Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films

Abstract

:1. Introduction

1.1. Research Background and Objective

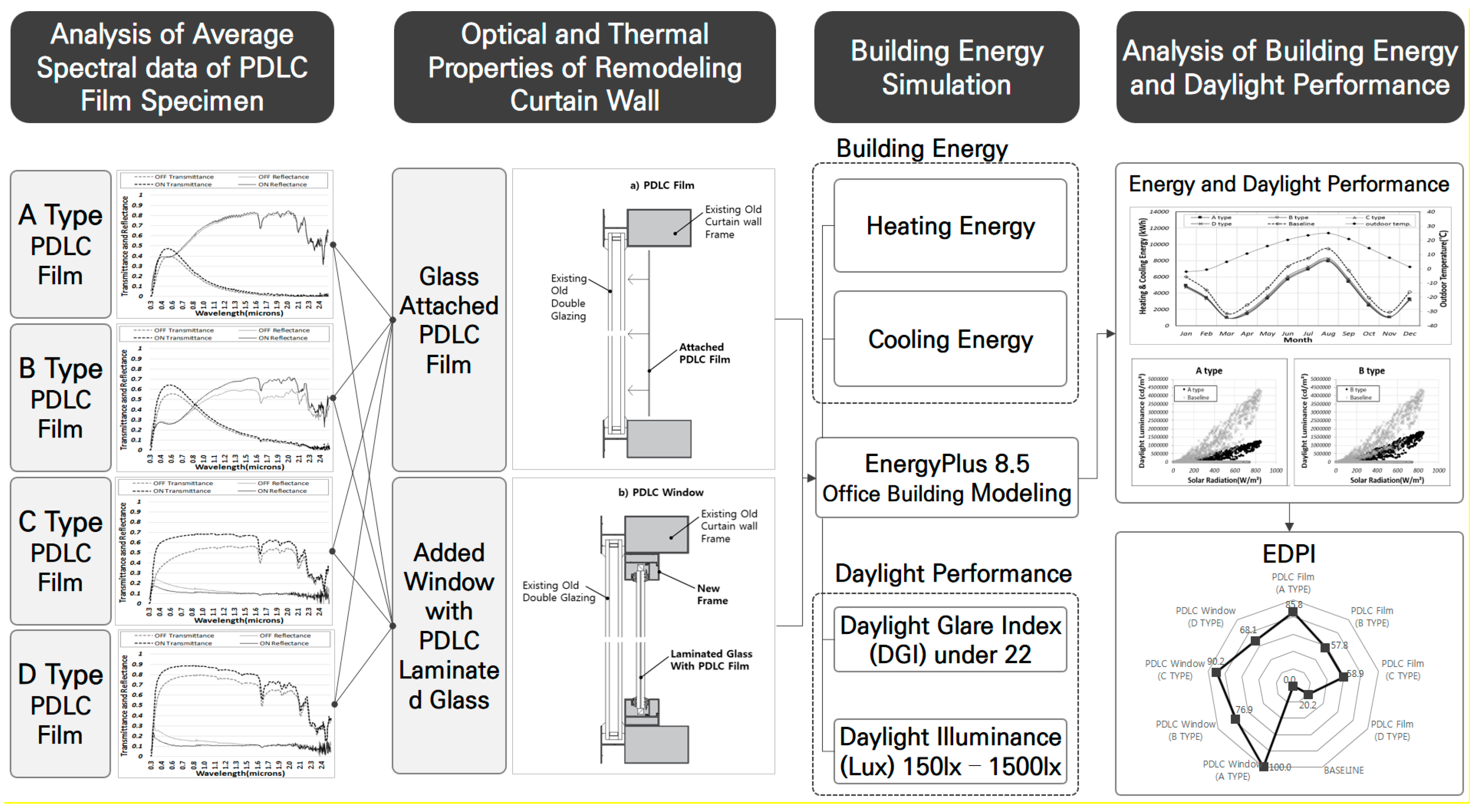

1.2. Research Method and Scope

2. Optical Properties of PDLC Film

3. Old Curtain Wall Remodeling Method Using PDLC Film

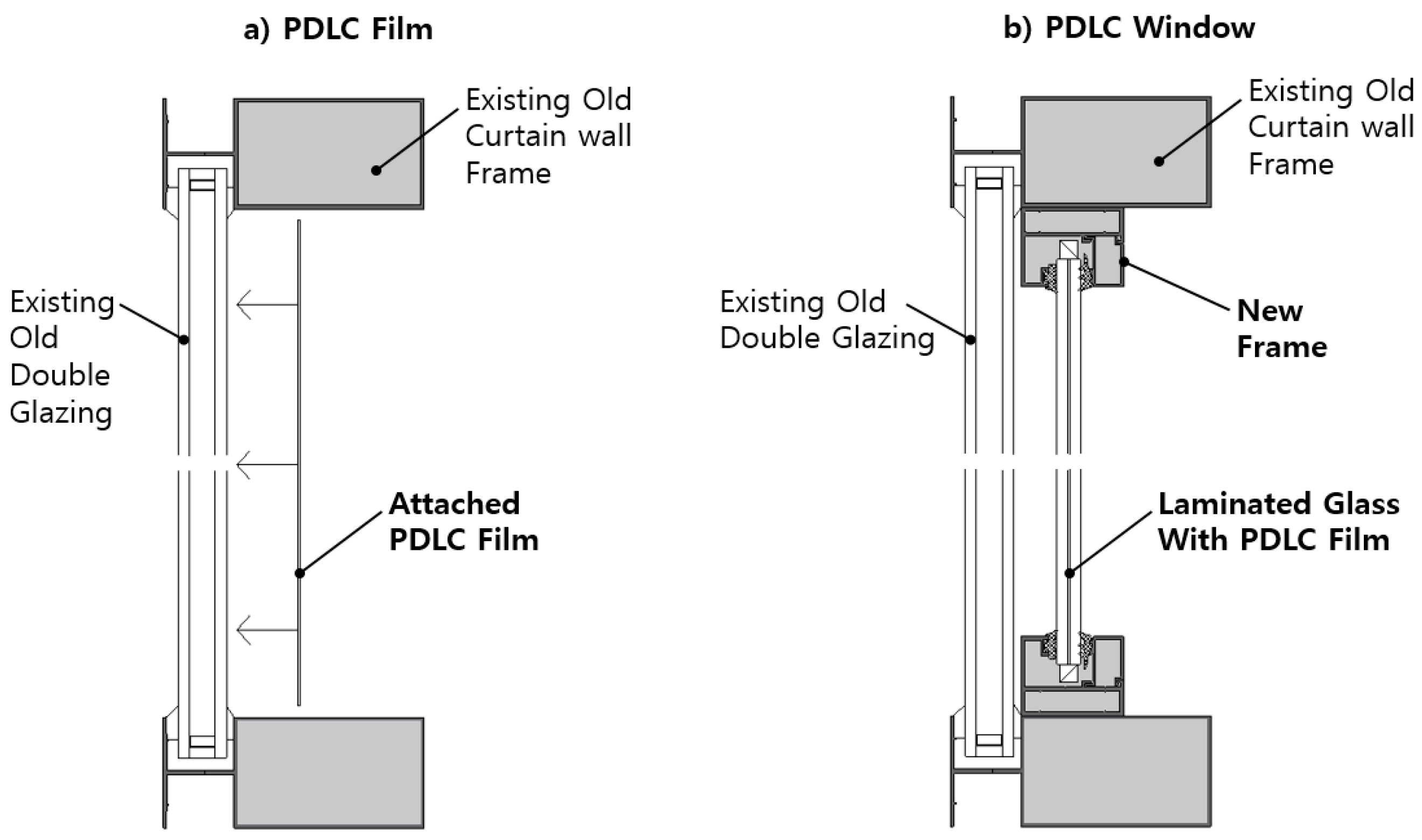

3.1. Overview of the Old Curtain Wall Remodeling Method Using PDLC Film

3.2. Optical and Thermal Properties According to the Application of Attached Remodeling PDLC Film

3.3. Optical and Thermal Properties According to the Application of PDLC Laminated Glass

4. Analytical Simulation Model for Building Energy Performance Evaluation

4.1. Overview of the Analytical Simulation Model

4.2. PDLC Control Condition

5. Results and Discussion

5.1. Building Energy Performance Evaluation Result According to Glass-Attached PDLC film Remodeling

5.2. Daylight Performance Evaluation Result According to Glass-Attached PDLC Film Remodeling

5.3. Annual Building Energy Performance Evaluation Result by PDLC Window Remodeling

5.4. Daylight Performance Evaluation Result by PDLC Window Remodeling

5.5. Evaluation Result of Integrated Heating and Cooling Energy and Daylight Performance

6. Conclusions

- (1)

- The optical properties of four types of PDLC films were analyzed using a spectrometer. The results showed that type A and B PDLC films are effective in blocking the NIR region and have a small variation range of transmittance depending on ON/OFF switching and type C and D PDLC films have large variation ranges in the visible light and NIR regions depending on ON/OFF switching.

