Abstract

The rapid proliferation of the ‘Internet of Things’ (IoT) now affords the opportunity to schedule the operation of widely distributed domestic refrigerator and freezers to collectively improve energy efficiency and reduce peak power consumption on the electrical grid. To accomplish this, the paper proposes the real-time estimation of the thermal mass of each refrigerator in a network using on-line parameter identification, and the co-ordinated (ON-OFF) scheduling of the refrigerator compressors to maintain their respective temperatures within specified hysteresis bands commensurate with accommodating food safety standards. A custom model predictive control (MPC) scheme is devised using binary quadratic programming to realize the scheduling methodology which is implemented through IoT hardware (based on a NodeMCU). Benefits afforded by the proposed scheme are investigated through experimental trials which show that the co-ordinated operation of domestic refrigerators can i) reduce the peak power consumption as seen from the perspective of the electrical power grid (i.e., peak load levelling), ii) can adaptively control the temperature hysteresis band of individual refrigerators to increase operational efficiency, and iii) contribute to a widely distributed aggregated load shed for demand side response purposes in order to aid grid stability. Importantly, the number of compressor starts per hour for each refrigerator is also bounded as an inherent design feature of the algorithm so as not to operationally overstress the compressors and reduce their lifetime. Experimental trials show that such co-ordinated operation of refrigerators can reduce energy consumption by ~30% whilst also providing peak load levelling, thereby affording benefits to both individual consumers as well as electrical network suppliers.

1. Introduction

Large populations of thermostatically controlled loads (TCLs) hold significant potential for performing ancillary services in power systems since they are well-established and widely distributed around the power network. In the domestic sector, refrigerators and freezers collectively constitute a very large electrical load since they are continuously connected and are present in almost all households. In 2018 for instance, the total demand for electricity in the UK was 334 TWh over the year, with domestic energy consumption accounting for 31.7% of the total [1,2]. It is estimated that there are around 50 million refrigerators in the UK alone with an annual energy consumption approaching 18 TWh/year [3]. Notably, the UK consumes ~1/69th of the total electrical power generated globally, and ~1/36th of the electricity globally consumed for refrigeration and freezing [4,5].

Following one of the first studies on modelling and control of TCLs in the 1980s [6,7], a number of more recent investigations have set out to model refrigerator populations, with authors developing models for large aggregated networks of TCLs and the impact of cooling appliances on the grid frequency. In reference [8], the thermal storage of domestic refrigerators is used to facilitate improved power balancing, whilst [9,10,11,12] propose a decentralized stochastic controller for the aggregated use of refrigerators to respond to mains frequency fluctuations. The use of food retailing refrigeration systems for a large supermarket chain to contribute to firm frequency response (FFR) and demand side response (DSR) is presented in [13]. The authors show the beneficial impact of responding to a DSR event on the temperature profiles of the refrigerators and the active power consumed by the compressors. In particular, it is shown that using refrigerators to respond to DSR events can actually provide greater overall efficiency since the refrigerators operate in more efficient regions of their operating envelope. In [14], large-scale control of domestic refrigerators is used to reduce peak power demand and reduce losses in a power distribution system. The proposed strategy considers the refrigerator’s thermal characteristics and incorporates models of door opening and food insertion. In [15], three experimental fuzzy logic control systems for a single domestic refrigerator are used to investigate its thermal and energy characteristics, whilst taking into consideration the frequency and duration of door opening. The fuzzy system controls the speed of the compressor in order to reduce energy consumption while keeping the temperature as close as possible to desired temperature boundaries.

Recent trends in the scheduling and control of TCLs show that model predictive control (MPC) is implemented in various domestic applications. It provides a control approach that determines optimal actuation inputs based on a model of known system dynamics, with ‘forward looking’ predictions of behaviour and the ability to inherently incorporate constraints and accommodate exogenous disturbances. A further advantage of MPC is given by its ease of reconfiguration and adaptability to changes in the control system. With the development of the ‘Internet of Things’ (IoT) and cloud computing, MPC is increasingly applied to building management and energy systems [16]. In [17], the use of MPC showed improved heating and energy savings in an old residential building, whilst [16] reports on the efficacy of various existing MPC algorithms for heating ventilation and air conditioning systems. In [18], a model predictive controller is developed for a domestic freezer, whilst the work in [19] develops a grey-box model for a domestic freezer and applies MPC to control its power consumption as a demand side management (DSM) application. Finally, a novel non-parametric adaptive MPC scheme for domestic refrigerators is proposed in [20], which reacts to hourly pricing DSM programs and facilitates a decrease in energy consumption during the peak periods.

