Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter

Abstract

:1. Introduction

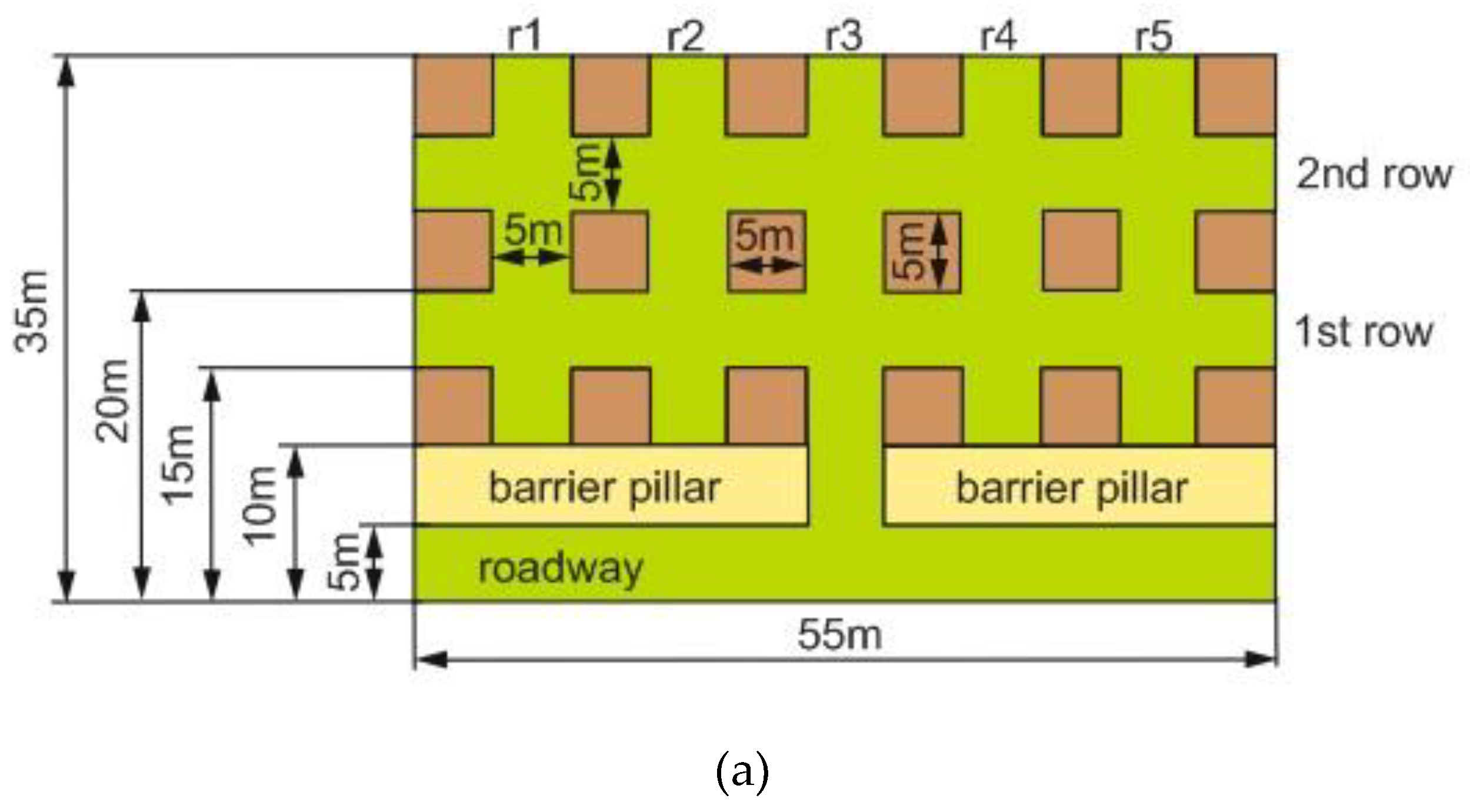

2. Room and Pillar Methods in Hard Rock Mining

2.1. Geological Conditions of the Modelled Ore Mine

- Ts—tensile strength of the main roof rocks, /MPa,

- h—thickness of the main roof (load-bearing layer), /m,

- q—unit pressure of the main roof, /MPa,

- b—thickness of the immediate roof, /ᵒ,

- —deflection angle of the immediate roof layers, /ᵒ.