- (2)

- To examine the degree of performance improvement by remodeling to improve the energy efficiency of old buildings using PDLC films, two remodeling methods were proposed. The first method was to attach a PDLC film to the double glazing of existing old curtain walls. The second method was to laminate a PDLC film between two glass substrates and configure a separate frame and attach a new window to the indoor side. The variations in thermal and optical properties when the two remodeling methods were applied to the existing curtain wall were analyzed. Then, the heating and cooling energy, discomfort glare, and indoor illuminance were analyzed using the EnergyPlus simulation tool. For the PDLC control conditions for simulation, solar radiation was blocked by switching PDLC off when discomfort glare occurs based on the DGI (daylight glare index) developed by Hopkinson.

- (3)

- The result of building energy performance evaluation according to the glass-attached PDLC film remodeling showed that types A, B, C, and D reduced energy by 17.0%, 15.8%, 7.3%, and 3.1%, respectively, compared with the office building with old curtain walls. When the annual discomfort glare time ratio was analyzed, the office building with old curtain walls generated an annual discomfort glare ratio of 42.7%. However, the attachment of PDLC film decreased the discomfort glare generation time ratio to 7.8%, 18.2%, 8.8%, and 34.2% for types A, B, C, and D, respectively. When the annual indoor daylight discomfort illuminance ratio was analyzed, it was 66.0% for the office building with existing old curtain walls. However, when the PDLC film was attached, it improved to 38.0%, 54.2%, 48.9%, and 60.4% for types A, B, C, and D, respectively. Therefore, the PDLC film-attached remodeling was shown to be effective in improving the building energy efficiency, reducing the discomfort glare, and securing useful indoor illuminance.

- (4)

- When the building energy performance of the remodeling method of forming and attaching a window with PDLC was evaluated, the energy consumption could be reduced by 22.4%, 21.3%, 20.5%, and 18.8% for types A, B, C, and D, respectively, compared with the office building with old curtain walls. The annual discomfort glare time ratio was analyzed, office buildings generated discomfort glare during 42.7% of the year. However, after PDLC window remodeling, the discomfort glare generation time ratio decreased to 5.4%, 11.6%, 6.5%, and 14.% for types A, B, C, and D, respectively. Furthermore, the annual indoor daylight discomfort illuminance ratio of office buildings with existing old curtain walls was 66.0%, but when the PDLC film was attached, it improved to 33.8%, 49.2%, 39.6%, and 51.7% for types A, B, C, and D, respectively. Therefore, the PDLC window remodeling had a greater performance improvement effect than the PDLC film attached remodeling method in terms of building energy and daylight environment.

- (5)

- The EDPI analysis result showed that the best conditions were achieved with the window remodeling method using type A PDLC. The window remodeling method using type A PDLC had the smallest annual heating and cooling energy consumption and the highest annual ratio of DGIs lower than 22, and the annual indoor appropriate illuminance ratio was also the highest, acquiring an EDPI score of 100 points. The second best performance method was the window remodeling method using type C PDLC. Its annual heating and cooling energy and annual indoor appropriate illuminance ratio were average, but it showed excellent discomfort glare reduction performance owing to a low visible light transmittance. The third best performance method was the type A PDLC film remodeling method. The type A PDLC film remodeling method showed average levels of heating and cooling energy but showed good results in terms of discomfort glare reduction performance and annual indoor appropriate illuminance ratio.

- (6)

- To generally summarize the results, window remodeling of old office buildings curtain walls using type A PDLC is expected to bring the most significant improvement effects in terms of energy and daylight performance. Even though the window remodeling method can maximize the improvement effect, when remodeling costs are also considered, applying the type A PDLC film could obtain economic efficiency as well as improvement effect.

