Planning of the Multi-Energy Circular System Coupled with Waste Processing Base: A Case from China

Abstract

:1. Introduction

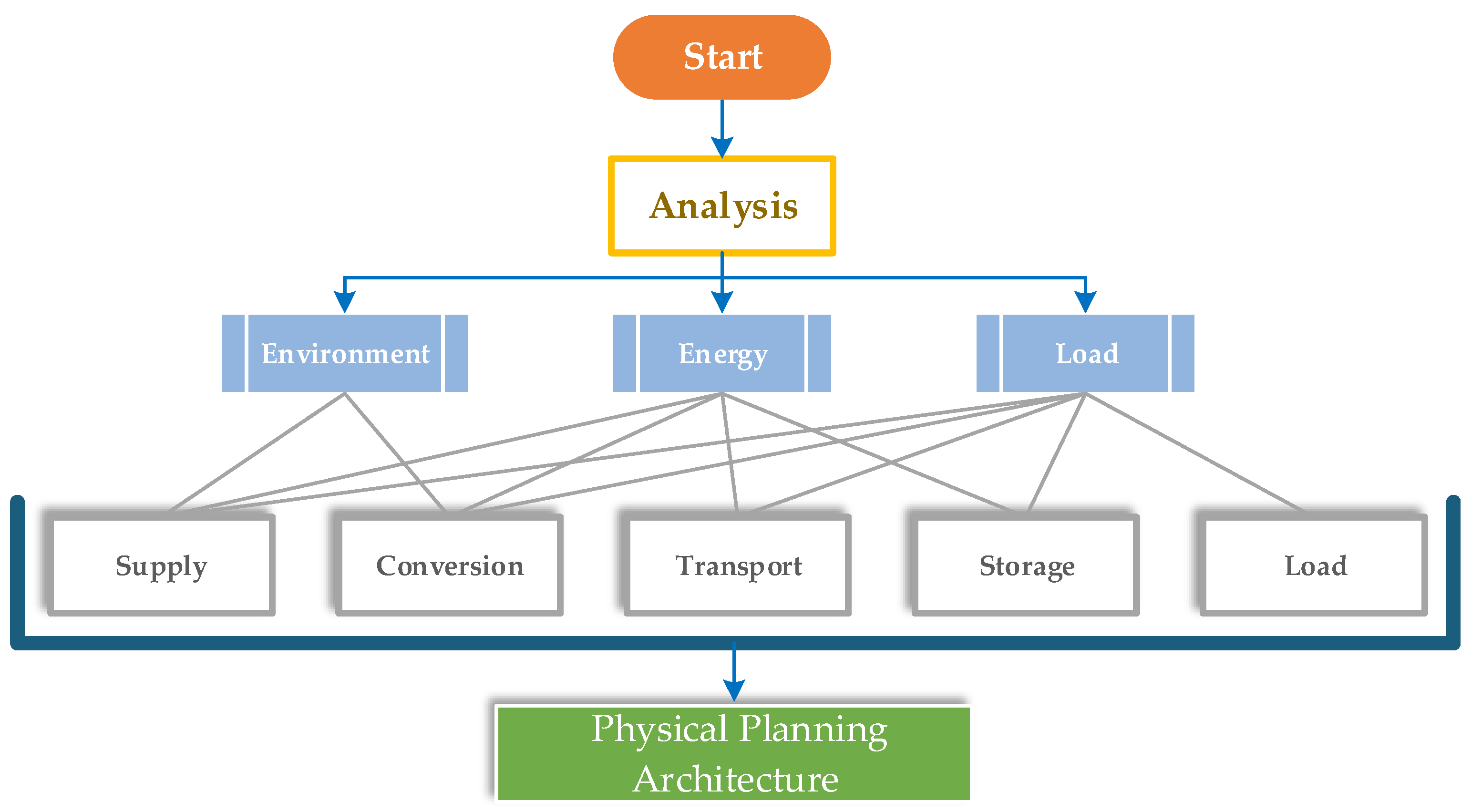

2. Design of Multi-Energy Planning

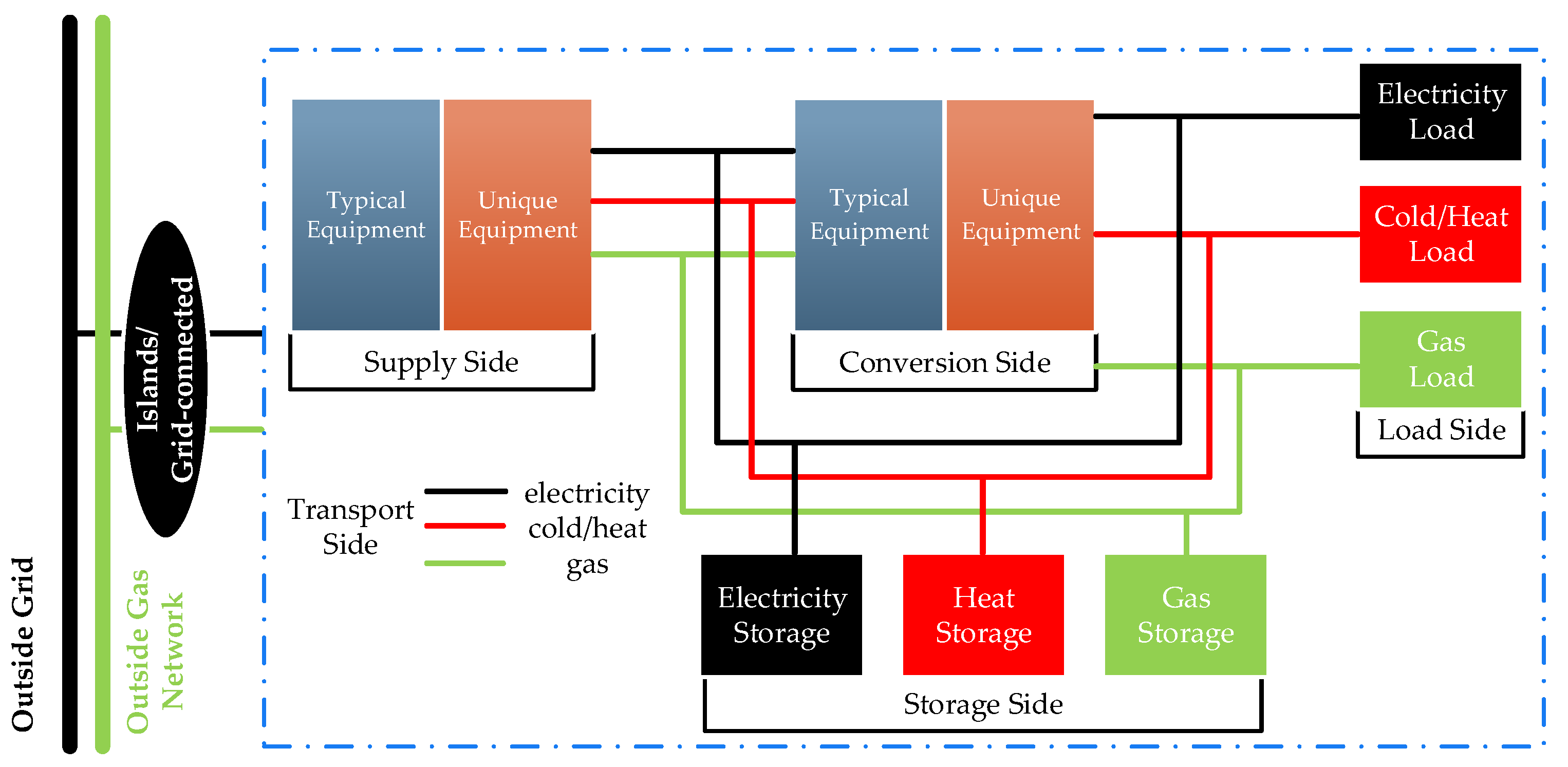

2.1. Physical Planning Architecture

2.2. Models of Equipment in MES

2.2.1. Typical Energy Equipment

2.2.2. Unique Energy Equipment

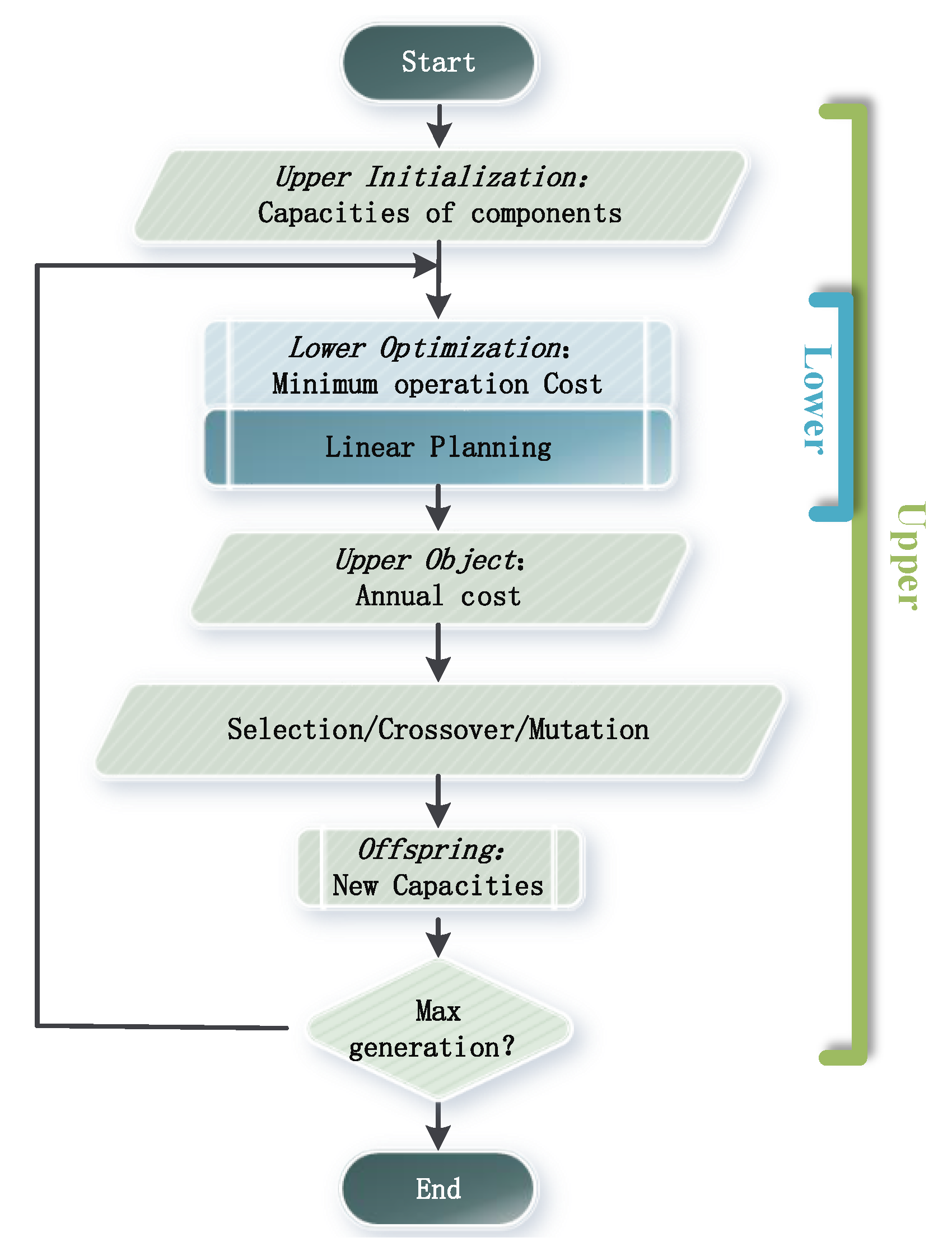

3. Optimization Model of MECS Coupled with WPB

