Experimental and Numerical Analysis on Flow Characteristics in a Double Helix Screw Pump

Abstract

:1. Introduction

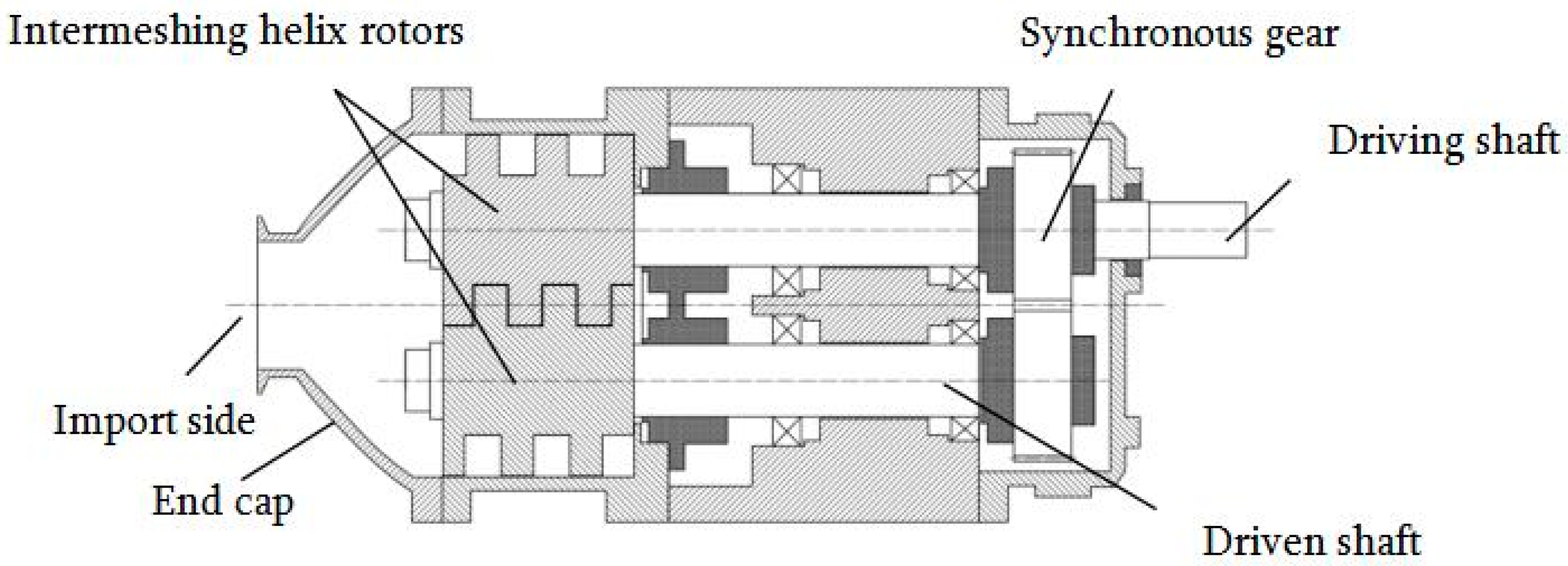

2. The Pump’s Main Characteristics and Working Principle

3. Numerical Simulation Method

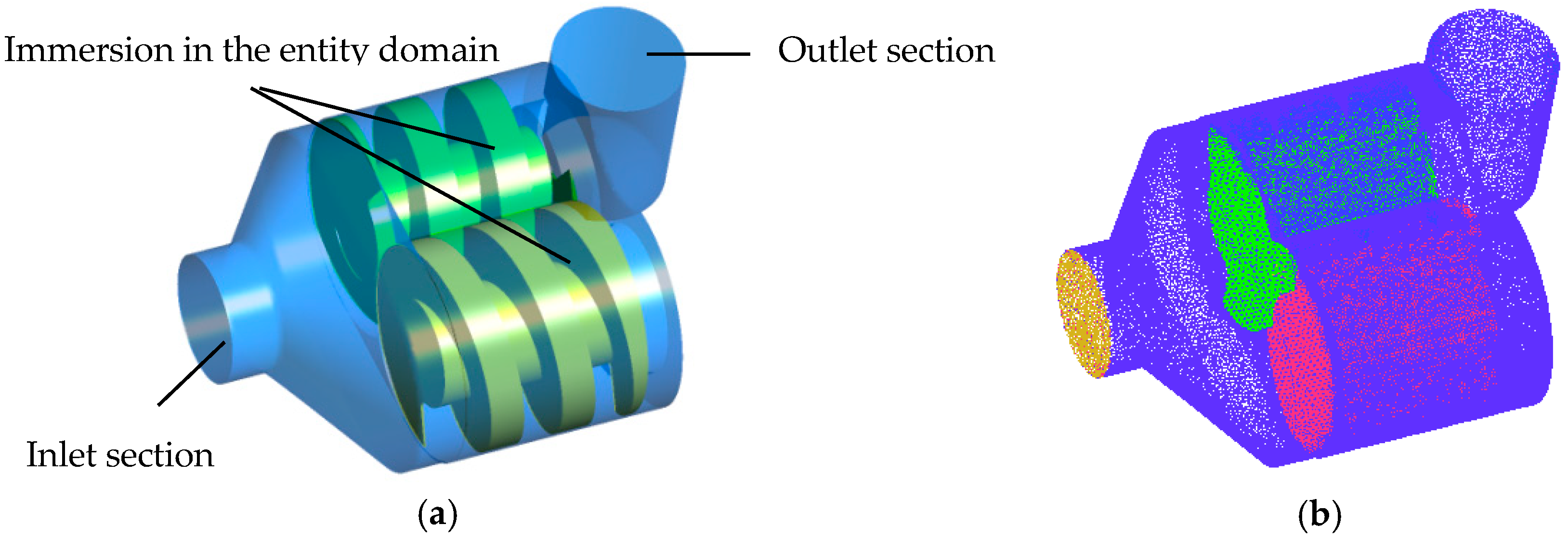

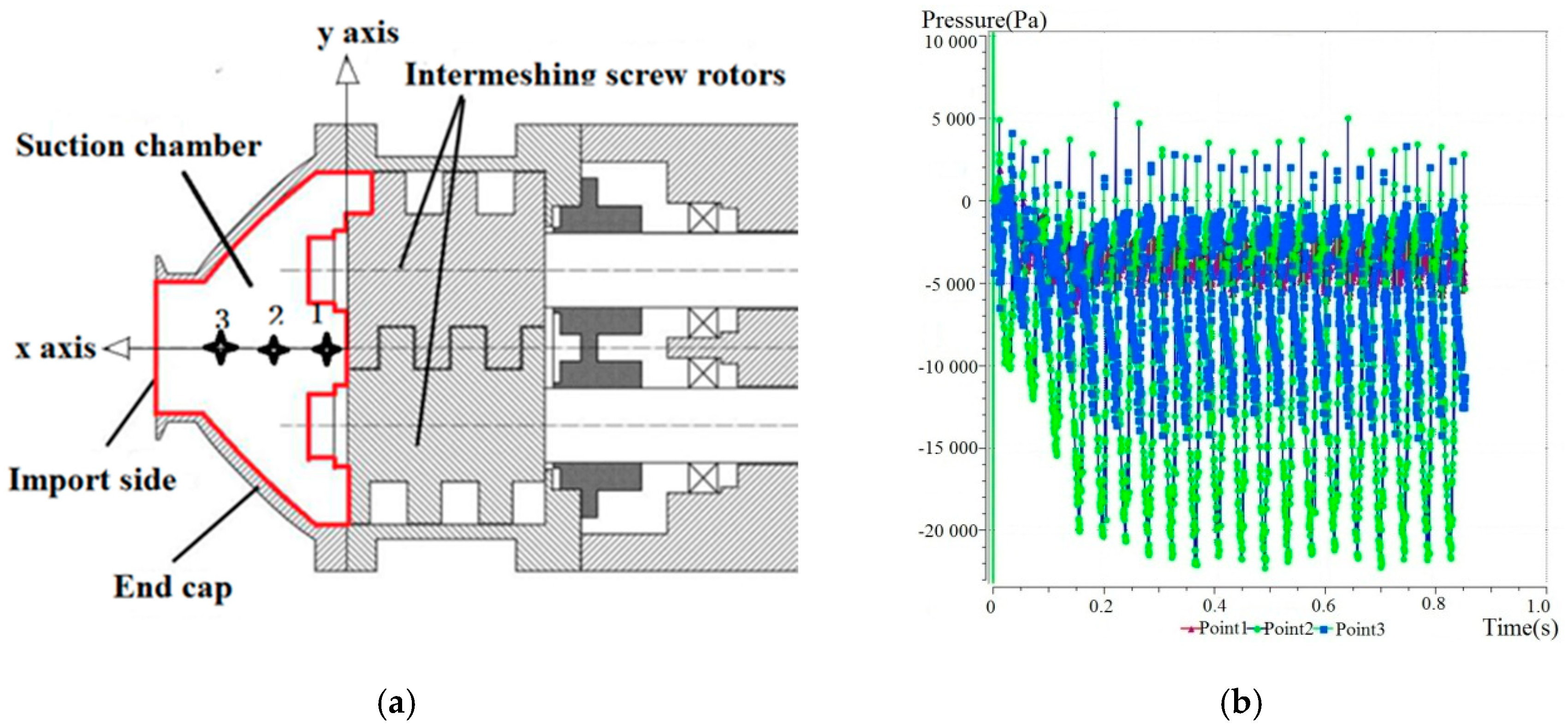

3.1. Immersed Solid Method

3.2. Control Equations and Turbulence Model

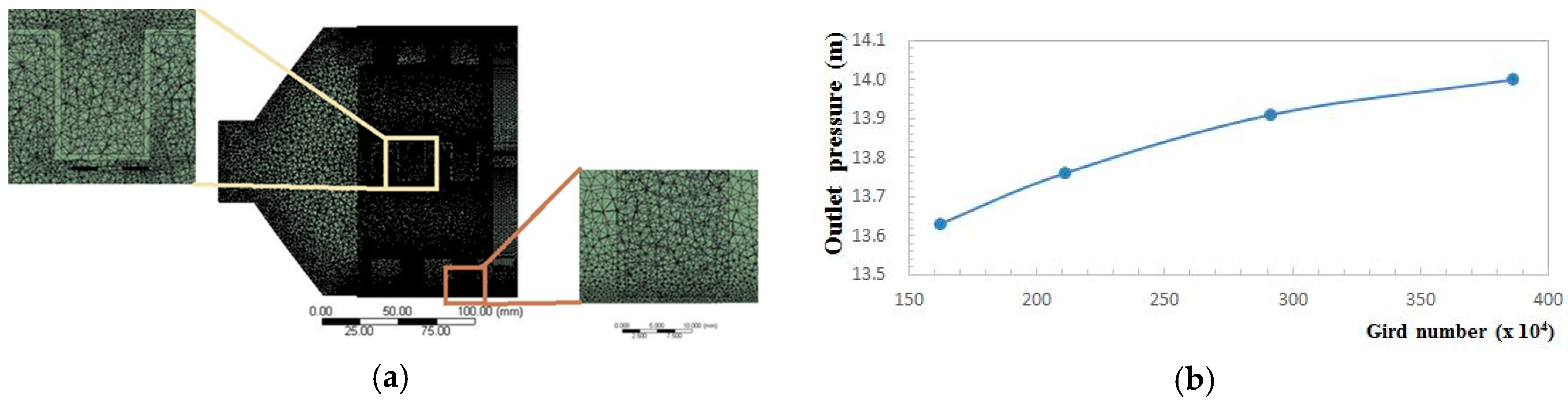

3.3. Meshing

- The rotor is considered as an immersed solid, keeping the momentum scaling factor at 10.0.

- The total pressure value is given at the inlet plane of the calculation domain. The pressure value levels are given relative to a standard atmospheric pressure of 101,325 Pascals.

- A volume flow rate is imposed as the outlet boundary condition; the flow direction is perpendicular to the exit boundary.

- The flow (water) is incompressible and at normal temperature. No heat exchange is taken into account.

- Calculations are performed for five different flow rates with different time steps. The inlet section location is closed to the experimental pressure tap. However, for simulation, another section is also tested, much further upstream, in order to check how initial conditions may influence the local numerical results.