Author Contributions

Funding

Conflicts of Interest

References

- Kassai, M. Experimental investigation of carbon dioxide cross-contamination in sorption energy recovery wheel in ventilation system. Build. Serv. Eng. Res. Technol. 2018, 39, 463–474. [Google Scholar] [CrossRef]

- Kassai, M.; Simonson, C.J. Performance investigation of liquid-to-air membrane energy exchanger under low solution/air heat capacity rates ratio conditions. Build. Serv. Eng. Res. Technol. 2015, 36, 535–545. [Google Scholar] [CrossRef]

- Lee, K.H.; Koo, B.K.; Park, B.R.; Ahn, Y.H. The development of an energy-efficient remodeling freamework in South Korea. Habitat. Int. 2015, 53, 430–441. [Google Scholar] [CrossRef]

- Paoletti, G.; Pascual, P.R.; Pernetti, R.; Lollini, R. Nearly Zero Energy Buildings: An Overview of the Main Construction Features across Europe. Buildings 2017, 7, 43. [Google Scholar] [CrossRef]

- Domjan, S.; Arkar, C.; Begelj, Ž.; Medved, S. Evolution of all-glass nearly Zero Energy Buildings with respect to the local climate and free-cooling techniques. Build. Environ. 2019, 160, 106183. [Google Scholar] [CrossRef]

- Oh, M.H.; Lee, K.H.; Yoon, J.H. Automated control strategies of inside slat-type blind considering visual comfort and building energy performance. Energy Build. 2012, 55, 728–737. [Google Scholar] [CrossRef]

- Moschella, A.; Gagliano, A.; Lo Faro, A.; Mondello, A.; Salemi, A.; Sanfilippo, G. A Methodology for an Integrated Approach for Seismic and Energy Refurbishment of Historic Buildings in Mediterranean Area. Sustainability 2018, 10, 2448. [Google Scholar] [CrossRef]

- Tina, G.M.; Gagliano, A.; Nocera, F.; Patania, F. Photovoltaic glazing: Analysis of thermal behavior and indoor comfort. Energy Procedia 2013, 42, 367–376. [Google Scholar] [CrossRef]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Casini, M. Active dynamic windows for buildings: A review. Renew. Energy 2018, 119, 923–934. [Google Scholar] [CrossRef]

- Reilly, S.; Arasteh, D.; Selkowitz, S.E. Thermal and optical analysis of switchable window glazings. Sol. Energy Mater. 1991, 22, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Jelle, B.P.; Hymd, A.; Gustavsen, A.; Arasteh, D.; Goudy, H.; Hart, R. Fenestration of today and tomorrow; a state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements, and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Durability of switching behavior after outdoor exposure for a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 178–184. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Daylighting performance and glare calculation of a suspended particle device switchable glazing. Sol. Energy 2016, 132, 114–128. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of colour properties due to switching behaviour of a PDLC glazing for adaptive building integration. Renew. Energy 2018, 120, 126–133. [Google Scholar] [CrossRef]

- Lampert, C.M. Large-area smart glass and integrated photovoltaics. Sol. Energy Mater. Sol. Cells 2003, 76, 489–499. [Google Scholar] [CrossRef]

- Lampert, C.M. Smart switchable glazing for solar energy and daylight control. Sol. Energy Mater. Sol. Cells 1998, 52, 207–221. [Google Scholar] [CrossRef]

- Ajaji, Y.; André, P. Thermal comfort and visual comfort in an office building equipped with smart electrochromic glazing: An experimental study. Energy Procedia 2015, 78, 2464–2469. [Google Scholar] [CrossRef]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of electrochromic windows impact in the energy performance of buildings in Mediterranean climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef]

- Fernandes, L.L.; Lee, E.S.; Ward, G. Lighting energy savings potential of split-pane electrochromic windows controlled for daylighting with visual comfort. Energy Build. 2013, 61, 8–20. [Google Scholar] [CrossRef] [Green Version]

- Piccolo, A.; Pennisi, F. Simone, Daylighting performance of an electrochomic window in a small-scale test-cell. Sol. Energy 2009, 83, 832–844. [Google Scholar] [CrossRef]

- Lee, E.S.; Yazdanian, M.; Selkowitz, S. The Energy-Savings Potential of Electrochromic Windows in the US Commercial Buildings Sector; Lawrence Berkeley National Laboratory Report LBL-54966; Lawrence Berkeley National Laboratory: Alameda, CA, USA, 2014.