The research presented in this paper is sub-divided into two main parts. The first provides a real-time recursive based system identification strategy to monitor and estimate the internal temperature of individual domestic refrigerators based on their internal thermal mass (product). This is ultimately used to adaptively modify the hysteresis temperature bounds of individual refrigerators, and in so doing, show that significant overall energy savings can be obtained. An important feature is that the proposed model has an ability to accommodate uncertain events, e.g., ambient conditions, opening and closing the door and changes in product mass. The second part of the paper proposes the use of a new, custom MPC control scheme for jointly scheduling the operation of multiple refrigerators. The effectiveness of the scheduling approach is analysed through experimental trials on a suite of common domestic refrigerators, and is shown to facilitate peak load levelling that can aid grid stability. Of notable importance is the formulation of life-time indices as part of the MPC strategy to accommodate a maximum number of compressor starts per hour as part of the scheduling to avoid too frequent on/off switching events. Moreover, when power consumption is beyond what can be reasonably supplied to support the cooling of all the refrigerators in the network, the proposed MPC formulation allows for the prioritization of power distribution to ‘preferred’ units.

2. Real-Time Identification of Refrigerator Dynamics

The realization of an MPC algorithm requires an underlying model of the controlled system. Since the dynamics of refrigerators change with ambient conditions, opening and closing of the door and changes in product thermal mass, an adaptive model is desirable. Here, the authors use an online recursive identification algorithm that captures the predominant dynamics and disturbance patterns of the refrigerator based on that proposed in [21]. The model (1) is widely used in the refrigerator control literature, including [8,9,10,11,18,22,23,24]:

where T(t) is the estimated internal temperature of the refrigerator at the time t. Parameter P(t) denotes the electrical power required during the last time interval, and is dependent on whether the compressor is turned on or off; is the state of device at time t (a binary ON (1) /OFF (0)); Ac is the overall thermal insulation (W/°C); ɳ is the coefficient of performance; mc is the thermal mass (J/°C); and is the sample time between t − 1 and t. Tamb(t) describes the ambient temperature at time t. To simplify notation, the following model (2) is used, where a represents the thermal characteristics of refrigerator inner temperature, b the impact of the energy transfers from the compressor due to the operation of the system, and c the impact of ambient temperature.

This can be reduced to the more compact notation:

where:

Subsequently, is obtained using the traditional recursive least squares (RLS) algorithm [25]:

