Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications †

Abstract

:1. Introduction

2. Background

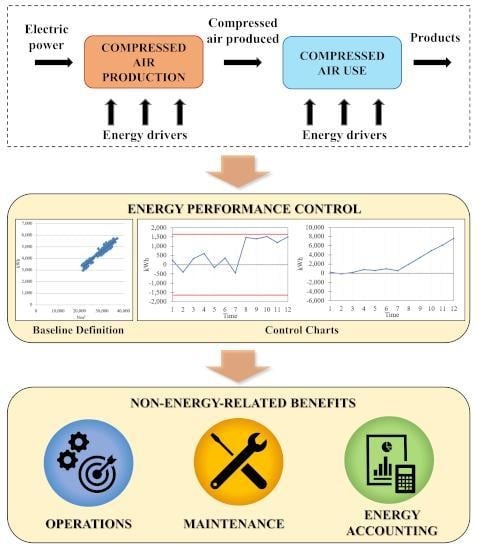

3. Methodology

3.1. Methodology for Real Time Energy Performance Control

- considering the most recent available one; this choice is the best one when changes to technical, technological or structural configurations of the analyzed center occurred;

- considering the data set that showed the best energy performance; this choice is usually considered with a view to continuous improvement because it implies a more challenging outcome in terms of energy objectives;

- considering the data set that showed the most constant and stable energy behavior; this choice is generally made when none of the two previous options is applicable.

3.2. Definition of the Best Operating Conditions of a System From an Energy Efficiency Perspective

3.3. Identification of Changes to Energy Consumption Patterns or Degradation of Energy Performances Often Linked to Sporadic Faults or Events

3.4. Improved Energy Accounting

4. Case Study

- Red period (“A”): Compressor 2 presented a higher specific consumption until around day 325 when a maintenance intervention solved the problem;

- Green period (“B”): a change to the activation sequence caused Compressor 3 to work mainly with Compressor 5, whereas the others were usually kept turned off;

- Orange period (“C”): Compressor 1 presented an evident malfunctioning, remaining stuck in stand-by for three whole consecutive days;

- Blue period (“D”): another change to the activation sequence caused Compressor 4 to work mainly with Compressor 5, whereas the others were usually kept turned off.

4.1. Definition of the Best Operating Conditions of a System from an Energy Efficiency Perspective

4.2. Identification of Changes to Energy Consumption Patterns or Degradation of Energy Performances Often Linked to Sporadic Faults or Events

4.3. Improved Energy Accounting

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Ref. | Domain | Asset | Specific Application | Type of Contribution | Case Study | Approach Described | |

|---|---|---|---|---|---|---|---|

| [79] | Capehart et al., 2002 | Accounting | Industrial plant | Energy Budget Control | Methodological Contribution | Yes | Mathematical model |

| [76] | Cesarotti et al., 2009 | Accounting | Industrial plant | Energy Budget Control | Methodological Contribution | Yes | Statistical model |

| [78] | Santolamazza et al., 2017 | Accounting | Industrial plant | Energy Budget Control | Methodological Contribution | Yes | Mathematical model |

| [88] | Torregrossa et al., 2018 | Accounting | Industrial plant | Energy Budget Control | Methodological Contribution | Yes | Machine Learning model |

| [77] | Pérez-Rave et al., 2017 | Accounting | Industrial plant | General Budget Control | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [28] | Benedetti et al., 2016 | Energy | Building | Energy consumption control | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [29] | Fan et al., 2018 | Energy | Building | Energy consumption control | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [8] | Hu et al., 2012 | Energy | Industrial machine | Energy consumption control | Methodological Contribution | Yes | Statistical model |

| [27] | Nikula et al., 2016 | Energy | Boiler | Energy consumption control | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [30] | Santolamazza et al., 2018 | Energy | Compressor | Energy consumption control | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [31] | Shrouf and Miragliotta, 2015 | Energy | Industrial plant | Energy consumption control | Literature Review/Conceptual Contribution | No | Not described |

| [32] | Sunthornnapha, 2017 | Energy | Industrial plant | Energy consumption control | Methodological Contribution | Yes | Different data modelling techniques |

| [33] | Torregrossa et al., 2017 | Energy | Pump | Energy consumption control | Methodological Contribution | Yes | Machine Learning model |

| [34] | Amasyali and El-Gohary, 2018 | Energy | Building | Energy consumption prediction | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [35] | Christensen and Himme, 2017 | Energy | Industrial machine | Energy consumption prediction | Methodological Contribution | Yes | Statistical model |

| [36] | Deb et al., 2017 | Energy | Building | Energy consumption prediction | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [37] | Foucquier et al., 2013 | Energy | Building | Energy consumption prediction | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [38] | Ngo, 2019 | Energy | Building | Energy consumption prediction | Methodological Contribution | Yes | Different data modelling techniques |

