A Simplified Numerical Model for the Prediction of Wake Interaction in Multiple Wind Turbines

Abstract

1. Introduction

2. Implementation of the Numerical Model

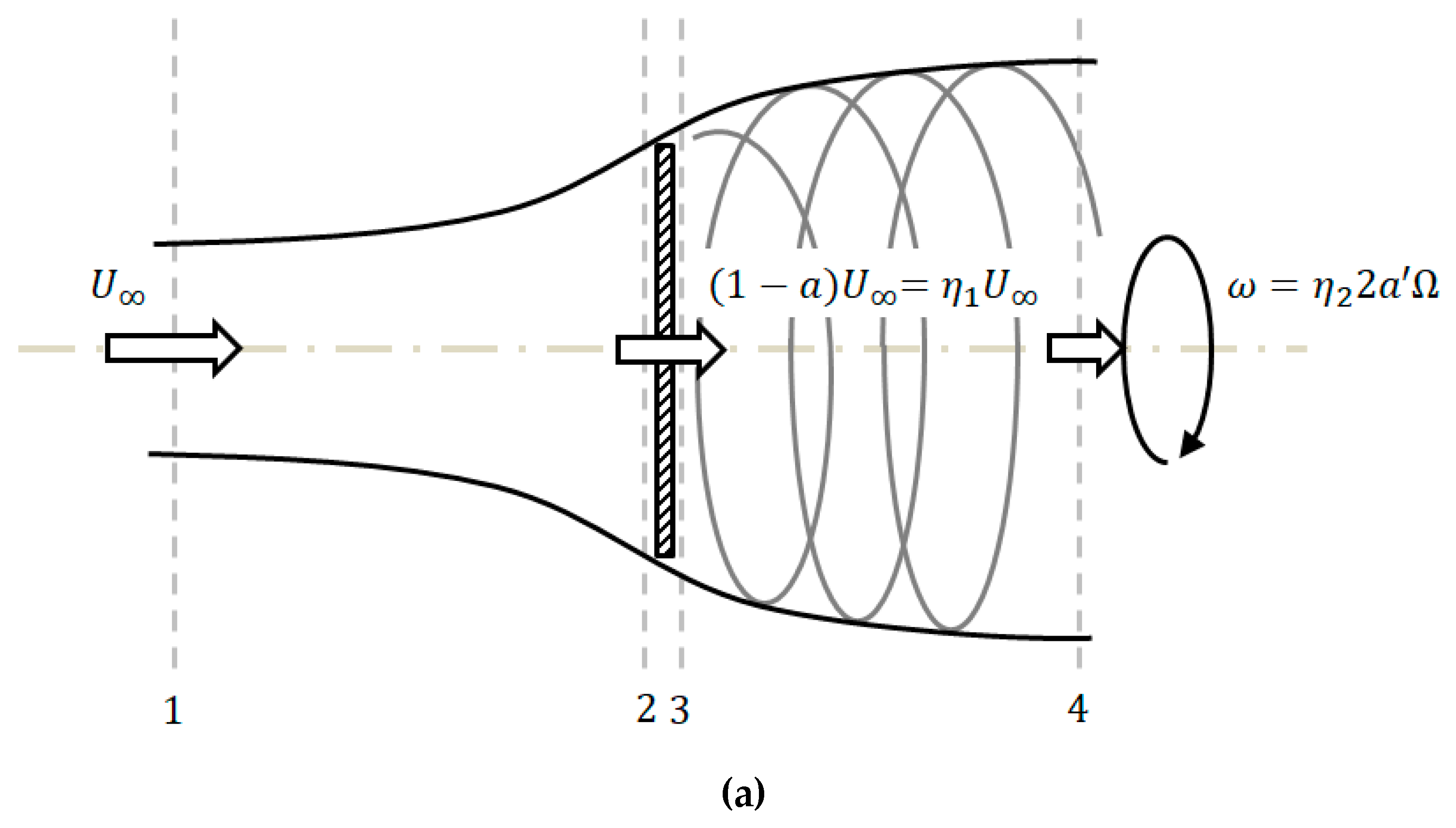

2.1. Classical Momentum Theory