3. Experimental System Identification

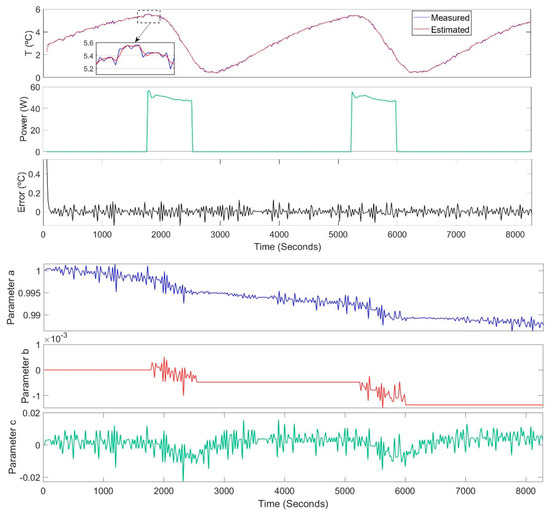

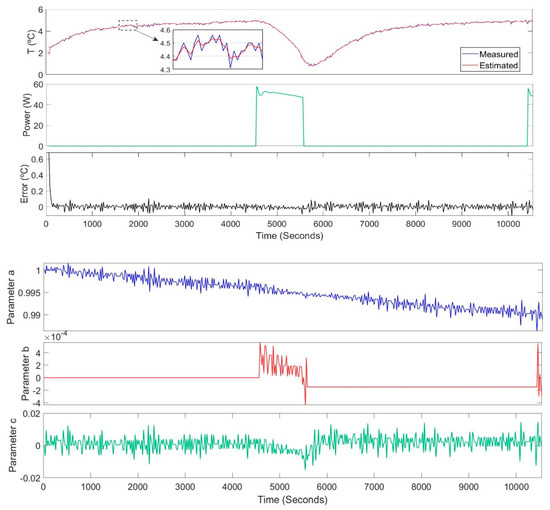

To show the efficacy of the parameter estimation algorithm, trials are initially undertaken on a single VonShef 13/291 (50 W) refrigerator. The refrigerator is instrumented with a DS18B20 waterproof sensor and a TMP102 module to monitor, respectively, the internal refrigeration temperature T and ambient temperature . A fixed sampling period of 20 s is used. Experimental measurements are taken to identify parameters when the refrigerator is both empty and when it contains product (six litres of water in this instance). The results are presented in Figure 1 and Figure 2 for each condition, respectively. It can be seen that the estimation of temperature rapidly converges to the correct value (due to the recursive optimization of model parameters) and the errors become negligible (<0.1 °C) in steady state. Notably, when employing RLS in this way, b responds to observations from the power usage of the compressor. When the compressor is in the OFF state, b remains constant, and when the compressor is in the ON state, b is allowed to dynamically adapt.

Figure 1.

Internal temperature and parameter estimation without product (empty).

Figure 2.

Internal refrigerator temperature and parameter estimation with additional product (6 L water).

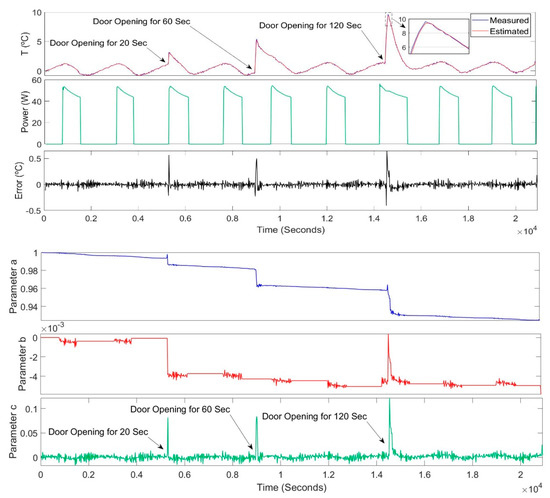

Figure 3 presents parameter identification results when the VonShef refrigerator is subject to three door-opening and -closing events that induce transient disturbances. The first event lasts for 20 s (one sample time), the second for 60 s and the third for 120 s. It can be seen that parameter tracking remains robust to the induced disturbances and very good temperature tracking performance is maintained.

Figure 3.

Internal temperature and parameter estimation with three different door opening events.

Figure 3 also shows how parameter c responds to the door opening events by recognizing the impact of exposure to the ambient temperature i.e., the internal temperature rises, and hence so does parameter c, and the time span of the change is reflected by how long the door was open—for instance, the rise in c for the 120 s door opening case is greater than of the 60 s door opening scenario, etc.

4. Load Levelling by the Scheduled Operation of Multi-Refrigerator Systems

A model predictive scheduling control scheme is used to control a set of domestic refrigerators [26]. A state space model of the refrigerator network with r inputs and n outputs is given in (9), where the parameters are obtained from the online identification process given previously.

where is the state vector, input vector ( and Tamb(t) are considered as input variables), system matrix, input matrix, the estimated fridge temperature, output matrix and where the t denotes discrete time quantities:

The proposed general form of the optimization model for controlling the aggregated refrigerators uses a binary quadratic cost function (J):

Refrigerator i operational constraint,

where N1 and N2 are the minimum and maximum prediction horizons and Nu is the control horizon. Weighting factors for predicted error and control increments are R(j) and Q(j), respectively. The parameter specifies the internal temperature references for each refrigerator which should be kept within upper and lower bounds, i is the refrigerator’s identifier and is a set of indices in the scheduling horizon. Constraint (12) ensures that maximum power consumption at a given time () does not exceed a specified value and constraints (13) and (14) ensure the minimum off-time (minoff) and minimum on-time (minon) per cycle for each refrigerator, respectively. This is an important consideration as it allows the number of compressor starts per hour to be bounded so that the scheduling algorithm does not detrimentally overstress any of the refrigerator compressors and reduce operational lifetime. The solution to the optimization problem to minimize J and calculate follows that provided in [27]. In the following, the parameters used in the MPC are N1 = 1, N2 = 5 and Nu = 5.

