Review on Power Performance and Efficiency of Wave Energy Converters

Abstract

:1. Introduction

2. Performance Analysis of Wave Energy Converters

- Since there are many different capture technologies of WECs available, it may difficult to compare the performance of different technologies at the same time.

- The scales and sizes of different wave energy converters will affect the comparison results. Therefore, in comparing similar WECs at different model sizes, a scaling ratio needs to be defined for different model sizes as well as the wave conditions in which those models were tested. For example, a laboratory-scaled WEC will probably be dominated by inertia forces instead of gravity forces since its size is usually small, while gravity forces may become dominated for a prototype scaled model tested in the field due to the increased size [30]. Furthermore, since a laboratory scaled model will probably contain fewer parts such as the power take-off (PTO), electrical, and transmission systems, the impacts on the WEC’s efficiency associated with these parts may make the results of simulation and laboratory scaled devices tests different from the results of field prototypes tests and the operating WECs.

- The performance of WECs can be greatly influenced by the wave condition at the test sites. For example, the performance of oscillating water columns and oscillating body systems, whose optimum capture occurs when the WEC is at resonance with the incoming waves [31,32,33,34,35], will be much lower if the WECs are tested in a site where most of the wave properties are outside the WEC’s resonance bandwidth.

- Pneumatic/hydrodynamic efficiency: This is the ratio of the primary energy absorbed by the device to the energy resource available within the interacting section of the device with the ocean wave.

- Turbine/mechanical efficiency: This is the ratio of the absorbed energy by the device to the mechanical energy through the power take-off device.

- Electrical efficiency: This is the ratio of the mechanical energy to electrical energy in situ through the appropriate generator.

- Transmission efficiency: This occurs during the conversion of the unstable electrical energy by the device to stable grid-acceptable electric energy.

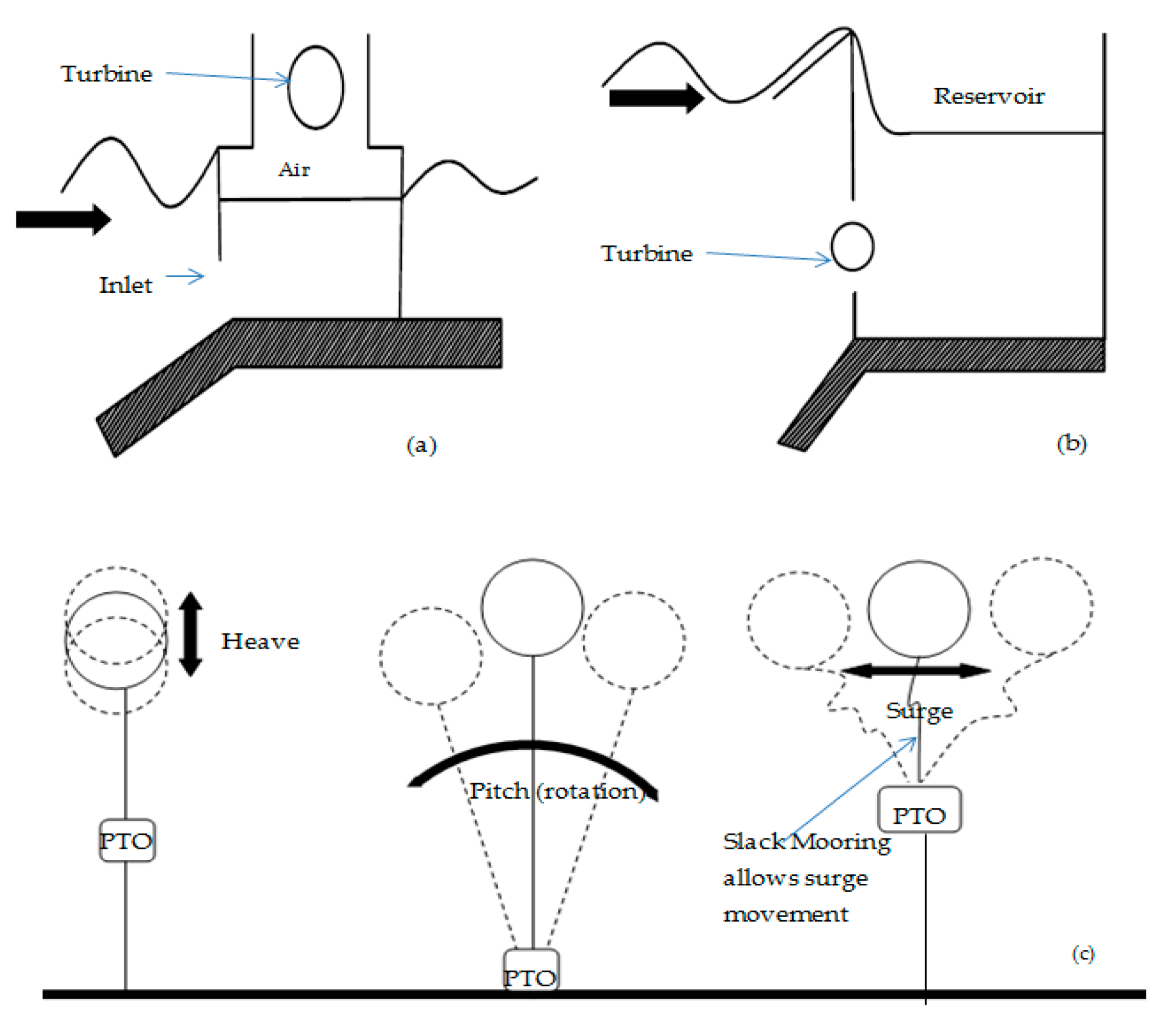

3. Oscillating Water Column Devices

3.1. Simulation and Numerical Analysis on Oscillating Water Columns

3.2. Efficiencies of Large-Scale Prototypes and Field Tests Results of OWCs

4. Oscillating Body Systems

4.1. Active and Passive Control to Increase Efficiency

4.2. Geometric Optimization to Increase Efficiency

4.3. Heaving Systems

5. Overtopping Wave Energy Converters

6. Comparing Power Efficiencies of Different Wave Energy Converter Types

7. Power Take-Off Systems

8. Cost Trends of Wave Energy Converters

9. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mork, G.; Barstow, S.; Kabuth, A.; Pontes, M.T. Assessing the global wave energy potential. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; pp. 447–454. [Google Scholar]

- Izadparast, A.H.; Niedzwecki, J.M. Estimating the potential of ocean wave power resources. Ocean Eng. 2011, 38, 177–185. [Google Scholar] [CrossRef]

- Mollison, D. Wave climate and the wave power resource. In Hydrodynamics of Ocean Wave-Energy Utilization; Springer: Berlin/Heidelberg, Germany, 1986; pp. 133–156. [Google Scholar]

- Lenee-Bluhm, P.; Paasch, R.; Özkan-Haller, H.T. Characterizing the wave energy resource of the US Pacific Northwest. Renew. Energy 2011, 36, 2106–2119. [Google Scholar] [CrossRef]

- Iglesias, G.; López, M.; Carballo, R.; Castro, A.; Fraguela, J.A.; Frigaard, P. Wave energy potential in Galicia (NW Spain). Renew. Energy 2009, 34, 2323–2333. [Google Scholar] [CrossRef]

- Citiroglu, H.K.; Okur, A. An approach to wave energy converter applications in Eregli on the western Black Sea coast of Turkey. Appl. Energy 2014, 135, 738–747. [Google Scholar] [CrossRef]

- Haces-Fernandez, F. Investigation on the Possibility of Extracting Wave Energy from the Texas Coast. Master’s Thesis, Texas A&M University, Kingsville, TX, USA, 2014. [Google Scholar]

- Ocean Energy Systems. Annual Report Ocean Energy Systems 2016. 2017. Available online: https://report2016.ocean-energy-systems.org/ (accessed on 11 March 2018).