- Papaefthimiou, S.; Syrrakou, E.; Yianoulis, P. Energy performance assessment of an electrochromic window. Thin Solid Films 2006, 502, 257–264. [Google Scholar] [CrossRef]

- DeForest, N.; Shehabi, A.; Garcia, G.; Greenbalt, J.; Masanet, E.; Lee, E.S.; Selkowitz, S.; Milliron, D.J. Regional performance targets for transparent near-infrared switching electrochromic window glazings. Build. Environ. 2013, 61, 160–168. [Google Scholar] [CrossRef]

- Cannavale, G.E.; Eperon, P.; Cossari, A.; Abate, H.J.; Snaith, G.; Gigli, P. Photovoltachromic cells for building integration. Energy Environ. Sci. 2015, 8, 1578–1584. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Bayrak Pehlivan, I.; Niklasson, G.A. Electrochromics on a roll: Web-coating and lamination for smart windows. Surf. Coat. Technol. 2017, 6–11. [Google Scholar] [CrossRef]

- Rottmann, M.; Kraft, A.; Heckner, K.H.; Hausler, T.; Fischer, U.; Stenzel, H. Large-area electrochromic safety glass; switching behaviour and transmission control of solar radiation. In Proceedings of the 9th International Glass Conference on Glass Processing Days, Tampere, Finland, 17–20 June 2005. [Google Scholar]

- Muehling, O.; Seeboth, A.; Haeusler, T.; Ruhmann, R.; Potechius, E.; Vetter, R. Variable solar control using thermotropic core/shell particles. Sol. Energy Mater. Sol. Cells 2019, 93, 1510–1517. [Google Scholar] [CrossRef]

- Feng, W.; Zou, L.; Gao, G.; Wu, G. Gasochromic smart window: Optical and thermal properties, energy simulation and feasibility analysis. Sol. Energy Mater. Sol. Cells 2016, 144, 316–323. [Google Scholar] [CrossRef]

- Nitz, P.; Hartwig, H. Solar control with thermotropic layers. Sol. Energy 2005, 79, 573–582. [Google Scholar] [CrossRef]

- Granqvist, C.G. Recent progress in thermochromics and electrochromics: A brief survey. Thin Solid Films 2016, 614, 90–96. [Google Scholar] [CrossRef]

- LBNL. Available online: https://windows.lbl.gov/software/optics (accessed on 14 September 2019).

- LBNL. Available online: https://windows.lbl.gov/software/window (accessed on 14 September 2019).

- LBNL. Available online: https://windows.lbl.gov/software/therm (accessed on 14 September 2019).

- KSCI. Available online: https://standard.go.kr/ (accessed on 9 June 2018).

- Finlayson, E.U.; Arasteh, D.K.; Huizenga, C.; Rubin, M.D.; Reilly, M.S. WINDOW 4.0: Documentation of Calculation Procedures; Lawrence Berkeley National Laboratory Report LBL-33943; Lawrence Berkeley National Laboratory: Alameda, CA, USA, 1993.

- EnergyPlus. EnergyPlus Input Output Reference. The Encyclopedic Reference to EnergyPlus Input and Output. Available online: http://www.energyplus.gov (accessed on 26 September 2019).

- EnergyPlus, EnergyPlus Engineering Reference. The Reference to EnergyPlus Calculations. Available online: http://www.energyplus.gov (accessed on 26 September 2012).

- Arasteh, D.K.; Reilly, M.S.; Rubin, M.D. A versatile procedure for calculating heat transfer through windows, American Society of Heating, Refrigeration and Air-Conditioning Engineers. ASHRAE Trans. 1989, 95, 755–765. [Google Scholar]

- Arasteh, D.K.; Kohler, J.C.; Griffith, B.T. Draft, Modeling Windows in EnergyPlus with only U, SHGC, and Optionally VT; Lawrence Berkeley National Laboratory: Alameda, CA, USA, 2009.

- Winkelmann, F.; Selkowitz, S. Day-Lighting Simulation in DOE-2: Theory, Validation and Applications; Lawrence Berkeley National Laboratory: Alameda, CA, USA, 1985.

- Lomanowski, B.A.; Wright, J.L. Modeling fenestration with shading devices in building energy simulation: A practical approach. In Proceedings of the 11th International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009. [Google Scholar]

- Petherbridge, P.; Hopkinson, R.G. Hopkinson. Discomfort Glare and the Lighting of Buildings. Trans. Illum. Eng. Soc. 1950, 15, 39–79. [Google Scholar]

- Winkelmann, F. Modeling Windows in EnergyPlus. In Proceedings of the 7th International IBPSA Conference, Rio di Janeiro, Brazil, 13–15 August 2001. [Google Scholar]

- The Korean Ministry of Land. Transport and Maritime Affairs, Standard for Energy Saving Design in Buildings; The Korean Ministry of Land: Sejong, Korea, 2019.

