Modelling and Analysis of Energy Harvesting in Internet of Things (IoT): Characterization of a Thermal Energy Harvesting Circuit for IoT based Applications with LTC3108

Abstract

:1. Introduction

2. Internet of Things (IoT) Power Requirements

3. Methodology

3.1. Thermoelectric Generator Model

3.1.1. Thermoelectric Generator SPICE Model Selection

3.1.2. Parameter Extraction from the Datasheet

- Reading and observing the maximum output voltage (VOPT) of the TEC1-12722 module:VOPT value is 16 V for Th = 27 °C

- Calculating the Seebeck Coefficient (Se):

- Determining the maximum performance for a zero temperature difference:

- Calculating Electrical resistance (RTEG):

3.2. LTSpice Simulation For Thermal Energy Harvesting Circuit With LTC3108

4. Thermal Energy Harvesting Circuit Characterization and Performance Curves

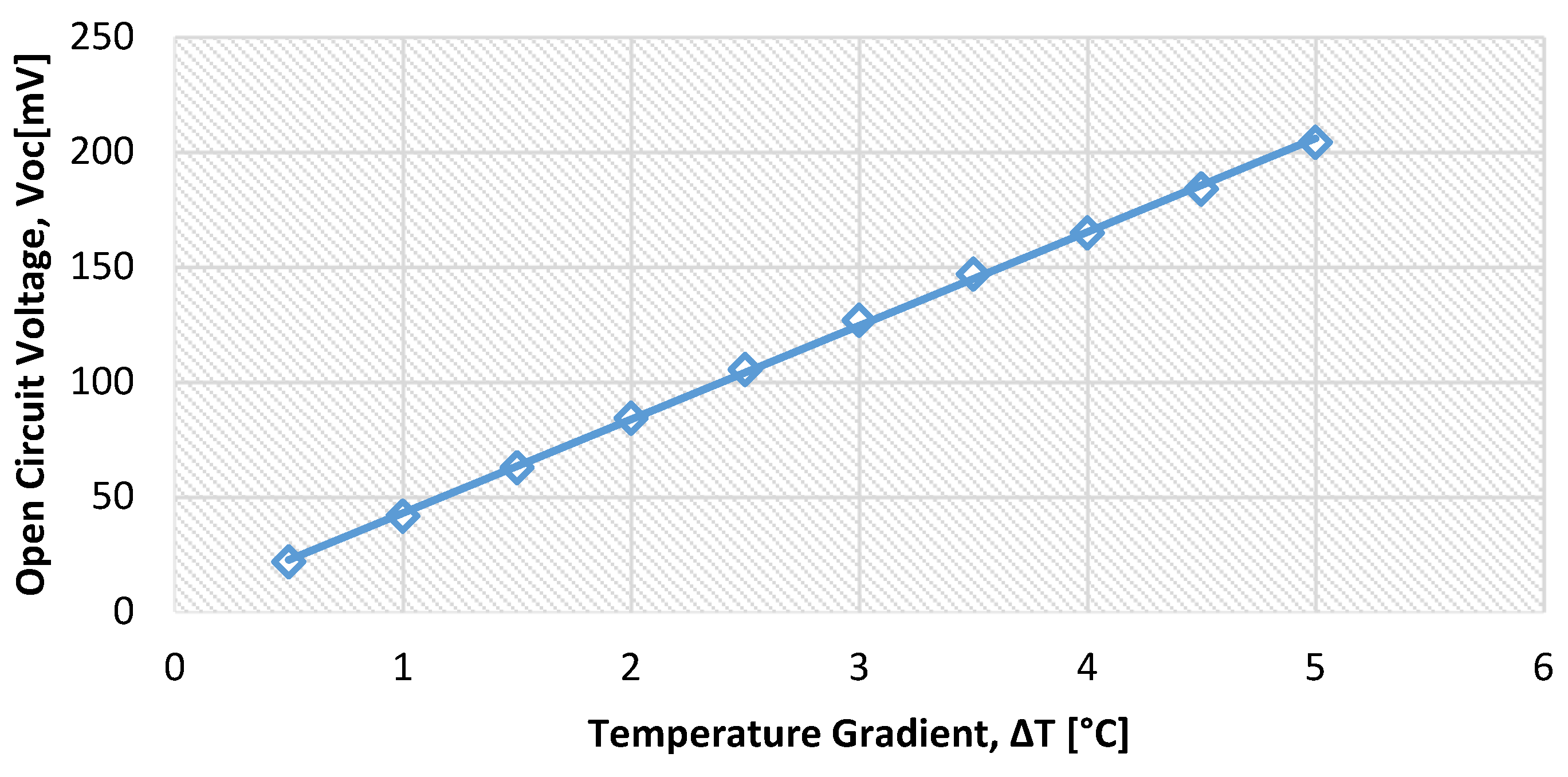

4.1. Open Circuit Testing

4.2. Setup 1: Setting VOUT at 2.3 V for Thermal EHC

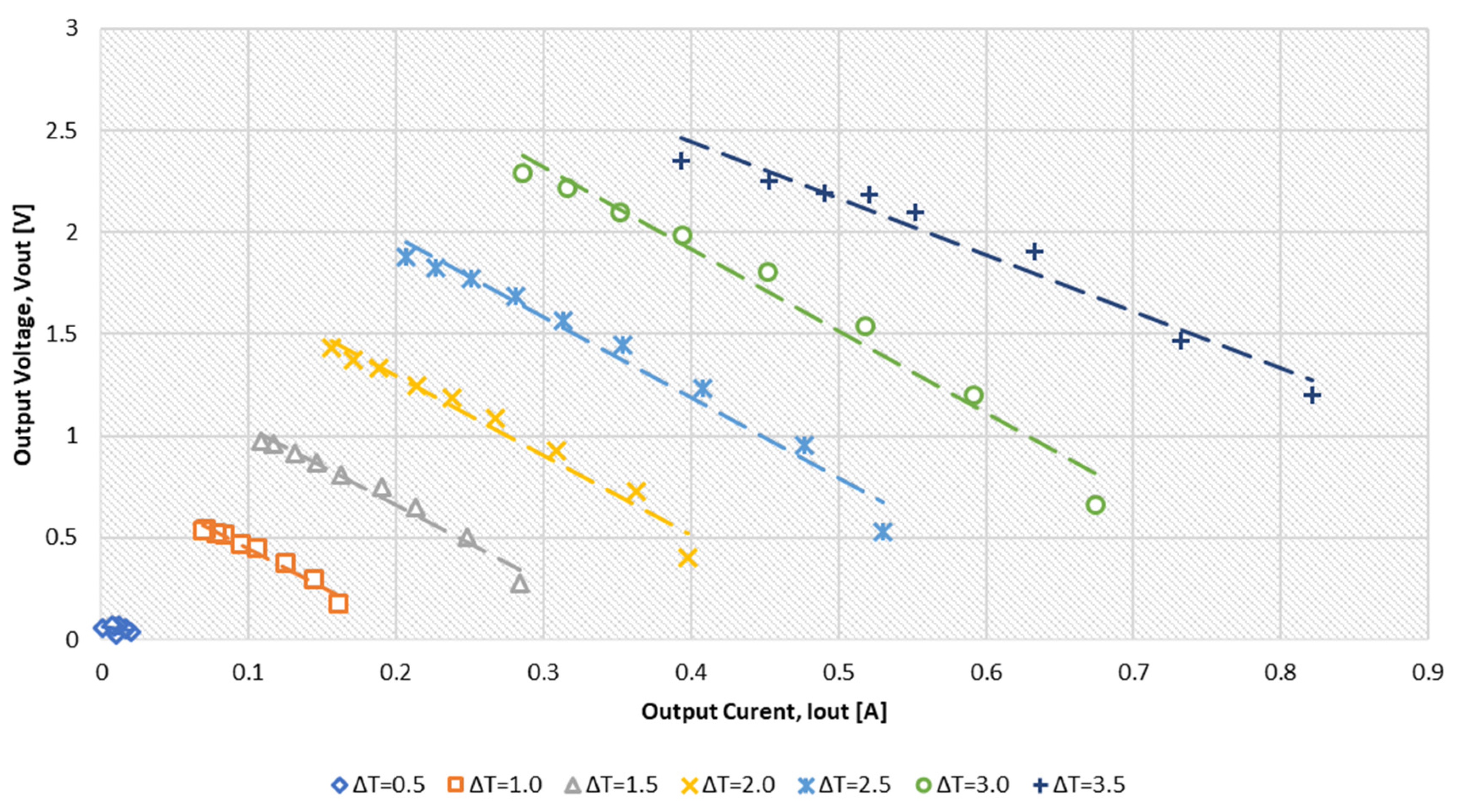

4.2.1. EHC Model I–V Curves at 2.3 VOUT

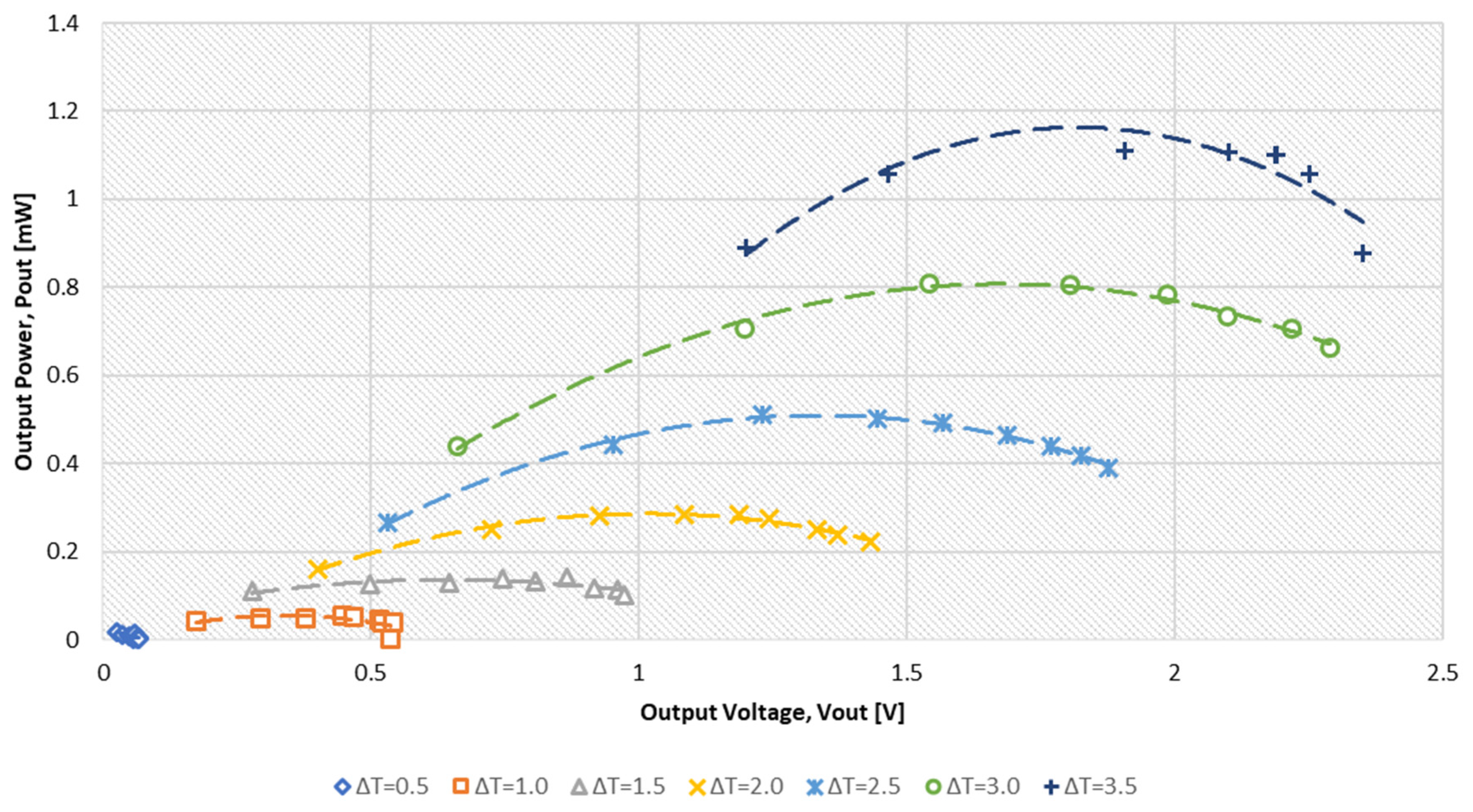

4.2.2. EHC Model Power Curves at 2.3 VOUT

4.3. Setup 2: Setting Vout at 3.3 V for Thermal EHC

4.3.1. EHC Model I–V Curves at 3.3 VOUT