- Jacobson, P.T.; Hagerman, G.; Scott, G. Mapping and Assessment of the United States Ocean Wave Energy Resource; No. DOE/GO/18173-1; Electric Power Research Institute: Palo Alto, CA, USA, 2011. [Google Scholar]

- Lawrence, J.; Kofoed-Hansen, H.; Chevalier, C. High-resolution metocean modelling at EMEC’s (UK) marine energy test sites. In Proceedings of the 8th European Wave and Tidal Energy Conference, Uppsala, Sweden, 7–10 September 2009; pp. 7–10. [Google Scholar]

- Neary, V.S.; Lawson, M.; Previsic, M.; Copping, A.; Hallett, K.C.; LaBonte, A.; Murray, D. Methodology for Design and Economic Analysis of Marine Energy Conversion (MEC) Technologies; No. SAND2014-3561C; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2014. [Google Scholar]

- Cada, G.; Ahlgrimm, J.; Bahleda, M.; Bigford, T.; Stavrakas, S.D.; Hall, D.; Sale, M. Potential impacts of hydrokinetic and wave energy conversion technologies on aquatic environments. Fisheries 2007, 32, 174–181. [Google Scholar] [CrossRef]

- Available online: https://www.oceanpowertechnologies.com/ (accessed on 14 November 2018).

- Brekken, T.K.; Von Jouanne, A.; Han, H.Y. Ocean wave energy overview and research at Oregon State University. In Proceedings of the Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Whittaker, T.; Collier, D.; Folley, M.; Osterried, M.; Henry, A.; Crowley, M. The development of Oyster—A shallow water surging wave energy converter. In Proceedings of the 7th European Wave and Tidal Energy Conference, Porto, Portugal, 1 September 2007; pp. 11–14. [Google Scholar]

- Available online: https://www.energy.gov/eere/water/about (accessed on 19 October 2018).

- Pelc, R.; Fujita, R.M. Renewable energy from the ocean. Mar. Policy 2002, 26, 471–479. [Google Scholar] [CrossRef]

- Aderinto, T.; Li, H. Ocean Wave Energy Converters: Status and Challenges. Energies 2018, 11, 1250. [Google Scholar] [CrossRef]

- Lehmann, M.; Karimpour, F.; Goudey, C.A.; Jacobson, P.T.; Alam, M.R. Ocean wave energy in the United States: Current status and future perspectives. Renew. Sustain. Energy Rev. 2017, 74, 1300–1313. [Google Scholar] [CrossRef]

- Clément, A.; McCullen, P.; Falcão, A.; Fiorentino, A.; Gardner, F.; Hammarlund, K.; Pontes, M.T. Wave energy in Europe: Current status and perspectives. Renew. Sustain. Energy Rev. 2002, 6, 405–431. [Google Scholar] [CrossRef]

- Falcao, A.D.O. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Whittaker, T.J.T.; McIlwaine, S.J.; Raghunathan, S. A review of the Islay shoreline wave power station. In Proceedings of the European Wave Energy Symposium, Edinburgh, Scotland, 21–24 July 1993; pp. 283–286. [Google Scholar]

- Ohneda, H.; Igarashi, S.; Shinbo, O.; Sekihara, S.; Suzuki, K.; Kubota, H.; Morita, H. Construction procedure of a wave power extracting caisson breakwater. In Proceedings of the 3rd Symposium on Ocean Energy Utilization, Tokyo, Japan, 22–23 January 1991; pp. 171–179. [Google Scholar]

- Ravindran, M.; Koola, P.M. Energy from sea waves—The Indian wave energy programme. Curr. Sci. 1991, 60, 676–680. [Google Scholar]

- Rusu, E.; Onea, F. Estimation of the wave energy conversion efficiency in the Atlantic Ocean close to the European islands. Renew. Energy 2016, 85, 687–703. [Google Scholar] [CrossRef]

- Rusu, L.; Onea, F. The performance of some state-of-the-art wave energy converters in locations with the worldwide highest wave power. Renew. Sustain. Energy Rev. 2017, 75, 1348–1362. [Google Scholar] [CrossRef]

- Babarit, A.; Hals, J.; Muliawan, M.J.; Kurniawan, A.; Moan, T.; Krokstad, J. Numerical benchmarking study of a selection of wave energy converters. Renew. Energy 2012, 41, 44–63. [Google Scholar] [CrossRef]

- Babarit, A. A database of capture width ratio of wave energy converters. Renew. Energy 2015, 80, 610–628. [Google Scholar] [CrossRef]

- Astariz, S.; Iglesias, G. The economics of wave energy: A review. Renew. Sustain. Energy Rev. 2015, 45, 397–408. [Google Scholar] [CrossRef]

- Hughes, S. Physical Models and Laboratory Techniques in Coastal Engineering; World Scientific: Singapore, 1993; p. 7. [Google Scholar]

- Aderinto, T.O.; Haces-Fernandez, F.; Li, H. Design and Potential Application of Small Scale Wave Energy Converter. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; p. V006T08A084. [Google Scholar] [CrossRef]

- Evans, D.V. A theory for wave-power absorption by oscillating bodies. J. Fluid Mech. 1976, 77, 1–25. [Google Scholar] [CrossRef]

- Budar, K.; Falnes, J. A resonant point absorber of ocean-wave power. Nature 1975, 256, 478–479. [Google Scholar] [CrossRef]

- Mei, C.C. Power extraction from water waves. J. Ship Res. 1976, 20, 63–66. [Google Scholar]

- Falnes, J. Optimum Control of Oscillation of Wave-Energy Converters. In Proceedings of the Eleventh International Offshore and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2002. [Google Scholar]

- Davidson Laboratory of Stevens Institute of Technology. Available online: http://www.stevens.edu/ses/davidson/facilities/design-evaluation (accessed on 19 November 2018).

- DeFrees Hydraulics Lab. Available online: http://www.cee.cornell.edu/about/facilities/defrees.cfm (accessed on 15 November 2018).