- Refrigerating and Air-Conditioning Engineers, Inc. ASHRAE Fundamentals Handbook, American Society of Heating; 1791 tullie circle, N.E.; Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2009. [Google Scholar]

- Hopkinson, R.G. Glare from daylighting in buildings. Appl. Ergon. 1972, 3, 206–215. [Google Scholar] [CrossRef]

- Oh, M.; Park, J.; Roh, S.; Lee, C. Deducing the optimal control method for electrochromic triple glazing through an integrated evaluation of building energy and daylight performance. Energies 2018, 11, 2205. [Google Scholar] [CrossRef]

| Division | A Type | B Type | C Type | D Type | |||||

|---|---|---|---|---|---|---|---|---|---|

| On | Off | On | Off | On | Off | On | Off | ||

| Solar Transmittance | 0.273 | 0.230 | 0.444 | 0.390 | 0.638 | 0.472 | 0.833 | 0.733 | |

| Solar Reflectance | front | 0.561 | 0.552 | 0.459 | 0.478 | 0.114 | 0.155 | 0.115 | 0.164 |

| back | 0.561 | 0.552 | 0.422 | 0.391 | 0.117 | 0.156 | 0.114 | 0.165 | |

| Visible Transmittance | 0.459 | 0.389 | 0.637 | 0.551 | 0.639 | 0.427 | 0.867 | 0.750 | |

| Visible Reflectance | front | 0.398 | 0.397 | 0.293 | 0.330 | 0.111 | 0.173 | 0.116 | 0.187 |

| back | 0.400 | 0.397 | 0.263 | 0.271 | 0.126 | 0.187 | 0.115 | 0.188 | |

| Emissivity | front | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 |

| back | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | |

| Division | U-Value (W/m2K) | Solar Heat Gain Coefficient (SHGC) | Tvis | ||

|---|---|---|---|---|---|

| Double glazing | 2.813 | 0.697 | 0.771 | ||

| Curtain wall Frame | Head | Frame | 8.570 | ||

| Edge | 2.934 | ||||

| Divider | Frame | 8.811 | |||

| Edge | 2.985 | ||||

| Sill | Frame | 8.816 | |||

| Edge | 2.985 | ||||

| Jamb | Frame | 10.605 | |||

| Edge | 2.861 | ||||

| Division | U-Value (W/m2K) | SHGC | Tvis |

|---|---|---|---|

| Curtain wall system | 3.806 | 0.583 | 0.647 |

| Division | 6 mm Clear Glass | Existing 6 mm Clear Glass + PDLC Film | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A Type | B Type | C Type | D Type | |||||||

| On | Off | On | Off | On | Off | On | Off | |||

| Solar Transmittance | 0.765 | 0.250 | 0.211 | 0.402 | 0.352 | 0.566 | 0.416 | 0.737 | 0.650 | |

| Solar Reflectance | front | 0.073 | 0.438 | 0.432 | 0.359 | 0.375 | 0.099 | 0.134 | 0.101 | 0.142 |

| back | 0.073 | 0.561 | 0.552 | 0.420 | 0.390 | 0.113 | 0.153 | 0.107 | 0.160 | |

| Visible Transmittance | 0.878 | 0.447 | 0.379 | 0.621 | 0.536 | 0.622 | 0.416 | 0.844 | 0.730 | |

| Visible Reflectance | front | 0.083 | 0.380 | 0.379 | 0.280 | 0.316 | 0.108 | 0.167 | 0.113 | 0.181 |

| back | 0.083 | 0.399 | 0.397 | 0.262 | 0.270 | 0.126 | 0.187 | 0.114 | 0.186 | |

| Emissivity | front | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 | 0.837 |

| back | 0.837 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | 0.767 | |

| Division | 26 mm Double Glazing | Existing Double Glazing + PDLC Film | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A Type | B Type | C Type | D Type | ||||||

| On | Off | On | Off | On | Off | On | Off | ||

| U-Value (W/m2K) | 2.813 | 2.811 | 2.811 | 2.811 | 2.811 | 2.811 | 2.811 | 2.811 | 2.811 |

