Numerical Study of Nacelle Wind Speed Characteristics of a Horizontal Axis Wind Turbine under Time-Varying Flow

Abstract

1. Introduction

2. Wind Turbine Model and Numerical Methods

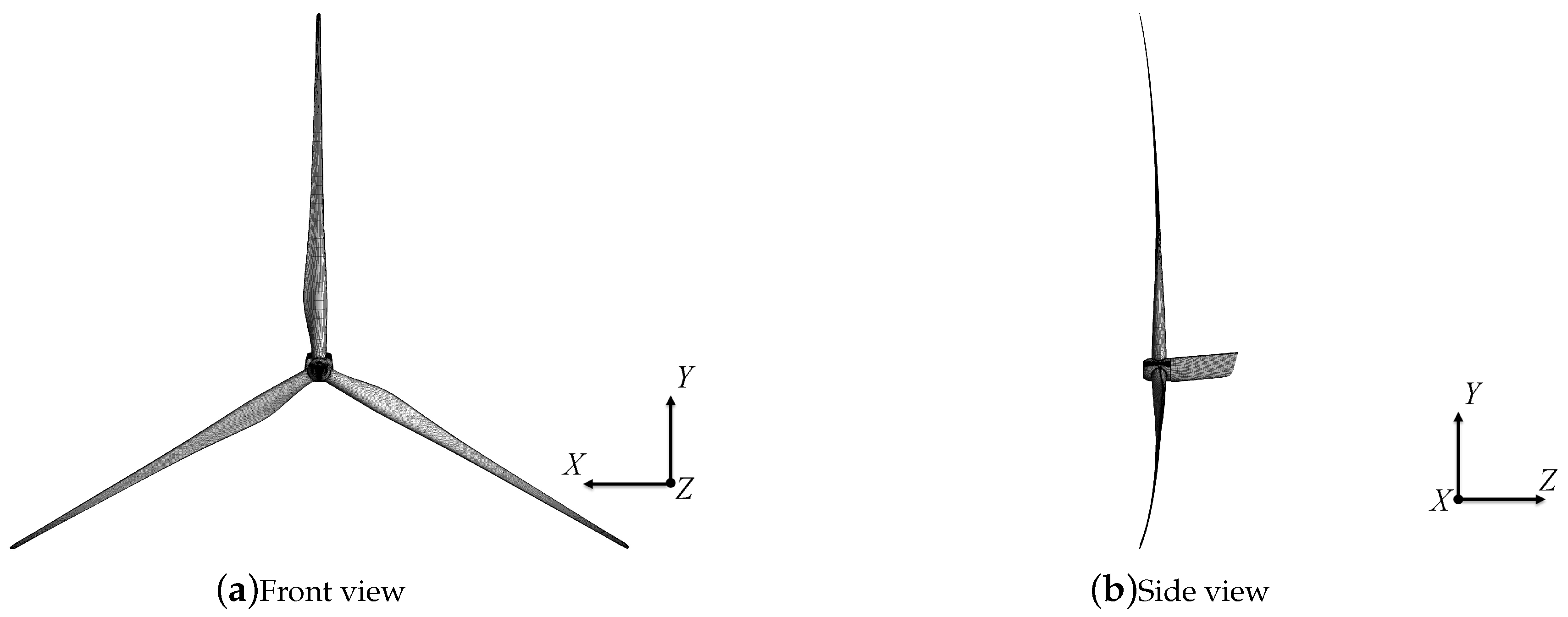

2.1. Wind Turbine Model

2.2. Computational Domain and Boundary Conditions

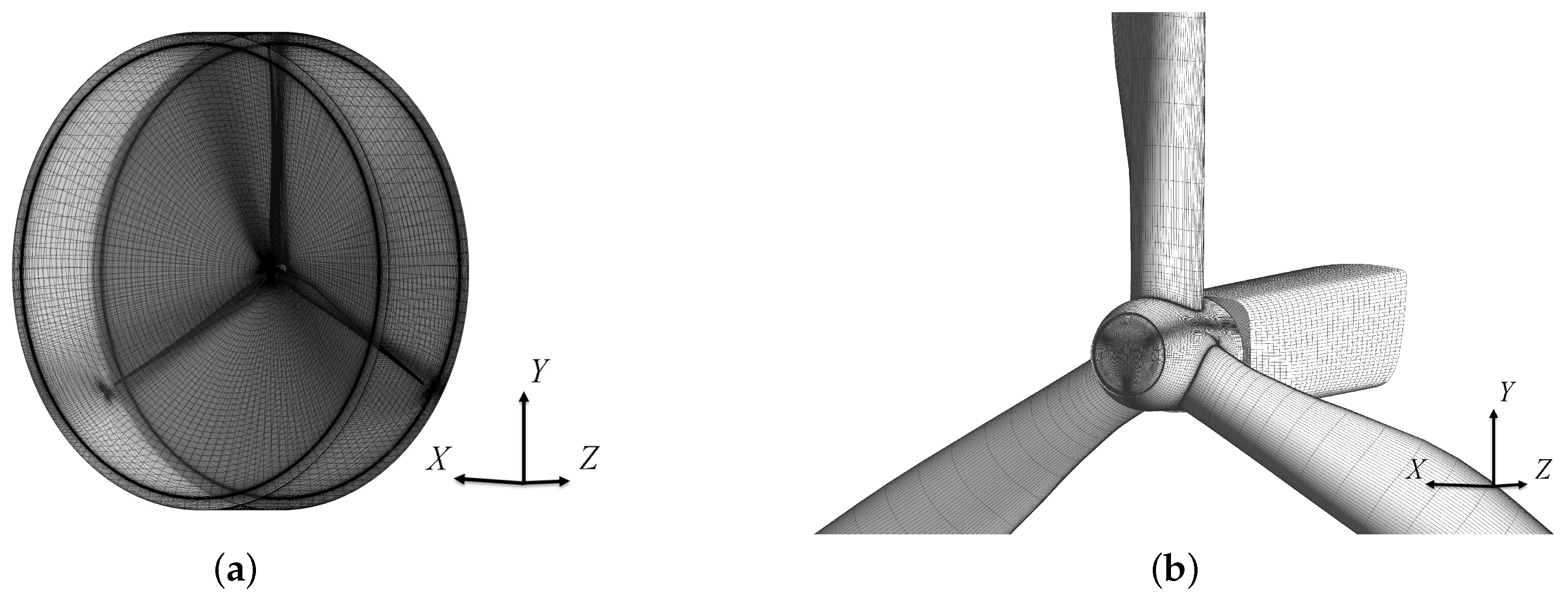