- Fluid Mechanics Laboratory at Clemson University. Available online: http://www.clemson.edu/ces/coastal/facilities.html (accessed on 20 November 2018).

- Haynes Coastal Engineering Laboratory. Available online: http://coastal.tamu.edu/forindustry.html (accessed on 19 November 2018).

- Available online: https://marineenergy.biz/2015/05/29/china-to-advance-wave-energy-with-three-test-sites/ (accessed on 19 November 2018).

- Wang, L.; Isberg, J.; Tedeschi, E. Review of control strategies for wave energy conversion systems and their validation: The wave-to-wire approach. Renew. Sustain. Energy Rev. 2018, 81, 366–379. [Google Scholar] [CrossRef]

- Available online: http://www.danwec.com/ (accessed on 19 November 2018).

- Available online: https://www.wavehub.co.uk/ (accessed on 19 November 2018).

- Available online: http://www.semrev.fr/en/ (accessed on 19 November 2018).

- Available online: https://tethys.pnnl.gov/annex-iv-sites/atlantic-marine-energy-test-site-amets (accessed on 19 November 2018).

- Available online: http://www.seai.ie/Renewables/Ocean_Energy/Belmullet_Wave_Energy_Test_Site/ (accessed on 19 November 2018).

- Available online: http://www.rundecentre.no/ (accessed on 19 November 2018).

- Palha, A.; Mendes, L.; Fortes, C.J.; Brito-Melo, A.; Sarmento, A. The impact of wave energy farms in the shoreline wave climate: Portuguese pilot zone case study using Pelamis energy wave devices. Renew. Energy 2010, 35, 62–77. [Google Scholar] [CrossRef]

- Available online: http://www.emec.org.uk/ (accessed on 19 November 2018).

- Available online: http://www.eve.es/energia_marina/index_cas.htm (accessed on 19 November 2018).

- Available online: http://www.plocan.eu/es/ (accessed on 19 November 2018).

- Available online: http://www.folkecenter.net/gb/rd/wave-energy/ (accessed on 19 November 2018).

- Available online: http://www.marine.ie/home/aboutus/organisationstaff/researchfacilities/Ocean+Energy+Test+Site.htm (accessed on 19 November 2018).

- Available online: http://www.fabtest.com/ (accessed on 19 November 2018).

- Available online: http://pacwaveenergy.org/ (accessed on 19 November 2018).

- Batten, B.; Hellin, D. The Pacific Marine Energy Center-South Energy Test Site (PMEC-SETS); (No. DOE_PMECSETS_-02072018); Oregon State Univ.: Corvallis, OR, USA, 2018. [Google Scholar]

- Available online: https://www.hnei.hawaii.edu/projects/wave-energy-test-site-wets (accessed on 20 November 2018).

- Ni, C. Development of Ocean Energy Test Field in China. J. Shipp. Ocean Eng. 2015, 5, 44–49. [Google Scholar]

- Masuda, Y. Wave-Activated Generator. U.S. Patent 4,539,485, 3 September 1985. [Google Scholar]

- Masuda, Y.; McCormick, M.E. Experiences in pneumatic wave energy conversion in Japan. In Utilization of Ocean Waves—Wave to Energy Conversion; ASCE: Reston, VA, USA, 1986; pp. 1–33. [Google Scholar]

- Bønke, K.; Ambli, N. Prototype wave power stations in Norway. In Utilization of Ocean Waves—Wave to Energy Conversion; ASCE: Reston, VA, USA, 1986; pp. 34–45. [Google Scholar]

- Malmo, O.; Reitan, A. Wave-power absorption by an oscillating water column in a channel. J. Fluid Mech. 1985, 158, 153–175. [Google Scholar] [CrossRef]

- Heath, T.; Whittaker, T.J.T.; Boake, C.B. The design, construction and operation of the LIMPET wave energy converter (Islay, Scotland). In Proceedings of the 4th European Wave Energy Conference, Aalborg, Denmark, 4 December 2000; pp. 49–55. [Google Scholar]

- Boake, C.B.; Whittaker, T.J.; Folley, M.; Ellen, H. Overview and initial operational experience of the LIMPET wave energy plant. In Proceedings of the Twelfth International Offshore and Polar Engineering Conference, Kitakyushu, Japan, 26–31 May 2002. [Google Scholar]

- Available online: http://www.yentha.com/news/view/4/innovation-lost-to-the-waves (accessed on 12 November 2018).

- Falcao, A.D.O. The shoreline OWC wave power plant at the Azores. In Proceedings of the Fourth European Wave Energy Conference, Aalborg, Denmark, 4 December 2000; pp. 4–6. [Google Scholar]

- Available online: http://www.pico-owc.net/ (accessed on 15 November 2018).

- Vieira, M.; Monk, K.; Sarmento, A.; Reis, L. The Pico power plant as an infrastructure for development, research and graduation. In Congresso de Ciência e Desenvolvimento dos Açores; ACDA: Angra do Heroísmo, Portugal, 2013. [Google Scholar]

- Le Crom, I.; Brito-Melo, A.; Neumann, F.; Sarmento, A.J.N.A. Portuguese grid connected OWC power plant: Monitoring Report. In Proceedings of the Twentieth International Offshore and Polar Engineering Conference, Beijing, China, 20–25 June 2010. [Google Scholar]

- Alcorn, R.; Hunter, S.C.O.T.T.; Signorelli, C.; Obeyesekera, R.A.N.J.I.; Finnigan, T.; Denniss, T. Results of the Testing of the Energetech Wave Energy Plant at Port Kembla 26 October 2005 Tech. Rep.; Energetech Australia Pty Limited: Kensington, Australia, 2005. [Google Scholar]

- Lindroth, S.; Leijon, M. Offshore wave power measurements—A review. Renew. Sustain. Energy Rev. 2011, 15, 4274–4285. [Google Scholar] [CrossRef]

- Torre-Enciso, Y.; Ortubia, I.; de Aguileta, L.L.; Marqués, J. Mutriku wave power plant: From the thinking out to the reality. In Proceedings of the 8th European Wave and Tidal Energy Conference, Uppsala, Sweden, 7–10 September 2009; Volume 710, p. 319329. [Google Scholar]

- Available online: https://www.power-technology.com/projects/mutriku-wave/ (accessed on 19 November 2018).

- Washio, Y.; Osawa, H.; Nagata, Y.; Fujii, F.; Furuyama, H.; Fujita, T. The offshore floating type wave power device “Mighty Whale”: Open sea tests. In Proceedings of the Tenth International Offshore and Polar Engineering Conference, Seattle, WA, USA, 28 May–2 June 2000. [Google Scholar]

- OES Annual Report 2014. REPUBLIC OF KOREA. Technology Demonstration. Available online: https://report2014.ocean-energy-systems.org/countryreports/republic-of-korea/technology-demonstration/ (accessed on 14 November 2018).