| SHGC | 0.697 | 0.475 | 0.402 | 0.498 | 0.470 | 0.633 | 0.567 | 0.680 | 0.633 |

| Tvis | 0.771 | 0.408 | 0.346 | 0.563 | 0.487 | 0.555 | 0.373 | 0.747 | 0.650 |

| Division | Existing Old Curtain Wall | Existing Old Curtain Wall + PDLC Film | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A Type | B Type | C Type | D Type | ||||||

| On | Off | On | Off | On | Off | On | Off | ||

| U-Value (W/m2K) | 3.806 | 3.802 | 3.802 | 3.802 | 3.802 | 3.802 | 3.802 | 3.802 | 3.802 |

| SHGC | 0.583 | 0.343 | 0.333 | 0.415 | 0.392 | 0.527 | 0.519 | 0.569 | 0.528 |

| Tvis | 0.647 | 0.343 | 0. 290 | 0.472 | 0.409 | 0.466 | 0.389 | 0.627 | 0.545 |

| Division | 26 mmDouble Glazing | Existing Double Glazing + PDLC Window | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A Type | B Type | C Type | D Type | ||||||

| On | Off | On | Off | On | Off | On | Off | ||

| U-Value (W/m2K) | 2.813 | 1.758 | 1.758 | 1.758 | 1.758 | 1.758 | 1.758 | 1.758 | 1.758 |

| SHGC | 0.697 | 0.541 | 0.536 | 0.557 | 0.551 | 0.566 | 0.549 | 0.584 | 0.575 |

| Tvis | 0.771 | 0.301 | 0.255 | 0.418 | 0.361 | 0.419 | 0.280 | 0.570 | 0.492 |

| Division | Head | Jamb | Sill | Divider |

|---|---|---|---|---|

| Existing old curtain wall |  |  |  |  |

| Frame U-value | 8.570 | 8.811 | 8.816 | 10.605 |

| Edge U-value | 2.934 | 2.985 | 2.985 | 2.861 |

| Division | Head | Jamb | Sill | Divider |

|---|---|---|---|---|

| Remodeling curtain wall with PDLC laminated glass |  |  |  |  |

| Frame U-value | 5.770 | 6.133 | 6.134 | 4.043 |

| Edge U-value | 2.121 | 2.022 | 2.022 | 2.083 |

| Division | Existing Old Curtain Wall | Existing Old Curtain Wall + PDLC Window | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A Type | B Type | C Type | D Type | ||||||

| On | Off | On | Off | On | Off | On | Off | ||

| U-Value (W/m2K) | 3.806 | 2.915 | 2.915 | 2.915 | 2.195 | 2.915 | 2.915 | 2.915 | 2.915 |

| SHGC | 0.583 | 0.369 | 0.365 | 0.381 | 0.376 | 0.387 | 0.375 | 0.400 | 0.393 |

| Tvis | 0.647 | 0.207 | 0.175 | 0.288 | 0.248 | 0.288 | 0.193 | 0.392 | 0.339 |

| Division | Properties | |

|---|---|---|

| 26 mm double glazing (6 mm clear glass + 14 air + 6 mm clear glass) | SHGC | 0.697 |

| Tvis | 0.771 | |

| Conductance | 2.813 W/m2K | |

| Frame (head, jamb, sill) | Width | 60 mm |

| Outside projection | 6 mm | |

| Inside projection | 106 mm | |

| Conductance | 8.732 W/m2K | |

| Ratio of frame-edge glass conductance to center of glass conductance | 1.055 | |

| Divider | Width | 60 mm |

| Outside projection | 6 mm | |

| Inside projection | 106 mm | |

| Conductance | 10.605 W/m2K | |

| Ratio of frame-edge glass conductance to center of glass conductance | 1.102 | |

| Division | Materials | Properties |

|---|---|---|

| Exterior wall | 200 mm concrete 65 mm insulation 19 mm gypsum board | U-value 0.280 W/m2K |

| Spandrel | 26 mm double glazing Spandrel air space 65 mm insulation 19 mm gypsum board | U-value 0.422 W/m2K |

| Exterior Floor | 75 mm insulation 200 mm concrete | U-value 0.418 W/m2K |

| Exterior Roof | 100 mm concrete 110 mm insulation Ceiling air space Acoustic tile | U-value 0.253 W/m2K |

| Division | Recommended Value |

|---|---|

| Art galleries | 16 |

| Hospital wards | 18 |

| Museums, School classroom | 20 |

| Laboratories, Offices | 22 |

| Division | Heating Energy (kWh) | Cooling Energy (kWh) | Total Energy (kWh) | Reducing Rate |