5. Experimental Results

The custom MPC algorithm is implemented with a sampling rate of 20 s and experimental trials are undertaken over a period of 210 min in each case, as follows:

- Refrigerators operate in isolation without any scheduling controller. This aligns with the normal operating conditions of domestic refrigerators and provides a comparative benchmark.

- is limited to 110 W: the maximum aggregated power for all refrigerators is constrained and all refrigerators are given equal supply priority weightings.

- is limited to 60 W and all refrigerators are given equal supply priority weightings.

- is limited to 60 W and the refrigerators are given unequal supply priority weightings.

For consistency, the ambient temperature is controlled to be within the range 23 °C ± 1 °C since it is known that this can have a significant influence on energy consumption [28,29].

5.1. Experimental Setup

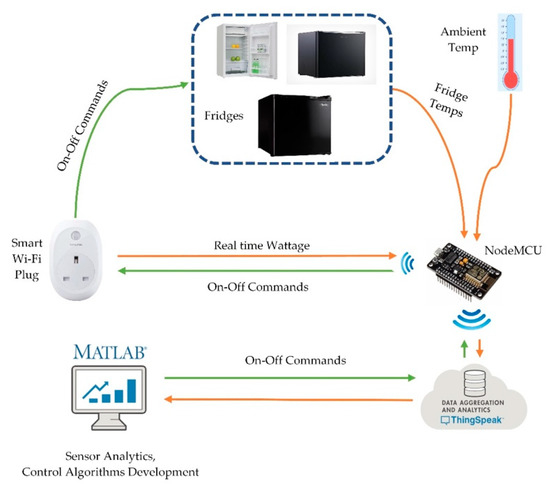

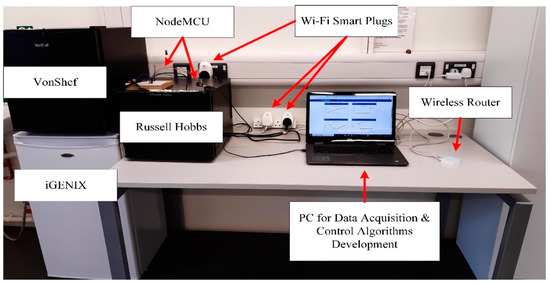

The laboratory-based test facility is shown in Figure 4 and includes a NodeMCU microcontroller to implement the MPC and an IoT smart plug based platform to provide ON-OFF control of the iGENIX IG 3920 (55 W), VonShef 13/291 (50 W) and the Russell Hobbs RHCLRF17B (50 W) domestic refrigerators (each refrigerator is controlled via its own smart plug). It is important to note that the RHCLRF17B uses thermoelectric cooling technology, so no refrigerant is used. Consequently, no compressor is required, and the unit normally operates at 100% duty (i.e., always ON) [30]. Internal and ambient temperatures are measured using a DS18B20 waterproof sensors and a TMP102 module, respectively. The test facility components and hardware setup can be found in Appendix A. The iGENIX, VonShef and Russell Hobbs refrigerators are unevenly loaded with 10 L, 6 L and 2 L of water, respectively, and the doors remained closed for the duration of the trials.

Figure 4.

Experimental setup.

Desired upper and lower temperature setpoints and minimum off and on times per cycle for each refrigerator are shown in Table 1.

Table 1.

Data for iGENIX, VonShef and Russell Hobbs.