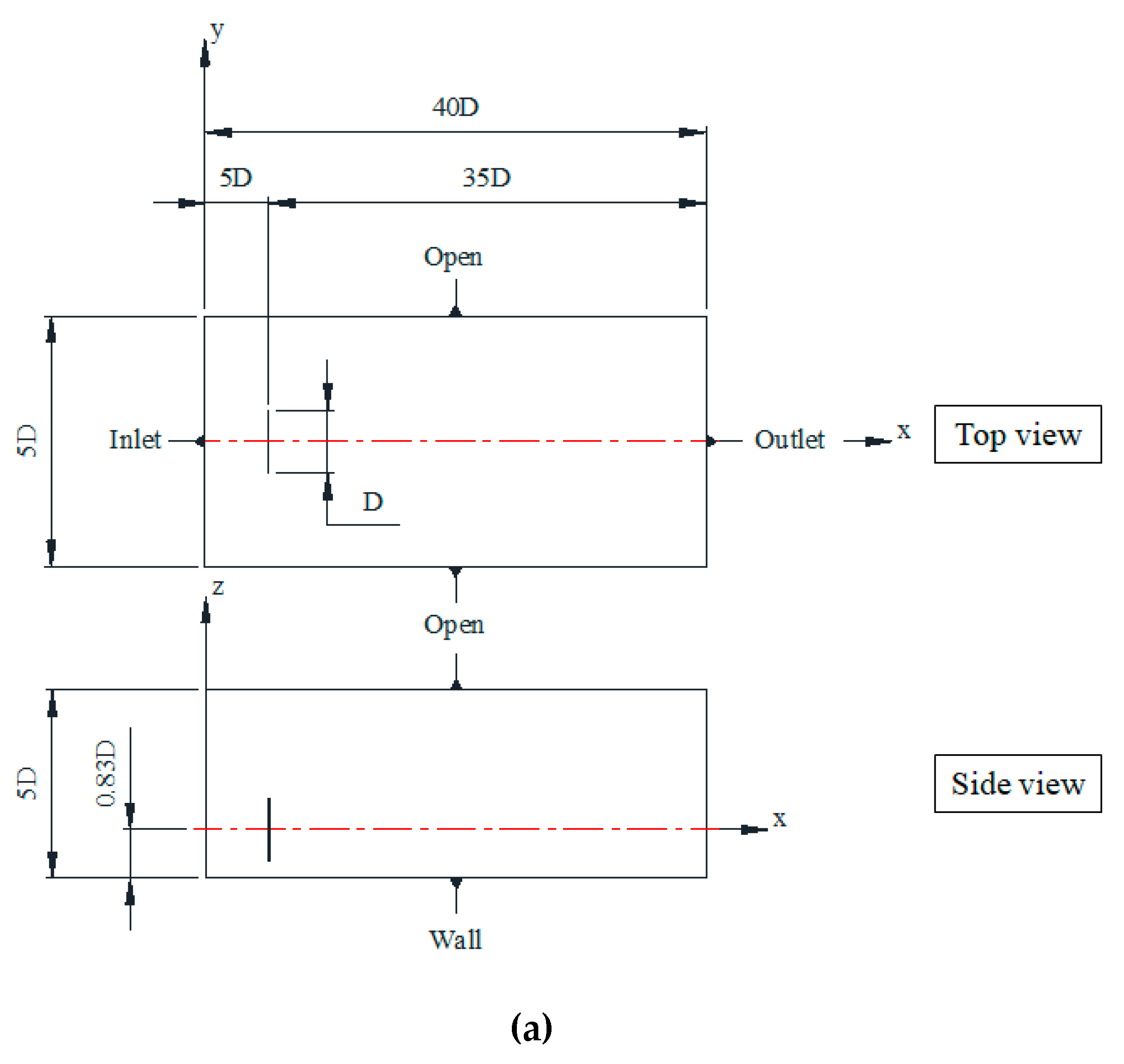

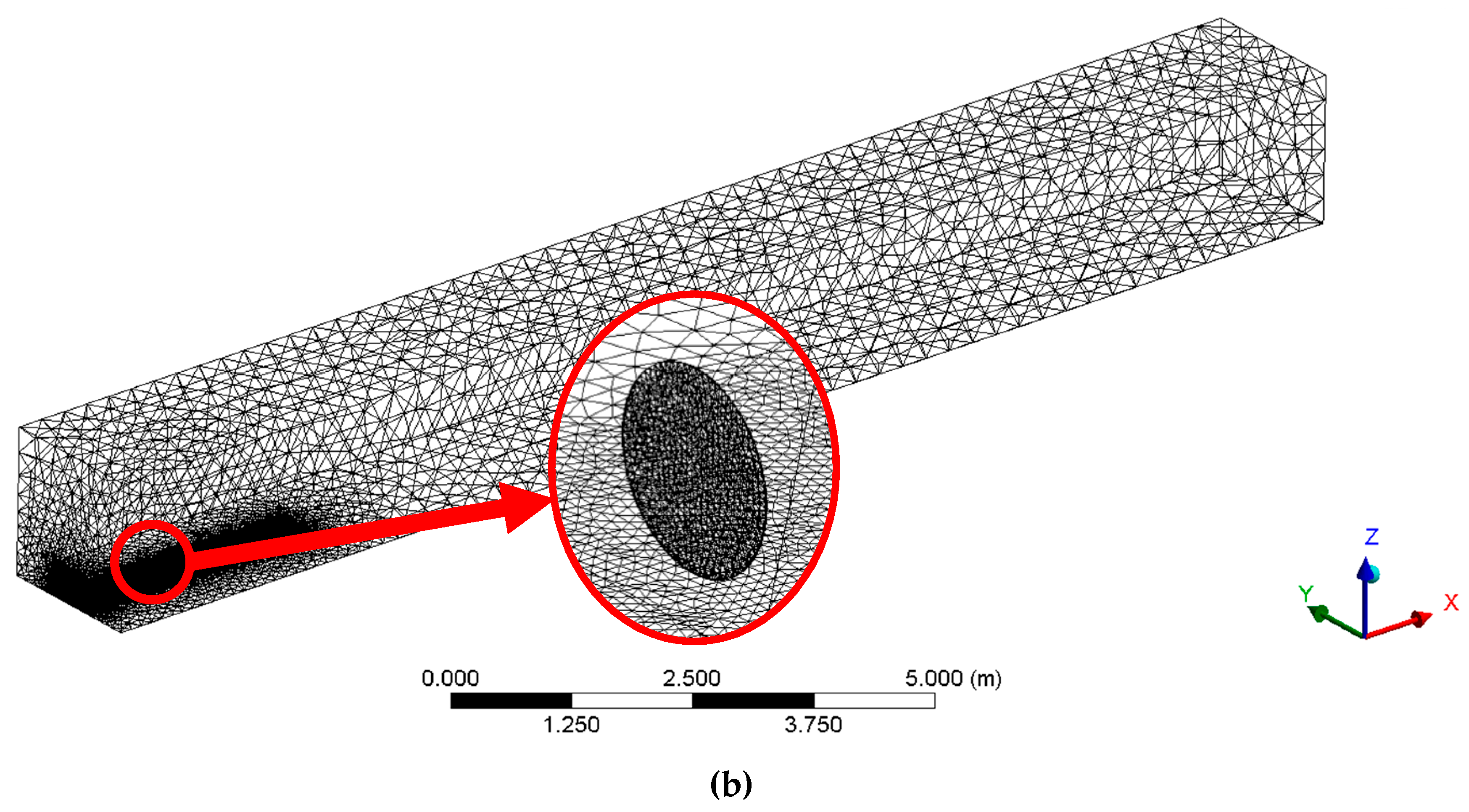

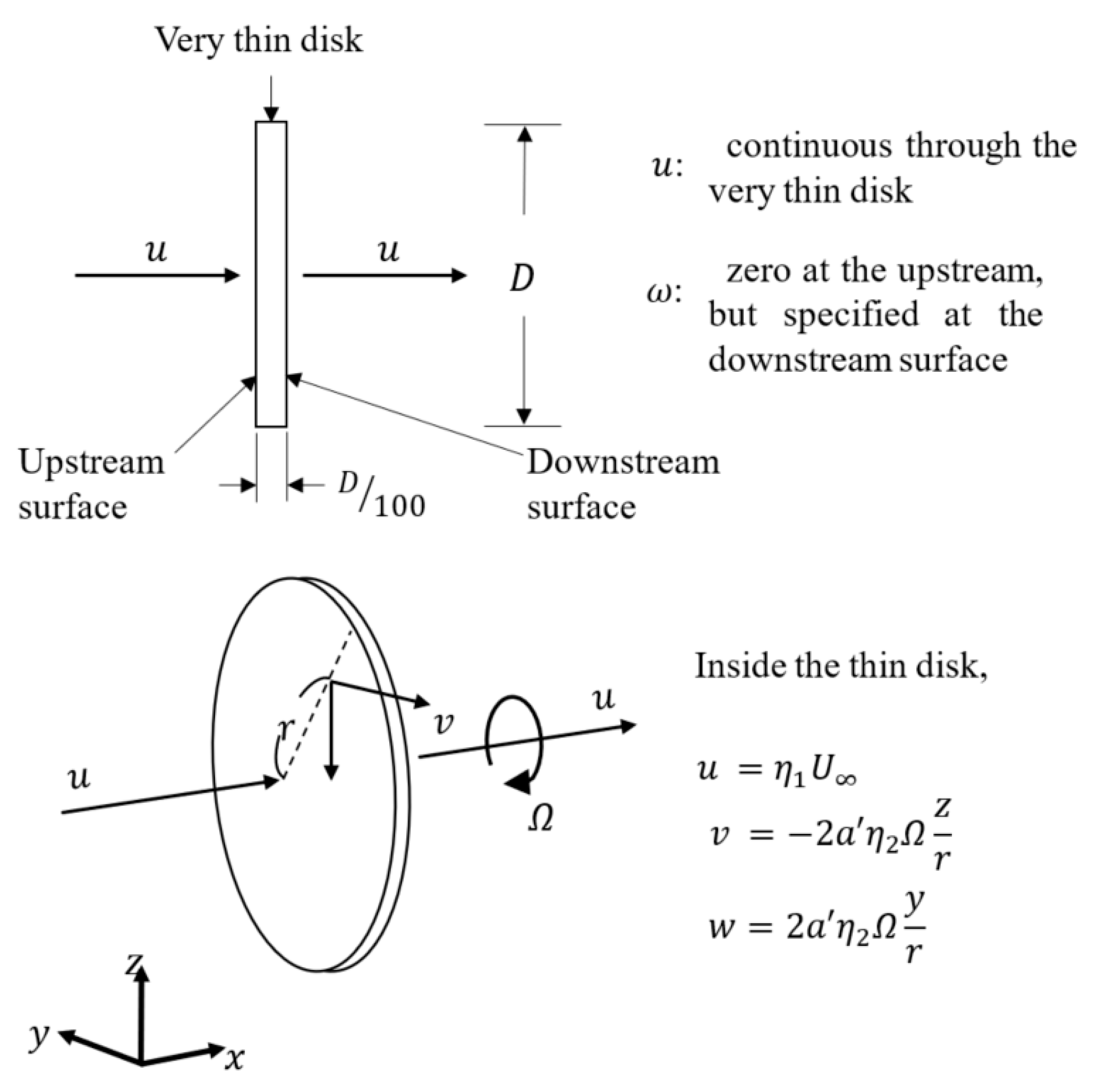

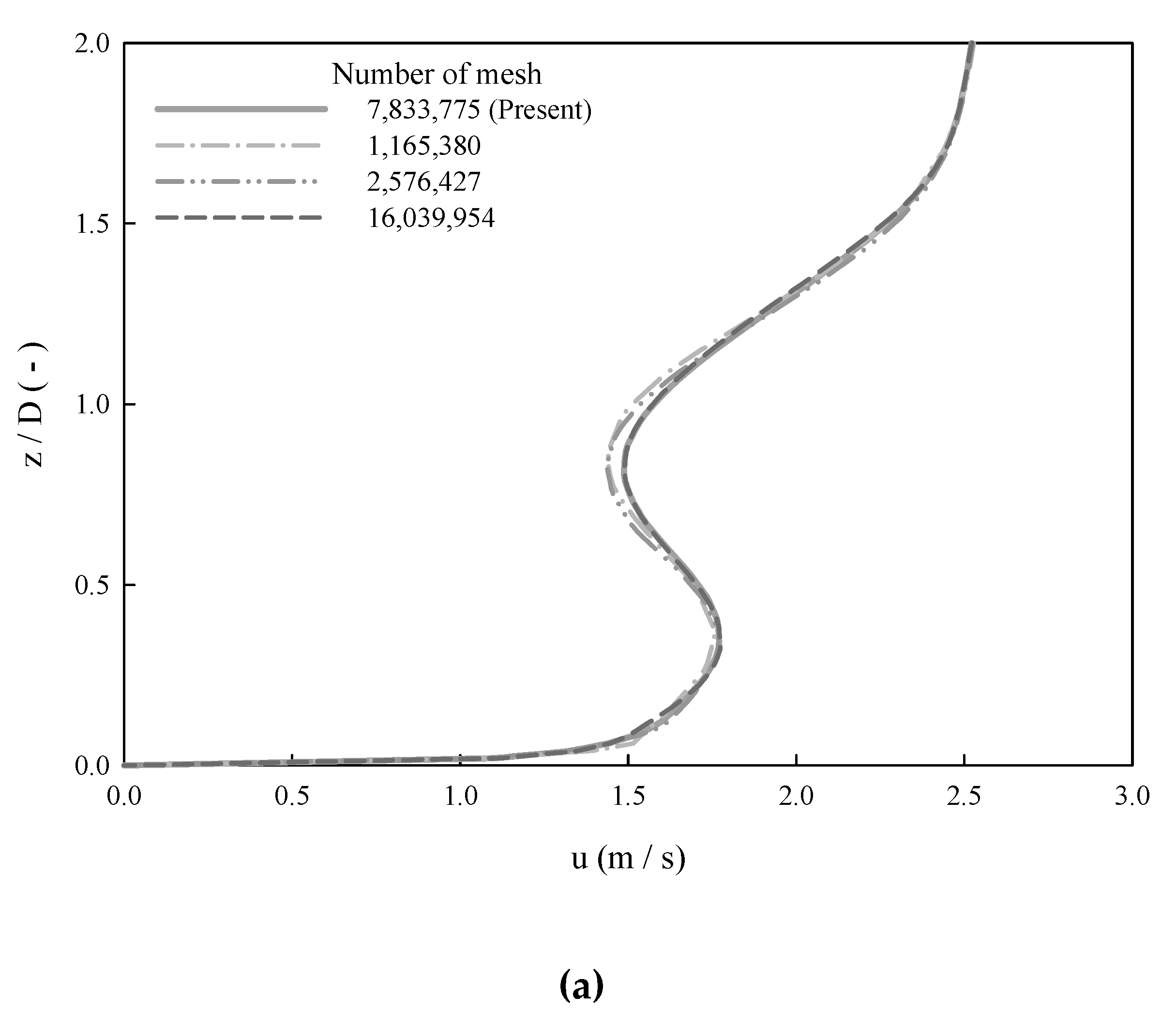

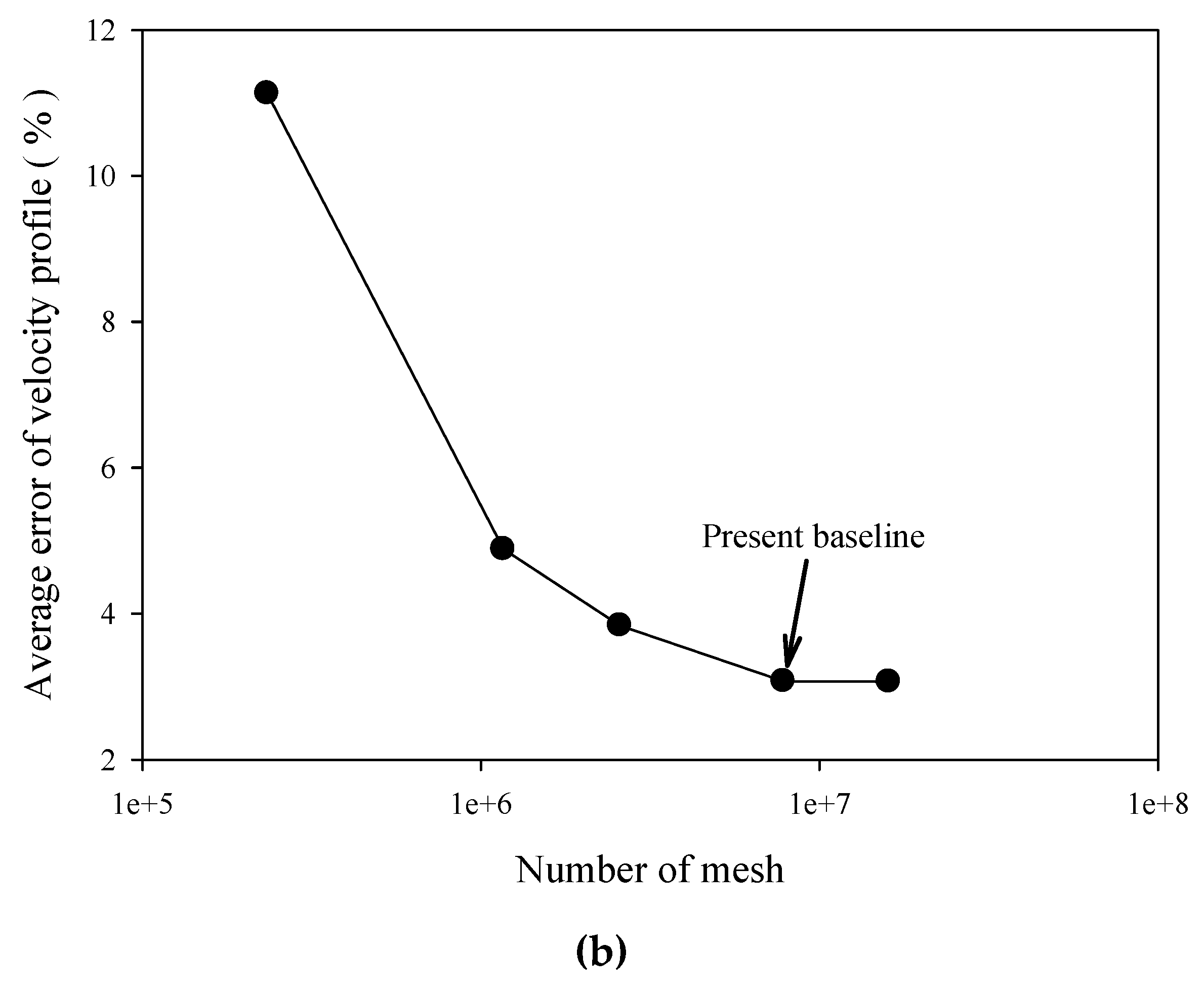

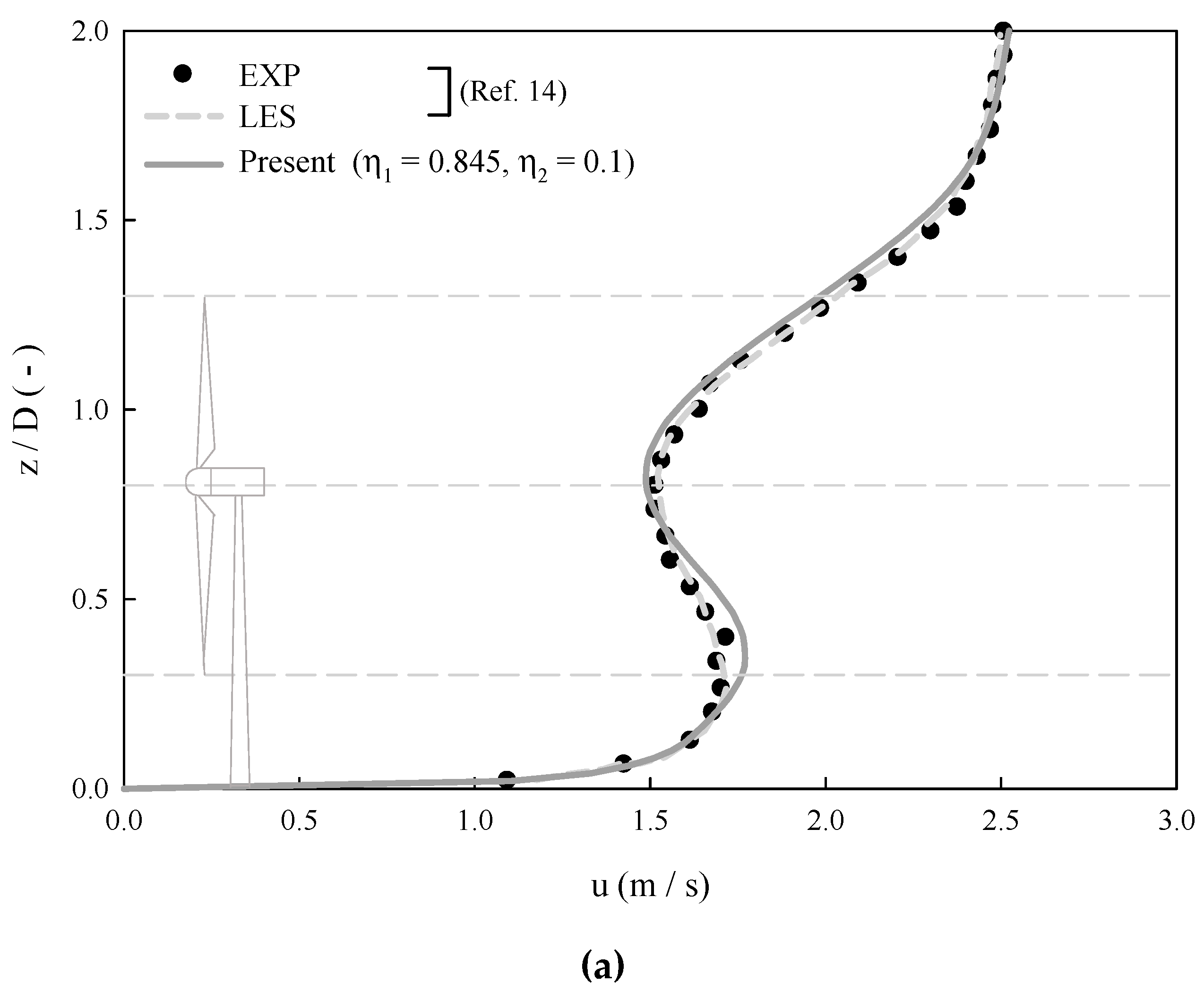

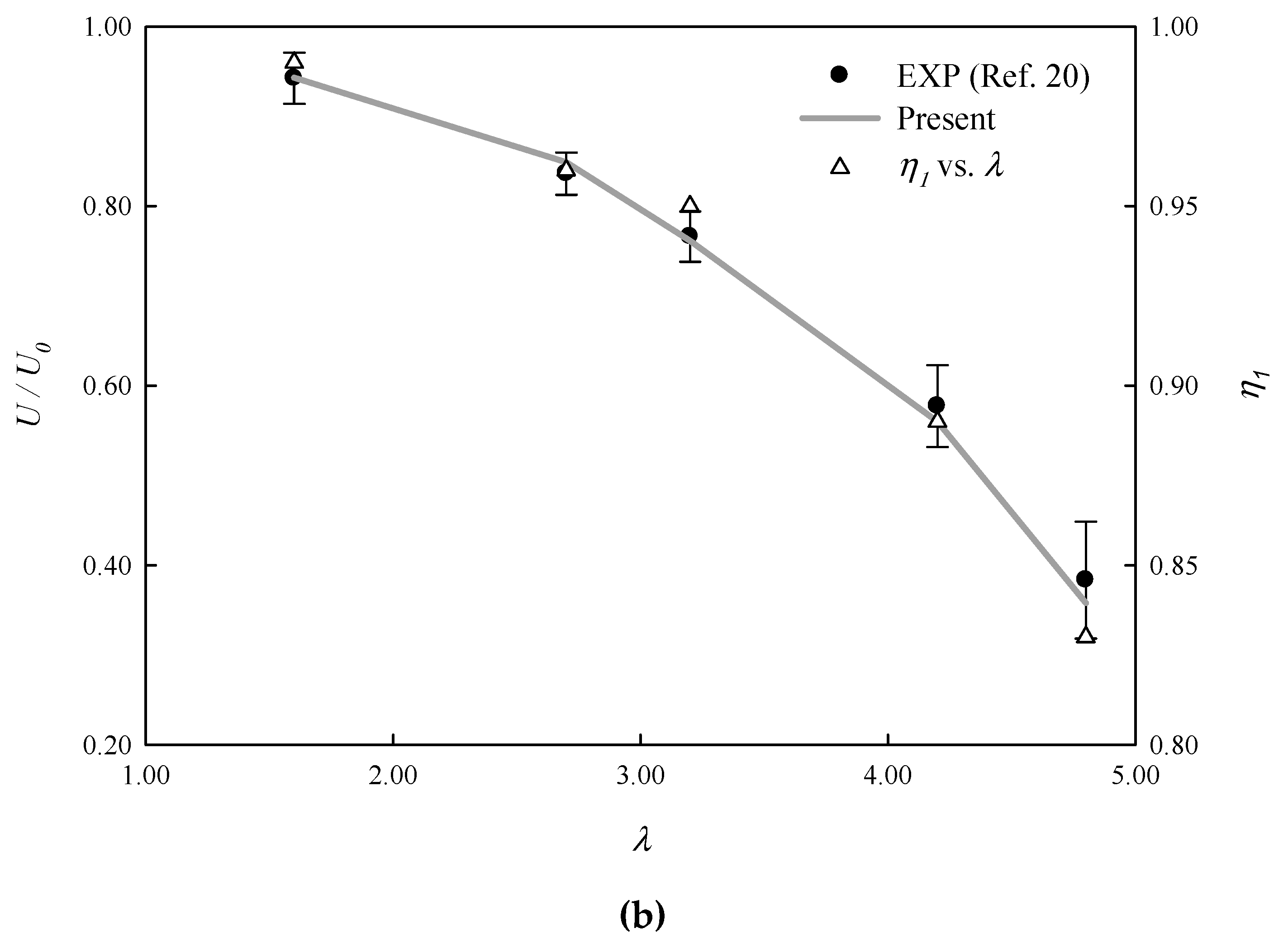

