Enhancement of a R-410A Reclamation Process Using Various Heat-Pump-Assisted Distillation Configurations

Abstract

:1. Introduction

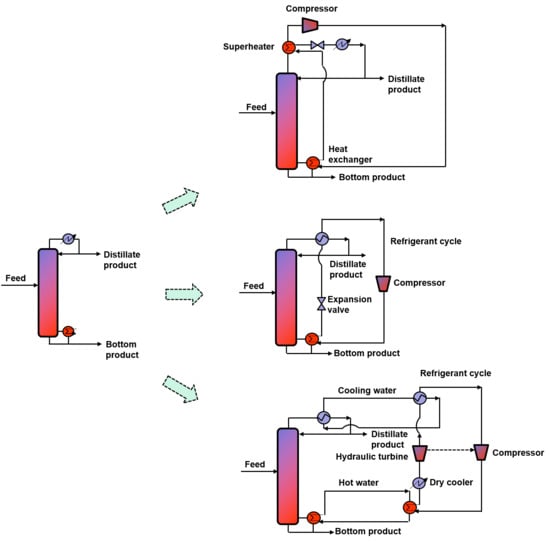

2. Proposed Configurations for Improving Reclamation Process

2.1. Mechanical Vapor Recompression

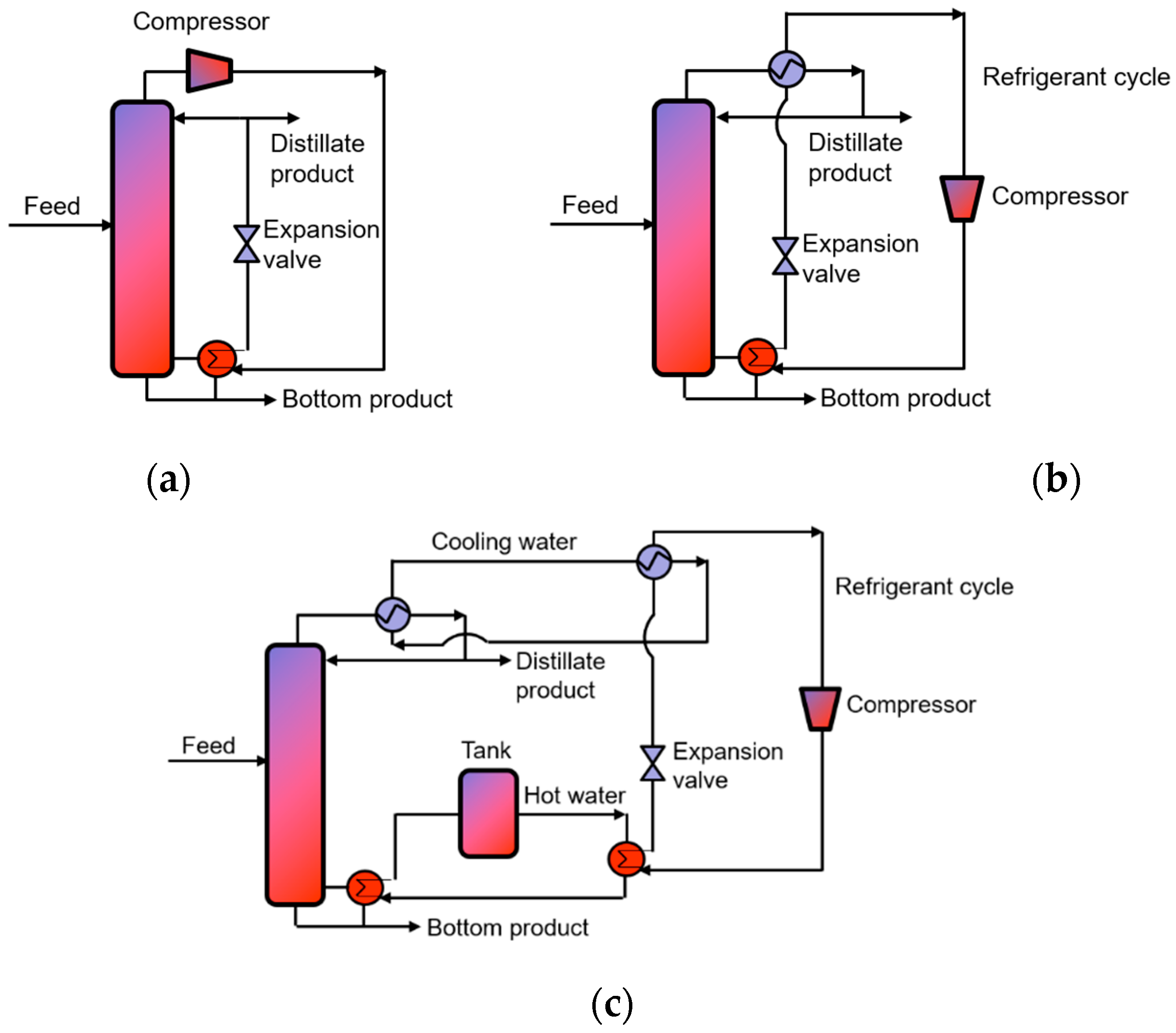

2.2. Vapor Compression Heat Pump

2.3. New Configuration