2.3. Computational Mesh

2.4. Computational Methods

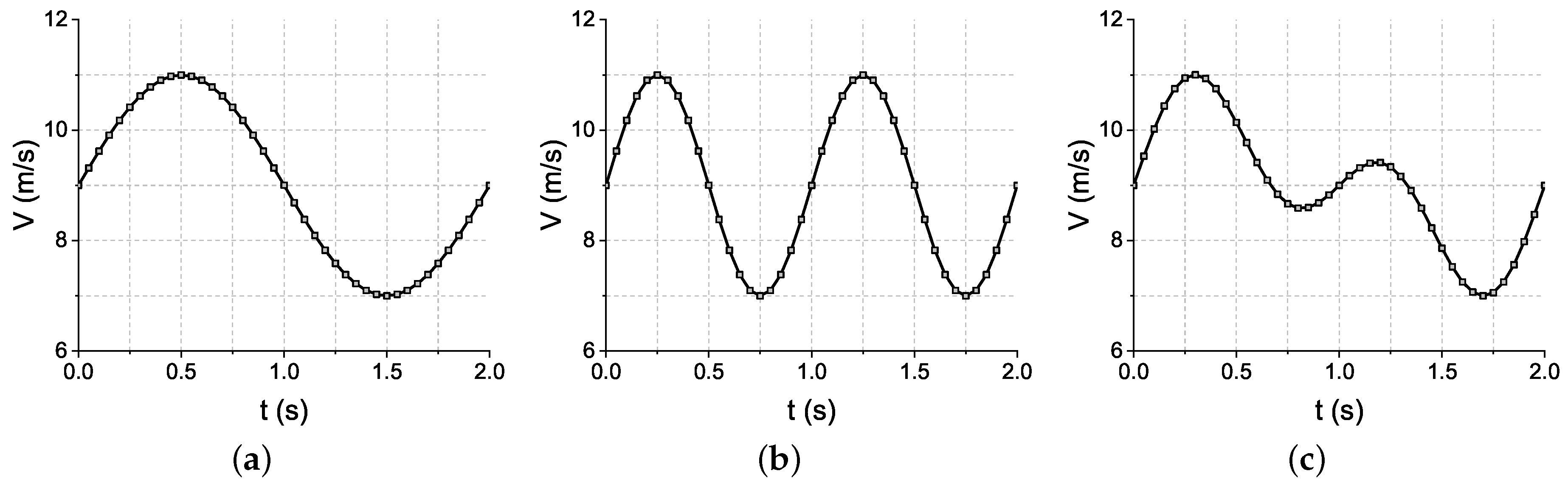

2.5. Settings of Inlet Flow

3. Analysis of Results and Discussion

3.1. Verification and Validation of Computational Results

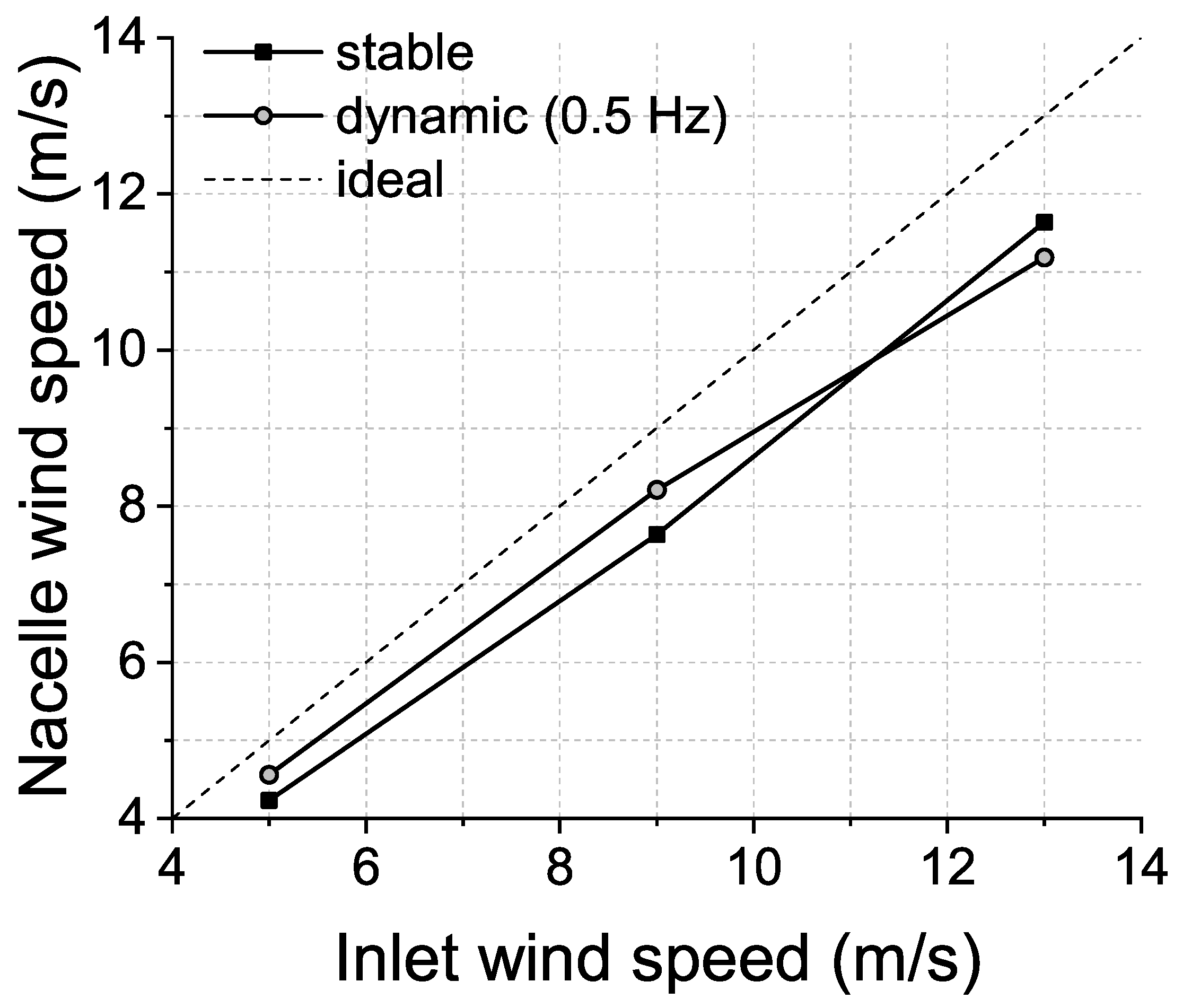

3.2. Nacelle Wind Speed Analysis with Stable Inlet Flow