3.1. Bi-Level Planning Optimization Model

3.1.1. The Upper Model

3.1.2. The Lower Model

3.2. Solution Algorithm

4. Case Analysis

4.1. Analysis of the Original WPB

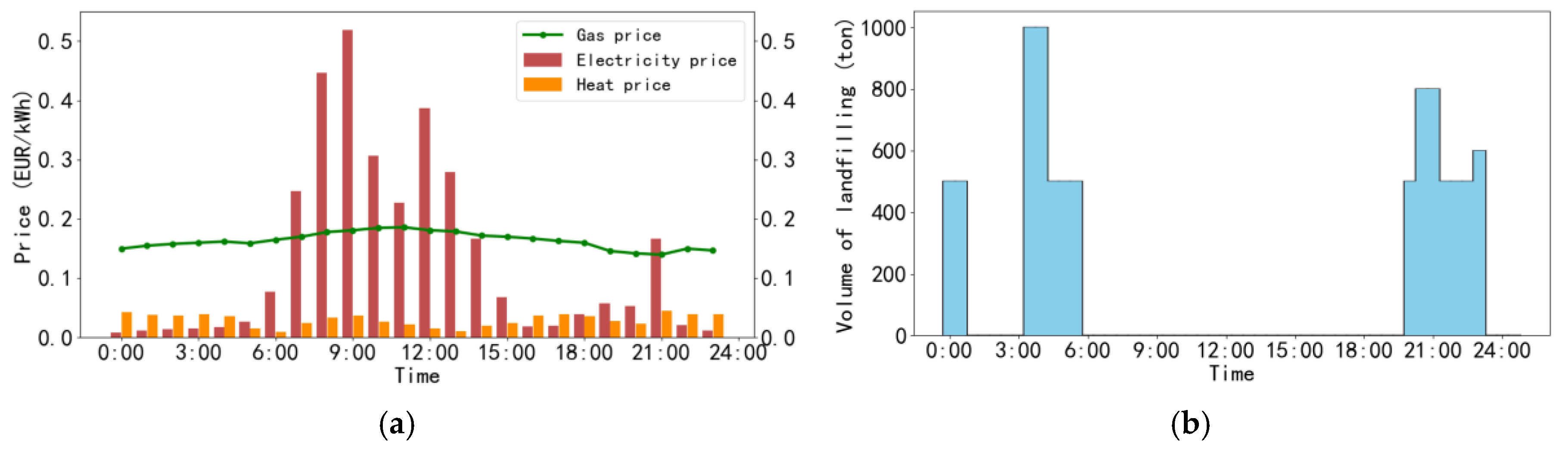

4.1.1. Energy Factor Analysis

4.1.2. Environment Factor Analysis

4.1.3. Load Factor Analysis

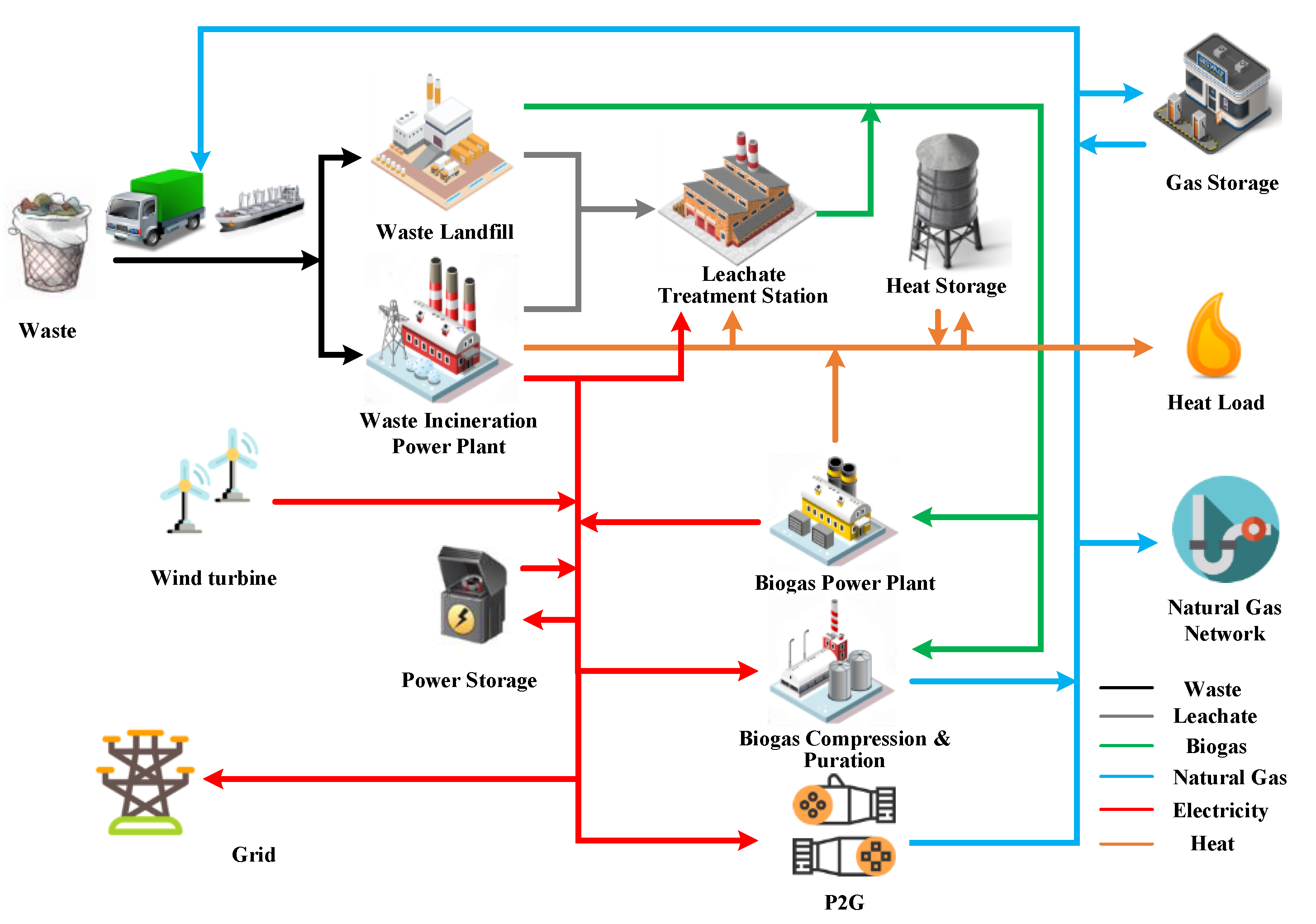

4.2. MECS Coupled with WPB

4.3. Basic Data

4.4. Results

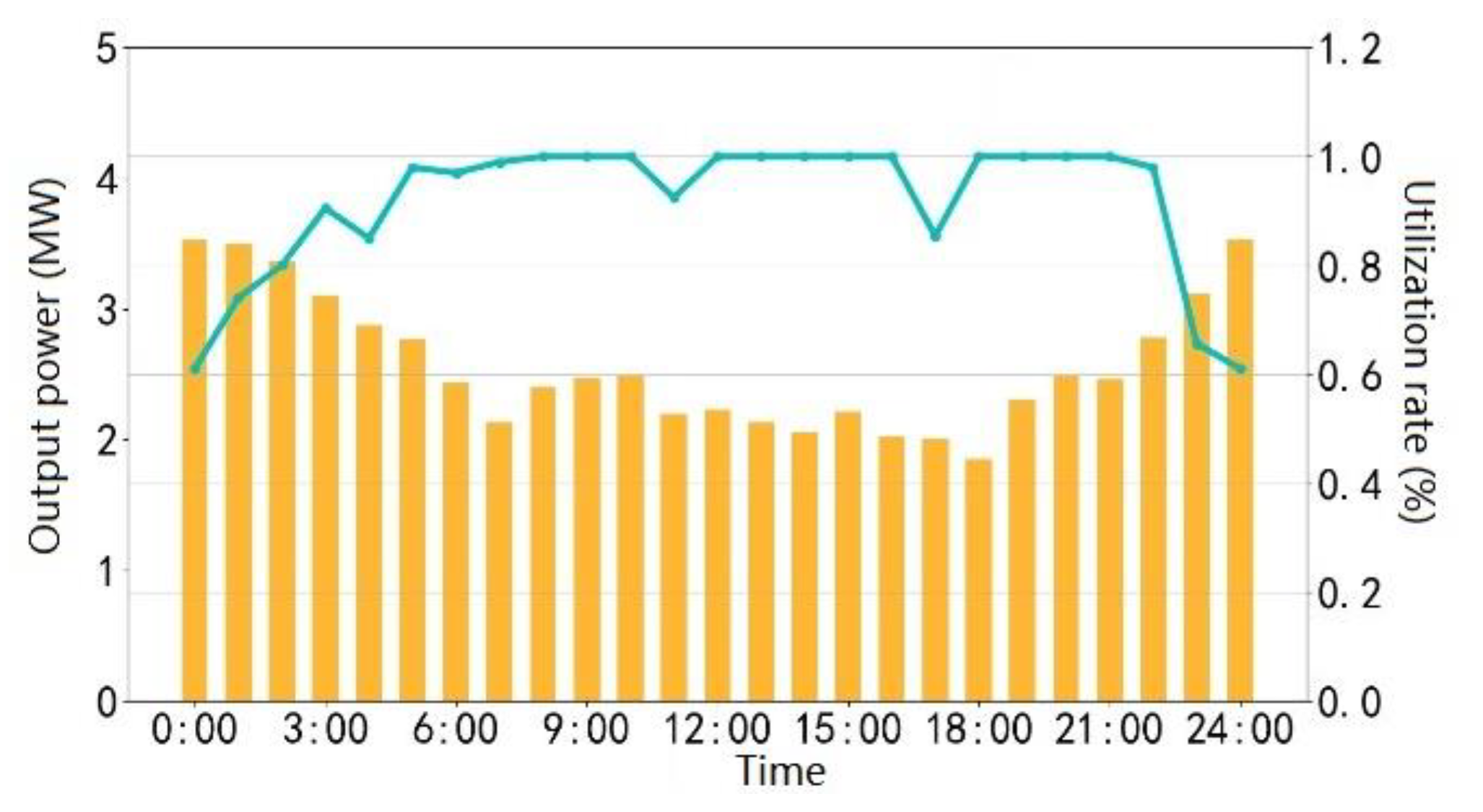