4. Experimental Set-Up and Results

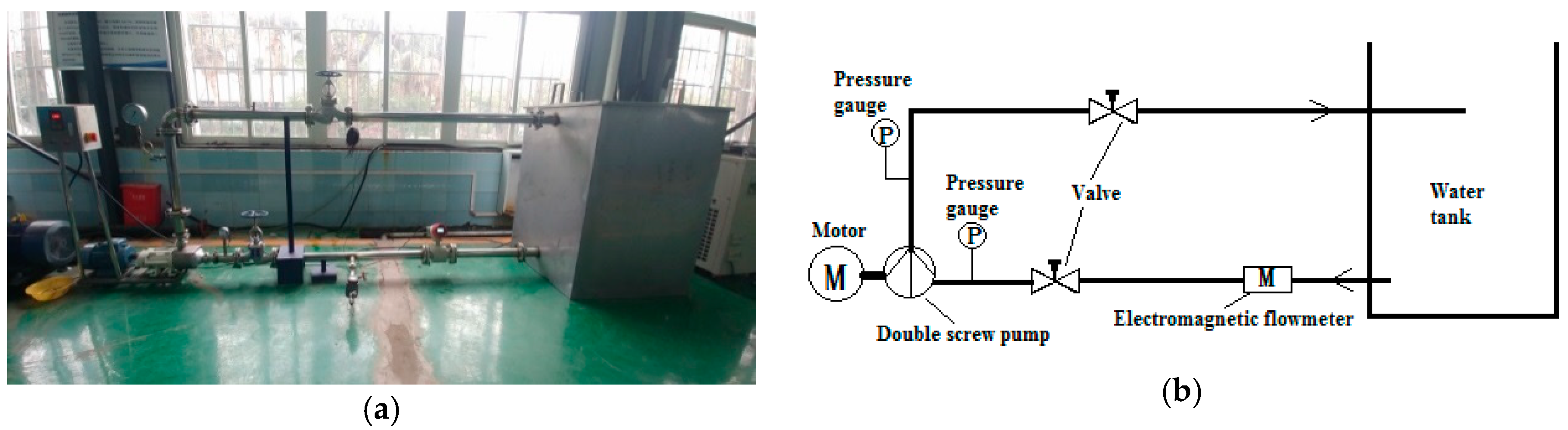

4.1. Experimental Set-Up

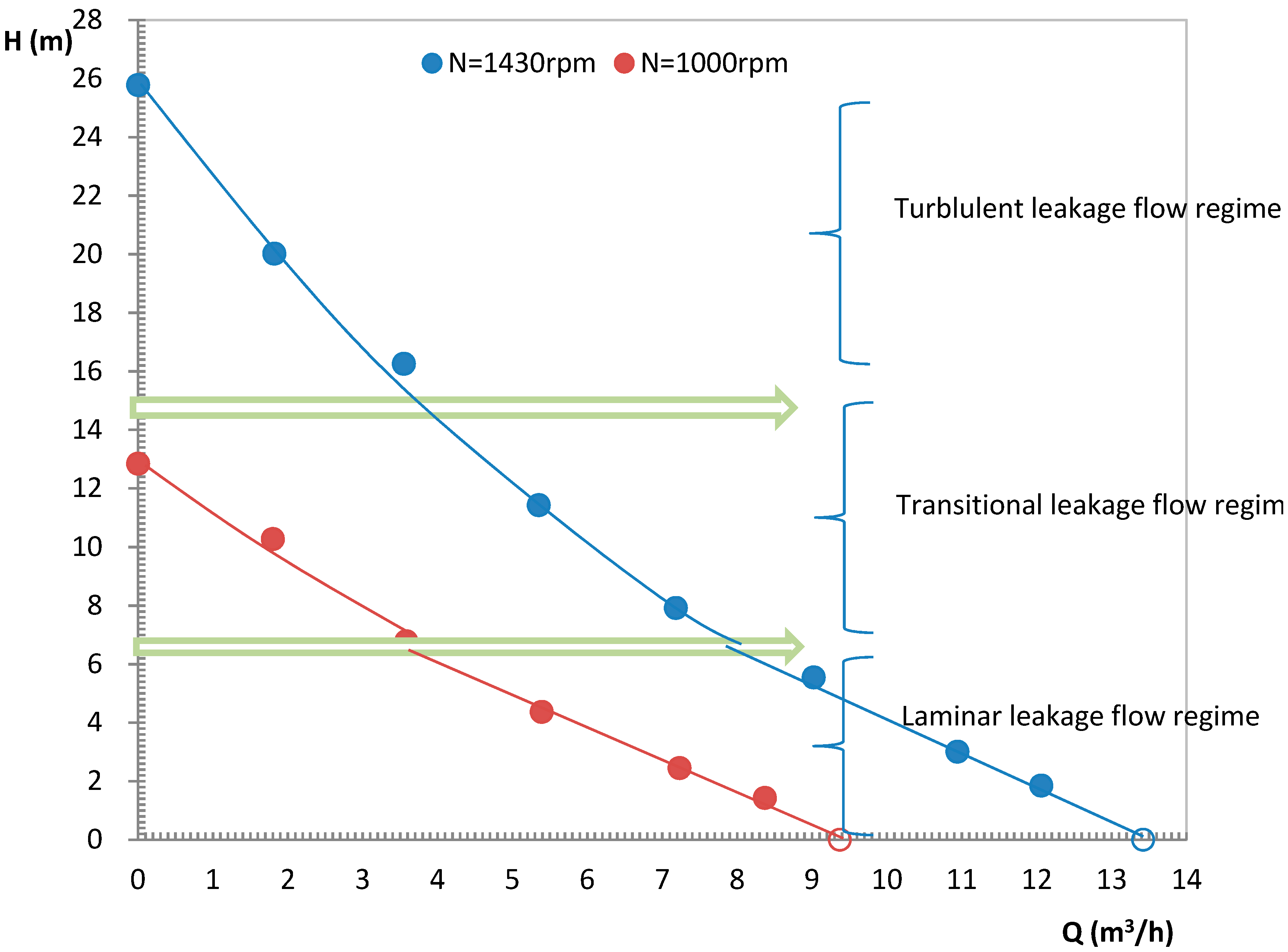

4.2. Experimental Results

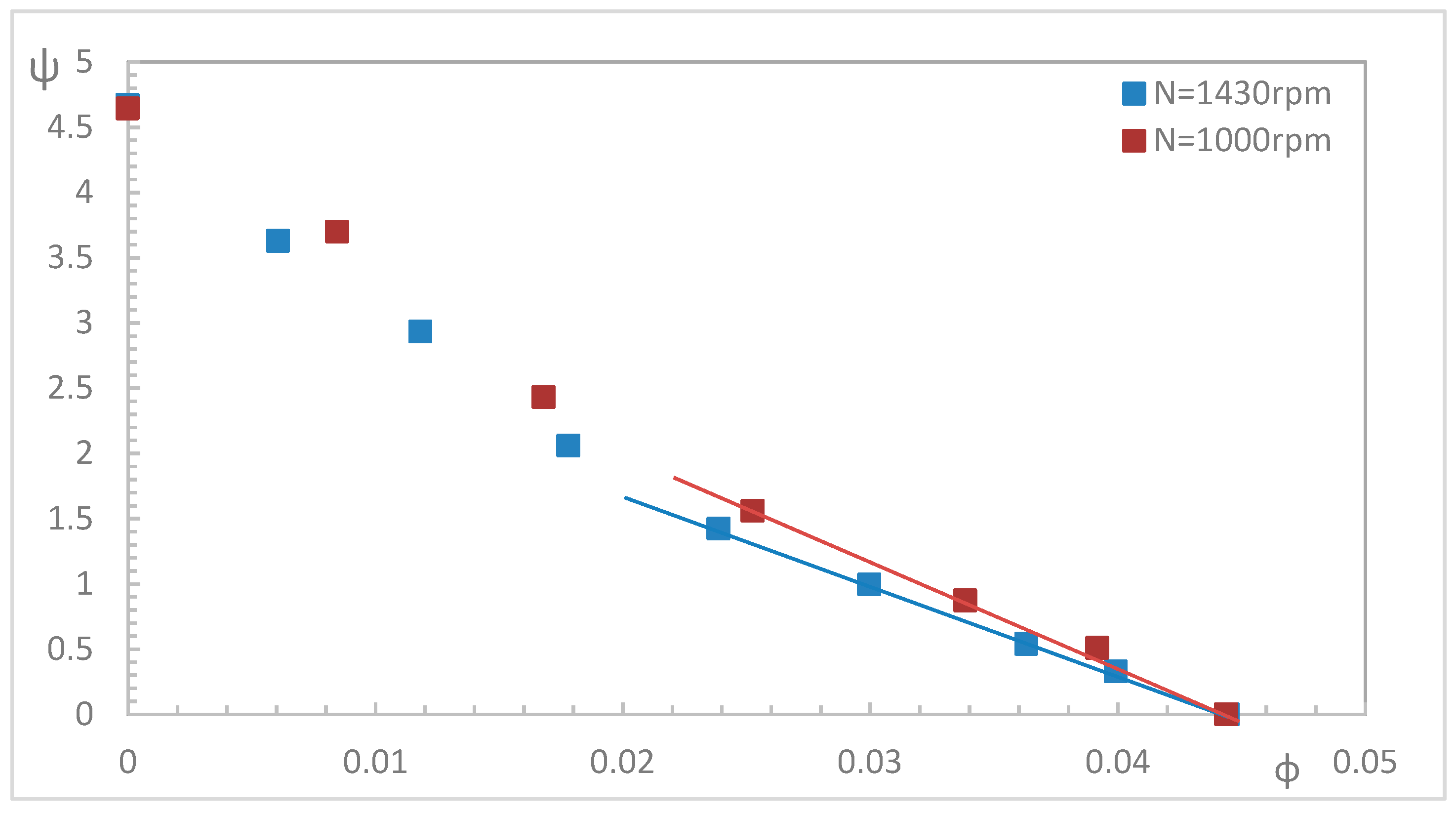

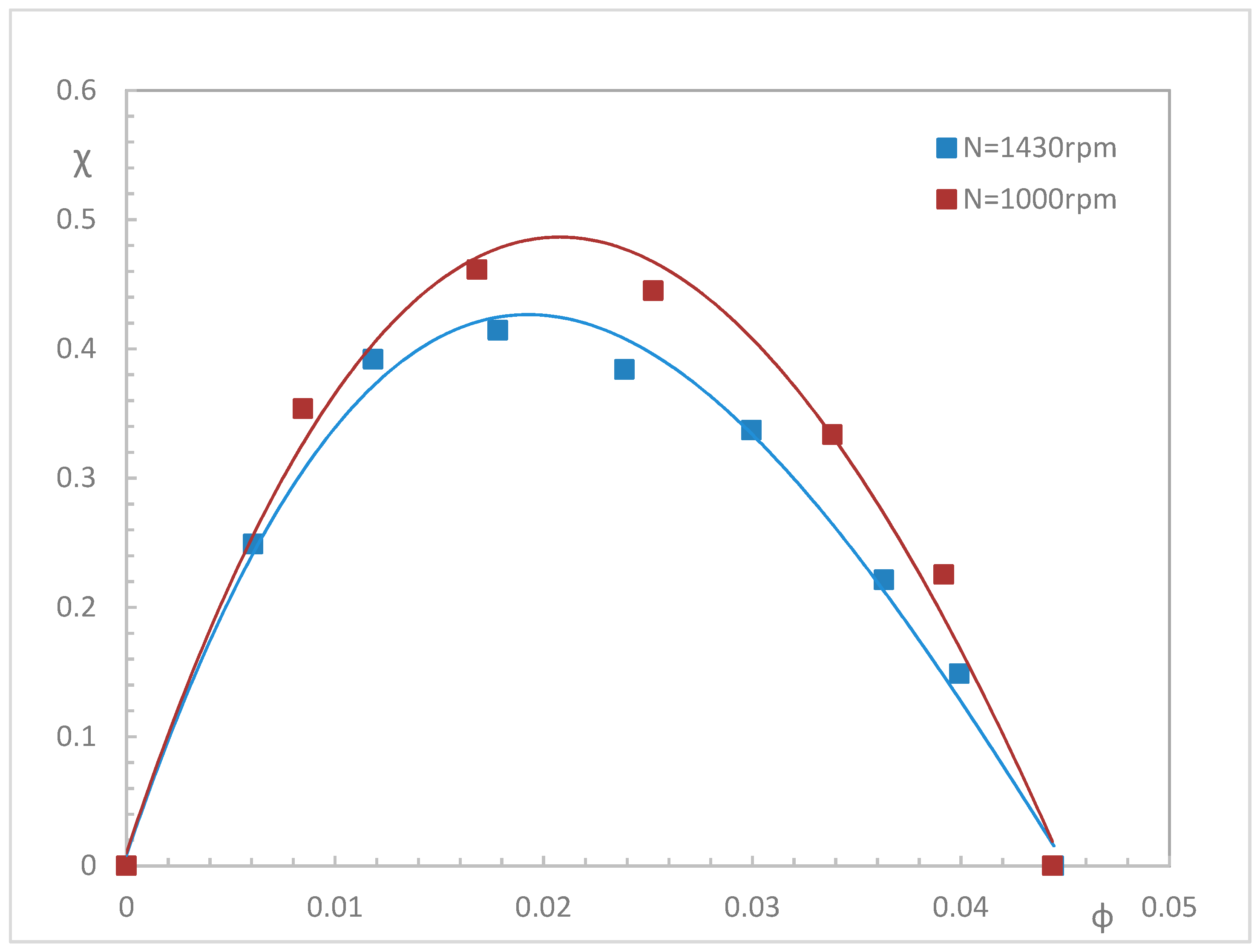

4.3. Non-Dimensional Performance Coefficients