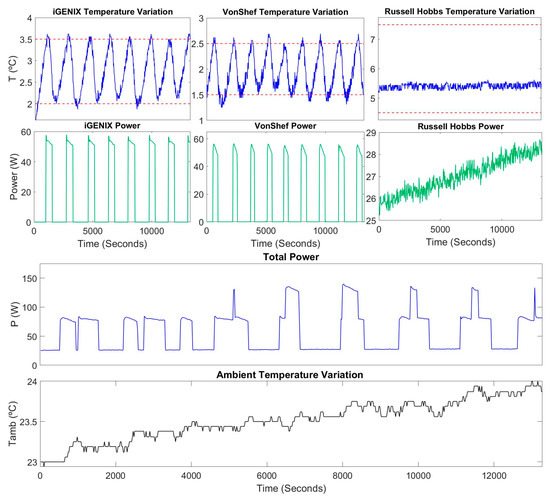

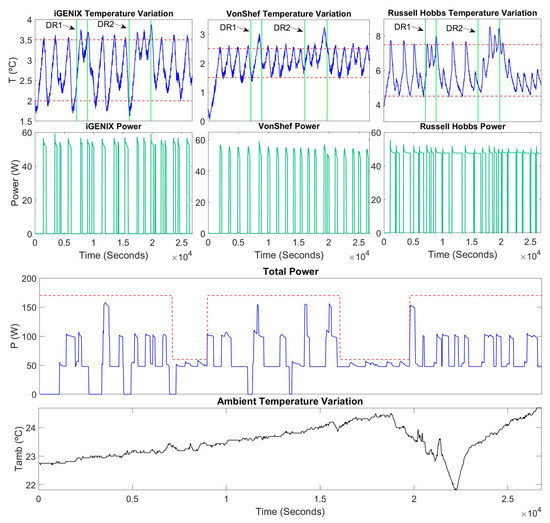

5.2. Trial A: Refrigerators Operate in Isolation without A Scheduling MPC Controller

This initial trial investigates how the refrigerators operate with no co-ordinated MPC scheduling applied. This effectively mimics how each would operate in a normal isolated domestic setting, and the aggregated power characteristic that would be obtained. Figure 5 shows each refrigerator’s internal temperature, the ambient temperature, individual power consumption and the total aggregated power consumption. The hysteresis controller described in [31] is used to adjust the upper and lower temperature setpoints for the VonShef and iGENIX units, whilst the Russell Hobbs unit employs thermoelectric cooling technology and, as such, it nominally has a 100% operational duty (not ON-OFF) with variable power usage, as can be seen from Figure 5. Of particular note from Figure 5 is that without any constraints or co-ordinated (scheduling) control, there are significant periods when all units are ON, and periods of relatively high peak power consumption are therefore evident.

Figure 5.

The refrigerators’ results and total power consumption for trial A.

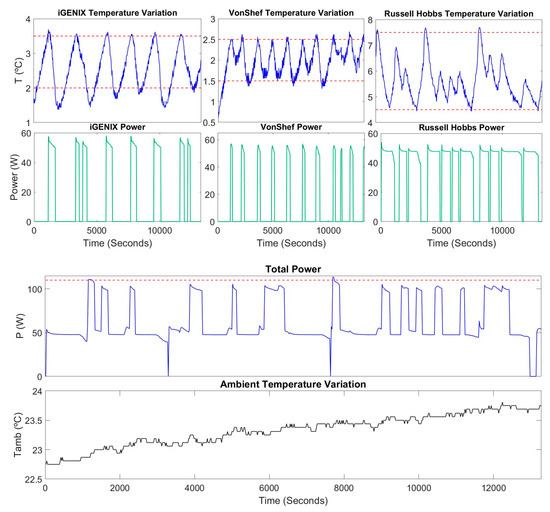

5.3. Trial B: MPC Scheduling with and Equal Supply Priority Is Given to All Refrigerators

Figure 6 shows results of a trial under the condition of Pmax = 110 W, effectively limiting the MPC algorithm to supplying power to a maximum of 2 refrigerators at any instant. In this case, the supply priority weightings are chosen to be equal with Q = [1,1,1] and R = [1, 1 1]. From the results of Figure 6, it is clear that all of the refrigerators can maintain their temperatures within required bounds, and demonstrates that although the peak power has been constrained, there remains sufficient power overhead to supply the cooling requirements of each unit.

