1. Introduction

Condition-based maintenance (CBM) is a preventive maintenance (PM) policy, which uses information and communication technologies to monitor equipment status and to inspect and test the degree of interior deterioration of equipment. Based on equipment reliability, and with the equipment operating status and other importance factors taken into consideration, CBM is more target-specific, rational, and scientific when making equipment inspection, maintenance, and repair decisions [

1,

2].

Maity et al. point out that time-based maintenance (TBM) may easily lead to over-maintenance or under-maintenance of electrical equipment. If equipment status information can be taken real-time and on-line by sensors and be provided to back-end platforms, data can be analyzed and actual equipment operating condition can be assessed. Thus, a maintenance plan based on the deterioration degree of individual equipment can be made, and proper maintenance can be achieved [

3]. Unnecessary maintenance is one of the major causes of power grid failures. To avoid this from happening, Ohlen built a power system monitor and control platform for on-site measurement and on-line real-time monitoring in order to provide data needed by CBM. The goal is to achieve best balance between operation and maintenance based on field equipment status information [

4]. The working environment, operation data, inspection and maintenance records, and conditions of internal parts of power transformers are included in a multistage hierarchical assessment index system. The relative deterioration degree (RDD) method is used to assess the degree of similarity between actual equipment operating status and fault condition, and the analytic hierarchy process (AHP) method and the fuzzy comprehensive evaluation (FCE) method are used to evaluate the health status of power transformers. The result may serve as the basis of preventive maintenance practices [

5]. A circuit breaker (CB) maintenance research focused on reliability is proposed which integrates intelligent electronic devices (IEDs) in an intelligent maintenance model. IEDs are used to build a CB status monitoring system and to collect relevant maintenance information. The fuzzy set theory, the AHP method, and the Dempster–Shafer evidence theory are applied to analyze and evaluate CB status. In addition, important influencing factors of CBs are collected, and the Delphi method is applied to calculate the weights of the importance factors and to analyze and evaluate the importance of CBs. Finally, reliability-focused maintenance decision analysis is performed based on the result of CB status and importance evaluation [

6]. The multistage FCE method is applied to evaluate the operating status of the protection system of a power grid. A multistage status index model is built based on equipment status data, actual system operating status, and the experience of operation personnel and experts. The output of the model is the comprehensive evaluation result. Finally, a maintenance strategy, including status evaluation result, maintenance grades, optimal maintenance time, and maintenance suggestions, is proposed and can be adopted by the inspection and maintenance personnel to perform CBM on power grid protection systems [

7,

8]. Qian et al. proposed a CBM approach for wind turbines based on long short-term memory (LSTM) algorithms to improve defect detection from supervisory control and data acquisition (SCADA). LSTM algorithms have the capability of capturing long-term dependencies hidden within a sequence of measurements, which can be exploited to increase the prediction accuracy for CBM [

9]. Some research works presented the discrete Markov chain model as a simplified probabilistic model for damages in wind turbine blades. The classic Bayesian pre-posterior decision theory is applied for the decision-making of the CBM strategy [

10,

11,

12]. Tian et al. presented a transformer assessing model for CBM by employing a Cauchy membership function for fuzzy grade division, and then a fuzzy evidence fusion method was represented to handle the fuzzy evidences fusion processes. This approach can recommend the condition-based maintenance of power transformer [

13].

An intelligent substation is an important link in the realization of a smart grid and is responsible for electric power delivery, power dispatch, power flow, and equipment monitoring and control. As the intelligent substation evolves along with the announcement of IEC 61,850 communication standards, more equipment can be easily integrated into power monitoring and control systems, and innovative and intelligent CBM strategies can be proposed for power equipment maintenance and replacement. There are many studies on equipment maintenance and management on the substation primary side, but few on the reliability evaluation of intelligent substation SCADA systems. The goal of this study is to improve the existing maintenance methods of substation SCADA system equipment, and to propose a condition-based equipment inspection and maintenance strategy. In this study, substation equipment status information is collected following the IEC 61,850 communication protocol, equipment operating status is analyzed through status inspection and testing platform in real time, and a SCADA system maintenance and management platform applying intelligent inspection and maintenance strategy is realized. The result of this study may serve as a valuable reference to the inspection and maintenance personnel and the operation and management personnel of a power utility when making a maintenance plan, and may help to improve the stability and reliability of the utility power supply.