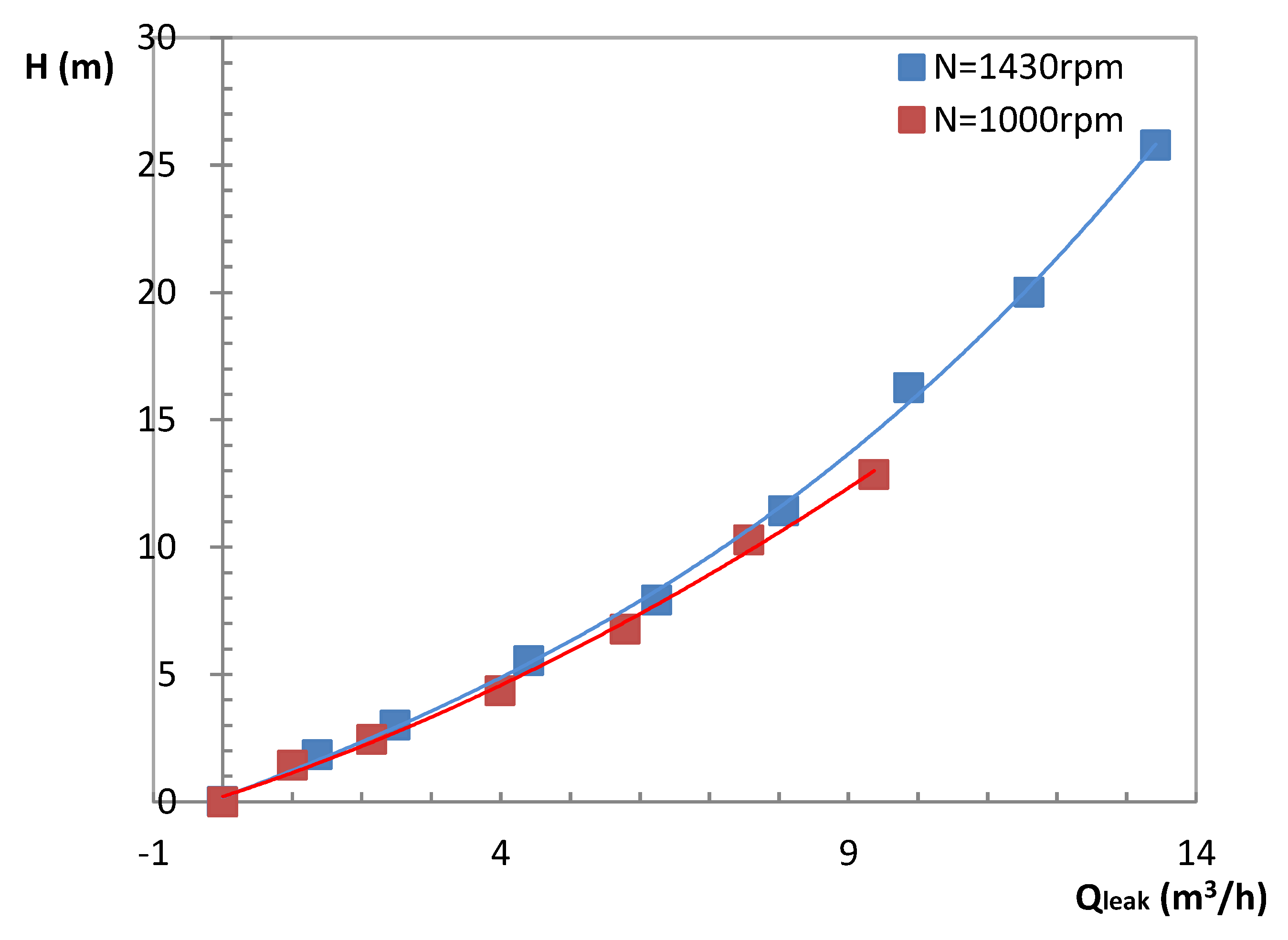

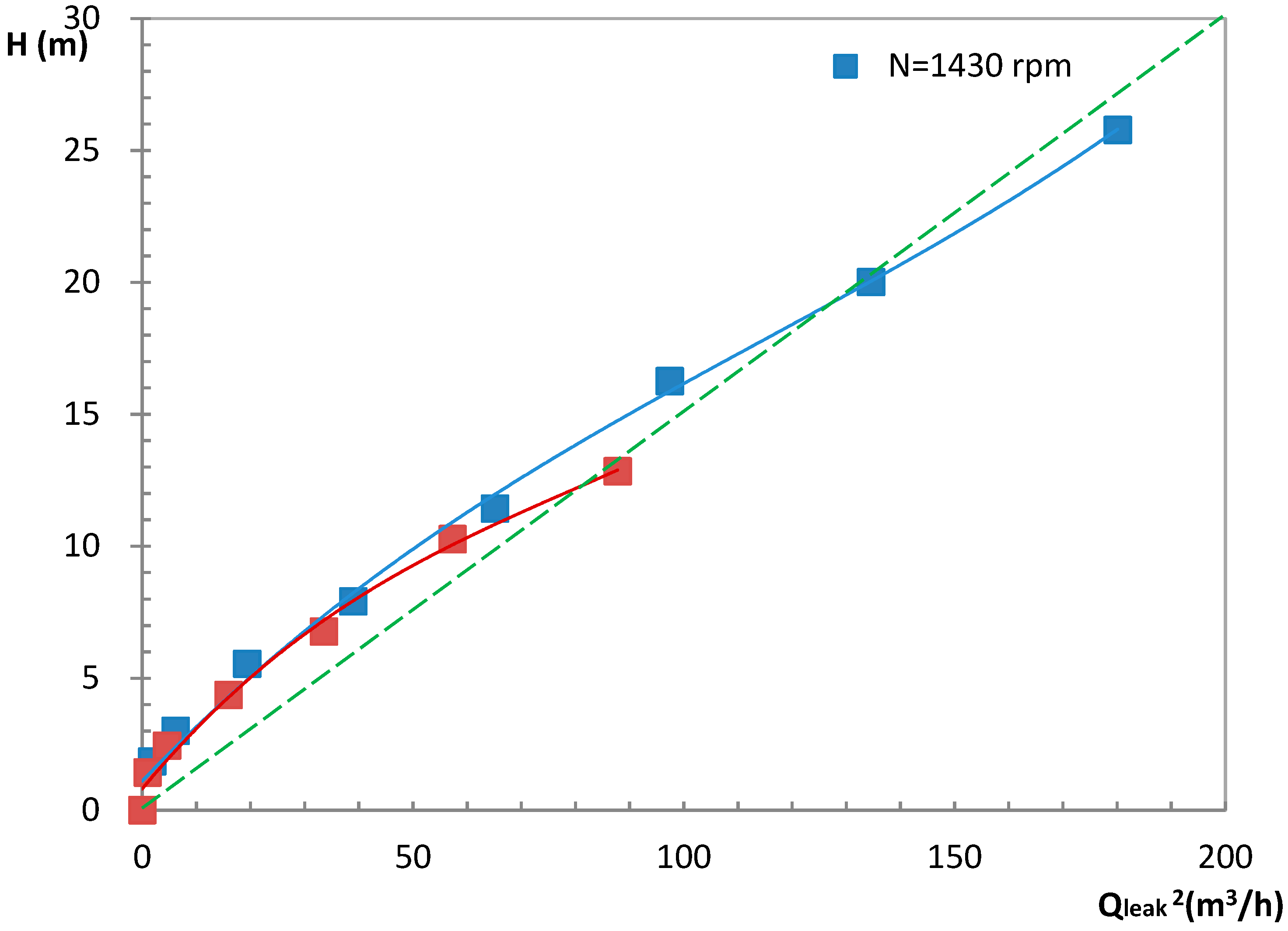

4.4. Leakage Volume Flow Rate Evaluation

4.4.1. Experimental Leakage Calculation

4.4.2. Analytical Leakage Evaluation

- where Δh is the difference of head in each land. Neglecting the losses at inlet and outlet pump end caps, the head difference of each land is obtained assuming the same head step value in each screw land. This is confirmed by the numerical results given in Section 6.

- k = 1.5 (k = k1 + k2; k1 = 0.5 for a sudden acceleration and k2 = 1.0 for a sudden expansion)