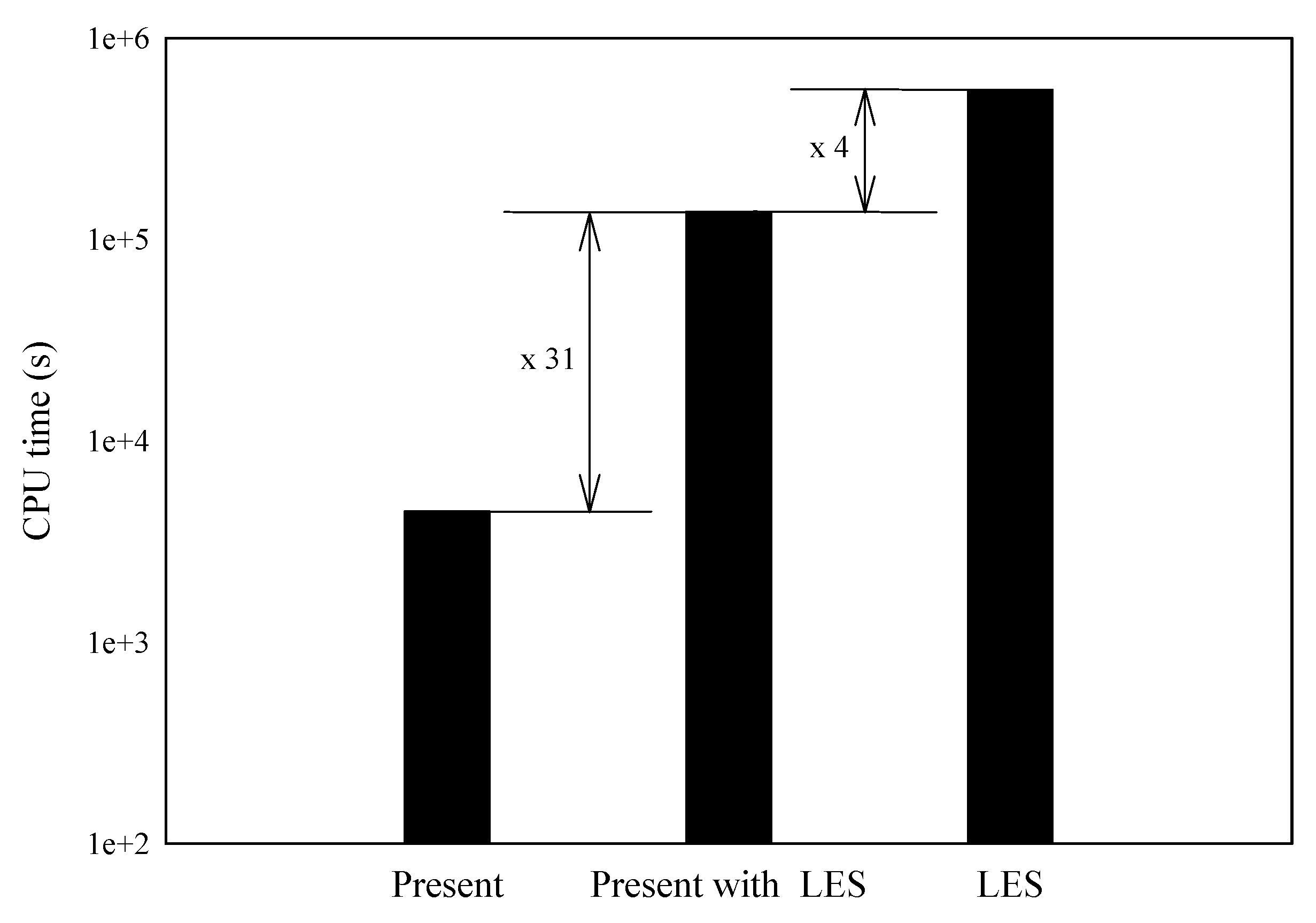

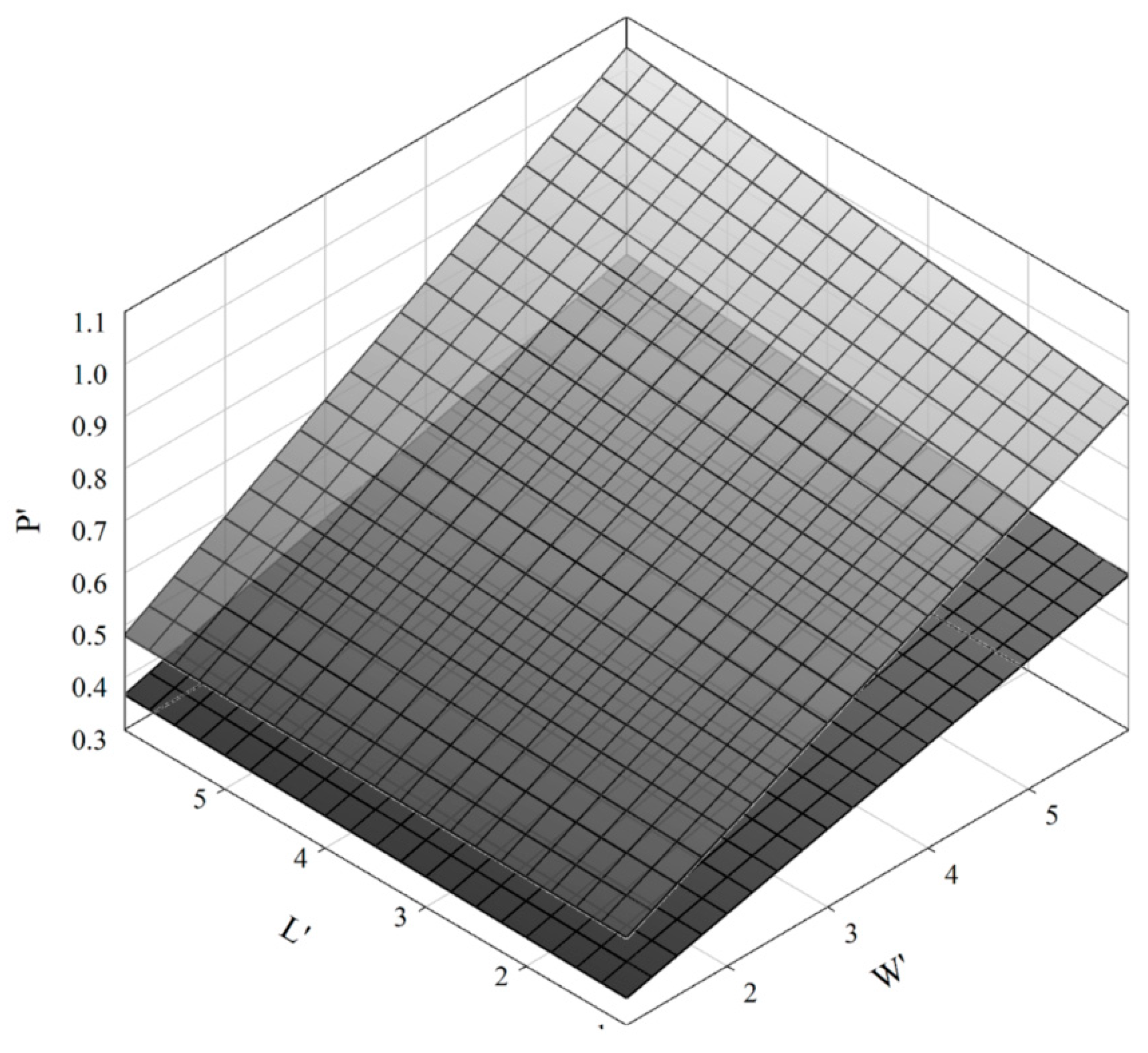

2.2. CFD Model: Single Turbine

2.3. CFD Model: Multiple Turbines

3. Conclusive Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Manwell, J.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design, and Application, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Weihing, P.; Meister, K.; Schulz, C.; Lutz, T.; Krämer, E. CFD simulations on interference effects between offshore wind turbines. J. Phys. Conf. Ser. 2015. [Google Scholar] [CrossRef]

- Sanderse, B. Aerodynamics of Wind Turbine Wakes: Literature Review; ECN-E-09-016; ECN Wind Energy: Petten, The Netherlands, 2003; pp. 1–46. [Google Scholar]

- Vermeer, L.J.; Sørensen, J.N.; Crespo, A. Wind turbine wake aerodynamics. Prog. Aerosp. Sci. 2003, 39, 467–510. [Google Scholar] [CrossRef]

- Crespo, A.; Hernandez, J.; Fraga, E.; Andreu, C. Experimental validation of the UPM computer code to calculate wind turbine wakes and comparison with other models. J. Wind. Eng. Ind. Aerodyn. 1998, 27, 77–88. [Google Scholar] [CrossRef]

- González-Longatt, F.; Wall, P.; Terzija, V. Wake effect in wind farm performance: Steady-state and dynamic behavior. Renew. Energy 2012, 39, 329–338. [Google Scholar] [CrossRef]