- Brito-Melo, A.; Hofmann, T.; Sarmento, A.J.N.A.; Clément, A.H.; Delhommeau, G. Numerical modelling of OWC-shoreline devices including the effect of surrounding coastline and non-flat bottom. Int. J. Offshore Polar Eng. 2001, 11, 2. [Google Scholar]

- Brito-Melo, A.; Gato, L.M.C.; Sarmento, A.J.N.A. Analysis of Wells turbine design parameters by numerical simulation of the OWC performance. Ocean Eng. 2002, 29, 1463–1477. [Google Scholar] [CrossRef]

- Hotta, H.; Washio, Y.; Yokozawa, H.; Miyazaki, T. R&D on wave power device “Mighty Whale”. Renew. Energy 1996, 9, 1223–1226. [Google Scholar]

- Sarmento, A.J.; e Melo, A.B.; Pontes, M.T. The influence of the wave climate on the design and annual production of electricity by OWC wave power plants. J. Offshore Mech. Arct. Eng. 2003, 125, 139–144. [Google Scholar] [CrossRef]

- Masuda, Y.; Xianguang, L.; Xiangfan, G. High performance of cylinder float backward bent duct buoy (BBDB) and its use in European seas. In Proceedings of the (First) European Wave Energy Symposium, Edinburgh, UK, 30 October–1 November 1993; pp. 323–337. [Google Scholar]

- Mamun, M.A.H.; Nagata, S.; Toyota, K.; Imai, Y.; Setoguchi, T. Numerical Simulation of Backward Bent Duct Buoy by Moving Particle Semi-implicit Method. In Proceedings of the 13th Asian Congress of Fluid Mechanics, Duaka, Bangladesh, 17–21 December 2010. [Google Scholar]

- Lee, K.R.; Koo, W.; Kim, M.H. Fully nonlinear time-domain simulation of a backward bent duct buoy floating wave energy converter using an acceleration potential method. Int. J. Nav. Archit. Ocean Eng. 2013, 5, 513–528. [Google Scholar] [CrossRef]

- Bailey, H.; Robertson, B.R.; Buckham, B.J. Wave-to-wire simulation of a floating oscillating water column wave energy converter. Ocean Eng. 2016, 125, 248–260. [Google Scholar] [CrossRef]

- Maldonado Rivera, C.I. Stochastic modelling of OWC device and power production. Master’s. Thesis, Pontificia Universidad Catolica De Chile Escuela De Ingenieria, Santiago, Chile, 2017. [Google Scholar]

- Henriques, J.C.C.; Portillo, J.C.C.; Gato, L.M.C.; Gomes, R.P.F.; Ferreira, D.N.; Falcão, A.F.O. Design of oscillating-water-column wave energy converters with an application to self-powered sensor buoys. Energy 2016, 112, 852–867. [Google Scholar] [CrossRef]

- Falcao, A.D.O.; Rodrigues, R.J.A. Stochastic modelling of OWC wave power plant performance. Appl. Ocean Res. 2002, 24, 59–71. [Google Scholar] [CrossRef]

- Falcao, A.D.O. Stochastic modelling in wave power-equipment optimization: Maximum energy production versus maximum profit. Ocean Eng. 2004, 31, 1407–1421. [Google Scholar] [CrossRef]

- Falcao, A.D.O.; Justino, P.A.P. OWC wave energy devices with air flow control. Ocean Eng. 1999, 26, 1275–1295. [Google Scholar] [CrossRef]

- Ning, D.Z.; Wang, R.Q.; Zou, Q.P.; Teng, B. An experimental investigation of hydrodynamics of a fixed OWC Wave Energy Converter. Appl. Energy 2016, 168, 636–648. [Google Scholar] [CrossRef]

- Iino, M.; Miyazaki, T.; Segawa, H.; Iida, M. Effect of inclination on oscillation characteristics of an oscillating water column wave energy converter. Ocean Eng. 2016, 116, 226–235. [Google Scholar] [CrossRef]

- Ashlin, S.J.; Sundar, V.; Sannasiraj, S.A. Effects of bottom profile of an oscillating water column device on its hydrodynamic characteristics. Renew. Energy 2016, 96, 341–353. [Google Scholar] [CrossRef]

- E Silva, S.R.; Gomes, R.P.F.; Falcão, A.F.O. Hydrodynamic optimization of the UGEN: Wave energy converter with U-shaped interior oscillating water column. Int. J. Mar. Energy 2016, 15, 112–126. [Google Scholar] [CrossRef]

- Henriques, J.C.C.; Gato, L.M.C.; Lemos, J.M.; Gomes, R.P.F.; Falcão, A.F.O. Peak-power control of a grid-integrated oscillating water column wave energy converter. Energy 2016, 109, 378–390. [Google Scholar] [CrossRef] [Green Version]

- Strati, F.M.; Malara, G.; Arena, F. Performance optimization of a U-Oscillating-Water-Column wave energy harvester. Renew. Energy 2016, 99, 1019–1028. [Google Scholar] [CrossRef]

- Henriques, J.C.C.; Gomes, R.P.F.; Gato, L.M.C.; Falcão, A.F.O.; Robles, E.; Ceballos, S. Testing and control of a power take-off system for an oscillating-water-column wave energy converter. Renew. Energy 2016, 85, 714–724. [Google Scholar] [CrossRef]

- Ceballos, S.; Rea, J.; Lopez, I.; Pou, J.; Robles, E.; O’Sullivan, D.L. Efficiency optimization in low inertia wells turbine-oscillating water column devices. IEEE Trans. Energy Convers. 2013, 28, 553–564. [Google Scholar] [CrossRef]

- Ceballos, S.; Rea, J.; Robles, E.; Lopez, I.; Pou, J.; O’Sullivan, D. Control strategies for combining local energy storage with wells turbine oscillating water column devices. Renew. Energy 2015, 83, 1097–1109. [Google Scholar] [CrossRef]

- Meyer, N.I.; Arnskov, M.M.; Bennetzen, L.V.; Burcharth, H.F.; Bunger, J.; Jacobsen, V.; Sørensen, J.N. Bølgekraftprogram: Afsluttende rapport fra Energistyrelsens Rådgivende Bølgekraftudvalg. Bølgekraftudvalgets Sekr. Rambøll Tek. 2002, 31, 2830. [Google Scholar]

- Pecher, A.; Kofoed, J.P.; Le Crom, I.; Neumann, F.; Azevedo, E.D.B. Performance assessment of the Pico OWC power plant following the EquiMar methodology. In Proceedings of the Twenty-First International Offshore and Polar Engineering Conference, Hawaii, HI, USA, 19–24 June 2011. [Google Scholar]

- Rendel Palmer & Tritton and Kennedy & Donkin. “United Kingdom Wave Energy Program—Consultants’ 1981 Assessment”, Department of Energy. 1982. Available online: http://www.homepages.ed.ac.uk/shs/MIT%20visit/9_Official%20Consultant%20Assessment%201981.pdf (accessed on 12 November 2019).