- λ = 64/Releak for a laminar flow regime

- λ = 0.3322 × Releak−0.25 for a turbulent flow regime; Releak = Vleak × δ/υ

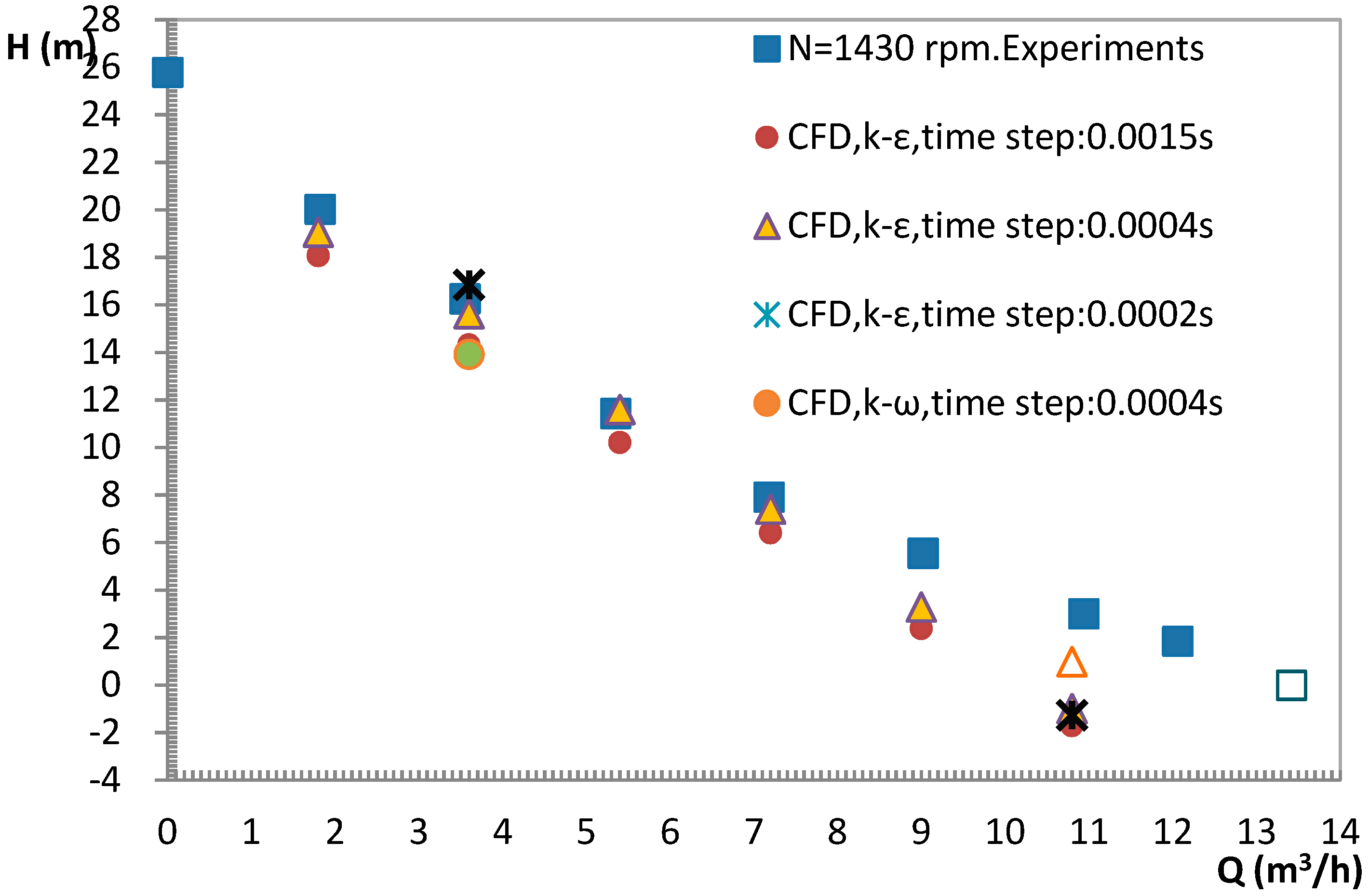

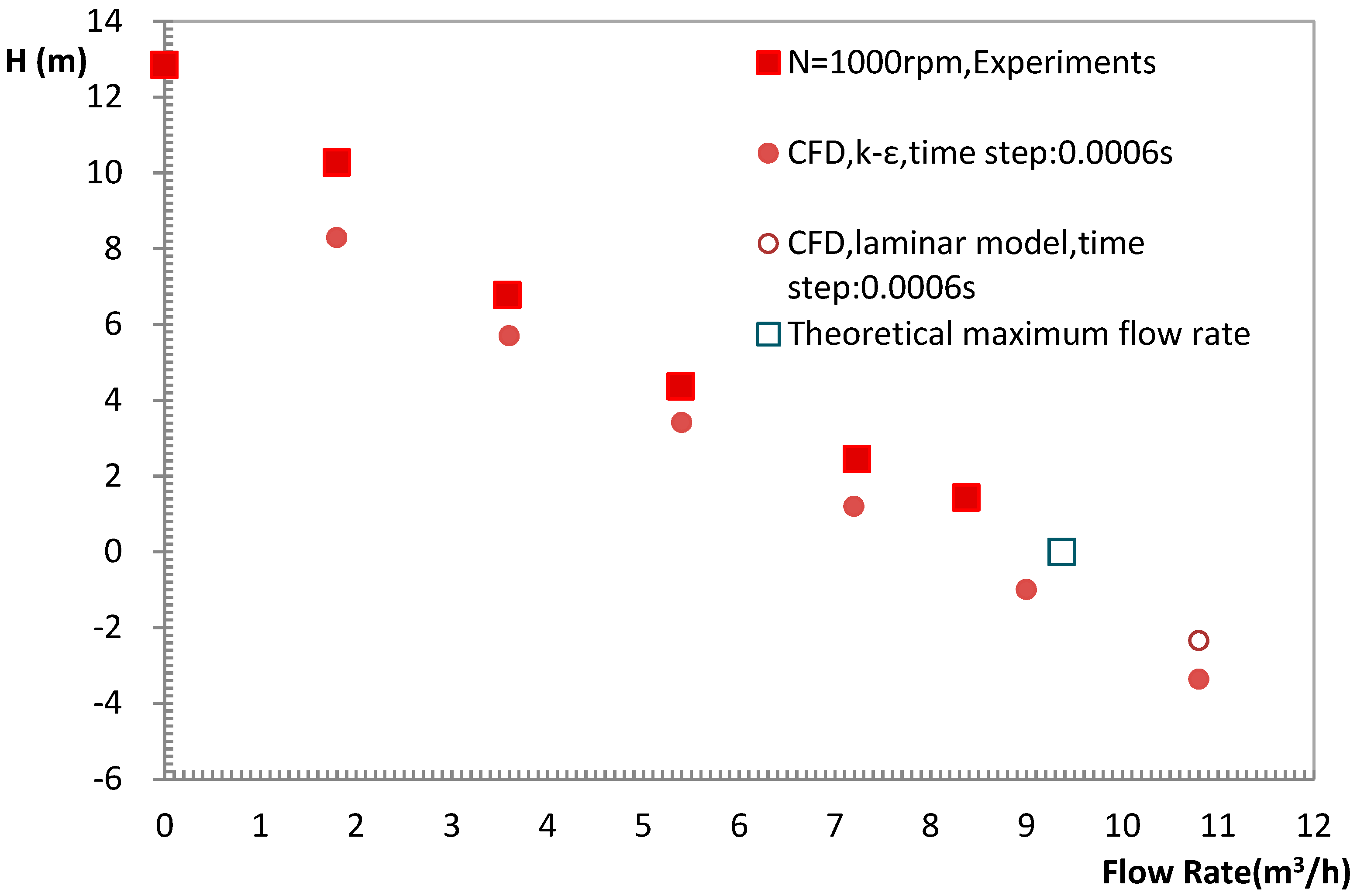

5. Comparisons between Experimental Performances and CFD Results

5.1. Numerical Set-Up Conditions

5.2. Overall Pump Performances

6. Local Results from CFD and Analysis

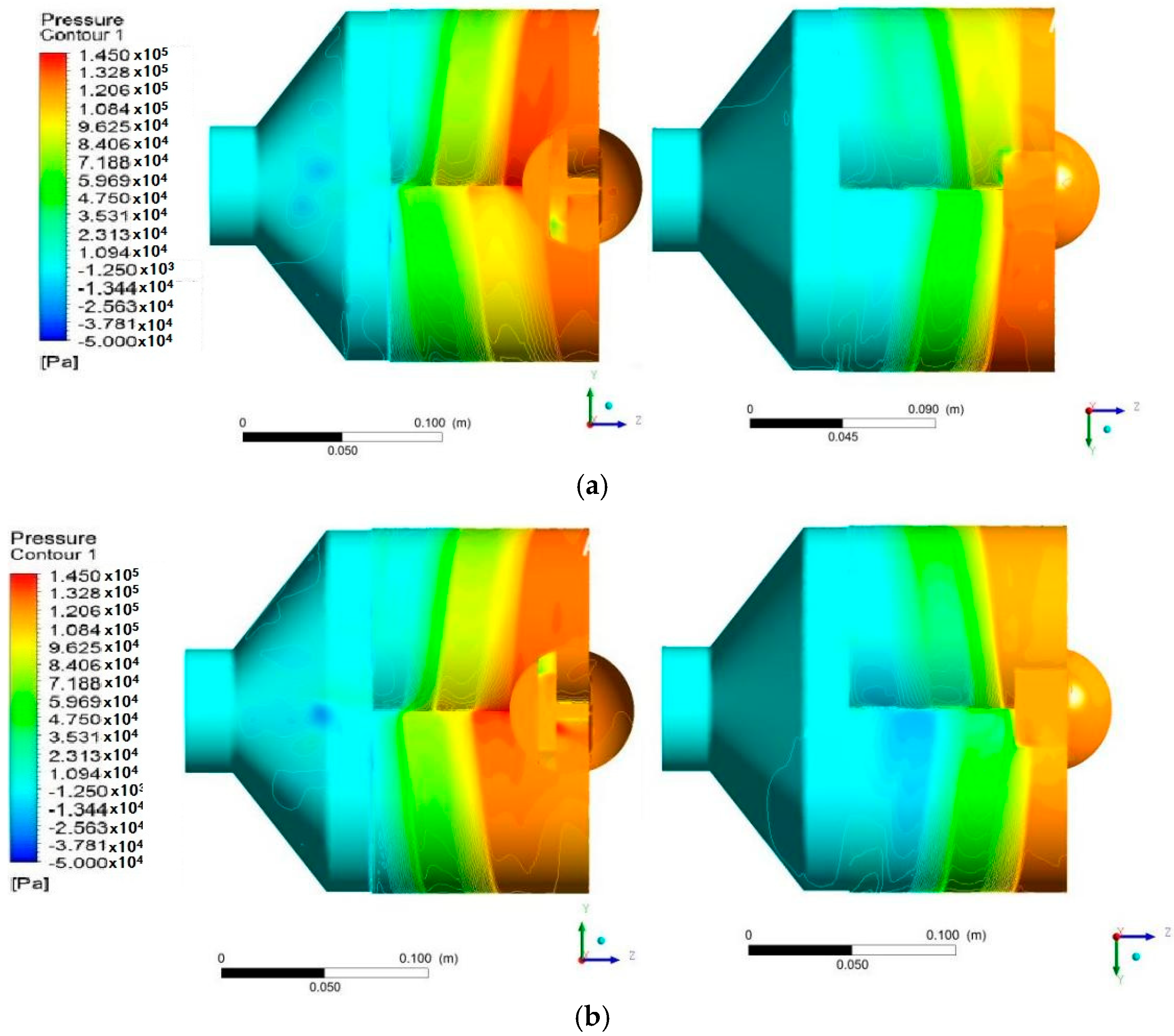

6.1. Pressure Distribution

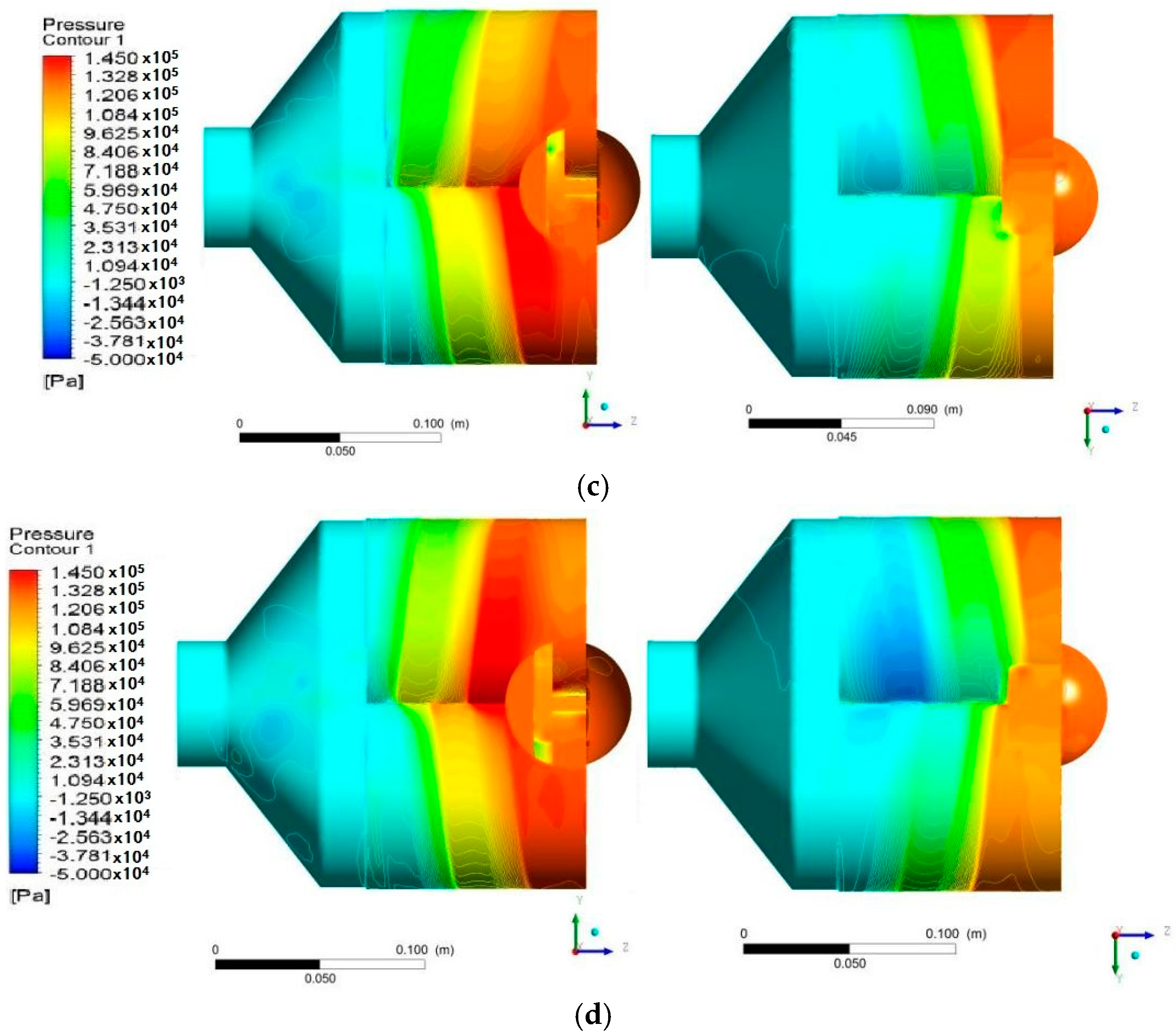

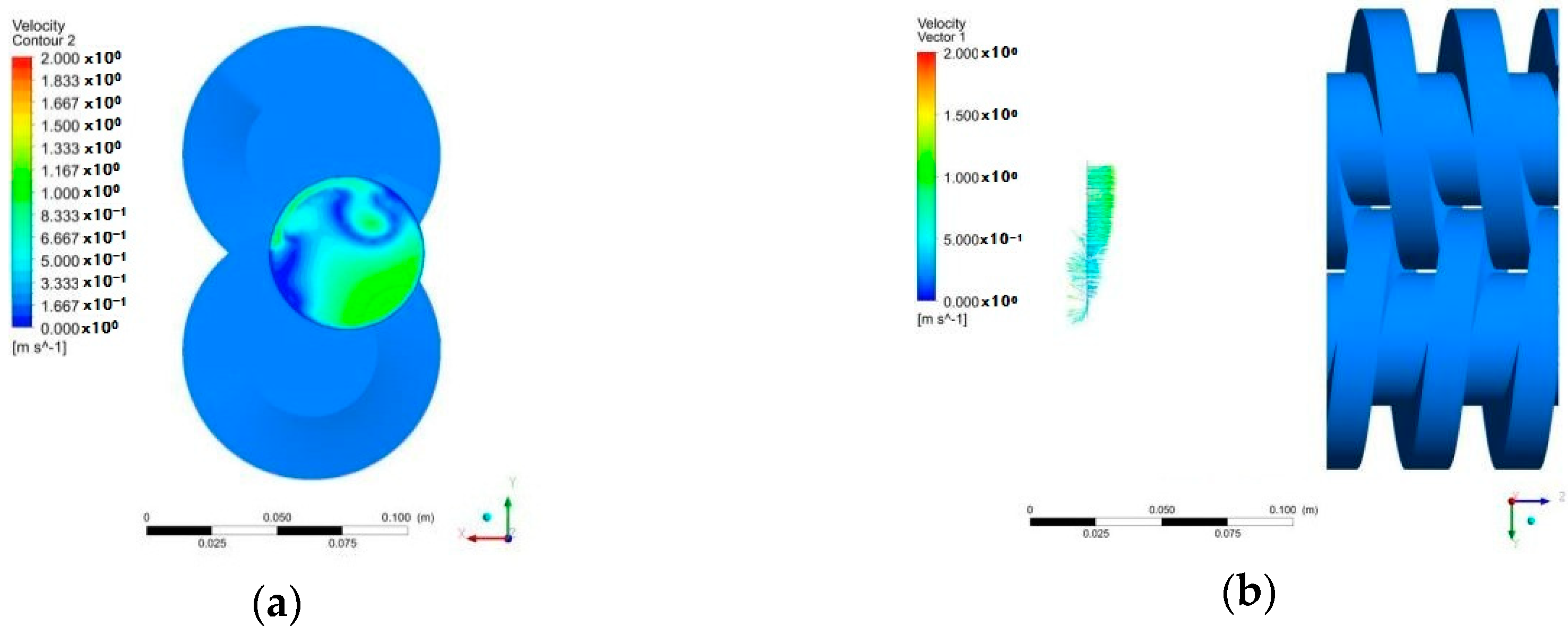

6.2. Velocity Distribution

6.3. Particular Velocity Fields

7. Conclusions

- (1)

- Overall performance measurements were performed in a twin screw pump for two rotational speeds, using water as the working fluid. As expected, the leakage amount was found to be independent of the rotational speed and only depends on the pressure difference.

- (2)

- Physical analysis allows the determination of laminar, transitional and turbulent leakage flow regimes that govern the leakage amount in such pump geometry.

- (3)

- Analytical evaluation based on loss friction models always overestimated leakage values compared with experimental ones. The empirical loss coefficient must be re-evaluated according to rotational effects and viscous forces that have been neglected in the present study.