2.2. Numerical Modeling of Fault Zones around Pits

- Cb—load-bearing capacity of the roof bolting, /kN,

- Q—weight of the weak layer supported by one bolt, /kN,

- n—safety factor (1.5 < n < 3),

- γ—unit weight of the weak layer, /kN/m3, (27 kN/m3),

- B—room width, /m, (5 m),

- h—range of the weak layer (fault zone), /m,

- x1, y1—bolt span, /m, (1 m).

3. Assessing the Influence of Adhesion Length on the Load-Bearing Capacity of Roof Bolting

The Load and Displacement Properties of Segmentally Installed Glue-in Roof Bolting

4. Discussion

- ΔL—bolt elongation /mm,

- F—tensile force on the bolt /kN,

- L—bolt length minus the glue-in part /mm,

- d—bolt diameter /mm,

- E—steel elasticity modulus, E = 210 GPa.

5. Conclusions

- The installation depth of 0.1 m made it possible to obtain the full specifications for the diameter of 0.032 m and maximum load-bearing capacity, 106.87 kN, was recorded.

- Increasing installation length to 0.2 m allowed us to prepare specifications for all four bolt hole diameters: 0.028 m; 0.032 m; 0.035 m; 0.037 m, until material discontinuity (the steel rod of the bolt at the diameter of the thread core) appeared.

- The maximum load-bearing capacities of the roof bolting with the increasing diameters of the bolt hole were: 103.17 kN, 111.40 kN, 99.55 kN, and 101.71 kN, respectively.

- For both 0.1 m and 0.2 m installation depths, the maximum load-bearing capacities were recorded for the diameter of 0.032 m.

- Glue-in roof bolting installed along 0.2 m for the bolt hole diameter of 0.032 m demonstrated the most favorable conditions for the joint operation of the roof bolting and the rock mass.

- The bolt’s extension from the hole during loading constitutes about 63% of the total recorded bolt displacement (extension and elongation) at the measurement station.

- For the installation depth of z = 0.1 m, it was found that this factor grows along with the growth of the hole diameter, within the range 0.028 to 0.037 m. No similar relationship was found for bolts with an installation depth of 0.2 m, which might require extending the scope of testing in the future.

Author Contributions

Funding

Conflicts of Interest

References

- Skrzypkowski, K. A new design of support for burst-prone rock mass in underground ore mining. E3S Web Conf. 2018, 71. [Google Scholar] [CrossRef]

- Campbell, R.; Mould, R.J. Impacts of gloving and un-mixed resin in fully encapsulated roof bolts on geotechnical design assumptions and strata control in coal mines. Int. J. Coal Geol. 2005, 64, 116–125. [Google Scholar] [CrossRef]

- Canbulat, I.; Van der Merwe, J.N. Design of optimum roof support systems in South African collieries using a probabilistic design approach. J. S. Afr. Inst. Min. Metall. 2009, 108, 71–88. [Google Scholar]

- Zou, J.; Zhang, P. Analytical model of fully grouted bolts in pull-out tests and in situ rock masses. Int. J. Rock Mech. Min. 2019, 113, 278–294. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Evaluation of Rock Bolt Support for Polish Hard Rock Mines. E3S Web Conf. 2018, 35. [Google Scholar] [CrossRef]

- Maepa, T.G.; Zvarivadza, T. Installation of resin-grouted rockbolts in hard rock mining:challenges and solutions for improved safety. J. S. Afr. Inst. Min. Metall. 2017, 117, 329–336. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Laboratory testing of a long expansion rock bolt support for energy-absorbing applications. E3S Web Conf. 2018, 29. [Google Scholar] [CrossRef]