- Valério, D.; Beirão, P.; da Costa, J.S. Optimisation of wave energy extraction with the Archimedes Wave Swing. Ocean Eng. 2007, 34, 2330–2344. [Google Scholar] [CrossRef]

- Yeung, R.W.; Jiang, Y. Shape effects on viscous damping and motion of heaving cylinders. J. Offshore Mech. Arct. Eng. 2014, 136, 041801. [Google Scholar] [CrossRef]

- Ferri, F.; Ambühl, S.; Fischer, B.; Kofoed, J.P. Balancing power output and structural fatigue of wave energy converters by means of control strategies. Energies 2014, 7, 2246–2273. [Google Scholar] [CrossRef] [Green Version]

- Sergiienko, N.Y.; Cazzolato, B.S.; Ding, B.; Hardy, P.; Arjomandi, M. Performance comparison of the floating and fully submerged quasi-point absorber wave energy converters. Renew. Energy 2017, 108, 425–437. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.; Kerrigan, E.C. Latching control of wave energy converters using derivative-free optimization. In Proceedings of the 52nd IEEE Conference on Decision and Control, Florence, Italy, 10–13 December 2013. [Google Scholar]

- Wu, J.; Yao, Y.; Zhou, L.; Göteman, M. Latching and Declutching Control of the Solo Duck Wave-Energy Converter with Different Load Types. Energies 2017, 10, 2070. [Google Scholar] [CrossRef] [Green Version]

- Budal, K.; Falnes, J. Interacting Point Absorbers with Controlled Motion. Power from Sea Waves; Academic Press: London, UK, 1980; pp. 381–399. [Google Scholar]

- Salter, S.H.; Taylor, J.R.M.; Caldwell, N.J. Power conversion mechanisms for wave energy. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2002, 216, 1–27. [Google Scholar] [CrossRef]

- Babarit, A.; Duclos, G.; Clément, A.H. Comparison of latching control strategies for a heaving wave energy device in random sea. Appl. Ocean Res. 2004, 26, 227–238. [Google Scholar] [CrossRef] [Green Version]

- Falcao, A.D.O. Phase control through load control of oscillating-body wave energy converters with hydraulic PTO system. Ocean Eng. 2008, 35, 358–366. [Google Scholar] [CrossRef]

- Korde, U.A. Latching control of deep water wave energy devices using an active reference. Ocean Eng. 2002, 29, 1343–1355. [Google Scholar] [CrossRef]

- Thomas, G.P.; Evans, D.V. Arrays of three-dimensional wave-energy absorbers. J. Fluid Mech. 1981, 108, 67–88. [Google Scholar] [CrossRef]

- Shadman, M.; Estefen, S.F.; Rodriguez, C.A.; Nogueira, I.C. A geometrical optimization method applied to a heaving point absorber wave energy converter. Renew. Energy 2018, 115, 533–546. [Google Scholar] [CrossRef]

- Goggins, J.; Finnegan, W. Shape optimisation of floating wave energy converters for a specified wave energy spectrum. Renew. Energy 2014, 71, 208–220. [Google Scholar] [CrossRef]

- Flocard, F.; Finnigan, T.D. Increasing power capture of a wave energy device by inertia adjustment. Appl. Ocean Res. 2012, 34, 126–134. [Google Scholar] [CrossRef]

- Esmaeilzadeh, S.; Alam, M.R. Shape Optimization of Wave Energy Converters for Broadband Directional Incident Waves. arXiv 2018, arXiv:1805.08294. [Google Scholar] [CrossRef] [Green Version]

- Bachynski, E.E.; Young, Y.L.; Yeung, R.W. Analysis and optimization of a tethered wave energy converter in irregular waves. Renew. Energy 2012, 48, 133–145. [Google Scholar] [CrossRef]

- Sjökvist, L.; Krishna, R.; Rahm, M.; Castellucci, V.; Anders, H.; Leijon, M. On the optimization of point absorber buoys. J. Mar. Sci. Eng. 2014, 2, 477–492. [Google Scholar] [CrossRef]

- Hirohisa, T. Sea trial of a heaving buoy wave power absorber. In Proceedings of the 2nd International Symposium on Wave Energy Utilization, Trondheim, Norway, 22–24 June 1982; pp. 403–417. [Google Scholar]

- Budal, K.; Falnes, J.; Iversen, L.C.; Lillebekken, P.M.; Oltedal, G.; Hals, T.; Høy, A.S. The Norwegian Wave-Power Buoy Project. 1982. Available online: http://hdl.handle.net/11250/246709 (accessed on 11 November 2019).

- Falnes, J. Wave-energy conversion through relative motion between two single-mode oscillating bodies. J. Offshore Mech. Arct. Eng. 1999, 121, 32–38. [Google Scholar] [CrossRef]

- Beatty, S.J.; Buckham, B.J.; Wild, P. Frequency response tuning for a two-body heaving wave energy converter. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 June 2008. [Google Scholar]

- Available online: https://www.oceanpowertechnologies.com/powerbuoy (accessed on 19 November 2018).

- Baudry, V.; Babarit, A. Assessment of the annual energy production of a heaving wave energy converter sliding on the mast of a fixed offshore wind turbine. In Proceedings of the Renewable Energy Congress XI (WREC XI), Abu Dhabi, UAE, 25–30 September 2010. [Google Scholar]

- Oskamp, J.A.; Özkan-Haller, H.T. Power calculations for a passively tuned point absorber wave energy converter on the Oregon coast. Renew. Energy 2012, 45, 72–77. [Google Scholar] [CrossRef] [Green Version]

- Zanuttigh, B.; Angelelli, E.; Kofoed, J.P. Effects of mooring systems on the performance of a wave activated body energy converter. Renew. Energy 2013, 57, 422–431. [Google Scholar] [CrossRef]

- Sjolte, J.; Bjerke, I.; Tjensvoll, G.; Molinas, M. Summary of performance after one year of operation with the Lifesaver Wave Energy Converter System. In Proceedings of the 10th European Wave and Tidal Energy Conference, Aalborg, Denmark, 2–5 September 2013. [Google Scholar]

- De Andrés, A.D.; Guanche, R.; Vidal, C.; Losada, Í.J. Analysis of the geometric tunability of a WEC from a worldwide perspective. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; p. V09AT09A039. [Google Scholar]

- Previsic, M.; Bedard, R.; Hagerman, G. E2I EPRI Assessment, Offshore Wave Energy Conversion Devices; Technical Report E2I EPRI WP-004-US-Rev 1; Electricity Innovation Institute: PALO ALTO, CA, USA, 2002.