Figure 6.

The refrigerators’ results and total power consumption for trial B.

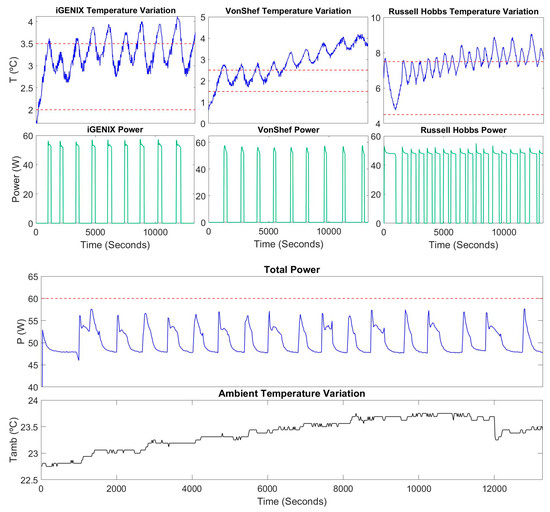

5.4. Trial C: MPC Scheduling with and Equal Supply Priority Given to All Refrigerators

Since there will always exist a minimum average power necessary to control the internal temperatures of all the refrigerators, it is instructive to investigate what happens when the demanded constraint on peak power () is reduced to a value that is below what is required for all the refrigerators to adequately cool their product. For this scenario, is now reduced to 60 W, effectively constraining the MPC to allow power delivery to allow only a single refrigerator at any instant, constituting a very severe power constraint for this refrigerator network. Again, the supply priority weighting matrices are chosen to be Q = [1,1,1] and R = [1, 1 1]. From the results of Figure 7 it can be seen that the temperatures now exceed the desired bounds due to the severe power constraint, although the temperature of the iGENIX unit is less affected as a result of its higher thermal product mass (10 L of water), and hence it takes longer for the temperature to rise and exceed the bounds. Nevertheless, it is clear from the results that the MPC controller still constrains the power to <60 W i.e., forces peak load levelling.

Figure 7.

Refrigerator’s internal temperature, ambient temperature, power consumption and total power consumption for trial C.

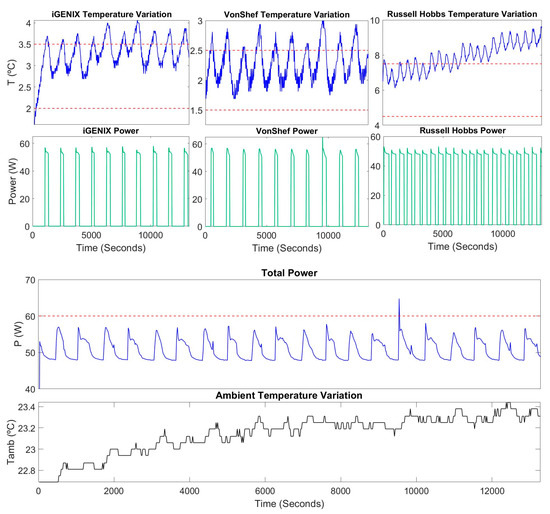

5.5. Trial D: MPC Scheduling with and Power Preferentially Delivered to the VonShef Unit

Finally, under conditions where is again limited so that it does not allow all refrigerators to maintain their temperature with required bounds (as in test trial C), the proposed MPC algorithm can readily accommodate preferred priority scheduling where the refrigerators can be allowed power preferentially. To show this, a trial similar to C) is conducted with Pmax = 60 W but with the priority biased towards delivering power to the VonShef unit i.e., in this case the weighting matrices are chosen to be Q = [1,2,1] and R = [1, 1 1]. Figure 8 shows the results of the experimental trial. A comparison with those from trial C shows that the Russell Hobbs refrigerator exceeds its bounds more rapidly, whilst the VonShef unit is given preferential power to better maintain its temperature (cf. Figure 7), albeit it still exceeds it bounds periodically due to the extremely severe power limitation.

Figure 8.

The refrigerators’ internal temperature, ambient temperature, power consumption and total power consumption for trial D.