- (4)

- CFD simulation results generally show better results compared with analytical ones. The pressure gradient in the rotor meshing area is related to the displaced volume with time.

- (5)

- In order to obtain suitable numerical outlet pressure delivery values, three rotating time steps were tested. A time step value corresponding to an angular rotor variation of at least three degrees was sufficient enough to reach experimental results within an error of less than 2%. In the same respect, stable periodic results were obtained for a minimum of six complete screw revolutions.

- (6)

- The main leakage areas correspond to the casing gap between the rotor and the pump casing. The results on leakage values strongly depend on a correct evaluation of the laminar and turbulent flow regime that depends on the local pressure differences.

- (7)

- The inlet flow before the screw inlet plane is highly non-uniform. This is related to the squeezing effect of the two rotors and the large local amount of leakage flows from the casing gap.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| dh | hydraulic diameter | (meters (m)) |

| g | acceleration | (meters per second squared (m/s−2)) |

| H | global pump head | (meters of water (m)) |

| k | loss coefficient | (-) |

| Q | volume flow rate | (meters cubed (m3) per hour (h)) |

| Releak | Reynolds number based on leak tip gap and leak velocity Vleak | (-) |

| S | front section of the one screw land | (meters squared (m2)) |

| Ut | tip speed screw rotational velocity | (meters per second (m/s)) |

| V | velocity | (meters per second (m/s)) |

| δ | tip radial gap | (meters (m)) |

| Δh | head value between each land | (meters of water (m)) |

| Φ | flow coefficient | (-) |

| λ | friction loss coefficient | (-) |

| Ψ | head coefficient | (-) |

| ρ | flow density | (kilograms per meter cubed (kg/m3)) |

| χ | fluid power coefficient | (-) |

| Ωs | specific speed Ωs = ω × Q0.5/(g × H)3/4 | (-) |

| Subscripts | ||

| leak | related to the leak |

References

- Vetter, G.; Wincek, M. Performance Prediction of Twin-Screw Pumps for Two-Phase Gas/Liquid Flow. In Proceedings of the Fluid Engineering Conference (FED); Pumping Machinery; ASME: Washington, DC, USA, 1993; Volume 154, pp. 331–340. [Google Scholar]