|---|---|---|---|---|

| A type | 20,566.5 | 28,484.9 | 49,051.4 | −17.0% |

| B type | 19,916.3 | 29,872.4 | 49,788.7 | −15.8% |

| C type | 16,686.2 | 38,099.9 | 54,786.0 | −7.3% |

| D type | 15,595.2 | 41,694.8 | 57,290.0 | −3.1% |

| Baseline | 14,525.7 | 44,600.8 | 59,126.5 | - |

| Division | Properties | |

|---|---|---|

| 62 mm glazing (6 mm clear glass + 14 air + 6 mm clear glass + 23.1 mm air + 13 mm PDLC laminated glass) | 1.758 W/m2K | |

| Frame (head, jamb, sill) | Width | 103 mm |

| Outside projection | 6 mm | |

| Inside projection | 106 mm | |

| Conductance | 6.012 W/m2K | |

| Ratio of frame-edge glass conductance to center of glass conductance | 1.169 | |

| Divider | Width | 150 mm |

| Outside projection | 6 mm | |

| Inside projection | 106 mm | |

| Conductance | 4.043 W/m2K | |

| Ratio of frame-edge glass conductance to center of glass conductance | 1.185 | |

| Division | Heating Energy (kWh) | Cooling Energy (kWh) | Total Energy (kWh) | Reducing Rate |

|---|---|---|---|---|

| A type | 12,085.6 | 33,820.6 | 45,906.2 | −22.4% |

| B type | 11,792.6 | 34,753.8 | 46,546.4 | −21.3% |

| C type | 11,597.8 | 35,423.6 | 47,021.4 | −20.5% |

| D type | 11,221.5 | 36,774.8 | 47,996.4 | −18.8% |

| Baseline | 14,525.7 | 44,600.8 | 59,126.5 | - |

| Division | Element (i) | Total | Avg. | |||

|---|---|---|---|---|---|---|

| Energy (kWh) | DGI Under 22 | LUX 150 lx–1500 lx | ||||

| Data (j) | PDLC Film (A type) | 48,969.8 | 92.2% | 62.0% | ||

| PDLC Film (B type) | 49,735.2 | 81.8% | 45.8% | |||

| PDLC Film (C type) | 54,791.0 | 91.2% | 51.1% | |||

| PDLC Film (D type) | 56,446.9 | 65.8% | 39.6% | |||

| PDLC Window (A type) | 45,906.2 | 94.6% | 66.2% | |||

| PDLC Window (B type) | 46,546.4 | 88.4% | 50.8% | |||

| PDLC Window (C type) | 47,021.4 | 93.5% | 60.4% | |||

| PDLC Window (D type) | 47,996.4 | 85.5% | 48.3% | |||

| Baseline | 59,126.5 | 57.3% | 34.0% | |||

| EDPI | PDLC Film (A type) | 76.8 | 93.4 | 87.0 | 257.3 | 85.8 |

| PDLC Film (B type) | 71.0 | 65.6 | 36.7 | 173.3 | 57.8 | |

| PDLC Film (C type) | 32.8 | 90.8 | 53.2 | 176.8 | 58.9 | |

| PDLC Film (D type) | 20.3 | 22.8 | 17.6 | 60.7 | 20.2 | |

| PDLC Window (A type) | 100.0 | 100.0 | 100.0 | 300.0 | 100.0 | |

| PDLC Window (B type) | 95.2 | 83.4 | 52.2 | 230.8 | 76.9 | |

| PDLC Window (C type) | 91.6 | 97.0 | 82.0 | 270.6 | 90.2 | |

| PDLC Window (D type) | 84.2 | 75.6 | 44.5 | 204.2 | 68.1 | |

| Baseline | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.; Lee, C.; Park, J.; Lee, K.; Tae, S. Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films. Energies 2019, 12, 3679. https://doi.org/10.3390/en12193679

Oh M, Lee C, Park J, Lee K, Tae S. Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films. Energies. 2019; 12(19):3679. https://doi.org/10.3390/en12193679

Chicago/Turabian StyleOh, Myunghwan, Chulsung Lee, Jaesung Park, Kwangseok Lee, and Sungho Tae. 2019. "Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films" Energies 12, no. 19: 3679. https://doi.org/10.3390/en12193679

APA StyleOh, M., Lee, C., Park, J., Lee, K., & Tae, S. (2019). Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films. Energies, 12(19), 3679. https://doi.org/10.3390/en12193679