- Kamizuru, Y. Development of Hydrostatic Drive Trains for Wave Energy Converters; Shaker: Herzogenrath, Germany, 2014. [Google Scholar]

- Pecher, A.; Kofoed, J.P.; Larsen, T.; Marchalot, T. Experimental study of the Weptos wave energy converter. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janiero, Brazil, 1–6 July 2012; pp. 525–534. [Google Scholar]

- Skyner, D.J. Solo Duck Linear Analysis; The University of Edinburgh: Edinburgh, UK, 1987. [Google Scholar]

- Babarit, A.; Clément, A.H.; Gilloteaux, J.C. Optimization and time-domain simulation of the SEAREV wave energy converter. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; pp. 703–712. [Google Scholar]

- Folley, M.; Whittaker, T.J.T.; Henry, A. The effect of water depth on the performance of a small surging wave energy converter. Ocean Eng. 2007, 34, 1265–1274. [Google Scholar] [CrossRef]

- Flocard, F.; Finnigan, T.D. Experimental investigation of power capture from pitching point absorbers. In Proceedings of the Eight European Wave and Tidal Energy Conference, Upsalla, Sweden, 7–10 September 2009. [Google Scholar]

- Henry, A.; Doherty, K.; Cameron, L.; Whittaker, T.; Doherty, R. Advances in the design of the Oyster wave energy converter. In Proceedings of the RINA Marine and Offshore Energy Conference, London, UK, 21–23 April 2010. [Google Scholar]

- Pecher, A.; Kofoed, J.P.; Larsen, T. Design specifications for the Hanstholm WEPTOS wave energy converter. Energies 2012, 5, 1001–1017. [Google Scholar] [CrossRef]

- Pecher, A.; Kofoed, J.P.; Larsen, T. The extensive R&D behind the Weptos WEC. Renew. Energ. Offshore 2015, 1, 351. [Google Scholar]

- Kofoed, J.P.; Tetu, A.; Ferri, F.; Margheritini, L.; Sonalier, N.; Larsen, T. Real Sea Testing of a Small Scale Weptos WEC Prototype. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Margheritini, L.; Kofoed, J.P. Weptos Wave Energy Converters to Cover the Energy Needs of a Small Island. Energies 2019, 12, 423. [Google Scholar] [CrossRef] [Green Version]

- Renzi, E.; Dias, F. Resonant behaviour of an oscillating wave energy converter in a channel. J. Fluid Mech. 2012, 701, 482–510. [Google Scholar] [CrossRef] [Green Version]

- Pecher, A.; Kofoed, J.P.; Espedal, J.; Hagberg, S. Results of an experimental study of the langlee wave energy converter. In Proceedings of the Twentieth International Offshore and Polar Engineering Conference, Beijing, China, 20–25 June 2010. [Google Scholar]

- Angelelli, E.; Zanuttigh, B.; Kofoed, J.P.; Glejbøl, K. Experiments on the WavePiston, Wave Energy Converter. In Proceedings of the EWTEC 2011, Southampton University, Southampton, UK, 5–9 September 2011. [Google Scholar]

- Cordonnier, J.; Gorintin, F.; De Cagny, A.; Clément, A.H.; Babarit, A. SEAREV: Case study of the development of a wave energy converter. Renew. Energy 2015, 80, 40–52. [Google Scholar] [CrossRef]

- Evans, D.V.; de O Falcao, A.F. Hydrodynamics of Ocean Wave Energy Utilization; Springer: Berlin, Germany, 1986; pp. 51–55. [Google Scholar]

- Kofoed, J.P.; Frigaard, P.; Friis-Madsen, E.; Sørensen, H.C. Prototype testing of the wave energy converter wave dragon. Renew. Energy 2006, 31, 181–189. [Google Scholar] [CrossRef] [Green Version]

- Margheritini, L.; Vicinanza, D.; Frigaard, P. Hydraulic characteristics of seawave slot-cone generator pilot plant at Kvitsøy (Norway). In Proceedings of the 7th European Wave Tidal Energy Conference, Porto, Portugal, 11–13 September 2007; pp. 1–9. [Google Scholar]

- Margheritini, L.; Vicinanza, D.; Frigaard, P. SSG wave energy converter: Design, reliability and hydraulic performance of an innovative overtopping device. Renew. Energy 2009, 34, 1371–1380. [Google Scholar] [CrossRef]

- Parmeggiani, S.; Chozas, J.F.; Pecher, A.; Friis-Madsen, E.; Sørensen, H.C.; Kofoed, J.P. Performance assessment of the wave dragon wave energy converter based on the EquiMar methodology. In Proceedings of the 9th European Wave and Tidal Energy Conference, Napoli, Italy, 5–9 September 2011. [Google Scholar]

- Pecher, A. Performance Evaluation of Wave Energy Converters. Ph.D. Thesis, Department of Civil Engineering, Aalborg University, Aalborg, Denmark, 2012. Available online: https://vbn.aau.dk/en/publications/performance-evaluation-of-wave-energy-converters-2 (accessed on 11 November 2018).

- Chozas, J.F.; Kofoed, J.P.; Jensen, N.E.H. User Guide—COE Calculation Tool for Wave Energy Converters: Ver. 1.6—April 2014, 1st ed.; DCE Technical Reports, No. 161; Department of Civil Engineering, Aalborg University: Aalborg, Denmark, 2014. [Google Scholar]

- Dalton, G.J.; Alcorn, R.; Lewis, T. A 10 year installation program for wave energy in Ireland: A case study sensitivity analysis on financial returns. Renew. Energy 2012, 40, 80–89. [Google Scholar] [CrossRef]

- Weiss, J.C.; Boehlert, B.B.; Baxter, J.R. Fiscal Cost-Benefit Analysis to Support the Rulemaking Process for 30 CFR 285 Governing Alternative Energy Production and Alternate Uses of Existing Facilities on the Outer Continental Shelf; OCS Study MMS 2007-050; Technical Report; USDOI/MMS, Offshore Environmental Division: Herndon, VA, USA, 2008; p. 101.

- Callaghan, J.; Boud, R. Future Marine Energy. Results of the Marine Energy Challenge: Cost Competitiveness and Growth of Wave and Tidal Stream Energy; Carbon Trust: London, UK, 2006. [Google Scholar]

- Bedard, R.; Hagerman, G.; Siddiqui, O. System Level Design, Performance and Costs for San Francisco California Pelamis Offshore Wave Power Plant; EPRI: San Francisco, CA, USA, 2004. [Google Scholar]

- Allan, G.; Gilmartin, M.; McGregor, P.; Swales, K. Levelised costs of Wave and Tidal energy in the UK: Cost competitiveness and the importance of “banded” Renewables Obligation Certificates. Energy Policy 2011, 39, 23–39. [Google Scholar] [CrossRef]

- De Andres, A.; MacGillivray, A.; Roberts, O.; Guanche, R.; Jeffrey, H. Beyond LCOE: A study of ocean energy technology development and deployment attractiveness. Sustain. Energy Technol. Assess. 2017, 19, 1–16. [Google Scholar] [CrossRef]

- Contestabile, P.; Di Lauro, E.; Buccino, M.; Vicinanza, D. Economic assessment of Overtopping BReakwater for Energy Conversion (OBREC): A case study in Western Australia. Sustainability 2016, 9, 51. [Google Scholar] [CrossRef]