| [39] | Pino-Mejías et al., 2017 | Energy | Building | Energy consumption prediction | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [40] | Wang et al., 2018 | Energy | Industrial plant | Energy consumption prediction | Methodological Contribution | Yes | Machine Learning model |

| [55] | Das et al., 2018 | Energy | Photovoltaic systems | Energy production forecasting | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [56] | Foley et al., 2012 | Energy | Wind turbines | Energy production forecasting | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [57] | Sharma and Kakkar, 2018 | Energy | Photovoltaic systems | Energy production forecasting | Methodological Contribution | Yes | Different data modelling techniques |

| [58] | Voyant et al., 2017 | Energy | Photovoltaic systems | Energy production forecasting | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [59] | Wang et al., 2016 | Energy | Wind turbines | Energy production forecasting | Methodological Contribution | Yes | Different data modelling techniques |

| [42] | Ahmad et al., 2018 | Energy | Building | Load Management | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [43] | Ahmad et al., 2018 | Energy | Electrical Grid | Load Management | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [44] | Chou and Tran, 2018 | Energy | Building | Load Management | Methodological Contribution | Yes | Different data modelling techniques |

| [45] | Diamantoulakis et al., 2015 | Energy | Electrical Grid | Load Management | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [46] | Ferreira et al., 2013 | Energy | Electrical Grid | Load Management | Methodological Contribution | Yes | Machine Learning model |

| [47] | Grolinger et al., 2016 | Energy | Building | Load Management | Methodological Contribution | Yes | Different data modelling techniques |

| [48] | Stoyanova et al., 2013 | Energy | Building | Load Management | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [49] | Tsekouras et al., 2008 | Energy | Electrical Grid | Load Management | Methodological Contribution | Yes | Machine Learning model |

| [50] | Tu et al., 2017 | Energy | Electrical Grid | Load Management | Literature Review/Conceptual Contribution | No | Not described |

| [51] | Vázquez-Canteli and Nagy, 2019 | Energy | Building | Load Management | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [52] | Wei et al., 2018 | Energy | Building | Load Management | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [53] | Yildiz et al., 2017 | Energy | Building | Load Management | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [54] | Zhou et al., 2013 | Energy | Electrical Grid | Load Management | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [89] | Debnath and Mourshed, 2018 | Energy | Different Systems | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [90] | Jha et al., 2017 | Energy | Different Renewable Energy Systems | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [91] | Koseleva and Ropaite, 2017 | Energy | Building | Various applications | Literature Review/Conceptual Contribution | No | Not described |

| [92] | Lund et al., 2017 | Energy | Different Systems | Various applications | Literature Review/Conceptual Contribution | No | Not described |

| [93] | Molina-Solana et al., 2017 | Energy | Building | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [94] | Shrouf et al., 2014 | Energy | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Not described |

| [26] | Capobianchi et al., 2011 | Energy | Industrial plant | Various applications | Methodological contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [95] | Yu et al., 2016 | Energy | Building | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [96] | Zhou et al., 2013 | Energy | Different Systems | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [41] | Kim and Kim, 2007 | Energy | Chiller | Energy consumption prediction | Methodological Contribution | Yes | Statistical model |

| [63] | Engelberth et al., 2018 | Maintenance | Compressor | Condition Monitoring | Methodological Contribution | Yes | Statistical model |

| [64] | Santolamazza et al., 2018 | Maintenance | Compressor | Condition Monitoring | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [65] | Stetco et al., 2019 | Maintenance | Wind turbines | Condition Monitoring | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [69] | Diez-Olivan et al., 2019 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [17] | Guillén López et al., 2018 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [70] | Karim et al., 2016 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | Yes | Not described |

| [71] | Kim et al., 2014 | Maintenance | Industrial plant | Diagnostic and Prognostic | Methodological Contribution | Yes | Different data modelling techniques |

| [72] | Lee et al., 2015 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [16] | Lee et al., 20006 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [73] | Lee et al., 2014 | Maintenance | Different Systems | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [74] | Roy et al., 2016 | Maintenance | Industrial machine | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [75] | Vogl et al., 2016 | Maintenance | Industrial plant | Diagnostic and Prognostic | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [66] | Romeo and Gareta, 2009 | Maintenance | Boiler | Fault detection | Methodological Contribution | Yes | Different data modelling techniques |

| [67] | Xiao, 2016 | Maintenance | Industrial plant | Fault detection | Methodological Contribution | Yes | Machine Learning model |

| [68] | Liu et al., 2018 | Maintenance | Industrial machine | Fault detection and diagnosis | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [14] | Qi et al., 2018 | Maintenance | Compressor | Fault detection and diagnosis | methodological Contribution | Yes | Machine Learning model |

| [12] | Tran et al., 2015 | Maintenance | Chiller | Fault detection and diagnosis | Methodological Contribution | Yes | Statistical/Machine Learning Model and Control Charts |