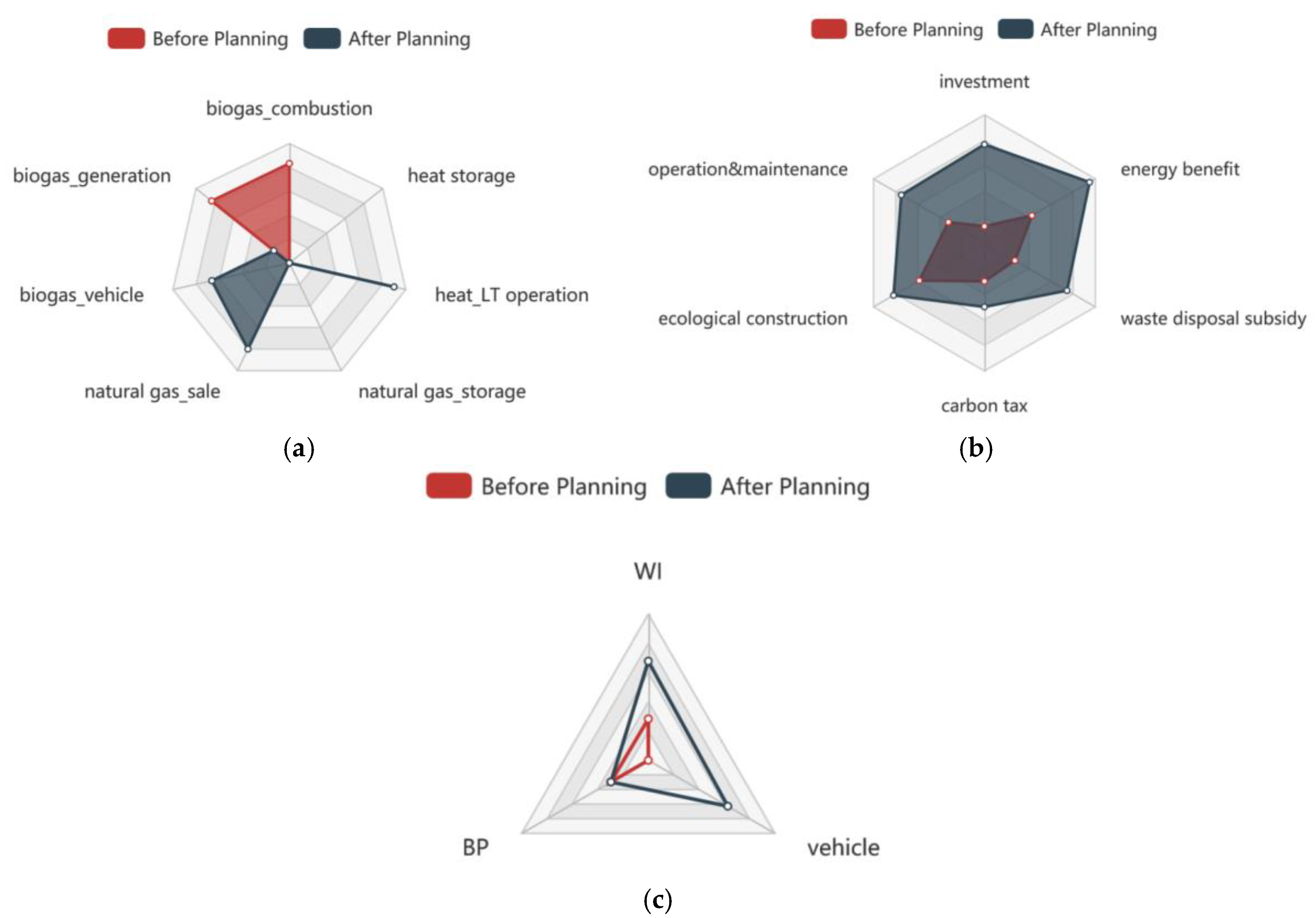

4.4.1. Improvement of Energy Efficiency

4.4.2. Growth of Economic Benefits

4.4.3. Promotion of Environmental Benefits

5. Conclusions

- (1)

- MECS is analyzed from three aspects: Energy, environment, and load. According to the results, the MECS is divided into supply, conversion, transmission, storage, and other blocks. According to the division of typical energy components and park-specific energy components, the physical planning architecture of MECS is built;

- (2)

- Based on the conventional location selection and capacity decision method of energy devices and the bi-level optimization model, the optimal scheduling of energy devices in MECS is transformed into the planning model;

- (3)

- The energy efficiency of biogas and heat is improved by constructing the BP and P2G. After planning, biogas and CH4 are recycled throughout the WPB, which is significant for the MECS. In addition, the original wasted heat energy in the WPB has also been fully utilized. Energy benefits for sale increases the total economic benefits, which is achieved by the supplement of power/heat/gas storage equipment. Energy storage devices make the way of energy supply and utilization in the WPB more flexible. The fuel of vehicles replaced by biogas helps enhance the carbon emission reduction.