3. Results and Discussion

3.1. Existing Conventional Distillation Column

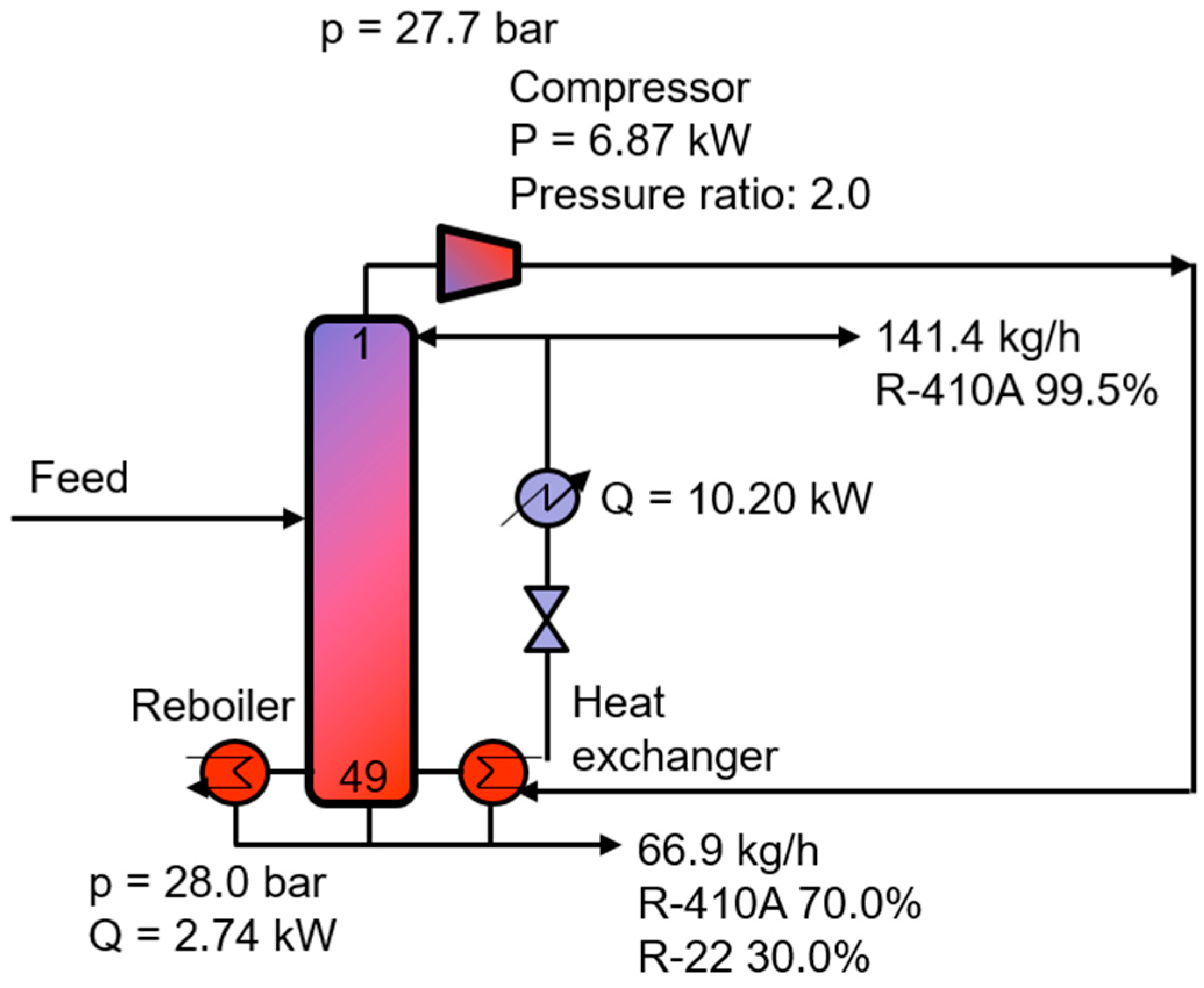

3.2. MVR Heat Pump

3.3. VC Heat Pump

- The bubble point of the working fluid at 1.01 bar must be less than the temperature of the top vapor by at least 10 °C.

- The dew point of the working fluid at higher pressure should be higher than the reboiler temperature by at least 10 °C.