| [13] | Xiao et al., 2011 | Maintenance | Chiller | Fault detection and diagnosis | Methodological Contribution | Yes | Statistical model |

| [62] | Y. Zhang et al., 2018 | Process Control | Industrial machine | Process Control | Methodological Contribution | Yes | Statistical model |

| [61] | Kadlec et al., 2009 | Process Control | Industrial plant | Soft Sensor | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [60] | Shang et al., 2014 | Process Control | Industrial plant | Soft Sensor | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [87] | Cesarotti et al., 2007 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Not described |

| [9] | Ge et al., 2017 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [10] | Ge, 2017 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [97] | Kusiak et al., 2013 | Different domains | Wind turbines | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [98] | Lee et al., 2013 | Different domains | Different Systems | Various applications | Literature Review/Conceptual Contribution | No | Not described |

| [99] | Lee et al., 2013 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [100] | Tao et al., 2018 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [101] | J. Wang et al., 2018 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

| [102] | K. Zhang et al., 2018 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | Yes | Different data modelling techniques |

| [103] | Zhang et al., 2017 | Different domains | Industrial plant | Various applications | Literature Review/Conceptual Contribution | No | Different data modelling techniques |

References

- Benedetti, M.; Bertini, I.; Bonfà, F.; Ferrari, S.; Introna, V.; Santino, D.; Ubertini, S. Assessing and Improving Compressed Air Systems’ Energy Efficiency in Production and Use: Findings from an Explorative Study in Large and Energy-Intensive Industrial Firms. Energy Procedia 2017, 105, 3112–3117. [Google Scholar] [CrossRef]

- Benedetti, M.; Bonfa, F.; Bertini, I.; Introna, V.; Ubertini, S. Explorative study on Compressed Air Systems’ energy efficiency in production and use: First steps towards the creation of a benchmarking system for large and energy-intensive industrial firms. Appl. Energy 2018, 227, 436–448. [Google Scholar] [CrossRef]

- Salvatori, S.; Benedetti, M.; Bonfà, F.; Introna, V.; Ubertini, S. Inter-sectorial benchmarking of compressed air generation energy performance: Methodology based on real data gathering in large and energy-intensive industrial firms. Appl. Energy 2018, 217, 266–280. [Google Scholar] [CrossRef]

- European Parliament; The Council of The European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on energy efficiency, amending Directives 2009/125/EC and 2010/30/EU and repealing Directives 2004/8/EC and 2006/32. OJ 2012, 315, 1–56. [Google Scholar]

- ISO International Standard Organization. ISO 50001 Energy Management Systems–Requirements with Guidance for Use 2018; ISO International Standard Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Efficiency Valuation Organization. IPMVP Volume I–Concepts and Options for Determining Energy and Water Savings 2012; Efficiency Valuation Organization: Washington, DC, USA, 2012. [Google Scholar]

- Tan, Y.S. Internet-of-Things Enabled Real-time Monitoring of Energy Efficiency on Manufacturing Shop Floors. Procedia CIRP 2017, 6, 376–381. [Google Scholar] [CrossRef]

- Hu, S.; Liu, F.; He, Y.; Hu, T. An on-line approach for energy efficiency monitoring of machine tools. J. Clean. Prod. 2012, 27, 133–140. [Google Scholar] [CrossRef]

- Ge, Z.; Song, Z.; Ding, S.X.; Huang, B. Data Mining and Analytics in the Process Industry: The Role of Machine Learning. IEEE Access 2017, 5, 20590–20616. [Google Scholar] [CrossRef]

- Ge, Z. Review on data-driven modeling and monitoring for plant-wide industrial processes. Chemometr. Intell. Lab. Syst. 2017, 171, 16–25. [Google Scholar] [CrossRef]

- Xenos, D.P.; Cicciotti, M.; Kopanos, G.M.; Bouaswaig, A.E.F.; Kahrs, O.; Martinez-Botas, R.; Thornhill, N.F. Optimization of a network of compressors in parallel: Real Time Optimization (RTO) of compressors in chemical plants–An industrial case study. Appl. Energy 2015, 144, 51–63. [Google Scholar] [CrossRef]

- Tran, D.A.T.; Chen, Y.; Chau, M.Q.; Ning, B. A robust online fault detection and diagnosis strategy of centrifugal chiller systems for building energy efficiency. Energy Build. 2015, 108, 441–453. [Google Scholar] [CrossRef]

- Xiao, F.; Zheng, C.; Wang, S. A fault detection and diagnosis strategy with enhanced sensitivity for centrifugal chillers. Appl. Therm. Eng. 2011, 31, 3963–3970. [Google Scholar] [CrossRef]

- Qi, G.; Zhu, Z.; Erqinhu, K.; Chen, Y.; Chai, Y.; Sun, J. Fault-diagnosis for reciprocating compressors using big data and machine learning. Simul. Model. Pract. Theory 2018, 80, 104–127. [Google Scholar] [CrossRef]