- Prang, A.J.; Cooper, P. Enhanced Multiphase Flow Predictions in Twin-Screw Pumps. In Proceedings of the Twenty-First International Pump Users Symposium; Turbomachinery Lab., Texas A&M University: College Station, TX, USA, 2004. [Google Scholar]

- Liu, P.; Patil, A.; Morrisson, G. Multiphase Flow Performance Prediction Model for Twin-Screw Pump. ASME J. Fluid Eng. 2018, 140, 031103. [Google Scholar] [CrossRef]

- Wang, C.L.; Xing, Y.; Ruan, J.S. Experimental study on screw groove of labyrinth screw pump. Pump Technol. 2006, 2, 18–20. [Google Scholar]

- Li, F.T. Screw Pump; Machinery Industry Press: Chengdu, China, 2010; Volume 3, pp. 147–171. [Google Scholar]

- Mao, H.Y.; Li, N.; Yang, B.; Zhang, J. Forming of the rotor tooth profile of cycloid rotor pump. Shandong Sci. 2003, 16, 26–29. [Google Scholar]

- Ryazantsev, V.M. Characteristics of screw pumps with screws of different profile. Chem. Pet. Eng. 1998, 34, 109–113. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Q.; Li, Z.; Yan, D. Leakage Mechanism of Screw Pump Based on Leakage Model in Fluid Mechanics. J. Agric. Mech. 2014, 45, 326–332. [Google Scholar]

- Tian, G.W.; Zhang, Y.C.; Li, J.Z. Computational fluid dynamics (CFD) simulation of the internal flow in a labyrinth screw pump. J. Beijing Univ. Chem. Technol. (Nat. Sci. Ed.) 2007, 34, 208–220. [Google Scholar]

- Wang, C.L.; Ma, Q.Y.; Xing, Y.; Li, T.T.; Yang, M. Numerical simulation and perform ance prediction inside trapeziform labyrinth screw pump. J. Jiangsu Univ. (Nat. Sci. Ed.) 2008, 2, 138–142. [Google Scholar]

- Tang, Q.; Zhang, Y.; Gao, Z. Numerical Simulation of Flow Field Dynamics Characteristics for Twin-screw Pump. China Mech. Eng. 2010, 21, 1453–1457. [Google Scholar]

- Yan, D.; Kovacevic, A.; Rane, S. Rotor Profile Design and Numerical Analysis of 2-3 Type Multiphase Twin-Screw Pumps. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 232, 186–202. [Google Scholar] [CrossRef]

- Yan, D.; Kovacevic, A.; Rane, S. Numerical Investigation of cavitation in Twin Screw Pumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 3733–3750. [Google Scholar] [CrossRef]

- Song, X.G.; Jung, J.H.; Lee, H.S.; Kim, D.K.; Park, Y.C. 2-D Dynamic Analysis of a Pressure Relief Valve by CFD. In Proceedings of the 9th Wseas International Conference on Applied Computer and Applied Computational Science, Hangzhou, China, 11–13 April 2010; pp. 136–140. [Google Scholar]

- Song, X.G.; Park, Y.C.; Park, J.H. Blowdown Prediction of a Conventional Pressure Relief Valve with a Simplified Dynamic Model. Math. Comput. Model. 2013, 57, 279–288. [Google Scholar] [CrossRef]

- ANSYS Inc. Release 15.0 Documentation for ANSYS; ANSYS Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- Xie, L.H.; Zhao, X.Y.; Zhang, J.M. ANSYS CFX Fluid Analysis and Simulation; Beijing Electronics Industry Press: Beijing, China, 2010. [Google Scholar]

- Fan, Y.L.; Zhang, J.W.; Hu, C.Y.; Li, S.X. Influences of Structural Parameters on Properties of Poppet Valves. China Mech. Eng. 2017, 28, 1714–1717. [Google Scholar]

- Chen, S.S.; Ge, Q.; Zhou, Z.F.; Yang, G.P.; Yan, D.F. Numerical simulation of three-dimensional turbulent flow for reversible intake passage in large pumping stations. J. Jiangsu Univ. (Nat. Sci. Ed.) 2005, 2, 102–105. [Google Scholar]

- Chen, S.S.; Zhou, Z.F.; Qu, L.F.; Yang, G.P.; Yan, D.F. Numerical simulation of three-dimensional turbulent flow for tank-style outle tpassage in large pumping stations. J. Jiangsu Univ. (Nat. Sci. Ed.) 2005, 6, 468–471. [Google Scholar]

- Hu, K.; Li, Z.B. ANSYS ICEM CFD Detailed Project Examples; Beijing People’s Posts and Telecommunications Press: Beijing, China, 2014. [Google Scholar]

- Jing, K. Numerical simulation of 3-D flow characteristics in twin screw extruders with combined screws. Mech. Des. Manuf. 2008, 5, 85–87. [Google Scholar]

- Berand, F.; Tanguy, P.A.; Thibault, F. A Three dimension Fictitious Domain Method for Incompressible Fluid Flow Problems. Int. J. Numer. Methods Fluids 1997, 25, 719–736. [Google Scholar] [CrossRef]

- Cao, F.; Peng, Y.; Xing, Z.; Shu, P. Thermo dynamic Performance Simulation of a Twin-screw Multiphase Pump. Proc. Inst. Mech. Eng. 2001, 215, 157–163. [Google Scholar]

- Tang, Q.; Misganaw, A.; Ye, X.Z.; Zhang, Y.X. Numerical anslysis for twin screw pump internal flow. Appl. Mech. Mater. 2012, 130–134, 3658–3663. [Google Scholar]

- Turhan, Y. Efficiency and Leakage Analysis of a Twin Screw Multiphase Pump. Ph.D. Thesis, Texas A&M University, University Town, TX, USA, 2014. [Google Scholar]

| Name | Value | Units |

|---|---|---|

| chamber’s depth | 24 | mm |

| chamber’s width | 18.2 | mm |

| tip radial gap between the screw land and pump housing | 1.15 | mm |

| screw tooth width | 16.4 | mm |

| flank clearance gap between active and passive screw teeth | 0.9 | mm |

| screw rotor length (axial extend) | 88 | mm |

| screw revolution number | 2.54 | circle |

| pitch of the screw | 34.6 | mm |

| screw tip diameter | 99 | mm |

| screw hub diameter | 51 | mm |

| pipe diameter at pump inlet section | 63 | mm |

| pipe diameter at pump outlet section | 63 | mm |

| distance between two rotors axis | 75.9 | mm |

| Grid Number | Outlet Pressure (m) |

|---|---|

| 1,621,784 | 13.63 |

| 2,109,872 | 13.76 |

| 2,915,482 | 13.91 |

| 3,862,159 | 14.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Jiang, Q.; Bois, G.; Li, H.; Liu, X.; Yuan, S.; Heng, Y. Experimental and Numerical Analysis on Flow Characteristics in a Double Helix Screw Pump. Energies 2019, 12, 3420. https://doi.org/10.3390/en12183420

Zhang W, Jiang Q, Bois G, Li H, Liu X, Yuan S, Heng Y. Experimental and Numerical Analysis on Flow Characteristics in a Double Helix Screw Pump. Energies. 2019; 12(18):3420. https://doi.org/10.3390/en12183420

Chicago/Turabian StyleZhang, Weibin, Qifeng Jiang, Gérard Bois, Hong Li, Xiaobing Liu, Shuai Yuan, and Yaguang Heng. 2019. "Experimental and Numerical Analysis on Flow Characteristics in a Double Helix Screw Pump" Energies 12, no. 18: 3420. https://doi.org/10.3390/en12183420

APA StyleZhang, W., Jiang, Q., Bois, G., Li, H., Liu, X., Yuan, S., & Heng, Y. (2019). Experimental and Numerical Analysis on Flow Characteristics in a Double Helix Screw Pump. Energies, 12(18), 3420. https://doi.org/10.3390/en12183420