- Husien, W.; El-Osta, W.; Dekam, E. Effect of the wake behind wind rotor on optimum energy output of wind farms. Renew. Energy 2013, 49, 128–132. [Google Scholar] [CrossRef]

- Bastankhah, M.; Porté-Agel, F. A new analytical model for wind-turbine wakes. Renew. Energy 2014, 70, 116–123. [Google Scholar] [CrossRef]

- Carbajo Fuertes, F.; Markfort, C.D.; Porte-Agel, F. Wind turbine wake characterization with nacelle-mounted wind lidars for analytical wake model validation. Remote. Sens. 2018, 10, 668. [Google Scholar] [CrossRef]

- Lee, M.; Lee, S.H.; Hur, N. A numerical study on the effect of mountainous terrain and turbine arrangement on the performance of wind power generation. Trans. KSME(B) 2010, 34, 901–906. [Google Scholar] [CrossRef]

- Archer, C.L.; Mirzacisefat, S.; Lee, S. Quantifying the sensitivity of wind farm performance to array layout options using large-eddy simulation. Geophys. Res. Lett. 2013, 40, 4963–4970. [Google Scholar] [CrossRef]

- Smith, C.M.; Barthelmie, R.J.; Churchfield, M.J.; Moriarty, P.J. Complex wake merging phenomena in large offshore wind farms. In Proceedings of the 20th Symposium on Boundary Layers and Turbulence, Boston, MA, USA, 9–13 July 2012; American Meteorological Society: Boston, MA, USA, 2012. [Google Scholar]

- Wu, Y.T.; Porte-Agel, F. Large-eddy simulation of wind-turbine wakes: Evaluation of turbine parametrisations. Bound. Layer. Meteorol. 2011, 138, 345–366. [Google Scholar] [CrossRef]

- Conzemius, R.J.; Lu, H.; Chamorro, L.; Wu, Y.T.; Porte-Agel, F. Development and testing of a wind simulator at an operating wind farm. In Proceedings of the AWEA 2010 Wind Power Conference and Exhibition, Dallas, TX, USA, 23–26 May 2010; Windpower, American Wind Energy Association: Washington, DC, USA, 2010. [Google Scholar]

- Son, E.K. Numerical Investigation of Wind Farm Characteristics with Rotor-Wake Interaction and Noise Propagation. Ph.D. Thesis, Seoul National University, Gwanak, Seoul, Korea, 2014. [Google Scholar]

- Shin, H.K.; Jang, M.S.; Bang, H.J.; Kim, S.H. Wind turbine wake model by porous disk CFD model. J. Wind. Energy 2013, 4, 68–74. [Google Scholar]

- Dilip, D.; Porte-Agel, F. Wind turbine wake mitigation through blade pitch offset. Energies 2017, 10, 757. [Google Scholar] [CrossRef]

- Ozbay, A. Experimental Investigations on the Wake Interferences of Multiple Wind Turbines. Master’s Thesis, Iowa State University, Ames, IA, USA, 2012. [Google Scholar]

- Whale, J.; Helmis, C.G.; Papadopoulos, K.H.; Anderson, C.G.; Skyner, D.J. A study of the near wake structure of a wind turbine comparing measurements from laboratory and full-scale experiments. Solar. Energy 1996, 56, 621–633. [Google Scholar] [CrossRef]

- Hasager, C.B.; Vincent, P.; Badger, J.; Badger, M.; di Bella, A.; Peña, A.; Husson, R.; Volker, P.J.H. Using satellite SAR to characterize the wind flow around offshore wind farms. Energies 2015, 8, 5413–5439. [Google Scholar] [CrossRef]

- Wan, S.; Cheng, L.; Sheng, X. Effect of yaw error on wind turbine running characteristics based on the equivalent wind speed model. Energies 2015, 8, 6286–6301. [Google Scholar] [CrossRef]

- Shin, J.H.; Chang, S.M. Development of a simplified numerical model for the analysis of the wake flow field of a turbine rotor. Wind. Energy J. 2019, 10, 24–30. [Google Scholar]

- Shin, J.H.; Chang, S.M.; Jang, M.N.; Lee, Y.J.; Youn, H.J. Quantitative analysis on the decrease of wind energy from the composition effect of the coastal forest for damage prevention—The correlation of dissipation ratio to stand density. J. Korean Soc. Hazard. Mitig. 2015, 15, 361–368. [Google Scholar] [CrossRef]

| Wind Speed (m/s) | ||

|---|---|---|

| 11 | −0.173 | 3.152 |

| 12 | −0.359 | 4.894 |

| 13 | −0.272 | 4.080 |

| 14 | −0.183 | 3.121 |

| 15 | −0.130 | 2.489 |

| 16 | −0.099 | 2.071 |

| 17 | −0.078 | 1.779 |

| Wind Turbine Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| 0.7 | 0.75 | 0.725 | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.-H.; Lee, J.-H.; Chang, S.-M. A Simplified Numerical Model for the Prediction of Wake Interaction in Multiple Wind Turbines. Energies 2019, 12, 4122. https://doi.org/10.3390/en12214122

Shin J-H, Lee J-H, Chang S-M. A Simplified Numerical Model for the Prediction of Wake Interaction in Multiple Wind Turbines. Energies. 2019; 12(21):4122. https://doi.org/10.3390/en12214122

Chicago/Turabian StyleShin, Jong-Hyeon, Jong-Hwi Lee, and Se-Myong Chang. 2019. "A Simplified Numerical Model for the Prediction of Wake Interaction in Multiple Wind Turbines" Energies 12, no. 21: 4122. https://doi.org/10.3390/en12214122

APA StyleShin, J.-H., Lee, J.-H., & Chang, S.-M. (2019). A Simplified Numerical Model for the Prediction of Wake Interaction in Multiple Wind Turbines. Energies, 12(21), 4122. https://doi.org/10.3390/en12214122