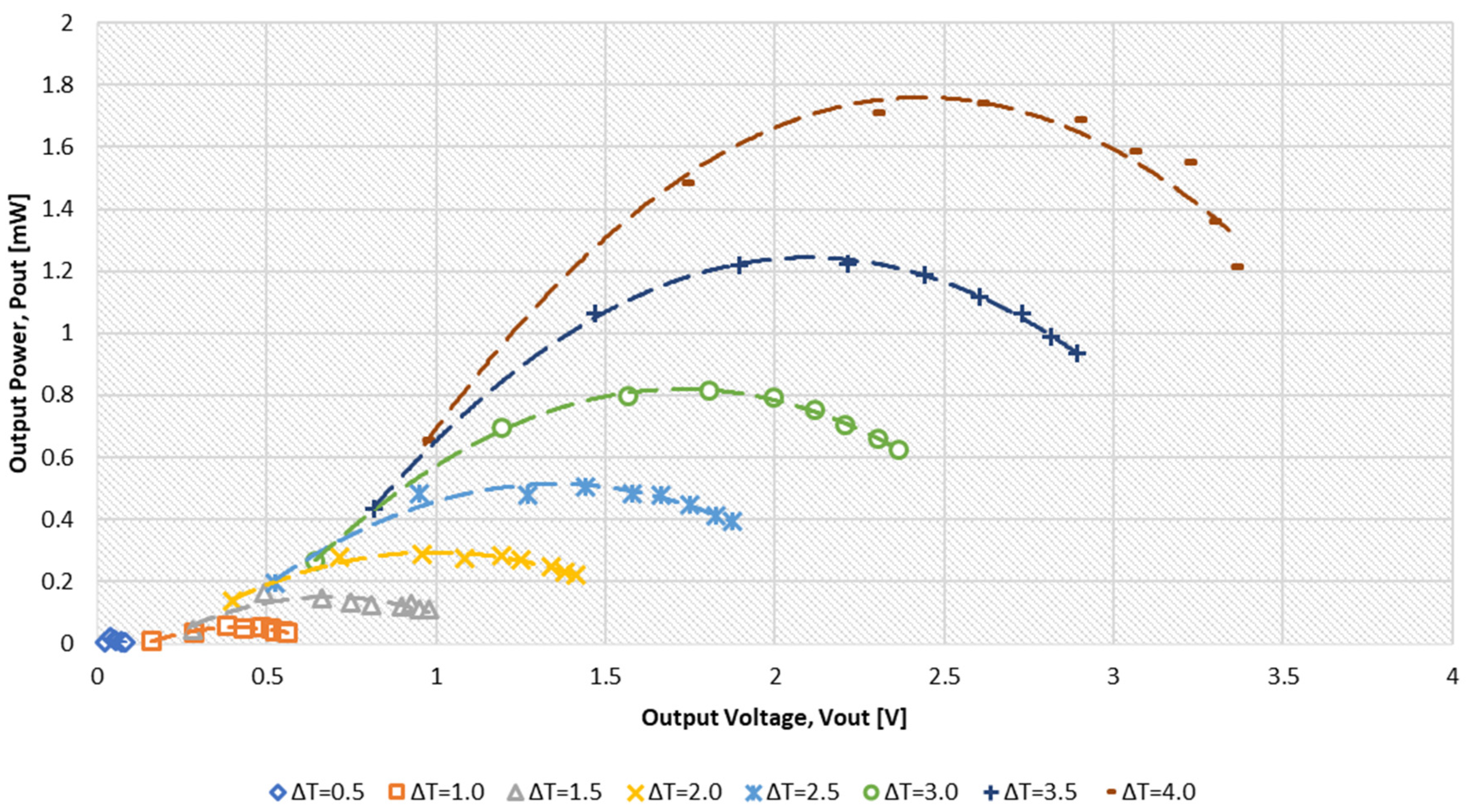

4.3.2. EHC Model Power Curves

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sarkar, S. Chapter 11 - Internet of Things—robustness and reliability. In Internet of Things: Principles and Paradigms; Buyya, R., Vahid Dastjerdi, A., Eds.; Morgan Kaufmann: Burlington, MA, USA, 2016; pp. 201–218. ISBN 978-0-12-805395-9. [Google Scholar]