The objective of this paper is to propose the CBM evaluation model of a smart substation control system through a SCADA platform where the real-time health condition of substation equipment can be monitored. The result of the evaluation can be categorized into four degrees: Good Condition, Attention Required, Critical Condition, as well as Immediate Inspection and Maintenance. The maintenance staff can analyze the equipment condition and make the maintenance plan in priority order.

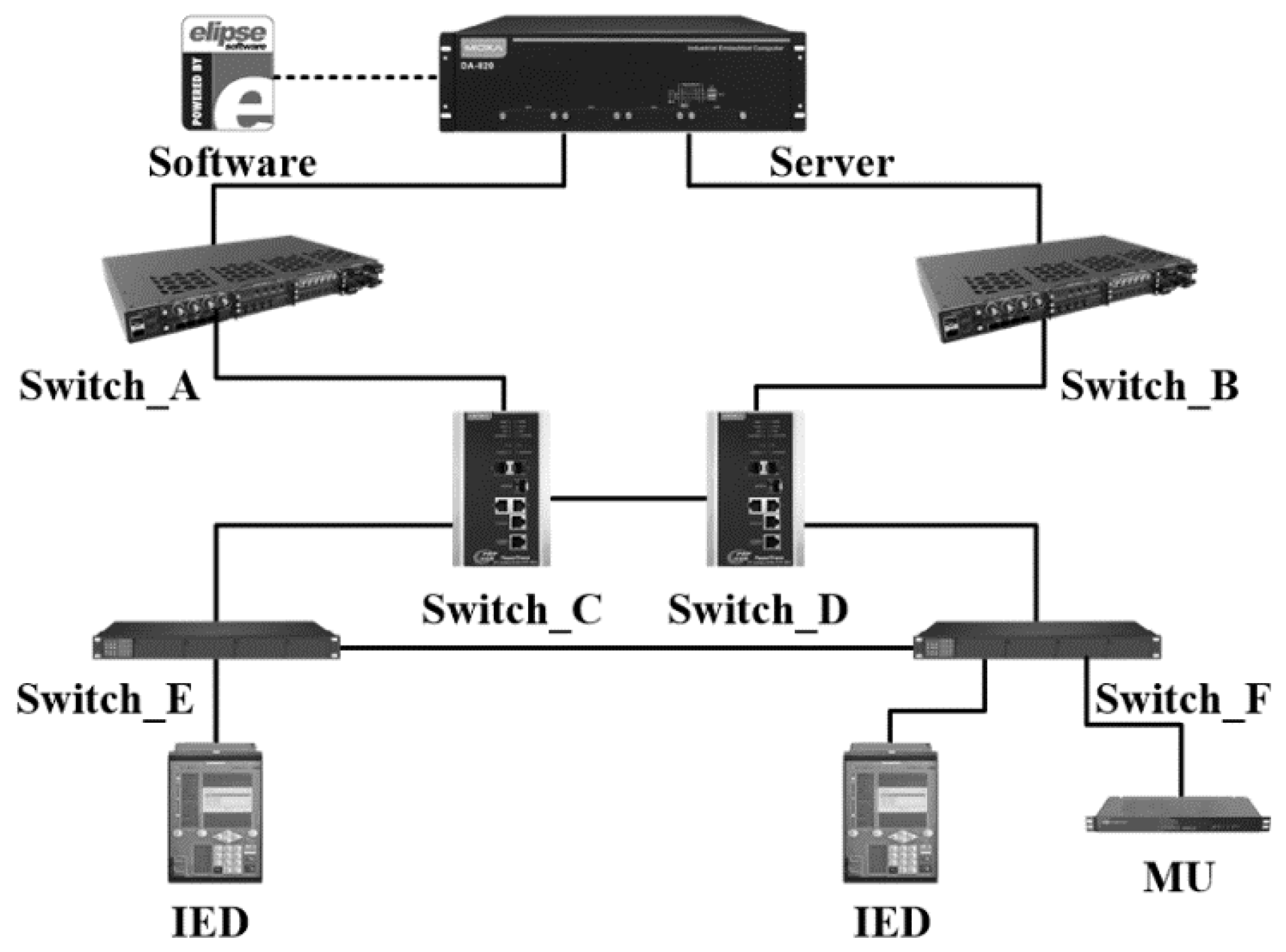

In this paper, an equipment status evaluation method is proposed, and a reliability evaluation model of an integrated intelligent substation SCADA system consisting of a server, SCADA human–machine interface (HMI) software, switches, IEDs, and merging units (MUs) is built in this study. First, the relative deterioration degree (RDD) method is applied to process the relevant parameters of performance-influencing factors. Then the comprehensive weighting method is applied to analyze the degree of importance of equipment. Finally, the fuzzy comprehensive evaluation (FCE) method is applied to perform comprehensive equipment status evaluation. The flowchart of the proposal is shown in