- Magoulès, F.; Zhao, H.-X. Data Mining and Machine Learning in Building Energy Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2016; p. 187. [Google Scholar]

- Lee, J.; Ni, J.; Djurdjanovic, D.; Qiu, H.; Liao, H. Intelligent prognostics tools and e-maintenance. Comput. Ind. 2006, 57, 476–489. [Google Scholar] [CrossRef]

- Guillén López, A.J.; Crespo Márquez, A.; Macchi, M.; Gómez Fernández, J.F. Prognostics and Health Management in Advanced Maintenance Systems. In Advanced Maintenance Modelling for Asset Management; Crespo Márquez, A., González-Prida Díaz, V., Gómez Fernández, J.F., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 79–106. ISBN 978-3-319-58044-9. [Google Scholar]

- Lee, J.; Kao, H.-A.; Yang, S. Service Innovation and Smart Analytics for Industry 4.0 and Big Data Environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Benedetti, M.; Cesarotti, V.; Introna, V. From energy targets setting to energy-aware operations control and back: An advanced methodology for energy efficient manufacturing. J. Clean. Prod. 2018, 167, 1518–1533. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6, 215824401665398. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Sharif Ullah, A. Modeling and simulation of complex manufacturing phenomena using sensor signals from the perspective of Industry 4.0. Adv. Eng. Inf. 2019, 39, 1–13. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.S.; Kubo, A. Hidden Markov model-based digital twin construction for futuristic manufacturing systems. AIEDAM 2019, 33, 317–331. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Cesarotti, V.; Deli Orazi, S.; Introna, V. Improve Energy Efficiency in Manufacturing Plants through Consumption Forecasting and Real Time Control: Case Study from Pharmaceutical Sector. In Proceedings of the International Conference on Advances in Production Management Systems (APMS 2010); Cernobbio, Como, Italy, 11–13 October 2010. [Google Scholar]

- Capobianchi, S.; Andreassi, L.; Introna, V.; Martini, F.; Ubertini, S. Methodology Development for a Comprehensive and Cost-Effective Energy Management in Industrial Plants. In Energy Management Systems; Kini, G., Ed.; InTech: London, UK, 2011; ISBN 978-953-307-579-2. [Google Scholar] [Green Version]

- Nikula, R.-P.; Ruusunen, M.; Leiviskä, K. Data-driven framework for boiler performance monitoring. Appl. Energy 2016, 183, 1374–1388. [Google Scholar] [CrossRef]

- Benedetti, M.; Cesarotti, V.; Introna, V.; Serranti, J. Energy consumption control automation using Artificial Neural Networks and adaptive algorithms: Proposal of a new methodology and case study. Appl. Energy 2016, 165, 60–71. [Google Scholar] [CrossRef]

- Fan, C.; Xiao, F.; Li, Z.; Wang, J. Unsupervised data analytics in mining big building operational data for energy efficiency enhancement: A review. Energy Build. 2018, 159, 296–308. [Google Scholar] [CrossRef]

- Santolamazza, A.; Cesarotti, V.; Introna, V. Evaluation of machine learning techniques to enact energy consumption control of compressed air generation in production plants. In Proceedings of the Summer School of Francesco Turco; AIDI–Italian Association of Industrial Operations Professors, Palermo, Italy, 12–14 September 2018; pp. 79–86. [Google Scholar]

- Shrouf, F.; Miragliotta, G. Energy management based on Internet of Things: Practices and framework for adoption in production management. J. Clean. Prod. 2015, 100, 235–246. [Google Scholar] [CrossRef]

- Sunthornnapha, T. Utilization of MLP and Linear Regression Methods to Build a Reliable Energy Baseline for Self-benchmarking Evaluation. Energy Procedia 2017, 141, 189–193. [Google Scholar] [CrossRef]

- Torregrossa, D.; Hansen, J.; Hernández-Sancho, F.; Cornelissen, A.; Schutz, G.; Leopold, U. A data-driven methodology to support pump performance analysis and energy efficiency optimization in waste water treatment plants. Appl. Energy 2017, 208, 1430–1440. [Google Scholar] [CrossRef]

- Amasyali, K.; El-Gohary, N.M. A review of data-driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 81, 1192–1205. [Google Scholar] [CrossRef]

- Christensen, B.; Himme, A. Improving environmental management accounting: How to use statistics to better determine energy consumption. J. Manag. Control 2017, 28, 227–243. [Google Scholar] [CrossRef]

- Deb, C.; Zhang, F.; Yang, J.; Lee, S.E.; Shah, K.W. A review on time series forecasting techniques for building energy consumption. Renew. Sustain. Energy Rev. 2017, 74, 902–924. [Google Scholar] [CrossRef]