- (1)

- Uncertainty factors in MECS, such as renewable energy and energy demand, are to be considered in the planning model in future research;

- (2)

- The energy collaborative optimization between multiple regions will be discussed in future research.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, W.; Zhang, N.; Yang, J.; Wang, Y.; Kang, C. Optimal Configuration Planning of Multi-Energy Systems Considering Distributed Renewable Energy. IEEE Trans. Smart Grid 2019, 10, 1452–1464. [Google Scholar] [CrossRef]

- Du, W.; Li, M. Government support and innovation for new energy firms in China. Appl. Econ. 2019, 51, 2754–2763. [Google Scholar] [CrossRef]

- Kubickova, M. The impact of government policies on destination competitiveness in developing economies. Curr. Issues Tour. 2019, 22, 619–642. [Google Scholar] [CrossRef]

- Rada, E.C.; Castagna, G.; Adami, L.; Torretta, V.; Ragazzi, M. Compensation opportunities and waste-to-energy plants. AIP Conf. Proc. 2018, 1968, 030065. [Google Scholar]

- Gitelman, L.; Magaril, E.; Khodorovsky, M. Interdisciplinarity as heuristic resource for energy management. Int. J. Energy Prod. Manag. 2016, 1, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Press, D.; Mazmanian, D. The greening of industry through ‘government-supervised self-regulation’. In Entrepreneurial Management and Public Policy, 2nd ed.; Nova Science Publishers: Hauppauge, NY, USA, 2011; pp. 233–249. [Google Scholar]

- Borisova, M.A.; Ryshikova, M.V.; Gomazova, A.A. Municipal Solid Waste Management in China. In Proceedings of the 2018 IEEE International Conference “Management of Municipal Waste as an Important Factor of Sustainable Urban Development” (WASTE), St. Petersburg, Russia, 4–6 October 2018; pp. 10–13. [Google Scholar]

- Zhong, Y.; Yu, Q.; Wu, P.; Wang, G. A Research into the Recycling System of Waste Electrical and Electronic Equipment in China. In Proceedings of the 2006 IEEE International Conference on Service Operations and Logistics, and Informatics, Shanghai, China, 21–23 June 2006; pp. 705–710. [Google Scholar]

- Ceseña, E.A.M.; Mancarella, P. Energy Systems Integration in Smart Districts: Robust Optimisation of Multi-Energy Flows in Integrated Electricity, Heat and Gas Networks. IEEE Trans. Smart Grid 2019, 10, 1122–1131. [Google Scholar] [CrossRef]

- Mavi, N.K.; Mavi, R.K. Energy and environmental efficiency of OECD countries in the context of the circular economy: Common weight analysis for malmquist productivity index. J. Environ. Manag. 2019, 247, 651–661. [Google Scholar] [CrossRef]

- Rada, E.C. Special waste valorization and renewable energy generation under a circular economy: Which priorities? WIT Trans. Ecol. Environ. 2019, 222, 145–157. [Google Scholar]

- Tsai, W.-T. Promoting the circular economy via waste-to-power (WTP) in Taiwan. Resources 2019, 8, 95. [Google Scholar] [CrossRef]

- Ragossnig, A.M.; Schneider, D.R. Circular economy, recycling and end-of-waste. Waste Manag. Res. 2019, 37, 109–111. [Google Scholar] [CrossRef] [Green Version]

- Rada, E.C.; Ragazzi, M.; Torretta, V.; Castagna, G.; Adami, L.; Cioca, L.I. Circular economy and waste to energy. AIP Conf. Proc. 2018, 1968, 030050. [Google Scholar]

- Tomić, T.; Schneider, D.R. The role of energy from waste in circular economy and closing the loop concept—Energy analysis approach. Renew. Sustain. Energy Rev. 2018, 98, 268–287. [Google Scholar] [CrossRef]

- Mohamad, N.F.; Hidayu, A.R.; Sherif, A.A.; Sharifah, A.S.A.K. Characteristics of bituminous coal, sub-bituminous coal and bottom ash from a coal-fired power plant. In Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 571–573. [Google Scholar]

- Martínez-Mares, A.; Fuerte-Esquivel, C.R.; de Ingeniería, I. Integrated energy flow analysis in natural gas and electricity coupled systems. In Proceedings of the 2011 North American Power Symposium, Boston, MA, USA, 4–6 August 2011; pp. 1–7. [Google Scholar]

- Zhu, G.; Zhao, G.; Zhang, Z.; Lu, X. Water quality of water source area in Taihu Lake and effect on water treatment process. In Proceedings of the 2011 International Conference on Consumer Electronics, Communications and Networks (CECNet), Xianning, China, 16–18 April 2011; pp. 3783–3786. [Google Scholar]

- Dai, Y.; Lu, Y.; Sun, Y.; He, Y. Wind energy resource assessment and derivation of characteristic wind speed in wind field of Inner Mongolia. In Proceedings of the 2011 International Conference on Consumer Electronics, Communications and Networks (CECNet), Xianning, China, 16–18 April 2011; pp. 3787–3790. [Google Scholar]

- Ramirez-Del-Barrio, P.; Mendoza-Araya, P.; Valencia, F.; León, G.; Cornejo-Ponce, L.; Montedonico, M.; Jiménez-Estévez, G. Sustainable development through the use of solar energy for productive processes: The Ayllu Solar Project. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017; pp. 1–8. [Google Scholar]