- Krasniqi, X.; Hajrizi, E. Use of IoT Technology to Drive the Automotive Industry from Connected to Full Autonomous Vehicles. IFAC-PapersOnLine. 2016, 49, 269–274. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.C.; Suryadevara, N.K. Internet of Things: Challenges and Opportunities. In Internet of Things: Challenges and Opportunities; Mukhopadhyay, S.C., Ed.; Springer International Publishing: Cham, The Netherlands, 2014; pp. 1–17. ISBN 978-3-319-04223-7. [Google Scholar]

- Kåberger, T. Progress of renewable electricity replacing fossil fuels. Glob. Energy Interconnect. 2018, 1, 48–52. [Google Scholar]

- Aksanli, B.; Rosing, T.S.; Monga, I. Benefits of Green Energy and Proportionality in High Speed Wide Area Networks Connecting Data Centers. In Proceedings of the Proceedings of the Conference on Design, Automation and Test in Europe, Dresden, Germany, 12–16 March 2012; EDA Consortium: San Jose, CA, USA, 2012; pp. 175–180. [Google Scholar]

- Dewan, A.; Ay, S.U.; Karim, M.N.; Beyenal, H. Alternative power sources for remote sensors: A review. J. Power Sources 2014, 245, 129–143. [Google Scholar] [CrossRef]

- Maharaj, S.; Govender, P. Waste energy harvesting with a thermoelectric generator. In Proceedings of the 2013 Proceedings of the 21st Domestic Use of Energy Conference, Cape Town, South Africa, 3–4 April 2013; pp. 1–6. [Google Scholar]

- Snyder, G.J. Thermoelectric Energy Harvesting. In Energy Harvesting Technologies; Priya, S., Inman, D.J., Eds.; Springer: Boston, MA, USA, 2009; pp. 325–336. ISBN 978-0-387-76464-1. [Google Scholar]

- Dziurdzia, P. Modeling and Simulation of Thermoelectric Energy Harvesting Processes. In Sustainable Energy Harvesting Technologies; Tan, Y.K., Ed.; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar] [Green Version]

- Srinivasan, B.; Gellé, A.; Gucci, F.; Boussard-Pledel, C.; Fontaine, B.; Gautier, R.; Halet, J.-F.; Reece, M.J.; Bureau, B. Realizing a stable high thermoelectric zT ∼ 2 over a broad temperature range in Ge1−x−yGaxSbyTe via band engineering and hybrid flash-SPS processing. Inorg. Chem. Front. 2019, 6, 63–73. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, L.-D. Thermoelectric materials: Energy conversion between heat and electricity. J. Materiomics 2015, 1, 92–105. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, B.; Fontaine, B.; Gucci, F.; Dorcet, V.; Saunders, T.G.; Yu, M.; Cheviré, F.; Boussard-Pledel, C.; Halet, J.-F.; Gautier, R.; et al. Effect of the Processing Route on the Thermoelectric Performance of Nanostructured CuPb18SbTe20. Inorg. Chem. 2018, 57, 12976–12986. [Google Scholar] [CrossRef] [PubMed]

- Mateu, L.; Codrea, C.; Lucas, N.; Pollak, M.; Spies, P. Human Body Energy Harvesting Thermogenerator for Sensing Applications. In Proceedings of the 2007 International Conference on Sensor Technologies and Applications (SENSORCOMM 2007), Valencia, Spain, 14–20 October 2007; pp. 366–372. [Google Scholar]

- Kotanagi, S. Thermoelectric generation unit and portable electronic device using the unit. U.S. Patent No. US6560167B1, 6 May 2003. [Google Scholar]

- Curry, J.; Harris, N. Powering the Environmental Internet of Things. Sensors 2019, 19, 1940. [Google Scholar] [CrossRef] [PubMed]

- Sachan, V.K.; Imam, S.A.; Beg, M.T. Energy-efficient Communication Methods in Wireless Sensor Networks: A Critical Review. International Journal of Computer Applications 2012, 39, 35–48. [Google Scholar]