- Foucquier, A.; Robert, S.; Suard, F.; Stéphan, L.; Jay, A. State of the art in building modelling and energy performances prediction: A review. Renew. Sustain. Energy Rev. 2013, 23, 272–288. [Google Scholar] [CrossRef] [Green Version]

- Ngo, N.-T. Early predicting cooling loads for energy-efficient design in office buildings by machine learning. Energy Build. 2019, 182, 264–273. [Google Scholar] [CrossRef]

- Pino-Mejías, R.; Pérez-Fargallo, A.; Rubio-Bellido, C.; Pulido-Arcas, J.A. Comparison of linear regression and artificial neural networks models to predict heating and cooling energy demand, energy consumption and CO2 emissions. Energy 2017, 118, 24–36. [Google Scholar] [CrossRef]

- Wang, S.; Liang, Y.C.; Li, W.D.; Cai, X.T. Big Data enabled Intelligent Immune System for energy efficient manufacturing management. J. Clean. Prod. 2018, 195, 507–520. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Kim, K.-S. Simplified energy prediction method accounting for part-load performance of chiller. Build. Environ. 2007, 42, 507–515. [Google Scholar] [CrossRef]

- Ahmad, T.; Chen, H.; Guo, Y.; Wang, J. A comprehensive overview on the data driven and large scale based approaches for forecasting of building energy demand: A review. Energy Build. 2018, 165, 301–320. [Google Scholar] [CrossRef]

- Ahmad, T.; Chen, H.; Wang, J.; Guo, Y. Review of various modeling techniques for the detection of electricity theft in smart grid environment. Renew. Sustain. Energy Rev. 2018, 82, 2916–2933. [Google Scholar] [CrossRef]

- Chou, J.-S.; Tran, D.-S. Forecasting energy consumption time series using machine learning techniques based on usage patterns of residential householders. Energy 2018, 165, 709–726. [Google Scholar] [CrossRef]

- Diamantoulakis, P.D.; Kapinas, V.M.; Karagiannidis, G.K. Big Data Analytics for Dynamic Energy Management in Smart Grids. Big Data Res. 2015, 2, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, A.M.S.; Cavalcante, C.A.M.T.; Fontes, C.H.O.; Marambio, J.E.S. A new method for pattern recognition in load profiles to support decision-making in the management of the electric sector. Int. J. Electr. Power Energy Syst. 2013, 53, 824–831. [Google Scholar] [CrossRef]

- Grolinger, K.; L’Heureux, A.; Capretz, M.A.M.; Seewald, L. Energy Forecasting for Event Venues: Big Data and Prediction Accuracy. Energy Build. 2016, 112, 222–233. [Google Scholar] [CrossRef] [Green Version]

- Stoyanova, I.; Marin, M.; Monti, A. Characterization of load profile deviations for residential buildings. In Proceedings of the IEEE PES ISGT Europe 2013, Lyngby, Denmark, 6–9 October 2013; pp. 1–5. [Google Scholar]

- Tsekouras, G.J.; Kotoulas, P.B.; Tsirekis, C.D.; Dialynas, E.N.; Hatziargyriou, N.D. A pattern recognition methodology for evaluation of load profiles and typical days of large electricity customers. Electr. Power Syst. Res. 2008, 78, 1494–1510. [Google Scholar] [CrossRef]

- Tu, C.; He, X.; Shuai, Z.; Jiang, F. Big data issues in smart grid–A review. Renew. Sustain. Energy Rev. 2017, 79, 1099–1107. [Google Scholar] [CrossRef]

- Vázquez-Canteli, J.R.; Nagy, Z. Reinforcement learning for demand response: A review of algorithms and modeling techniques. Appl. Energy 2019, 235, 1072–1089. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, X.; Shi, Y.; Xia, L.; Pan, S.; Wu, J.; Han, M.; Zhao, X. A review of data-driven approaches for prediction and classification of building energy consumption. Renew. Sustain. Energy Rev. 2018, 82, 1027–1047. [Google Scholar] [CrossRef]

- Yildiz, B.; Bilbao, J.I.; Sproul, A.B. A review and analysis of regression and machine learning models on commercial building electricity load forecasting. Renew. Sustain. Energy Rev. 2017, 73, 1104–1122. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, S.; Shen, C. A review of electric load classification in smart grid environment. Renew. Sustain. Energy Rev. 2013, 24, 103–110. [Google Scholar] [CrossRef]

- Das, U.K.; Tey, K.S.; Seyedmahmoudian, M.; Mekhilef, S.; Idris, M.Y.I.; Van Deventer, W.; Horan, B.; Stojcevski, A. Forecasting of photovoltaic power generation and model optimization: A review. Renew. Sustain. Energy Rev. 2018, 81, 912–928. [Google Scholar] [CrossRef]