- Moghaddam, M.P.; Damavandi, M.Y.; Bahramara, S.; Haghifam, M.R. Modeling the impact of multi-energy players on electricity market in smart grid environment. In Proceedings of the 2016 IEEE Innovative Smart Grid Technologies—Asia (ISGT-Asia), Melbourne, VIC, Australia, 28 November–1 December 2016; pp. 454–459. [Google Scholar]

- Van Beuzekom, I.; Gibescu, M.; Slootweg, J.G. A review of multi-energy system planning and optimization tools for sustainable urban development. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–7. [Google Scholar]

- Hosseinpour, J.; Chitsaz, A.; Liu, L.; Gao, Y. Simulation of eco-friendly and affordable energy production via solid oxide fuel cell integrated with biomass gasification plant using various gasification agents. Renew. Energy 2020, 145, 757–771. [Google Scholar] [CrossRef]

- Fathabadi, H. Two novel methods for converting the waste heat of PV modules caused by temperature rise into electric power. Renew. Energy 2019, 142, 543–551. [Google Scholar] [CrossRef]

- Shamsi, S.S.M.; Negash, A.A.; Cho, G.B.; Kim, Y.M. Waste heat and water recovery system optimization for flue gas in thermal power plants. Sustainability 2019, 11, 1881. [Google Scholar] [CrossRef]

- Gitelman, L.D.; Kozhevnikov, M.V.; Starikov, E.M.; Rada, E.C. Scaling up the innovation process in the energy sector on the basis of technology entrepreneurship. In WIT Transactions on Ecology and the Environment; WIT Press: Southampton, UK, 2019; Volume 222, pp. 1–12. [Google Scholar]

- Montorsi, L.; Milani, M.; Venturelli, M. Economic assessment of an integrated waste to energy system for an urban sewage treatment plant: A numerical approach. Energy 2018, 158, 105–110. [Google Scholar] [CrossRef]

- Bao, Z.; Zhou, Q.; Wu, L.; Yang, Z.; Zhang, J. Optimal capacity planning of MG with multi-energy coordinated scheduling under uncertainties considered. IET Gener. Transm. Distrib. 2017, 11, 4146–4157. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, J.; Luo, Z.; Zhou, F.; Liu, X.; Lu, T. Optimal Planning of Multi-Energy System Considering Thermal Storage Capacity of Heating Network and Heat Load. IEEE Access 2019, 7, 13364–13372. [Google Scholar] [CrossRef]

- Huang, G.H.; Baetz, B.W.; Patry, G.G. Grey fuzzy integer programming: An application to regional waste management planning under uncertainty. Socio-Econ. Plan. Sci. 1995, 29, 17–38. [Google Scholar] [CrossRef]

- Yousefi, H.; Ghodusinejad, M.H.; Kasaeian, A. Multi-objective optimal component sizing of a hybrid ICE+PV/T driven CCHP microgrid. Appl. Therm. Eng. 2017, 122, 126–138. [Google Scholar] [CrossRef]

- Wang, J.; Jing, Y.; Zhang, C. Optimization of capacity and operation for CCHP system by genetic algorithm. Appl. Energy 2010, 87, 1325–1335. [Google Scholar] [CrossRef]

- Wang, J.; Zhai, Z.J.; Jing, Y.; Zhang, C. Particle swarm optimization for redundant building cooling heating and power system. Appl. Energy 2010, 87, 3668–3679. [Google Scholar] [CrossRef]

- Bracco, S.; Dentici, G.; Siri, S. Economic and environmental optimization model for the design and the operation of a combined heat and power distributed generation system in an urban area. Energy 2013, 55, 1014–1024. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J.; Zhao, P.; Dai, Y. Multi-objective optimization of a combined cooling, heating and power system driven by solar energy. Energy Convers. Manag. 2015, 89, 289–297. [Google Scholar] [CrossRef]

- Abdollahi, G.; Sayyaadi, H. Application of the multi-objective optimization and risk analysis for the sizing of a residential small-scale CCHP system. Energy Build. 2013, 60, 330–344. [Google Scholar] [CrossRef]

- Xie, D.; Lu, Y.; Sun, J.; Gu, C.; Li, G. Optimal Operation of a Combined Heat and Power System Considering Real-time Energy Prices. IEEE Access 2016, 4, 3005–3015. [Google Scholar] [CrossRef]

- Clegg, S.; Mancarella, P. Integrated Modeling and Assessment of the Operational Impact of Power-to-Gas(P2G) on Electrical and Gas Transmission Networks. IEEE Trans. Sustain. Energy 2015, 6, 1234–1244. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, T.; Li, G.; Chen, H.; Li, X.; Ning, R. Bi-level optimal dispatch of wind power integrated energy system considering electric rotation gas absorption. Proc. CSEE 2018, 38, 5668–5679. [Google Scholar]

- Wu, C.; Tang, W.; Bai, M.; Zhang, L.; Cong, P. User-side energy Internet planning based on bilevel programming. Trans. China Electrotech. Soc. 2017, 32, 122–131. [Google Scholar]

- Zhou, Y.; Sun, G.; Huang, W.; Xu, E.; Wei, Z.; Chen, S.; Chen, F. Integrated Energy Coordination and Dispatch Optimization Model for Multi-Area Virtual Power Plants. Proc. CSEE 2017, 37, 6780–6790+7069. [Google Scholar]