3.3. Nacelle Wind Speed Analysis with Dynamic Inlet Flow

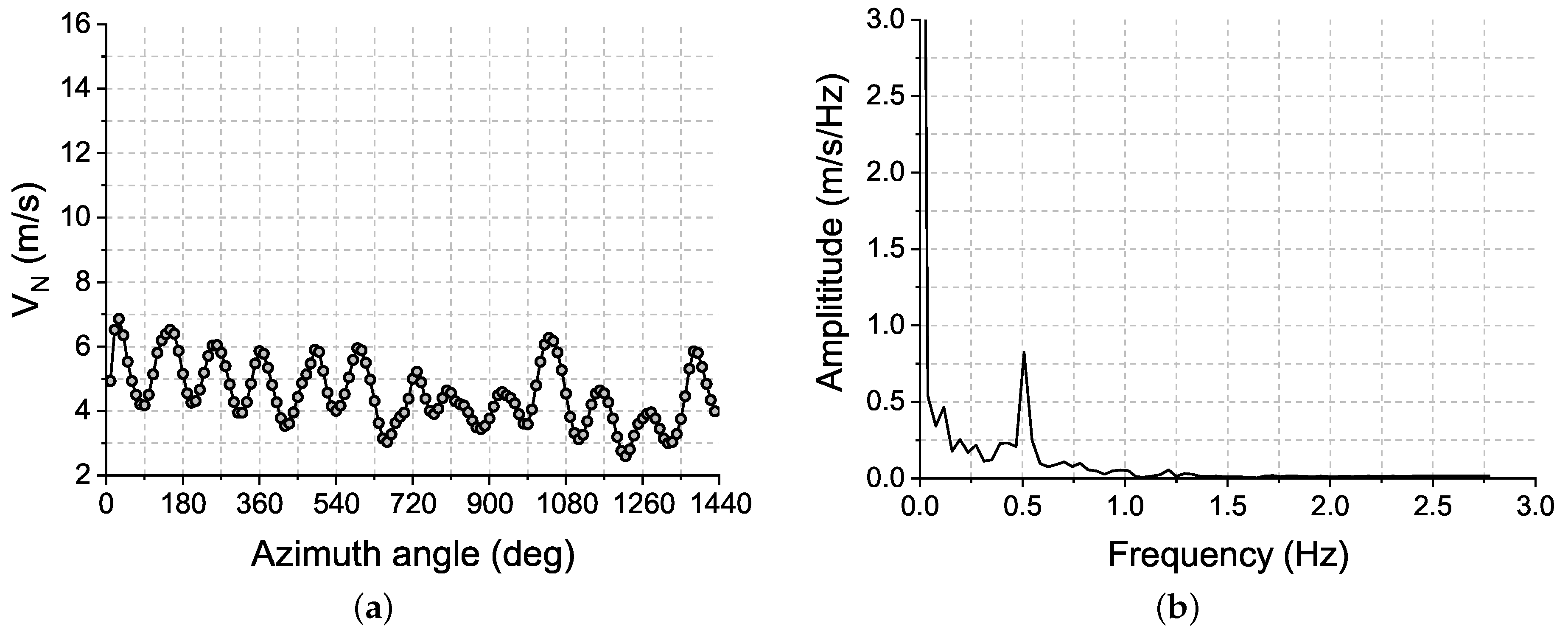

3.3.1. Averaged Inlet Wind Speed of 9 m/s

3.3.2. Variable Averaged Inlet Wind Speeds

3.4. Frequency Decomposition Analysis

4. Conclusions

- Under stable inflow conditions, blade rotation affected the variation characteristics of nacelle wind speed most significantly. Numerical simulations with a stable inlet condition underestimated the nacelle wind speed at low inlet wind speeds, and overestimated the nacelle wind speed at high inlet wind speeds.

- The blade pitch control has an influence on the NTF rule. Under a larger pitch angle, the NTF curve has a tendency to deviate from the linear function.