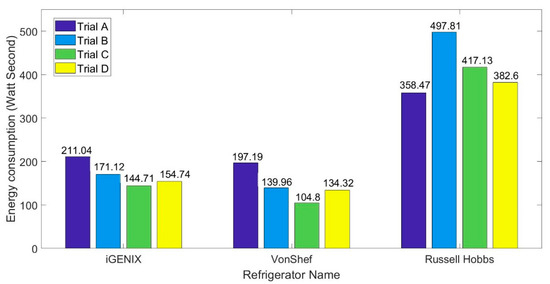

5.6. Comparison of Energy Consumption

The energy consumption during each of the trials has been measured and summarised in Figure 9. It can be seen that in trial D, the VonShef unit consumed 29.52 Watt-seconds more energy and Russel Hobbs 34.53 Watt-seconds less energy compared to trial C. This is due to the higher priority weightings for the VonShef unit in D. In trial B, iGENIX and VonShef have energy savings of up to 19% and 29%, respectively compared to trial A, though in both A and B, all of the refrigerators remain within the required temperature bounds. In contrast, Russell Hobbs consumed more energy in B compared to A because it uses thermoelectric technology instead of a compressor and therefore loses stored thermal energy more rapidly, and hence is turned ON more. Moreover, the Russell Hobbs unit operates at around 27 W in isolated mode, but this power usage reaches 50 W when the MPC controller schedules its operation. These results indicate that in addition to facilitating peak load levelling, operational energy savings can be accrued in compressor-based refrigerators.

Figure 9.

The refrigerators’ energy consumption for Scenario A, B, C and D.

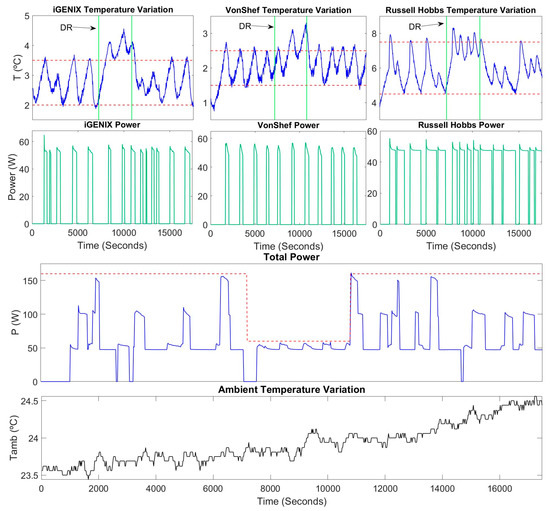

6. Domestic Refrigerators and Demand Side Response (DSR)

The advent and proliferation of IoT will ultimately allow the aggregation of widely distributed networks of domestic appliances, such as refrigerators and freezers, to take part in demand side response (DSR) load-shedding events to help maintain grid frequency stability. Indeed, the advantages of using widely distributed networks of retail refrigerators to contribute to DSR events has already been recognized and reported in [13,32]. Here then, an experimental study investigates how domestic refrigerators can respond to DSR events using the presented MPC methodology. Specifically, results stemming from the initiation of two DSR events for the small network of refrigerators used in this study are given in Figure 10, where each refrigerator unit is given equal supply priority weighting on power, and load shedding is initiated by instantaneously reducing Pmax to 60 W. The first event occurs at t = 7140 s and lasts for 30 min and the second occurs at t = 16,060 s and lasts for one hour. Moreover, Figure 11 shows a similar condition with a DSR demanded at t = 7200 s and ending at t = 10,780 s but where the Russell Hobbs unit is given preferential access to power through the weighting matrices Q = [1,1,3] and R = [1, 1 1]. As can be seen from the measurements of Figure 10 and Figure 11, the refrigerators are able to respond instantly to power shedding events, and the total power usage has been reduced to 60 W when required. In addition, from Figure 11 it can be seen that the Russell Hobbs unit largely remains within the temperature limits due to the additional priority bias given to it by the MPC. Although only on a very small scale, this demonstrates the potential for the co-ordinated scheduling of widely distributed domestic refrigerators for contributing to aggregated load shedding events.

Figure 10.

Results for a demand side response (DSR) event with equal priority weighting given to all units.