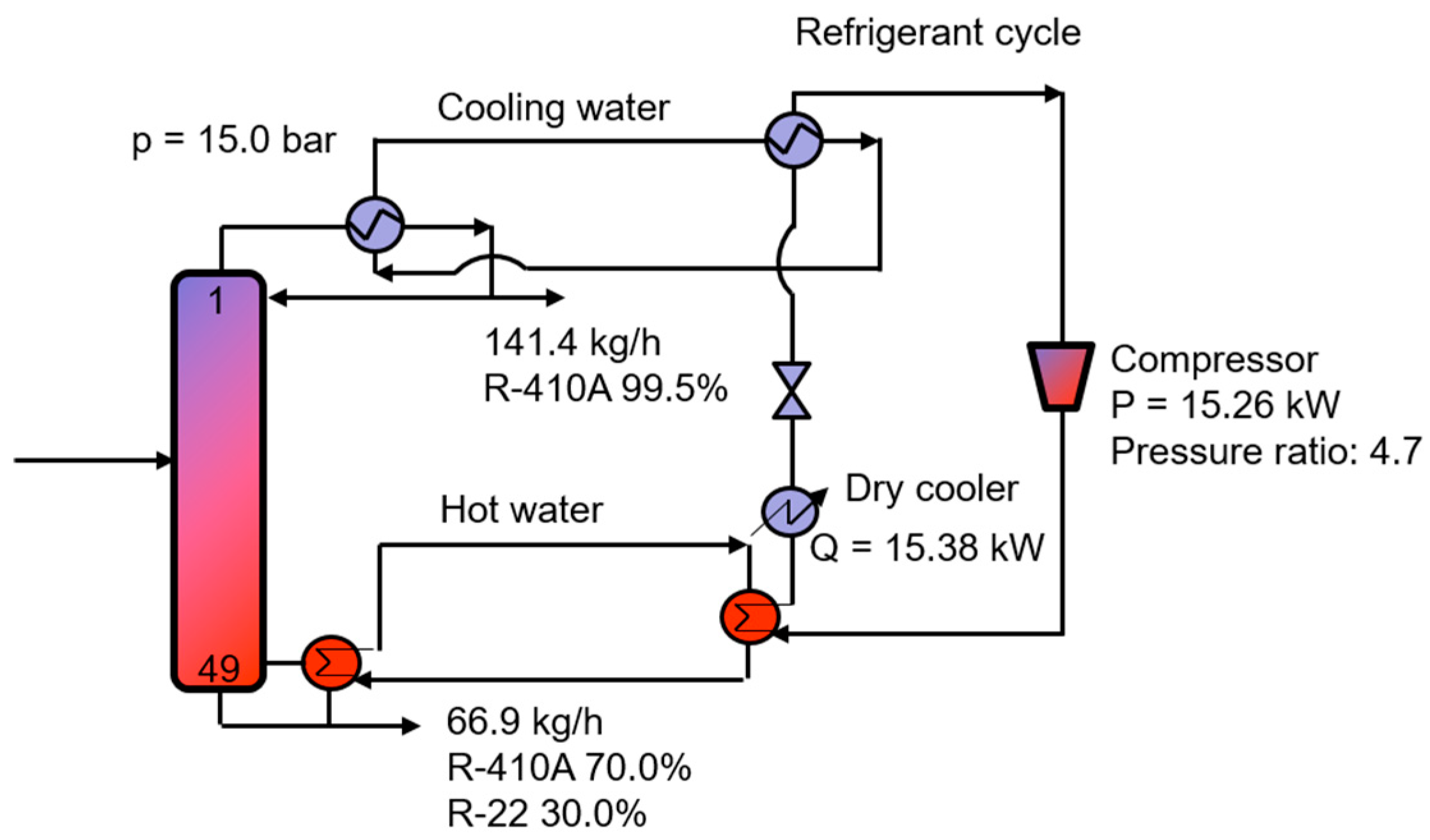

3.4. New Heat Pump Configuration

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Summary of Refrigerant Reclamation Trends. Available online: https://www.epa.gov/section608/summary-refrigerant-reclamation (accessed on 11 August 2019).

- Available online: https://www.agas.co.uk/products-services/recovery-reclamation-disposal (accessed on 11 August 2019).

- Refrigerant reclaim solutions. Available online: http://www.linde-gas.com/en/images/Refrigerant%20Reclaim%20Solutions%20brochure_tcm17-108595.pdf (accessed on 11 August 2019).

- Refrigerant 410A. Available online: https://www.rses.org/assets/r410a/R-410A.PDF (accessed on 11 August 2019).

- Available online: https://www.boconline.co.uk/en/products-and-supply/refrigerant-gases/reclaim-recovery-and-waste-management/index.html (accessed on 11 August 2019).

- Gregorio, T. Apparatus and Process for the Separation and Purification of Ideal and Non-Ideal Refrigerant Mixtures. US8075742, 13 December 2011. [Google Scholar]

- Wanigarathna, D.J.A.; Gao, L.; Takanami, T.; Zhang, Q.; Liu, B. Adsorption separation of R-22, R-32 and R-125 fluorocarbons using 4A molecular sieve zeolite. Chem. Select 2016, 1, 3718–3722. [Google Scholar]

- Chew, J.M.; Reddy, C.C.S.; Rangaiah, G.P. Improving energy efficiency of dividing-wall columns using heat pumps, organic rankine cycle and kalina cycle. Chem. Eng. Process 2014, 76, 45–59. [Google Scholar] [CrossRef]

- Long, N.V.D.; Minh, L.Q.; Nhien, L.C.; Lee, M. A novel self-heat recuperative dividing wall column to maximize energy efficiency and column throughput in retrofitting and debottlenecking of a side stream column. Appl. Energy 2015, 159, 28–38. [Google Scholar] [CrossRef]

- Minh, L.Q.; Long, N.V.D.; Duong, P.L.T.; Jung, Y.; Bahadori, A.; Lee, M. Design of an extractive distillation column for the environmentally benign separation of zirconium and hafnium tetrachloride for nuclear power reactor applications. Energies 2015, 8, 10354–10369. [Google Scholar] [CrossRef]