- Under dynamic inflow conditions with time scale and amplitude conforming to the IEC standard, the nacelle wind speed was dominated by the inlet flow variations. The fluctuations and amplitudes of the dominant frequency for high wind speeds were more significant than those for low wind speeds. The inlet wind speed fluctuation reduced the influence of blade rotation and wake.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| D | rotor diameter |

| d | diameter of the hub |

| f | fluctuation frequency |

| notch filter | |

| low pass filter | |

| t | time |

| expected value of turbulence intensity at 15 m/s | |

| V | instantaneous inlet velocity |

| time-averaged inlet velocity | |

| fluctuation amplitude of inlet velocity | |

| wind speed at hub height | |

| nacelle wind speed | |

| pitching angle | |

| rotational speed | |

| representative value of the turbulence standard deviation | |

| AD | acutator-disk |

| ADM-R | Actuator–Disk Model with Rotation |

| ADM-NR | Actuator–Disk Model without Rotation |

| BEM | Blade Element Momentum |

| CFD | Computational Fluid Dynamics |

| FFT | Fast Fourier Transforms |

| LES | Large-Eddy Simulation |

| HAWT | Horizontal Axis Wind Turbine |

| HWA | Hot Wire Anemometry |

| NTF | Nacelle Wind Speed Transfer Function |

| RANS | Reynolds-Averaged Navier–Stokes |

| StD | Standard Deviation |

| T-SST | Transitional Shear Stress Transport |

References

- Wagner, R.; Courtney, M.S.; Pedersen, T.F.; Davoust, S. Uncertainty of power curve measurement with a two-beam nacelle-mounted LIDAR. Wind Energy 2016, 19, 1269–1287. [Google Scholar] [CrossRef]

- Shin, D.; Ko, K. Application of the Nacelle Transfer Function by a Nacelle-Mounted Light Detection and Ranging System to Wind Turbine Power Performance Measurement. Energies 2019, 12, 1087. [Google Scholar] [CrossRef]

- IEC. IEC 61400-1:2005(E) Wind Turbines—Part 1: Design Requirements; IEC: Geneva, Switzerland, 2005; pp. 22–24. [Google Scholar]

- Kirshna, V.B.; Ormel, F.; Hansen, K.S. Alternative approach for establishing the nacelle transfer function. Wind Eng. 2016, 40, 307–318. [Google Scholar] [CrossRef]

- Ormel, F. Advanced nacelle anemometry and SCADA-data, analysis techniques and limitations. In Proceedings of the EWEA Technology Workshop on Analysis of Operating Wind Farms, Lyon, France, 2–3 July 2012. [Google Scholar]

- Vermeer, L.J.; Sørensen, J.N.; Crespo, A. Wind turbine wake aerodynamics. Prog. Aerosp. Sci. 2003, 39, 467–510. [Google Scholar] [CrossRef]

- Jensen, N.O. A Note on Wind Generator Interaction; Risø National Laboratory: Roskilde, Denmark, 1983. [Google Scholar]

- Larsen, G.C. A Simple Wake Calculation Procedure; Risø National Laboratory: Roskilde, Denmark, 1988. [Google Scholar]

- Ainslie, J.F. Calculating the flow field in the wake of wind turbines. J. Wind. Eng. Ind. Aerodyn. 1988, 27, 213–224. [Google Scholar] [CrossRef]

- Whale, J.; Anderson, C.G.; Bareiss, R.; Wagner, S. An experimental and numerical study of the vortex structure in the wake of a wind turbine. J. Wind. Eng. Ind. Aerodyn. 2000, 84, 1–21. [Google Scholar] [CrossRef]

- Massouh, F.; Dovrev, I. Exploration of the vortex wake behind of wind turbine rotor. J. Phys. Conf. Ser. 2007, 75, 012036. [Google Scholar] [CrossRef]

- Micallef, D.; Ferreira, C.S.; Snat, T.; van Bussel, G. Experimental and numerical investigation of tip vortex generation and evolution on horizontal axis wind turbines. Wind Energy 2016, 19, 1485–1501. [Google Scholar] [CrossRef]

- Ebert, P.R.; Wood, D.H. The near wake of a model horizontal-axis wind turbine-I. Experimental arrangements and initial results. Renew. Energy 1997, 12, 225–243. [Google Scholar] [CrossRef]