- Natsui, M.; Suzuki, D.; Tamakoshi, A.; Watanabe, T.; Honjo, H.; Koike, H.; Nasuno, T.; Ma, Y.; Tanigawa, T.; Noguchi, Y.; et al. 12.1 An FPGA-Accelerated Fully Nonvolatile Microcontroller Unit for Sensor-Node Applications in 40nm CMOS/MTJ-Hybrid Technology Achieving 47.14μW Operation at 200MHz. In Proceedings of the 2019 IEEE International Solid- State Circuits Conference - (ISSCC), San Francisco, CA, USA, 17–21 February 2019; pp. 202–204. [Google Scholar]

- Nesarajah, M.; Frey, G. Thermoelectric power generation: Peltier element versus thermoelectric generator. In Proceedings of the IECON 2016 - 42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4252–4257. [Google Scholar]

- Hebei, I.T. (Shanghai) Co., Ltd. Thermoelectric Cooler, TEC1-12706. Available online: http://www.hebeiltd.com.cn/peltier.datasheet/TEC1-12706.pdf (accessed on 17 August 2019).

- Thermoelectric Generator Module: GM250-127-14-10. Available online: https://www.europeanthermodynamics.com/products/datasheets/GM250-127-14-10-v2.pdf (accessed on 15 July 2019).

- Thermonamic Module: TEC1-12722. Available online: http://www.thermonamic.com/TEC1-12722-English.pdf (accessed on 15 July 2019).

- Siouane, S.; Jovanović, S.; Poure, P. Equivalent Electrical Circuits of Thermoelectric Generators under Different Operating Conditions. Energies 2017, 10, 386. [Google Scholar] [CrossRef]

- Ando, O.H., Jr.; Izidoro, C.L.; Gomes, J.M.; Correia, J.H.; Carmo, J.P.; Schaeffer, L. Acquisition and Monitoring System for TEG Characterization. Int. J. Distrib. Sens. Netw. 2015, 11, 531516. [Google Scholar] [CrossRef]

- Ando Junior, O.H.; Calderon, N.H.; De Souza, S.S. Characterization of a Thermoelectric Generator (TEG) System for Waste Heat Recovery. Energies 2018, 11, 1555. [Google Scholar] [CrossRef]

- Kubov, V.I.; Dymytrov, Y.Y.; Kubova, R.M. LTspice-model of thermoelectric Peltier-Seebeck element. In Proceedings of the 2016 IEEE 36th International Conference on Electronics and Nanotechnology (ELNANO), Kiev, Ukraine, 19–21 April 2016; pp. 47–51. [Google Scholar]

- Moumouni, Y.; Baker, R.J. Improved SPICE modeling and analysis of a thermoelectric module. In Proceedings of the 2015 IEEE 58th International Midwest Symposium on Circuits and Systems (MWSCAS), Fort Collins, CO, USA, 2–5 August 2015; pp. 1–4. [Google Scholar]

- Kubov, V.I.; Dymytrov, Y.Y. Simple method of thermoelectric cooler (Peltier device) parameters determination based on datasheet and modeling results. Available online: https://www.researchgate.net/publication/316658067_Simple_method_of_thermoelectric_cooler_Peltier_device_parameters_determination_based_on_datasheet_and_modeling_results (accessed on 14 May 2019).

- LTC3108 Dual TEG Energy Harvester (3.3V/2.2V) Operates from Temperature Differentials of Either Polarity Circuit Collection | Analog Devices. Available online: https://www.analog.com/en/design-center/reference-designs/circuit-collections/ltc3108-dual-teg-energy-harvester-3-3v-2-2v-operates-from-temperature-differentials-of-either.html#cc-documentation (accessed on 10 July 2019).

- Magno, M.; Brunelli, D.; Sigrist, L.; Andri, R.; Cavigelli, L.; Gomez, A.; Benini, L. InfiniTime: Multi-sensor wearable bracelet with human body harvesting. Sustain. Comput. Inform. Syst. 2016, 11, 38–49. [Google Scholar] [CrossRef]

- Montecucco, A.; Knox, A.R. Maximum Power Point Tracking Converter Based on the Open-Circuit Voltage Method for Thermoelectric Generators. IEEE Trans. Power Electron. 2015, 30, 828–839. [Google Scholar] [CrossRef]

- Schmidt, C.L.; Skarstad, P.M. The future of lithium and lithium-ion batteries in implantable medical devices. J. Power Sources 2001, 97–98, 742–746. [Google Scholar] [CrossRef]