- Lee, J.; Son, Y.; Lee, K.S.; Won, W. Economic analysis and environmental impact assessment of heat pump-assisted distillation in a gas fractionation unit. Energies 2019, 12, 852. [Google Scholar] [CrossRef]

- Bruinsma, D.; Spoelstra, S. Heat pumps in distillation. In Proceedings of the Distillation & Absorption Conference, Eindhoven, The Netherlands, 12–15 September 2010. [Google Scholar]

- Kazemi, A.; Mehrabani-Zeinabad, A.; Beheshti, M. Recently developed heat pump assisted distillation configurations: A comparative study. Appl. Energy 2018, 211, 1261–1281. [Google Scholar] [CrossRef]

- Long, N.V.D.; Lee, M. Advances in Distillation Retrofit, 1st ed.; Springer: New York, NY, USA, 2017. [Google Scholar]

- Kiss, A.A.; Ferreira, C.A.I. Heat Pumps in Chemical Process Industry, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Schinitzer, H.; Moser, F. Heat Pumps in Industry; Elsevier: Amsterdam, The Netherlands, 1985. [Google Scholar]

- Ranade, S.; Chao, Y. Industrial heat pumps: Where and when? Hydrocarb. Process 1990, 71–73. [Google Scholar]

- Mizsey, P.; Fonyo, Z. Energy integrated distillation system design enhanced by heat pumping. Distill. Absorpt. 1992, 1369–1376. [Google Scholar]

- Annakou, O.; Mizsey, P. Rigorous investigation of heat pump assisted distillation. Heat Recov. Syst. CHP 1995, 15, 241–247. [Google Scholar] [CrossRef]

- Long, N.V.D.; Lee, M. Review of retrofitting distillation columns using thermally coupled distillation sequences and dividing wall columns to improve energy efficiency. J. Chem. Eng. Jpn. 2014, 47, 87–108. [Google Scholar] [CrossRef]

- Long, N.V.D.; Lee, M. Novel acid gas removal process based on self-heat recuperation technology. Int. J. Greenh. Gas Control 2017, 64, 34–42. [Google Scholar] [CrossRef]

- Pleşu, V.; Ruiz, A.E.B.; Bonet, J.; Llorens, J. Simple equation for suitability of heat pump use in distillation. Compu. Aided Chem. Eng. 2014, 33, 1327–1332. [Google Scholar]

- Aspen Technology. Aspen Physical Property System; Aspen Technology: Bedford, MA, USA, 2013. [Google Scholar]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Analysis, Synthesis and Design of Chemical Processes, 4th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Modla, G.; Lang, P. Heat pump systems with mechanical compression for batch distillation. Energy 2013, 62, 403–417. [Google Scholar] [CrossRef]

- R-407C. Available online: https://www.gas-servei.com/productos/refrigerantes/refrigerantes-hfc/gasficha/r-407c/ (accessed on 11 August 2019).

- R407 A. Available online: http://www.refrigerants.com/ (accessed on 11 August 2019).

- Kazemi, A.; Faizi, V.; Mehrabani-Zeinabad, A.; Hosseini, M. Evaluation of performance of heat pump assisted distillation of ethanol-water mixture. Sep. Sci. Technol. 2017, 52, 1387–1396. [Google Scholar] [CrossRef]

- Gadalla, M.A.; Olujic, Z.; Jansens, P.J.; Jobson, M.; Smith, R. Reducing CO2 emissions and energy consumption of heat-integrated distillation systems. Environ. Sci. Technol. 2005, 39, 6860–6870. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, A.Q.; Ali, W.; Long, N.V.D.; Khan, M.S.; Lee, M. Energy efficiency enhancement of a single mixed refrigerant LNG process using a novel hydraulic turbine. Energy 2018, 144, 968–976. [Google Scholar]