- Du, H.; Jiao, X.; Wang, R.; Yao, Q. Trend Analysis on Leachate Yield of Domestic Waste Incineration Power Plant. Environ. Sanit. Eng. 2019, 27, 48–50+54. [Google Scholar]

- Tsai, W.-T. Analysis of municipal solid waste incineration plants for promoting power generation efficiency in Taiwan. J. Mat. Cycles Waste Manag. Jpn. 2016, 18, 393–398. [Google Scholar] [CrossRef]

- Maciel, F.J.; Juca, J.F.T. Evaluation of landfill gas generation and emissions in a MSW large -scale experimental cell in Brazil. Waste Manag. 2011, 31, 966–977. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Y. Computation of Leachate Generation on MSW Landfill. Envir. Sanitation Eng. China 2005, 13, 53–56. [Google Scholar]

- Tang, X. The Application of Biogas Power Generation in Sewage Treatment System-Biogas Power Generation Application in Leachate Treatment System of Waste Incineration Power Plant. Technol. Innov. Appl. 2017, 16, 91–92. [Google Scholar]

- You, Z.; You, S.; Li, X.; Hao, C. Biogas power plants waste heat utilization researches. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 2478–2481. [Google Scholar]

- Yadav, S.D.; Kumar, B.; Thipse, S.S. Biogas purification: Producing natural gas quality fuel from biomass for automotive applications. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 450–452. [Google Scholar]

- Li, Z.; Wang, C.; Liang, J.; Zhao, P.; Zhang, Z. Expansion Planning Method of Integrated Energy System Considering Uncertainty of Wind Power. Power Syst. Technol. 2018, 42, 3477–3487. [Google Scholar]

- Lei, J.; Yu, L.; Guo, X.; Li, P.; Li, C.; Wu, Y. Planning Method for Integrated Energy System with the Consideration of Coupling among Power, Heat, and Gas. Proc. CSU-EPSA 2019, 31, 19–24. [Google Scholar]

- Melchiorre, C.; Stefano, C.; Piero, P.; Mauro, R. Two-Level Evolutionary Multi-objective Optimization of a District Heating System with Distributed Cogeneration. Energies 2019, 12, 114. [Google Scholar]

| Equipment | Investment ($) | Original Capacity | Operation and Maintenance Cost ($) | Efficiency |

|---|---|---|---|---|

| WL | 6.1429/t | Nearly full | 0.84/t | Biogas (80%) Leachate (0.8 m3/t) |

| WI | 3557.1/t | 30 MW | 13.5/t | Power (495.3 kWh/t) Leachate (21.95%) |

| LT | 18,386/m3 | 3200 m3 | 5.93/m3 | Power (32.71 kWh/t) Leachate (20.5 m3/m3) |

| BP | 1700/kW | 15 MW | 0.0074/kWh | Power (40%) |

| WT | / | 4 MW | / | / |

| Equipment | Investment ($) | Operation and Maintenance Cost ($) | Efficiency |

|---|---|---|---|

| BCP | 65/m3 | 0.0525/m3 | 50% |

| P2G | 800/kW | 0.042/kWh | 45% |

| PS | 142.86/kWh | 0.00027/kWh | Charge (90%) Discharge (90%) |

| GS | 6428.6/m3 | 0.315/m3 | Charge (58.4%) Discharge (75%) |

| HS | 5/kWh | 0.00024/kWh | Charge (90%) Discharge (90%) |

| Equipment | Capacity (Unit) | |

|---|---|---|

| Intrinsic Equipment (Extension) | WL | 4896 t/day |

| WI | 1064.52 t/day | |

| LT | 1628.71 m3/day | |

| BP | 4.16k W/day | |

| Muti-Energy Complementary Equipment (Construction) | BCP | 146,610.48 m3/day |

| P2G | 723 kw/day | |

| PS | 483.87 kWh/day | |

| HS | 87.10 kWh/day | |

| GS | 193.55 m3/day |

| Energy (Utilization Ratio) | Economy ($) (* 104) | Environment (t/day) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Items | Biogas/Natural Gas | Heat | Expenditure | Income | Intrinsic | New | ||||||||||

| a1 | a2 | a3 | sale | GS | b1 | HS | c1 | c2 | c3 | c4 | d1 | d2 | WI | BP | a3 | |

| Original | 0.5 | 0.5 | / | / | / | 0 | / | 2.6 | 6.5 | 14.7 | 0.06 | 5.5 | 64.3 | 1135.9 | 88.9 | / |

| Current | 0 | 0.1 | 0.1 | ~0.8 | ~0 | 0.9 | ~0 | 15.4 | 15.0 | 20.5 | 0.1 | 14.9 | 142.3 | 2717.7 | ~88.9 | 2515.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Chen, A.; Gu, H.; Wang, X.; Xie, D.; Gu, C. Planning of the Multi-Energy Circular System Coupled with Waste Processing Base: A Case from China. Energies 2019, 12, 3910. https://doi.org/10.3390/en12203910

Zhang L, Chen A, Gu H, Wang X, Xie D, Gu C. Planning of the Multi-Energy Circular System Coupled with Waste Processing Base: A Case from China. Energies. 2019; 12(20):3910. https://doi.org/10.3390/en12203910

Chicago/Turabian StyleZhang, Luqing, Aikang Chen, Han Gu, Xitian Wang, Da Xie, and Chenghong Gu. 2019. "Planning of the Multi-Energy Circular System Coupled with Waste Processing Base: A Case from China" Energies 12, no. 20: 3910. https://doi.org/10.3390/en12203910