- Ebert, P.R.; Wood, D.H. The near wake of a model horizontal-axis wind turbine part 3: Properties of the tip and hub vortices. Renew. Energy 2001, 22, 461–472. [Google Scholar] [CrossRef]

- Hu, H.; Yang, Z.F.; Sarkar, P. Dynamic wind loads and wake characteristics of a wind turbine model in an atmospheric boundary layer wind. Exp. Fluids 2012, 52, 1277–1294. [Google Scholar] [CrossRef]

- Tian, W.; Ozbay, A.; Wang, X.D.; Hu, H. Experimental investigation on the wake interference among wind turbines sited in atmospheric boundary layer winds. Acta Mech. Sin. 2017, 33, 742–753. [Google Scholar] [CrossRef]

- Zhang, W.; Markfort, C.D.; Porté-Agel, F. Near-wake flow structure downwind of a wind turbine in a turbulent boundary layer. Exp. Fluids 2012, 52, 1219–1235. [Google Scholar] [CrossRef]

- Krogstad, P.; Adaramola, M.S. Performance and near wake measurements of a model horizontal axis wind turbine. Wind Energy 2012, 15, 743–756. [Google Scholar] [CrossRef]

- Akay, B.; Ragni, D.; Simõ Ferreira, C.J.; van Bussel, G.J.W. Experimental investigation of the root flow in a horizontal axis wind turbine. Wind Energy 2014, 17, 1093–1109. [Google Scholar] [CrossRef]

- Wang, J.W.; Yuan, R.Y.; Dong, X.Q.; Zhang, S.X.; Song, Y.; Gao, Z.Y.; Luo, K.; Qiu, K.Z.; Ni, M.J.; Cen, K.F. Time resolved particle image velocimetry experimental study of the near wake characteristics of a horizontal axis wind turbine. J. Zhejiang-Univ.-Sci. (Applied Phys. Eng.) 2015, 16, 586–595. [Google Scholar] [CrossRef]

- Tari, P.H.; Siddiqui, K.; Hangan, H. Flow characterization in the near-wake region of a horizontal axis wind turbine. Wind Energy 2016, 19, 1249–1267. [Google Scholar] [CrossRef]

- Sanderse, B.; Van der Pijl, S.P.; Koren, B. Review of computational fluid dynamics for wind turbine wake aerodynamics. Wind Energy 2011, 14, 799–819. [Google Scholar] [CrossRef]

- Chamorro, L.P.; Porté-Agel, F. A wind-tunnel investigation of wind-turbine wakes: Boundary-layer turbulence effects. Bound.-Layer Meteorol. 2009, 132, 129–149. [Google Scholar] [CrossRef]

- Wu, Y.T.; Porté-Agel, F. Large-eddy simulation of wind-turbine wakes: Evaluation of turbine parameterizations. Bound.-Layer Meteorol. 2011, 138, 345–366. [Google Scholar] [CrossRef]

- Lignarolo, L.E.M.; Mehta, D.; Stevens, R.J.; Yilmaz, A.E.; van Kuik, G.; Andersen, S.J.; Meneveau, C.; Ferreira, C.J.; Ragni, D.; Meyers, J.; et al. Validation of four LES and a vortex model against stereo-PIV measurements in the near wake of an actuator disk and a wind turbine. Renew. Energy 2016, 94, 510–523. [Google Scholar] [CrossRef]

- Sørensen, N.N.; Bechmann, A.; Réthoré, P.-E.; Zahle, F. Near wake Reynolds-averaged Navier–Stokes predictions of the wake behind the MEXICO rotor in axial and yawed flow conditions. Wind Energy 2014, 17, 75–88. [Google Scholar] [CrossRef]

- O’Brien, J.M.; Young, T.M.; Early, J.M.; Griffin, P.C. An assessment of commercial CFD turbulence models for near wake HAWT modelling. J. Wind. Eng. Ind. Aerodyn. 2018, 176, 32–53. [Google Scholar] [CrossRef]

- Masson, C.; Smaïli, A. Numerical study of turbulent flow around a wind turbine nacelle. Wind Energy 2006, 9, 218–298. [Google Scholar] [CrossRef]

- Ameur, K.; Masson, C.; Eecen, P.J. two-dimensional and three-dimensional numerical simulation of the wind-rotor/nacelle interaction in atmospheric boundary layer. J. Wind. Eng. Ind. Aerodyn. 2011, 99, 833–844. [Google Scholar] [CrossRef][Green Version]

