2.1. Overviews

In general, linear synchronous motor propulsion systems (LSMPSs) include two sub-systems: one is the LSM and the other is the propulsion power supply system (PPSS). As shown in

Figure 1, the LSMs are composed of DC fields and multi-phase armatures while the PPSSs consist of pulse width modulation (PWM) converters, variable-voltage variable-frequency (VVVF) inverters, section switches, and sub-sonic light detection and ranging (LiDAR) sensors for the synchronization between the on-board DC fields and armatures.

In fact, there are two choices for system engineers: to adopt or eliminate the armatures between arrival and departure in the proposed LSMPSs. This is because EDSs with HTS magnets for levitation result in low magnetic resistance forces of below 2 kN; therefore, the pods are outside of the departure region in which armatures are not installed, and so pods can be continuously operated as there is a small decrease in velocity. However, at the same time, the pods are completely out of the control of the control tower, in the same way as a bullet. On the other hand, when armatures are installed for the entire region, the pods are always under control, but the construction cost will be further increased. Depending on the installation location of the armature between the pod and ground, there are two types of LSMs: short and long-armature LSMs. Short-armature LSMs can be free from the complexities of PPSSs [

19]. At the same time, on the other hand, pods should not only have an on-board PPSS, which increases the weight of pods a great deal, but also contact-power transfer systems from the ground infrastructure to pods. In fact, the contact—i.e., pantograph—power transfer systems have a speed limit below 600 km/h [

20] due to the arc problem. On the other hand, contactless-power transfers—i.e., capacitive and inductive power transfer—could be one of the strong candidates to mitigate the problem.

Therefore, in order to achieve a sub-sonic velocity for the Hyperloop, the long-armature LSMs, which have double-sided long-armature windings in the sub-vacuum tubes, and DC fields on pods, as shown in

Figure 2a, would be the best choice at the moment. This is because the required power of the PPSSs can be directly supplied from a public power system regardless of its operating velocity. With the concept of long-armature LSMs, high-temperature superconducting (HTS) magnets installed on pods are adopted for the proposed sub-sonic LSM as the DC fields to maximize the air-gap between pods and armatures and to achieve the optimal design of LSMs and PPSS for the Hyperloop [

20,

21].

In addition, among the various types of LSMs with HTS magnets, the three-phase, double-layer, and concentrated winding method are adopted for the highly efficient design of armatures [

22] and their mass production in the future, while air-cores are chosen to avoid magnetic saturation and unwanted forces on pods due to the high magnetic fluxes generated by HTS magnets [

20,

21], as shown in

Figure 2b.