- Kanoğlu, M. Cryogenic turbine efficiencies. Exergy Int. J. 2001, 1, 202–208. [Google Scholar] [CrossRef]

- Minh, N.Q.; Hewitt, N.J.; Eames, P.C. Improved vapour compression refrigeration cycles: Literature review and their application to heat pumps. In Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue University, IN, USA, 17–20 July 2006. [Google Scholar]

- Wang, H.; Peterson, R.; Harada, K.; Miller, E.; Ingram-Goble, R.; Fisher, L.; Yih, J.; Ward, C. Performance of a combined organic rankine cycle and vapor compression cycle for heat activated cooling. Energy 2011, 36, 447–458. [Google Scholar] [CrossRef]

- Ferrara, G.; Ferrari, L.; Fiaschi, D.; Galoppi, G.; Karellas, S.; Secchi, R.; Tempesti, D. A small power recovery expander for heat pump COP improvement. Energy Procedia 2015, 81, 1151–1159. [Google Scholar] [CrossRef]

- Gordon, J.L. hydraulic turbine efficiency. Can. J. Civ. Eng. 2001, 28, 238–253. [Google Scholar] [CrossRef]

- Johnson, L.L.; Renaudin, G. Liquid turbines improve LNG operations. Oil Gas J. 1996, 94, 31–32. [Google Scholar]

- Kimmel, H.E.; Cathery, S. Thermo-fluid dynamics and design of liquid-vapour two-phase LNG expanders. In Proceedings of the GPA Europe Technical Meeting, Paris, France, 24–26 February 2010. [Google Scholar]

| Number of trays | 49 |

| Tray type | Packing |

| HETP (m) | 0.43 |

| Column diameter (m) | 0.25 |

| Max flooding (%) | 68.3 |

| Energy requirement of condenser (kW) | 48.50 |

| Energy requirement of reboiler (kW) | 48.15 |

| R-410A purity (mass%) | 99.5 |

| Structural Alternative | Existing Conventional Column | MVR Heat Pump | MVR Heat Pump with Superheating | VC Heat Pump | New Heat Pump | New Heat Pump with Hydraulic Turbine |

|---|---|---|---|---|---|---|

| Energy requirement saving in condenser (%) | - | 79.0 | 85.2 | 83.1 | 68.3 | 74.9 |

| Energy requirement saving in reboiler (%) | - | 94.3 | 100.0 | 100.0 | 100.0 | 100.0 |

| Annual operating cost saving (%) | - | 56.2 | 60.8 | 54.5 | 15.6 | 33.2 |

| CO2 emission saving (%) | - | 53.2 | 57.6 | 50.7 | 8.6 | 27.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, N.V.D.; Han, T.H.; Lee, D.Y.; Park, S.Y.; Hwang, B.B.; Lee, M. Enhancement of a R-410A Reclamation Process Using Various Heat-Pump-Assisted Distillation Configurations. Energies 2019, 12, 3776. https://doi.org/10.3390/en12193776

Long NVD, Han TH, Lee DY, Park SY, Hwang BB, Lee M. Enhancement of a R-410A Reclamation Process Using Various Heat-Pump-Assisted Distillation Configurations. Energies. 2019; 12(19):3776. https://doi.org/10.3390/en12193776

Chicago/Turabian StyleLong, Nguyen Van Duc, Thi Hiep Han, Dong Young Lee, Sun Yong Park, Byeng Bong Hwang, and Moonyong Lee. 2019. "Enhancement of a R-410A Reclamation Process Using Various Heat-Pump-Assisted Distillation Configurations" Energies 12, no. 19: 3776. https://doi.org/10.3390/en12193776

APA StyleLong, N. V. D., Han, T. H., Lee, D. Y., Park, S. Y., Hwang, B. B., & Lee, M. (2019). Enhancement of a R-410A Reclamation Process Using Various Heat-Pump-Assisted Distillation Configurations. Energies, 12(19), 3776. https://doi.org/10.3390/en12193776