- Ameur, K.; Masson, C. Effects of wind turbine rotor modelling on nacelle anemometry. Wind Eng. 2013, 37, 617–636. [Google Scholar] [CrossRef]

- Zahle, F.; Sørensen, N. Characterization of the unsteady flow in the nacelle region of a modern wind turbine. Wind Energy 2011, 14, 271–283. [Google Scholar] [CrossRef]

- Ansys, Inc. Fluent Manual 14.5; Ansys, Inc.: Canonsburg, PA, USA, 2012. [Google Scholar]

- Wang, X.D.; Ye, Z.L.; Kang, S.; Hu, H. Investigations on unsteady aerodynamic characteristics of a horizontal-axis wind turbine during dynamic yaw process. Energies 2019, 12, 3124. [Google Scholar] [CrossRef]

| Case No. | (m/s) | (m/s) | f (Hz) | (rpm) | (°) | Time Step Size (s) |

|---|---|---|---|---|---|---|

| 1 | 5 | 0 | - | 9.38 | 0.5 | 0.089 |

| 2 | 9 | 0 | - | 13.4 | 0.5 | 0.062 |

| 3 | 13 | 0 | - | 13.4 | 0.5 | 0.062 |

| 4 | 9 | 2 | 0.5 | 13.4 | 0.5 | 0.062 |

| 5 | 9 | 2 | 1 | 13.4 | 0.5 | 0.062 |

| 6 | 9 | 1, 0.5 | 13.4 | 0.5 | 0.062 | |

| 7 | 5 | 1 | 0.5 | 9.38 | 0.5 | 0.089 |

| 8 | 13 | 2 | 0.5 | 13.4 | 11 | 0.062 |

| Wind Speed | ||

|---|---|---|

| 5 | 1.31 | 1 |

| 9 | 1.73 | 2 |

| 13 | 2.1 | 2 |

| Case No. | Inlet | Minimum | Average | Maximum | StD |

|---|---|---|---|---|---|

| 1 | 5 | 2.38 | 4.23 | 5.24 | 0.65 |

| 2 | 9 | 5.35 | 7.64 | 9.59 | 1.13 |

| 3 | 13 | 7.21 | 11.64 | 13.7 | 1.25 |

| Case No. | Inlet | Minimum | Average | Maximum | StD |

|---|---|---|---|---|---|

| 2 | 9 | 5.35 | 7.64 | 9.59 | 1.13 |

| 4 | 9 | 5.59 | 8.29 | 11.74 | 1.47 |

| 5 | 9 | 4.71 | 8.52 | 12.20 | 1.63 |

| 6 | 9 | 3.95 | 8.21 | 12.61 | 1.44 |

| Case No. | Inlet | Minimum | Average | Maximum | StD |

|---|---|---|---|---|---|

| 7 | 5 | 2.60 | 4.56 | 6.86 | 0.95 |

| 6 | 9 | 3.95 | 8.21 | 12.61 | 1.44 |

| 8 | 13 | 5.55 | 11.19 | 15.30 | 2.37 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, Y.; Wang, L.; Ding, L.; Hu, H. Numerical Study of Nacelle Wind Speed Characteristics of a Horizontal Axis Wind Turbine under Time-Varying Flow. Energies 2019, 12, 3993. https://doi.org/10.3390/en12203993

Wang X, Liu Y, Wang L, Ding L, Hu H. Numerical Study of Nacelle Wind Speed Characteristics of a Horizontal Axis Wind Turbine under Time-Varying Flow. Energies. 2019; 12(20):3993. https://doi.org/10.3390/en12203993

Chicago/Turabian StyleWang, Xiaodong, Yunong Liu, Luyao Wang, Lin Ding, and Hui Hu. 2019. "Numerical Study of Nacelle Wind Speed Characteristics of a Horizontal Axis Wind Turbine under Time-Varying Flow" Energies 12, no. 20: 3993. https://doi.org/10.3390/en12203993

APA StyleWang, X., Liu, Y., Wang, L., Ding, L., & Hu, H. (2019). Numerical Study of Nacelle Wind Speed Characteristics of a Horizontal Axis Wind Turbine under Time-Varying Flow. Energies, 12(20), 3993. https://doi.org/10.3390/en12203993