2.2. Analysis of Linear Synchronous Motors with HTS Magnets

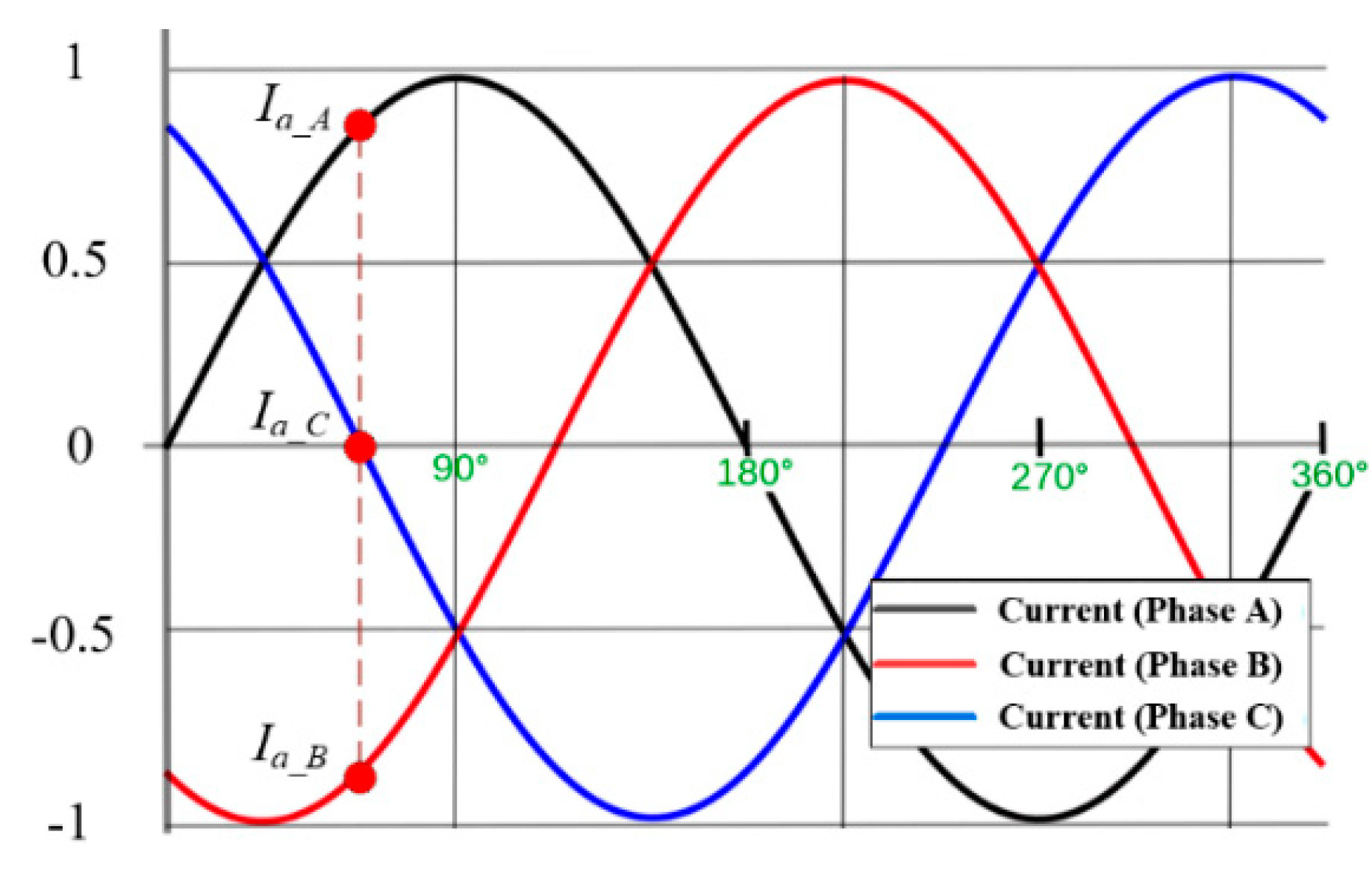

When three-phase armature windings are perfectly aligned and synchronized with DC field windings—i.e., with a power angle of 90°—each phase of the armature windings generates the maximum thrust forces, with the second harmonics of its operating frequency fs on pods with a 120° phase shift, while the sum of the thrust forces results in a total force including its sixth harmonics, as shown in

Figure 3a. At the same time, each phase of the armature windings evenly generates guidance forces, and their sum then goes to zero with the same sixth harmonics, as shown in

Figure 3b.

Simply, assuming

lf =

la and

wf =

wa, the generated maximum forces

Fmax on pods can be described as follows:

where

c is the design constant including winding and geometric factors,

is the permeability of free space,

ma is the number of phases,

pe is the number of field pole pairs,

is the pole pitch,

is the gap constant,

g is the air-gap,

lf and

wf are the effective length and width of field windings,

Na and

Nf are the number of coil turns per phase for armature and DC field windings, and

Ia and

If are the current of armature and DC field windings, respectively. In

Figure 4,

la and

wa show the effective length and width of armature windings, and

gc is the center difference between field and armature windings.

From Equation (1), the thrust force

Ft and guidance force

Fg can be obtained as follows:

where

is the power angle. In order to achieve the most efficient operation of the proposed LSMs, the largest

Ft and the smallest

Fg can be guaranteed when

is maintained near 90°. For this issue, the real-time location measurement of pods with high-resolutions is a significant technological requirement; therefore, sub-sonic LiDAR sensors are newly adopted for the Hyperloop using the proposed LSMs.

In the case when

increases from 90°, the thrust forces gradually decrease while repulsive forces significantly increase, as shown in

Figure 5. On the other hand, when

decreases from 90°, thrust forces decrease as attractive forces significantly increase. Therefore, in terms of the dynamic stability of pods,

should be controlled above 90° to avoid unwanted physical contacts between pods and armatures at a sub-sonic velocity, as these could lead to massive accidents. As shown in

Figure 6, each phase of armatures with the DC fields can be simplified as the ideal voltage source, controlled voltage source, controlled current source, inductor and resistance as follows:

where

VT is the stator voltage for each phase,

Ra and

La are the total resistance and inductance of armature windings for each phase, respectively,

Np is the number of armature poles for each phase,

Rpa and

Lpa are the resistance and inductance of each pole of armature windings,

Ei is the induced voltage generated by moving pods with DC fields on each phase of armature windings,

ci is the induced voltage constant, vs. is the speed of pods, and

is the magnetic flux passing through the armature windings.

At the same time, the mechanical force

Fm, which is the same as thrust force

Ft, total resistance forces

Fr, and effective thrust forces

Ff are included in the simplified equivalent circuits and can be summarized as follows:

where

Fa is the aerodynamic resistance force,

Fd is the electrodynamic resistance force,

Fi is the incline resistance force, and

ms and

as are the mass and acceleration of pods. In general, for the LSM design of the Hyperloop,

Fr can be simplified as

Fm because the Hyperloop is supposed to be operated in flat sub-vacuum tubes resulting in the significant decrease of

Fa and

Fi. Due to conductive and ferromagnetic materials being used in guideways and tubes as well as electrodynamic levitations, on the other hand, finding the optimal design approach to reducing the electrodynamic resistance force should be one of the main research issues for efficient sub-sonic linear motors.

Next, the electrical power

Pe and mechanical power

Pm can be simply defined as follows:

where

γ is the phase difference between the induced voltage and armature phase current.

The electrical parameters of LSMs can be summarized in the phase diagram, as shown in

Figure 7, while power equations can be also obtained from the phase diagram as follows:

where

P is the active power including electrical DC and AC losses and mechanical propulsion power,

Q is the reactive power mainly coming from the inductance of armature windings, and

S is the complex power, which is equal to the capacity of LSMs as well as inverters.