Figure 1. The evaluation result serves as a useful guide for system maintenance and management personnel, equipment manufacturers, and power equipment repair crews when maintenance is made. Eventually, an intelligent substation SCADA system example platform is built in the Tai-Tam substation of the Taipower company. Two operation cases of this platform have been applied for validation.

4. Case Study

An intelligent substation SCADA system example platform is built in the Tai-Tam substation of the Taipower company. The hardware configuration of this platform is shown in

Figure 4. Two operation cases of this platform have been explored and analyzed to determine the priority for equipment maintenance and repair. For case 1, the actual measured values of equipment influencing factors and the corresponding fuzzified RDDs are shown in

Table 4,

Table 5,

Table 6,

Table 7 and

Table 8. The membership degrees of the equipment influencing factors are shown in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13.

The analytic hierarchy process (AHP) method is applied in the intelligent substation SCADA system analysis to calculate the equipment subjective weights, as shown in

Table 14. The maximum eigenvalue and the corresponding eigenvector are

= 5.0438 and E = [0.7149 0.2241 0.3732 0.5170 0.1794], respectively. The consistency index and the consistency ratio are CI = 0.0110,

n = 5, RI = 1.12, and CR = 0.0098, respectively. Since CR ≦ 0.1, the weights are acceptable.

The subjective, objective, and comprehensive weights of the server status evaluation are shown in

Table 15. The AHP method is applied and the maximum eigenvalue and the corresponding eigenvector are

= 5.0164 and E = [0.2240 0.3262 0.1863 0.0854 0.1781], respectively. The consistency index and the consistency ratio are CI = 0.0041,

n = 5, RI = 1.12, and CR = 0.0037, respectively. Since CR ≦ 0.1, the weights are acceptable.

The subjective, objective, and comprehensive weights of the SCADA HMI software status evaluation are shown in

Table 16. The AHP method is applied and the maximum eigenvalue and the corresponding eigenvector are

= 4.0803 and E = [0.8001 0.4425 0.2237 0.3376], respectively. The consistency index and the consistency ratio are CI = 0.0268,

n = 4, RI = 0.9, and CR = 0.0297, respectively. Since CR ≦ 0.1, the weights are acceptable.

The subjective, objective, and comprehensive weights of the switch status evaluation are shown in

Table 17,

Table 18,

Table 19 and

Table 20. The AHP method is applied and the maximum eigenvalue and the corresponding eigenvector are

= 5.0494 and E = [0.4118 0.7113 0.4775 0.2052 0.2331], respectively. The consistency index and the consistency ratio are CI = 0.0124,

n = 5, RI = 1.12, and CR = 0.0110, respectively. Since CR ≦ 0.1, the weights are acceptable.

The subjective, objective, and comprehensive weights of the IED status evaluation are shown in

Table 21 and

Table 22. The AHP method is applied and the maximum eigenvalue and the corresponding eigenvector are

= 5.0096 and E = [0.2105 0.6576 0.6058 0.2915 0.2671], respectively. The consistency index and the consistency ratio are CI = 0.0024,

n = 5, RI = 1.12, and CR = 0.0021, respectively. Since CR ≦ 0.1, the weights are acceptable.

The subjective, objective, and comprehensive weights of the MU status evaluation are shown in

Table 23. The AHP method is applied and the maximum eigenvalue and the corresponding eigenvector are

= 6.0210 and E = [0.1981 0.5283 0.4586 0.4479 0.4720 0.2187], respectively. The consistency index and the consistency ratio are CI = 0.0042,

n = 6, RI = 1.24, and CR = 0.0034, respectively. Since CR ≦ 0.1, the weights are acceptable.

As a demonstration, the procedures and the numerical calculations of the FCE matrix for case 1 in this study are described in detail as follows.

