. Long-term performance of a 200 liter modularized microbial fuel cell system treating municipal wastewater: Treatment, energy, and cost. Environ. Sci. Water Res. Technol. 2016, 2, 274–281. [Google Scholar] [CrossRef]

- Janicek, A.; Fan, Y.; Liu, H. Design of microbial fuel cells for practical application: A review and analysis of scale-up studies. Biofuels 2014, 5, 79–92. [Google Scholar] [CrossRef]

- Logan, B. Scaling up microbial fuel cells and other bioelectrochemical systems. Appl. Microbiol. Biotechnol. 2010, 85, 1665–1671. [Google Scholar] [CrossRef] [PubMed]

- Ghadge, A.N.; Jadhav, D.A.; Ghangrekar, M.M. Wastewater treatment in pilot-scale microbial fuel cell using multi-electrode assembly with ceramic separator suitable for field applications. Environ. Prog. Sustain. Energy 2016, 35, 1809–1817. [Google Scholar] [CrossRef]

- Jadhav, D.A.; Ghadge, A.N.; Ghangrekar, M.M. Simultaneous organic matter removal and disinfection of wastewater with enhanced power generation in microbial fuel cell. Bioresour. Technol. 2014, 163, 328–334. [Google Scholar] [CrossRef] [PubMed]

| Types | Substrates | Electrode | Electron Acceptor | Power Density | Ref. | |

|---|---|---|---|---|---|---|

| Anode | Cathode | |||||

| Single chamber | Glucose | Graphite carbon fiber brush | Pt (30%) coated carbon cloth | Oxygen | 2.4 W m−2 | [46] |

| Single chamber | Acetate-amended Wastewater | Graphite fiber brush | Activated carbon catalyst on Stainless steel mesh | Oxygen | 1.1 W m−2 | [47] |

| Double chamber | Glucose | Carbon paper | Carbone cloth | Permanganate | 0.12 W m−2 | [48] |

| Double chamber | Glucose | Graphite plate | Graphite plate | Hexacynoferrate | 4.3 W m−2 | [49] |

| Stacked | Sodium acetate | Granular activated carbon | Granular activated carbon | Oxygen | 50.9 W m−3 | [50] |

| Stacked | Neat undiluted urine | Untreated carbon fiber veil | Coating activated carbon paste on polytetrafluooethylene | Oxygen | 0.8 W m−3 | [51] |

| Configuration | No. of Reactors | Total Volume (L) | Electrode | Connection | Internal Resistance (Ω) | OCV (V) | Maximum Power Density (W m−3) | Maximum Current Density (A m−3) | Organic conc. or OLR | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Two-chamber MFC stack | 6 | 0.936 | Graphite granules | Cu wire | 6.5 (s) 1) | 4.16 (s) 0.67 (p) | 308 (s) 263 (p) 2) | 0.085 A (s) 0.425 A (p) | 1.62 g COD L−1 d−1 | [64] |

| Bipolar two-chamber MFC stack | 4 | 20 | Ti plates | Ti plates | 1.2 mΩ m−3 (s) | 4.06 (s) | 144 (s) | 2.8 A m−2 | - | [63] |

| Two-chamber MFC stack | 3 | 1.8 | Graphite | Cu wire | 11.5 Ω m−2 (s) 1 Ω m−2 (p) | 1.042 (s) 0.687 (p) | 0.11 W m−2 (s) 0.13 W m−2 (p) | 0.098 A m−2 (s) 0.381 A m−2 (p) | 30 g L−1 of G-F-S 4) | [69] |

| Two chamber MFC stack | 4 | - | Carbon cloth | - | - | 3.27 (s) 0.82 (p) | 2.22 W m−2 (s) 1.98 W m−2 (p) | 16.9 A m−2 (s) 4.45 A m−2 (p) | 0.5 g COD L−1 | [70] |

| Single-chamber MFC stack | 10 | 0.063 | Carbon fiber veil | - | - | 3.6 (s) | 0.97 (p) | ~7.1 (p) | 5 mM of acetate | [78] |

| Tubular type of single-chamber MFC stack | 5 | 1.475 | A: Graphite felt C: Carbon fiber cloth | Ti wire | 10–15 (p) | 2.1 (s) | 67.5 W m−2 (s) 175.7 W m−2 (p) | 0.128 A m−2 (s) 0.675 A m−2 (p) | 4.9 g COD L−1 d−1 | [79] |

| Tubular type of single-chamber MFC stack | 40 | 10 | A; Graphite felt C: Metal catalyst | Ti wire | 800 (s) 15 (s-p) 3) | 23 (s) 3.25 (s-p) | 4.1 (s) 6.0 (s-p) | 2.1 (s) 13.8 (s-p) | 1.06 g COD L−1 d−1 | [72] |

| Cascade type of single-chamber 3D-printed MFC stack | 40 | 0.8 | Carbon veil | - | - | 13 (20 units used) | - | - | 25 mM of acetate | [75] |

| Horizontally stackable type of single-chamber MFC | 1 (32) 5) | 250 | A: Carbon brush C: Carbon mesh | Ti wire | 2.3 × 108 Ω m−2 | 0.8 (p) | 0.116 W | 0.435 A | ~0.32 g COD L−1 | [80] |

| Bipolar plate single-chamber MFC stack | 3 | 0.35 | Graphite felt | Graphite plate | 634 | 1.58 (s) | 0.023 W m−2 (s) | 0.037 A m−2 | 10 mM of acetate | [65] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flimban, S.G.A.; Ismail, I.M.I.; Kim, T.; Oh, S.-E. Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications: Design, Major Elements, and Scalability. Energies 2019, 12, 3390. https://doi.org/10.3390/en12173390

Flimban SGA, Ismail IMI, Kim T, Oh S-E. Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications: Design, Major Elements, and Scalability. Energies. 2019; 12(17):3390. https://doi.org/10.3390/en12173390

Chicago/Turabian StyleFlimban, Sami G. A., Iqbal M. I. Ismail, Taeyoung Kim, and Sang-Eun Oh. 2019. "Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications: Design, Major Elements, and Scalability" Energies 12, no. 17: 3390. https://doi.org/10.3390/en12173390

APA StyleFlimban, S. G. A., Ismail, I. M. I., Kim, T., & Oh, S. -E. (2019). Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications: Design, Major Elements, and Scalability. Energies, 12(17), 3390. https://doi.org/10.3390/en12173390