- Villaescusa, E.; Varden, R.; Hassell, R. Quantifying the performance of resin anchored rock bolts in the Australian underground hard rock mining industry. Int. J. Rock Mech. Min. 2008, 45, 94–102. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, N.; Li, G.; Guo, G. Pullout Test on Fully Grouted Bolt Sheathed by Different Length of Segmented Steel Tubes. Shock Vib. 2017, 2017, 4304190. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Skrzypkowski, K.; Herezy, Ł. Laboratory method for evaluating the characteristics of expansion rock bolts subjected to axial tension. Arch. Min. Sci. 2015, 60, 209–224. [Google Scholar] [CrossRef]

- Marcon, M.; Vorel, J.; Nincevic, K.; Wan-Wendner, K. Modeling Adhesive Anchors in a Discrete Element Framework. Materials 2019, 10, 917. [Google Scholar] [CrossRef] [PubMed]

- Kılıc, A.; Yasar, E.; Celik, A.G. Effect of grout properties on the pull-out load capacity of fully grouted rock bolt. Tunn. Undergr. Space Technol. 2002, 17, 355–362. [Google Scholar] [CrossRef]

- Kılıc, A.; Yasar, E.; Atis, C.D. Effect of bar shape on the pull-out capacity of fully-grouted rockbolts. Tunn. Undergr. Space Technol. 2003, 18, 1–6. [Google Scholar] [CrossRef]

- Li, C.C.; Kristjansson, G.; Høien, A.H. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef] [Green Version]

- Martín, L.B.; Tijani, M.; Hadj-Hassen, F.; Noiret, A. Assessment of the bolt-grout interface behaviour of fully grouted rockbolts from laboratory experiments under axial loads. Int. J. Rock Mech. Min. 2013, 63, 50–61. [Google Scholar] [CrossRef]

- Ma, S.; Nemcik, J.; Aziz, N. An analytical model of fully grouted rock bolts subjected to tensile load. Constr. Build. Mater. 2013, 49, 519–526. [Google Scholar] [CrossRef]

- Hagan, P.C. The effect of resin annulus on anchorage performance of fully encapsulated rockbolts. In Proceedings of the 10th Congress of the International Society of Rock Mechanics: ‘Technology Roadmap for Rock Mechanics’, Sandton, South Africa, 8–12 September 2003; International Society for Rock Mechanics: Lisbon, Portugal, 2003; pp. 113–118. [Google Scholar]

- Zhang, Y.; Ni, P. Design optimization of room and pillar mines: A case study of the Xianglushan tungsten mine. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 352–364. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, M.; Xu, X.; Li, X.; Ma, Y.; Ma, Z. Research on Catastrophic Pillar Instability in Room and Pillar Gypsum Mining. Sustainability 2018, 10, 3773. [Google Scholar] [CrossRef]

- Hudeček, V.; Šancer, J.; Zubíček, V.; Golasowký, J. Czech Republic. Experience in the adoption of Room & pillar mining method in the company OKD a.s., Czech Republic. Acta Montan Slovaca 2017, 22, 303–312. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Compressibility of materials and backfilling mixtures with addition of solid wastes from flue-gas treatment and fly ashes. E3S Web Conf. 2018, 71. [Google Scholar] [CrossRef]

- Zhou, N.; Yan, H.; Jiang, S.; Sun, Q.; Ouyang, S. Stability Analysis of Surrounding Rock in Paste Backfill Recovery of Residual Room Pillars. Sustainability 2019, 11, 478. [Google Scholar] [CrossRef]

- Luo, Y. Room and pillar panel design method to avoid surface subsidence. Min. Eng.-Littleton 2015, 67, 105–110. [Google Scholar]

- Wagner, H. Deep Mining: A Rock Engineering Challenge. Rock Mech. Rock Eng. 2019, 52, 1417–1446. [Google Scholar] [CrossRef] [Green Version]

- Piechota, S. Technika Podziemnej Eksploatacji złóż rud (Techniques of Underground Mining of Ore Deposits); University Script No. 1129; AGH Publishing House: Kraków, Poland, 1998; p. 191. [Google Scholar]

- Rocscience. Available online: https://www.rocscience.com (accessed on 29 April 2019).

- Epstal. Available online: http://epstal.pl/en/reinforcing-steel/properties (accessed on 29 May 2019).

- PRIG. Available online: https://prig-kleje.pl (accessed on 29 May 2019).