- De Andres, A.; Medina-Lopez, E.; Crooks, D.; Roberts, O.; Jeffrey, H. On the reversed LCOE calculation: Design constraints for wave energy commercialization. Int. J. Mar. Energy 2017, 18, 88–108. [Google Scholar] [CrossRef]

- Frost, C.; Findlay, D.; Macpherson, E.; Sayer, P.; Johanning, L. A model to map levelised cost of energy for wave energy projects. Ocean Eng. 2018, 149, 438–451. [Google Scholar] [CrossRef]

- Castro-Santos, L.; Garcia, G.P.; Estanqueiro, A.; Justino, P.A. The Levelized Cost of Energy (LCOE) of wave energy using GIS based analysis: The case study of Portugal. Int. J. Electr. Power Energy Syst. 2015, 65, 21–25. [Google Scholar] [CrossRef] [Green Version]

- Haces-Fernandez, F.; Li, H.; Ramirez, D. Assessment of the Potential of Energy Extracted from Waves and Wind to Supply Offshore Oil Platforms Operating in the Gulf of Mexico. Energies 2018, 11, 1084. [Google Scholar] [CrossRef] [Green Version]

- Haces-Fernandez, F.; Li, H.; Jin, K. INVESTIGATION INTO THE POSSIBILITY OF EXTRACTING WAVE ENERGY FROM THE TEXAS COAST. Int. J. Energy Clean Environ. 2019, 20, 23–41. [Google Scholar] [CrossRef]

| Test Center | Scale | Wave Resource (kW/m) | Grid Connection | Distance from Shore/Water Depth |

|---|---|---|---|---|

| Danish Marine Test Site (DanWEC), Denmark [42] | Full | 5 | Yes | 200 m/12 m |

| Wave Hub, England [43] | Full | 20 | Yes | 16 km/55–65 m |

| SEM-REV, France [44] | Full | 15 | Yes | 15 km/35 m |

| Atlantic Marine Energy Test site, Ireland [45,46] | Full | * 70–75 ** 55–60 | Yes | * 10 km/100 m ** 6.5 km/50 m |

| Runde Island, Norway [47] | Full | NA | Yes | 500 m/30–35 m |

| Pilot zone, Portugal [48] | Full | 32 | Yes | 5–8 km/30–90 m |

| European Marine Energy Centre (EMEC), Scotland [49] | Full | 22–25 | Yes | 1–2 km/20–75 m |

| Biscay Marine Energy Platform (Bimep), Spain [50] | Full | 21 | Yes | 1.7 km/50–90 m |

| Plocan, Canary Islands, Spain [51] | Full | 8–10 | Yes | 2 km/30–1000 m |

| Nissum Bredning, Denmark [52] | 1:4–1:10 | Hs = 1.2 m | Yes | 200 m/4–10 m |

| The Galway Bay Wave Energy Test Site, Ireland [53] | 1:3–1:5 | 3 | No | 2.4 km/21–24 m |

| European Marine Energy Centre (EMEC), Scotland [49] | 1:10 | Hs ~0.35 m | Yes | 500 m/21–25 m |

| Famouth Bay test site, England [54] | N/A | N/A | No | 3–5 km/20–50 m |

| Pacific Marine Energy Centre USA [55,56] | Full, Large, Small | >15 kW/m | Yes | 16 km/Several meters over 100 m |

| The Hawai‘i Wave Energy Test Site (WETS), USA [57] | Large | N/A | No | N/A |

| Shandong Test Site, China [58] | Large | 4 kW/m | Yes | 30 m |

| Name/Location | Capacity | Comments |

|---|---|---|

| KVAENER/Norway [61,62] | 500 kW (Operation) | N/A |

| Japan [23] | 60 kW | Prototype |

| LIMPET/Scotland [63,64] | 75 kW prototype, * 500 kW operated | * Downgraded to 250 kW later |

| India [24,65] | 150 kW | N/A |

| Pico/Portugal [66,67,68,69] | 400 kW | N/A |

| Australia [70,71] | 450 kW | N/A |

| Mutriku Spain [72,73] | 296 kW | 16 units with 18.5 kW each |

| Mighty Whale [74] | 110 kW | N/A |

| KRISO/South Korea [75] | 500 kW | N/A |

| ID | Scale of Wave Data | Efficiency | Comments |

|---|---|---|---|

| 1 | Laboratory [80,81,82] | Information not available | Simulation and numerical analysis done to verify lab tests |

| 2 | 36 sea states at the Canadian Pacific site [83] | 11.6% | Annual, pre-design analysis including pneumatic, mechanical, and electrical efficiency |

| 3 | Real sea state at Monte Redondo in Chile [84] | (a) * 40.87% (b) ** 24.42% (c) *** 17.9% | * Rectangular cross-section (6.0 m by 12 m) ** Circular cross-section (radius = 7.6 m) *** Circular cross-section (radius = 6.77 m) Only pneumatic efficiency calculated |

| 4 | 14 sea states on the western coast of Portugal [85] | 2% | Simulation + geometric optimization of OWC |

| 5 | Pico Wave site [86,87,88] | * 10% (b) ** 31% [87,88] | * Increase in efficiency by using control valves ** Average annual output vs. rated power of air turbine |

| 6 | Laboratory [89] | N/A | Geometry optimization. Maximum efficiency occurs when the ratio of the cross-sectional areas of the orifice and the air chamber = 0.66 (pneumatic efficiency) |

| 7 | Laboratory [90] | 45% | Pneumatic efficiency |

| 8 | Laboratory [91] | * 71% | Geometry optimization: Bottom profile * Instantaneous peak value at resonance for a circular bottom profile |

| 9 | (a) Sea states @ western coast of Portugal [92] (b) Sea states @ western coast of Portugal [93] | N/A | (a) Shape optimization. Almost sixfold increase in pneumatic efficiency claimed (b) Geometry optimization of device and turbine optimization50% increase in electrical energy |

| 10 | Sea states from Italian coast [94] | * 15% | Turbine optimization * Increase in electrical efficiency |

| ID | Type | Scale | Efficiency | Comments |

|---|---|---|---|---|

| 11 | Spar Buoy [95] | 1:7 (Wave Tank) | N/A | Aimed to use control strategy to increase turbine efficiency |

| 12 | Generic OWC [96] | 1:50 (Wave tank) | ~30% | From pneumatic to mechanical stage |

| 13 | Generic OWC [97] | 1:50 (Wave tank) | * ~30% ** ~7.5% | * Mechanical efficiency ** Electrical efficiency |

| 14 | Mighty Whale [74] | 1:1 Sea trials | * ~5% ** ~15% | * Mechanical efficiency ** Electrical efficiency |