- (1)

Server FCE matrix

B1 and its numerical value

T1:

- (2)

SCADA HMI software fuzzy evaluation matrix

B2 and its numerical value

T2:

- (3)

Switches fuzzy evaluation matrix B3:

The PT-G7828_A fuzzy evaluation matrix

B31 and its numerical value

T31:

The PT-G503_A fuzzy evaluation matrix

B33 and its numerical value

T33:

In order to improve the data transmission reliability, parallel redundancy protocol (PRP) and high-availability seamless redundancy (HSR) are introduced in the network communication configuration, where PRP is followed using switches PT-G7828_A and PT-G7828_B, while HSR is achieved using PT-G503_A, PT-G503_B, PT-7728_A, and PT-7728_B. The six switches are represented by one equivalent switch to simplify the calculation with fuzzy evaluation matrix

B3 and its numerical value

T3:

- (4)

IEDs fuzzy evaluation matrix R4:

The IED_A fuzzy evaluation matrix

B41 and its numerical value

T41:

The equivalent IED fuzzy evaluation matrix

B4 and its numerical value

T4:

- (5)

The MU fuzzy evaluation matrix

R5 and its numerical value

T5:

- (6)

The fuzzy evaluation matrix

S and its numerical value

T:

The equipment FCE result of case 1 is shown in

Table 24. All of the equipment is newly purchased in case 1. The status evaluation of the intelligent substation SCADA system of case 1 is 99.15 or “in Good Condition” and no inspection or maintenance schedule is required. Taipower company Tai-Tam substation CBM platform of the intelligent substation SCADA system is shown in

Figure 5.

The system in case 2 is old and has run for years, with all of the switches functioning in abnormal status, as shown in

Table 25. The status evaluation of the SCADA system of case 2 is 69.07 or “Immediate Inspection and Maintenance Required”, as shown in

Table 24. Although the SCADA system has a high reliability network configuration, its reliability is reduced drastically due to the serious deterioration of the switch, and immediate maintenance of all switches is required. The recommended maintenance order for the switches is Switch_C → Switch_A, Switch_B, Switch_E, and Switch_F → Switch_D. If the system is still in critical condition after the communication problem is resolved, the SCADA HMI software should be maintained too.

5. Conclusion

Smart substations play a vital role in power systems. However, the installation of a large number of secondary equipment makes the traditional correct maintenance and time base maintenance unable to meet the system requirements. It is imperative to develop a new equipment maintenance management strategy. In recent years, equipment maintenance strategies have been further developed and optimized by monitoring equipment abnormalities and considering the importance of equipment. Implementing a CBM system for a smart substation can effectively avoid over-maintenance or lack of maintenance of equipment, reducing unnecessary power outage tests, as well as the maintenance workload and cost. It can significantly improve the system operational reliability and economic efficiency.

In contrast to a conventional maintenance strategy, a condition-based maintenance and management strategy is proposed in this study, where equipment status information is gathered through the IEC 61,850 communication protocol. The relative deterioration degree theory (RDD) and fuzzy theory (FT) are used to evaluate the condition of the equipment, combining the subjective analytic hierarchy process (AHP) method with the objective entropy weighting method to analyze the important factor of equipment. The fuzzy comprehensive evaluation (FCE) method is applied to evaluate the equipment of an intelligent substation SCADA system based on the equipment condition and their importance. The evaluated equipment includes the server, SCADA HMI software, switch, IED, and MU.

Each equipment in the substation plays a different role according to its function. Assigning them reasonable weights by the scientific approach is an important process for state evaluation. The comprehensive weighting method proposed in this paper that combines the subjective analytic hierarchy process (AHP) method and the objective entropy weighting method can inherit the advantages of two kinds of weighting methods. This approach not only presents the subjective professional experience of decision makers, but also considers the truth of the objective facts. It can accurately evaluate equipment status in the smart substation control system.

The result shows that the equipment status maintenance and management platform developed in this study can diagnose the equipment operating status in real time. The inspection and maintenance personnel can analyze the overall equipment condition by knowing which one of the four status ratings, i.e., "in Good Condition", "Attention Required", "in Critical Condition", and "Immediate Inspection and Maintenance Required", the equipment status has, and can determine the priority for equipment maintenance. The evaluation result can serve as a valuable reference to utility companies when making maintenance plans.