- Gljuscic, P.; Zelenika, S.; Kamenar, E. Characterisation of Performances of Thermoelectric Generators for Energy Harvesting Applications. In DAAAM Proceedings; Katalinic, B., Ed.; DAAAM International: Vienna, Austria, 2018; Volume 1, pp. 0025–0030. ISBN 978-3-902734-20-4. [Google Scholar]

- TEG2-126LDT for Body & Sensor Power Thermoelectric Harvesting Applications. Available online: https://tecteg.com/wp-content/uploads/2015/01/TEG1-PB-12611-6.0_CBH-1-Final-November-17th-update.pdf (accessed on 2 September 2019).

- TEG2-07025HT-SS liquid to liquid applications. Available online: https://espressomilkcooler.com/wp-content/uploads/2014/05/Spec-TEG2-07025HT-SS-rev1.pdf (accessed on 2 September 2019).

- TEG1-PB-12611-6.0_CBH-1 TECTEG Power Generation. Available online: https://tecteg.com/wp-content/uploads/2015/01/TEG1-PB-12611-6.0_CBH-1-Final-November-17th-update.pdf (accessed on 2 September 2019).

- Costa, A.; Costa, D.; Morgado, J.; Santos, H.; Ferreira, C. Autonomous Wireless Sensor with a Low Cost TEG for Application in Automobile Vehicles. Procedia Eng. 2014, 87, 1226–1229. [Google Scholar] [CrossRef] [Green Version]

- Raheem, A.; Sai Rakesh, D.; Srinivasa Reddy, K.; Srikanth, K. Wireless Charge of Wearable Device Using Human Warmth; V.R. SIDHARTHA ENGINEERING COLLEGE: Vijayawada, India, 2019. [Google Scholar]

| Sensor Type | Power Consumption |

|---|---|

| Gas sensor | 500 mW–800 mW |

| Image sensor | 150 mW |

| Pressure sensor | 10 mW–15 mW |

| Acceleration sensor | 3 mW |

| Temperature sensor | 0.5 mW–5 mW |

| Performance Metrics | NV-MCU | JSSC2017 | ISSCC2016 | VLSI2015 | ISSCC2015 | ISSCC2014 |

|---|---|---|---|---|---|---|

| Architecture | Cortex-M0 32 bit | Cortex-M0 32 bit | 8051 8 bit | MSP430 16 bit | MSP430 16 bit | MSP430 16 bit |

| Frequency [MHz] | 200 | 30 | 100 | 25 | 16 | 20 |

| Active power [μW/Mhz] | 26.7 | 28.92 | 33 | 33 | 28.3 | 145 |

| Standby power [μW] | 0.7 | 0.009 | N/A | 0.7 | 0.32 | 1.2 |

| Average power@ intermittent operation [μW] | 47.14 | 143.3 | >2900 | 583.2 | 499.8 | 2560 |

| Parameters | Calculated Values | Units |

|---|---|---|

| RTEG | 53 | mV/K |

| Se | 0.692 | Ω |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afghan, S.A.; Géza, H. Modelling and Analysis of Energy Harvesting in Internet of Things (IoT): Characterization of a Thermal Energy Harvesting Circuit for IoT based Applications with LTC3108. Energies 2019, 12, 3873. https://doi.org/10.3390/en12203873

Afghan SA, Géza H. Modelling and Analysis of Energy Harvesting in Internet of Things (IoT): Characterization of a Thermal Energy Harvesting Circuit for IoT based Applications with LTC3108. Energies. 2019; 12(20):3873. https://doi.org/10.3390/en12203873

Chicago/Turabian StyleAfghan, Syeda Adila, and Husi Géza. 2019. "Modelling and Analysis of Energy Harvesting in Internet of Things (IoT): Characterization of a Thermal Energy Harvesting Circuit for IoT based Applications with LTC3108" Energies 12, no. 20: 3873. https://doi.org/10.3390/en12203873

APA StyleAfghan, S. A., & Géza, H. (2019). Modelling and Analysis of Energy Harvesting in Internet of Things (IoT): Characterization of a Thermal Energy Harvesting Circuit for IoT based Applications with LTC3108. Energies, 12(20), 3873. https://doi.org/10.3390/en12203873