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Dudek, P. Application of long expansion rock bolt support in the underground mines of Legnica-Głogów Copper District. Studia Geotechnica et Mechanica 2017, 39, 47–57. [Google Scholar] [CrossRef]

- Polish Standard: PN-G-15091. Requirements. Polish Committee for Standardization; Polish Committee for Standardization: Warszawa, Poland, 1998.

| Adhesion Length (m) | Hole Diameter (m) | |||

|---|---|---|---|---|

| 0.028 | 0.032 | 0.035 | 0.037 | |

| Load-Bearing Capacity (kN) | ||||

| 0.1 | 82.69 | 106.87 | 83.74 | 73.18 |

| comments | extension from the hole | thread stripping | extension from the hole | extension from the hole |

| 0.2 | 103.17 | 111.40 | 99.55 | 101.71 |

| comments | thread stripping | |||

| Bolt Hole Diameter, d (m) | Changes in Extension ΔW and Bolt Strain ΔL | |

|---|---|---|

| For bolt installing depth: z = 0.1 m | ||

| 0.028 | S = ΔW + ΔL = 0.0951 · F − 0.4844 | ΔW = 0.0568 · F − 0.4844 |

| 0.032 | S = ΔW + ΔL = 0.1081 · F − 0.5275 | ΔW = 0.0698 · F − 0.5275 |

| 0.035 | S = ΔW + ΔL = 0.1079 · F − 0.2548 | ΔW = 0.0695 · F − 0.2548 |

| 0.037 | S = ΔW + ΔL = 0.1108 · F − 0.6641 | ΔW = 0.0724 · F − 0.6641 |

| Bolt Hole Diameter, d (m) | Changes in Extension ΔW and Bolt Strain ΔL | |

|---|---|---|

| For bolt installing depth: z = 0.2 m | ||

| 0.028 | S = ΔW + ΔL = 0.0927 · F − 0.1763 | ΔW = 0.057 · F − 0.1763 |

| 0.032 | S = ΔW + ΔL = 0.1071 · F − 0.0214 | ΔW = 0.0713 · F − 0.0214 |

| 0.035 | S = ΔW + ΔL = 0.1008 · F − 0.133 | ΔW = 0.065 · F − 0.133 |

| 0.037 | S = ΔW + ΔL = 0.0954 · F − 0.5345 | ΔW = 0.0596 · F − 0.5345 |

| Bolt Flexibility Factor; Wp (mm/kN) | ||||||

|---|---|---|---|---|---|---|

| Hole Diameter (m) | Installing Depth: z = 0.1 m | Installing Depth: z = 0.2 m | ||||

| Wp1 (ΔW + ΔL) | Wp2 (ΔW) | ΔW/(ΔW + ΔL) | Wp1 (ΔW + ΔL) | Wp2 (ΔW) | ΔW/(ΔW + ΔL) | |

| 0.028 | 0.0951 | 0.0568 | 59.7% | 0.0927 | 0.057 | 61.5% |

| 0.032 | 0.1081 | 0.0698 | 64.6% | 0.1071 | 0.0713 | 66.6% |

| 0.035 | 0.1079 | 0.0695 | 64.4% | 0.1008 | 0.065 | 64.5% |

| 0.037 | 0.1108 | 0.0724 | 65.3% | 0.0954 | 0.0596 | 62.5% |

| Average: | 63.5% | 63.8% | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter. Energies 2019, 12, 3754. https://doi.org/10.3390/en12193754

Skrzypkowski K, Korzeniowski W, Zagórski K, Zagórska A. Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter. Energies. 2019; 12(19):3754. https://doi.org/10.3390/en12193754

Chicago/Turabian StyleSkrzypkowski, Krzysztof, Waldemar Korzeniowski, Krzysztof Zagórski, and Anna Zagórska. 2019. "Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter" Energies 12, no. 19: 3754. https://doi.org/10.3390/en12193754

APA StyleSkrzypkowski, K., Korzeniowski, W., Zagórski, K., & Zagórska, A. (2019). Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter. Energies, 12(19), 3754. https://doi.org/10.3390/en12193754