| 15 | Swank DK3 [98] | N/A | 20% | Pneumatic efficiency |

| 16 | Mutriku [72] | 1:40 (Wave tank) | 7% | Pneumatic efficiency |

| 17 | Pico [99] | 1:1 Sea trials | 20% | Pneumatic efficiency |

| 18 | Lanchester Clam [100] | Wave tank | 23% | Pneumatic efficiency |

| ID | Name/Type | Scale | Wave Energy Potential | Efficiency | Comment |

|---|---|---|---|---|---|

| 1 | Single cylindrical body [124] | Simulation | 26 kW/m (Yeu test Site) | (a) 4% (b) 3% (c) 6% (d) 6% (e) 9% | Hydrodynamic efficiency of devices with five different widths |

| 2 | Single cylindrical body [125] | Simulation | 40 kW/m (Oregon site) | 19% | Hydrodynamic efficiency |

| 3 | DEXA WEC [126] | Model scale 1:30 (width 0.81 m) | 26 kW/m (Yeu test Site) | 8% | Model was extrapolated to a device of 22 m width. Hydrodynamic efficiency |

| 4 | Lifesaver [127] | Simulation and ~1-year sea trial | 26 kW/m | 12% | Hydrodynamic efficiency |

| 5 | Multibody system [128] | Simulation | Various | (a) 10% (b) 15% | Hydrodynamic efficiency |

| 6 | Single cylindrical body [11] | Simulation | 34 kW/m | 16% | Hydrodynamic efficiency |

| 7 | Single body [98] | Model tests | 16 kW/m | 14% | Hydrodynamic efficiency |

| 8 | Danish Wave Energy Program System [98] | Model tests | 16 kW/m | 30% | Hydrodynamic efficiency |

| 9 | AquaBuoy [129] | Simulation of prototype sized | * 12 kW/m, ** 21 kW/m *** 26 kW/m **** 15 kW/m | * (a) 20% ** (b) 17% *** (c) 14% **** (d) 21% | Hydrodynamic efficiency |

| 10 | SeaDog [127] | Simulation of prototype sized | * 12 kW/m, ** 21 kW/m *** 26 kW/m **** 15 kW/m | * (a) 24% * (b) 16% *** (c) 16% **** (d) 21% | Hydrodynamic efficiency |

| 11 | Wavebob [129] | Simulation of prototype sized | * 12 kW/m, ** 21 kW/m *** 26 kW/m **** 15 kW/m | * (a) 40% ** (b) 51% *** (c) 46% **** (d) 45% | N/A |

| 12 | Two-body floating System [29] | Simulation | * 15 kW/m, ** 22 kW/m *** 27 kW/m **** 37 kW/m | * (a) 27% ** (b) 29% *** (c) 36% **** (d) 27% | Hydrodynamic efficiency |

| 13 | Floating buoy array [29] | Simulation | 15 | 11% | Hydrodynamic efficiency |

| 14 | Two-body floating buoy [130] | Simulation | 31 | 25% | Hydrodynamic efficiency |

| ID | Name/Type | Scale | Wave Energy Potential | Efficiency | Comment |

|---|---|---|---|---|---|

| 1 | Salter’s Duck [132] | Full-scale experiments and simulation | * 16 kW/m ** 23 kW/m *** 27 kW/m **** 38 kW/m | (a) * 65% (b) ** 75% (c) *** 79% (d) ****68% | Analysis performed with optimal and reactive control of the device Width of device is 30 m |

| 2 | Top Hinged Flap [134] | Full-scale simulation | 25 | 25% | Width of device is 12 m |

| 3 | Biopower [135] | Full-scale simulation | * 10 kW/m ** 67 kW/m | Average 45% | * Summer resource potential ** Winter resource potential Width of device is 6.6 m |

| 4 | Based on Oyster [136] | Wave tank | NA | 35%–65% | Width of device is 6 m–24 m |

| 5 | Weptos [131,137,138] | Various | 6–29 kW/m (Different test sites) | 12%–32% | Width ranged from 2.9 m–9.6 m (development program of the Weptos WEC from lab testing, prototype testing to sea trials |

| 6 | Offshore 1 (Weptos) [139] | Sea trials | Up to 57% | Efficiency achieved when period is about 2 s | |

| 7 | Weptos [140] | Simulations | 4.38 kW/m | 50%–57% | Efficiency when period is 2.9–3.4 s. 10 rotors/side Active width = 30 m, I rotor = 3 m width |

| 8 | Variant of Oyster [141] | Simulations | 26 kW/m | (a) * 22% (b) ** 40% (c) *** 15% | * Width 6 m ** Width 12 m *** Width 18 m |

| 9 | Pelamis [48] | Simulation, experiments, and simulations | * 12 kW/m ** 21 kW/m *** 26 kW/m **** 15 kW/m | (a) * 21% (b) ** 15% (c) *** 14% (d) **** 18% | Reports from various experiments, tests, etc. |

| 10 | Langlee Technology [142] | Lab experiments | 16 kW/m | (a) * 7% (b) ** 9% | * 25 m width ** 37.5 m width |

| 11 | Wave Piston [143] | Simulation | * 12 kW/m ** 3.5 kW/m | (a) * 8% (b) ** 15% | |

| 12 | SEAREV [144] | Simulation | 25 kW/m | (a) * 20% (b) ** 16% (c) *** 25% | * 13.6 m width ** 30 m width *** 30 m width |

| ID | Name/Type | Scale | Wave Energy Potential | Efficiency | Comment |

|---|---|---|---|---|---|

| 1 | Sea Wave Slope Cone Generator (SSG) [147] | Experimental (1/60) of original | 19.5 kW/m | 23% | * Experiments modeled for a field scale of 10 m opening width |

| 2 | Wavedragon [148] | Sea trial and simulation | * 6 kW/m ** 24 kW/m | (a) * 27% (b) ** 18% | * width of device is 65 m ** width of device is 97 m |

| 3 | Bolgehovlen [149] | Prototype scale | 16 kW/m | 8% | 10 m width |

| 4 | Wavedragon [98] | Prototype scale | * 16 kW/m ** 12 kW/m *** 21 kW/m **** 26 kW/m ***** 15 kW/m | (a) * 23% (b) ** 26% (c) *** 23% (d) **** 21% (e) ***** 22% | Width 300 m |

| 5 | Power Pyramid [98] | 16 kW/m | 3% | 125 m width | |

| 6 | Sucking Sea Shaft [98] | 16 kW/m | 12% | 125 m width |

| PTO Type | Efficiency (%) |

|---|---|

| Hydraulic | 65 |

| Water | 85 |

| Air turbines | 55 |

| Mechanical drive | 90 |

| Direct drive linear generator | 95 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aderinto, T.; Li, H. Review on Power Performance and Efficiency of Wave Energy Converters. Energies 2019, 12, 4329. https://doi.org/10.3390/en12224329

Aderinto T, Li H. Review on Power Performance and Efficiency of Wave Energy Converters. Energies. 2019; 12(22):4329. https://doi.org/10.3390/en12224329

Chicago/Turabian StyleAderinto, Tunde, and Hua Li. 2019. "Review on Power Performance and Efficiency of Wave Energy Converters" Energies 12, no. 22: 4329. https://doi.org/10.3390/en12224329