- Foley, A.M.; Leahy, P.G.; Marvuglia, A.; McKeogh, E.J. Current methods and advances in forecasting of wind power generation. Renew. Energy 2012, 37, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Kakkar, A. Forecasting daily global solar irradiance generation using machine learning. Renew. Sustain. Energy Rev. 2018, 82, 2254–2269. [Google Scholar] [CrossRef]

- Voyant, C.; Notton, G.; Kalogirou, S.; Nivet, M.-L.; Paoli, C.; Motte, F.; Fouilloy, A. Machine learning methods for solar radiation forecasting: A review. Renew. Energy 2017, 105, 569–582. [Google Scholar] [CrossRef]

- Wang, J.; Song, Y.; Liu, F.; Hou, R. Analysis and application of forecasting models in wind power integration: A review of multi-step-ahead wind speed forecasting models. Renew. Sustain. Energy Rev. 2016, 60, 960–981. [Google Scholar] [CrossRef]

- Shang, C.; Yang, F.; Huang, D.; Lyu, W. Data-driven soft sensor development based on deep learning technique. J. Process Control 2014, 24, 223–233. [Google Scholar] [CrossRef]

- Kadlec, P.; Gabrys, B.; Strandt, S. Data-driven Soft Sensors in the process industry. Comput. Chem. Eng. 2009, 33, 795–814. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Peng, K.; Chu, R.; Dong, J. Implementing multivariate statistics-based process monitoring: A comparison of basic data modeling approaches. Neurocomputing 2018, 290, 172–184. [Google Scholar] [CrossRef]

- Engelberth, T.; Krawczyk, D.; Verl, A. Model-based method for condition monitoring and diagnosis of compressors. Procedia CIRP 2018, 72, 1321–1326. [Google Scholar] [CrossRef]

- Santolamazza, A.; Cesarotti, V.; Introna, V. Anomaly detection in energy consumption for Condition-Based maintenance of Compressed Air Generation systems: An approach based on artificial neural networks. IFAC PapersOnLine 2018, 51, 1131–1136. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- Romeo, L.M.; Gareta, R. Fouling control in biomass boilers. Biomass Bioenergy 2009, 33, 854–861. [Google Scholar] [CrossRef]

- Xiao, W. A probabilistic machine learning approach to detect industrial plant faults. Int. J. Progn. Health Manag. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84966359883&partnerID=40&md5=536a49cd2e7d4809b45c73215dfecba7 (accessed on 2 July 2019).

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Proc. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Karim, R.; Westerberg, J.; Galar, D.; Kumar, U. Maintenance Analytics–The New Know in Maintenance. IFAC PapersOnLine 2016, 49, 214–219. [Google Scholar] [CrossRef]

- Kim, H.; Na, M.G.; Heo, G. Application of monitoring, diagnosis, and prognosis in thermal performance analysis for nuclear power plants. Nucl. Eng. Technol. 2014, 46, 737–752. [Google Scholar] [CrossRef]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar] [Green Version]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mech. Syst. Signal Proc. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous maintenance and the future–Foundations and technological challenges. CIRP Ann. 2016, 65, 667–688. [Google Scholar] [CrossRef]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2016, 30, 79–95. [Google Scholar] [CrossRef]

- Cesarotti, V.; Di Silvio, B.; Introna, V. Energy budgeting and control: A new approach for an industrial plant. Int. J. Energy Sector Manag. 2009, 3, 131–156. [Google Scholar] [CrossRef]

- Pérez-Rave, J.; Muñoz-Giraldo, L.; Correa-Morales, J.C. Use of control charts with regression analysis for autocorrelated data in the context of logistic financial budgeting. Comput. Ind. Eng. 2017, 112, 71–83. [Google Scholar] [CrossRef]

- Santolamazza, A.; Introna, V.; Cesarotti, V. Energy budget control in manufacturing systems with on-site energy generation: An advanced methodology for analyzing specific cost variations. In Proceedings of the Summer School Francesco Turco, AIDI–Italian Association of Industrial Operations Professors, Palermo, Italy, 13–15 September 2017; pp. 404–410. [Google Scholar]

- Capehart, L.; Turner, C.; Kennedy, J. Guide to Energy Management, 4th ed.; Fairmont Press: Lilburn, GA, USA, 2002; ISBN 978-0-8247-4120-4. [Google Scholar]

- ISO International Standard Organization. ISO/IEC 13273-1:2015 Energy Efficiency and Renewable Energy Sources–Common International Terminology Energy Efficiency 2015; ISO International Standard Organization: Geneva, Switzerland, 2015. [Google Scholar]

- Morvay, Z.K.; Gvozdenac, D.D. Applied Industrial Energy and Environmental Management; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 978-0-470-71437-9. [Google Scholar]

- Song, B.; Ao, Y.; Xiang, L.; Lionel, K.Y.N. Data-driven Approach for Discovery of Energy Saving Potentials in Manufacturing Factory. Procedia CIRP 2018, 69, 330–335. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Braaksma, A.J.J.; Klingenberg, W.; Veldman, J. Failure mode and effect analysis in asset maintenance: A multiple case study in the process industry. Int. J. Prod. Res. 2013, 51, 1055–1071. [Google Scholar] [CrossRef]

- Bishop, C. Pattern Recognition and Machine Learning; Springer-Verlag: New York, NY, USA, 2006. [Google Scholar]

- Kerzner, H. Project Management, a System Approach to Planning, Scheduling, and Controlling, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Cesarotti, V.; Ciminelli, V.; Di Silvio, B.; Fedele, T.; Introna, V. Energy budgeting and control for industrial plant through consumption analysis and monitoring. In Proceedings of the IASTED International Conference on Power and Energy Systems, Clearwater, FL, USA, 3–5 January 2007; pp. 389–394. [Google Scholar]

- Torregrossa, D.; Leopold, U.; Hernández-Sancho, F.; Hansen, J. Machine learning for energy cost modelling in wastewater treatment plants. J. Environ. Manag. 2018, 223, 1061–1067. [Google Scholar] [CrossRef]

- Debnath, K.B.; Mourshed, M. Forecasting methods in energy planning models. Renew. Sustain. Energy Rev. 2018, 88, 297–325. [Google Scholar] [CrossRef] [Green Version]

- Jha, S.K.; Bilalovic, J.; Jha, A.; Patel, N.; Zhang, H. Renewable energy: Present research and future scope of Artificial Intelligence. Renew. Sustain. Energy Rev. 2017, 77, 297–317. [Google Scholar] [CrossRef]

- Koseleva, N.; Ropaite, G. Big Data in Building Energy Efficiency: Understanding of Big Data and Main Challenges. Procedia Eng. 2017, 172, 544–549. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart energy and smart energy systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Molina-Solana, M.; Ros, M.; Ruiz, M.D.; Gómez-Romero, J.; Martin-Bautista, M.J. Data science for building energy management: A review. Renew. Sustain. Energy Rev. 2017, 70, 598–609. [Google Scholar] [CrossRef] [Green Version]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor Darul Ehsan, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Yu, Z.; Haghighat, F.; Fung, B.C.M. Advances and challenges in building engineering and data mining applications for energy-efficient communities. Sustain. Cities Soc. 2016, 25, 33–38. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Fu, C.; Yang, S. Big data driven smart energy management: From big data to big insights. Renew. Sustain. Energy Rev. 2016, 56, 215–225. [Google Scholar] [CrossRef]

- Kusiak, A.; Zhang, Z.; Verma, A. Prediction, operations, and condition monitoring in wind energy. Energy 2013, 60, 1–12. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Yang, S.; Kao, A. Predictive Manufacturing System–Trends of Next-Generation Production Systems. IFAC Proc. Vol. 2013, 46, 150–156. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, S.; Yang, H.; Lv, J.; Liu, Y. A big data driven analytical framework for energy-intensive manufacturing industries. J. Clean. Prod. 2018, 197, 57–72. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2017, 142, 626–641. [Google Scholar] [CrossRef]

| MEASURED DATA | ||||

|---|---|---|---|---|

| Label and Unit | Frequency | Collection Period | Meter/Collection Method | |

| Inputs /Outputs | Electric absorption compressor 1 [kW] | 15 min | Last solar year (April to April) | Schneider PM9C energy meter; data on company’s online server |

| Electric absorption compressor 2 [kW] | 15 min | Last solar year (April to April) | Schneider PM9C energy meter; data on company’s online server | |

| Electric absorption room B [kW] | 15 min | Last solar year (April to April) | Schneider PM9C energy meter; data on company’s online server | |

| Compressed air flow room A [Nm3/h] | 15 min | Last solar year (April to April) | Emerson Rosemount™ 485 Annubar™ (averaging Pitot tube); data on company’s online server | |

| Compressed air flow room B [Nm3/h] | 15 min | Last solar year (April to April) | Rosemount™ 485 Annubar™ (averaging Pitot tube); data on company’s online server | |

| Energy Drivers | External temperature [°C] | 15 min | Last solar year (April to April) | Data transmitted by closest weather station |

| External humidity [%] | 15 min | Last solar year (April to April) | Data transmitted by closest weather station | |

| Pressure set point [bar] | 15 min | Last solar year (April to April) | Juno Midas pressure transmitter; data on company’s online server | |

| Compressors’ working hours | Weekly | Last solar year (April to April) | Measure collected by operators on each compressor’s screen and recorded on a shared spreadsheet | |

| Regression Analysis Results Considering All Parameters | Regression Analysis Results Considering Only Compressed Air Production | ||

|---|---|---|---|

| Coefficient of determination (R2) | 0.96 | Coefficient of determination R2 | 0.94 |

| P_value | 9.45 × 10−137 | P_value | 1.69 × 10−125 |

| P_value intercept | 0.76 | P_value intercept | 0.34 |

| P_value compressed air production | 8.32 × 10−119 | ||

| P_value external temperature | 2.06 × 10−17 | ||

| P_value external humidity | 0.01 | ||

| P_value pressure | 0.84 | ||

| ESTIMATED BUDGET | ||||

|---|---|---|---|---|

| Month | 1 | 2 | 3 | |

| Production Dept. 1 | Units | 4,047,800 | 3,757,201 | 3,294,456 |

| Production Dept. 2 | Units | 5,475,148 | 4,427,156 | 5,889,159 |

| Compressed air consumption Dept. 1 | Nm3 | 12,805,432 | 11,219,241 | 8,693,420 |

| Compressed air consumption Dept. 2 | Nm3 | 15,916,589 | 12,785,528 | 17,153,518 |

| Electricity consumption of the generation phase | kWh | 4,448,464 | 3,664,935 | 3,970,917 |

| Standard unit cost of electricity | €/kWh | 0.158 | 0.158 | 0.158 |

| Standard unit cost of compressed air | €/m3 | 0.024 | 0.024 | 0.024 |

| Estimated budget Dept. 1 | € | 313,362 | 270,638 | 211,023 |

| Estimated budget Dept. 2 | € | 389,495 | 308,421 | 416,382 |

| Estimated budget for the generation phase | € | 702,857 | 579,060 | 627,405 |

| ACTUAL BUDGET | ||||

|---|---|---|---|---|

| Month | 1 | 2 | 3 | |

| Production Dept. 1 | Units | 3,679,818 | 3,415,637 | 3,361,690 |

| Production Dept. 2 | Units | 6,016,646 | 4,865,007 | 6,009,346 |

| Compressed air consumption Dept. 1 | Nm3 | 10,531,292 | 8,339,483 | 9,268,500 |

| Compressed air consumption Dept. 2 | Nm3 | 17,317,964 | 14,076,891 | 17,130,719 |

| Electricity consumption of the generation phase | kWh | 4,114,206 | 342,4346 | 4,220,230 |

| Standard unit cost of electricity | €/kWh | 0.159 | 0.159 | 0.159 |

| Standard unit cost of compressed air | €/m3 | 0.023 | 0.024 | 0.025 |

| Estimated budget Dept. 1 | € | 247,372 | 202,558 | 235,587 |

| Estimated budget Dept. 2 | € | 406,786 | 341,913 | 435,429 |

| Estimated budget for the generation phase | € | 654,159 | 544,471 | 671,017 |

| FLEXIBLE CONSUMPTION | ||||

|---|---|---|---|---|

| Month | 1 | 2 | 3 | |

| Compressed air consumption Dept. 1 | Nm3 | 10,796,859 | 9,354,867 | 9,060,406 |

| Compressed air consumption Dept. 2 | Nm3 | 17,534,410 | 14,093,684 | 17,512,598 |

| Electricity consumption of the generation phase | kWh | 4,303,499 | 3,401,105 | 4,062,650 |

| Month | 1 | 2 | 3 | ||

|---|---|---|---|---|---|

| Budget performance—generation system | Δ TOT | € | −48,699 | −34,589 | 43,612 |

| ΔI | € | −29,908 | 3672 | 24,898 | |

| ΔP (Nm3) | € | −22,904 | −41,685 | 14,494 | |

| Δp | € | 4114 | 3424 | 4220 | |

| Budget performance—Dept. 1 | Δ TOT | € | −65,990 | −68,081 | 24,564 |

| ΔI | € | −6499 | −24,494 | 5051 | |

| ΔP (units) | € | −49,152 | −44,974 | 8908 | |

| Δp | € | −10,339 | 1387 | 10,605 | |

| Budget performance—Dept. 2 | Δ TOT | € | 17,291 | 33,492 | 19,047 |

| ΔI | € | −5297 | −405 | −9270 | |

| ΔP (units) | € | 39,590 | 31,556 | 8716 | |

| Δp | € | −17,002 | 2341 | 19,601 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benedetti, M.; Bonfà, F.; Introna, V.; Santolamazza, A.; Ubertini, S. Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications. Energies 2019, 12, 3935. https://doi.org/10.3390/en12203935

Benedetti M, Bonfà F, Introna V, Santolamazza A, Ubertini S. Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications. Energies. 2019; 12(20):3935. https://doi.org/10.3390/en12203935

Chicago/Turabian StyleBenedetti, Miriam, Francesca Bonfà, Vito Introna, Annalisa Santolamazza, and Stefano Ubertini. 2019. "Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications" Energies 12, no. 20: 3935. https://doi.org/10.3390/en12203935

APA StyleBenedetti, M., Bonfà, F., Introna, V., Santolamazza, A., & Ubertini, S. (2019). Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications. Energies, 12(20), 3935. https://doi.org/10.3390/en12203935