Figure 11.

Results for DSR event (Russell Hobbs unit is given greater priority weighting).

7. Impact of Hysteresis Band and Internal Thermal Mass on Refrigerator Operational Efficiency

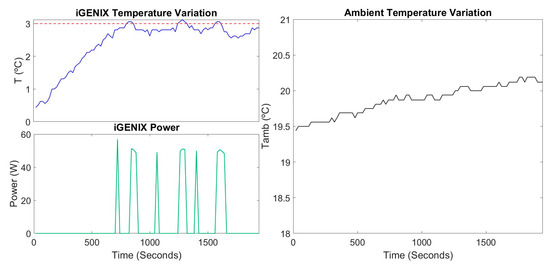

As well as contributing to the co-ordinated operation of multiple refrigerators, the proposed MPC algorithm also allows for reductions in energy consumption of individual refrigerator units by virtue of being able to adaptively change the temperature hysteresis boundaries in real-time. It is shown below that knowledge of the underlying dynamics of each refrigerator from its identified parameters (an integral part of the MPC) allows the hysteresis bands to be tailored to how much product is contained within the refrigerator. The benefits afforded by this are shown through experimental trials on the candidate iGENIX unit. Initially, an experimental trial is undertaken with the temperature-controlled hysteresis band set to ±0 °C i.e., effectively mimicking a non-hysteresis type control scheme. The results are given in Figure 12, which shows a high degree of compressor switching activity to try and maintain perfect temperature tracking.

Figure 12.

Internal temperature and power variation with ±0 °C hysteresis band.

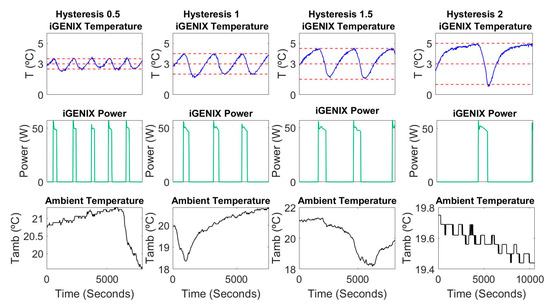

Two additional trials are then undertaken with i) no product in the refrigerator, and ii) with 10L of water in the refrigerator. Operation of the refrigerator using different hysteresis bands is investigated under the two scenarios. Specifically, hysteresis bands of ±0.5 °C, ±1 °C, ±1.5 °C and ±2 °C are used in each case. The results are shown in Figure 13 and Figure 14. Notably, it can be seen that smaller hysteresis bands create more compressor ON-OFF events in both cases. Moreover, the empty condition requires a greater number of compressor starts than when there is product in the refrigerator, due to the availability of increased thermal mass in the latter case. For commercial compressors the number of starts per hour are typically assumed to be ≤6 [33,34], and this is the value used in the MPC algorithm.

Figure 13.

Internal temperature, ambient temperature and consumed power for hysteresis bands of ±0.5 °C, ±1 °C, ±1.5 °C and ±2 °C without internal product (refrigerator empty).

Figure 14.

Internal temperature, ambient temperature and consumed power for hysteresis bands of ±0.5 °C, ±1 °C, ±1.5 °C and ±2 °C with internal product consisting of 10 L of water.

Of particular interest is the amount of energy consumed by the refrigerators when different hysteresis bands are employed. For the cases considered, Figure 15 shows the energy usage of each case projected over 1 year of usage. The results indicate that with appropriate real-time adaptive identification and control the hysteresis band can be changed to accommodate varying product, and hence improve the long-term energy consumption. For instance, in the two scenarios identified, energy savings of up to 20% and 10%, respectively, can be expected between best and worst case conditions. Notably, increasing the product’s thermal mass has the impact of making the refrigerator less sensitive to the imposed hysteresis band.

Figure 15.

Projected annual energy consumption for different hysteresis bands (empty and including internal product (10 L of water)).

8. Conclusions

The research presented in the paper has proposed a time-varying priority-based on/off scheduling algorithm that can effectively schedule networks of widely distributed refrigerators. Specifically, binary quadratic programming is used to formulate a model predictive control problem. Comparative studies of measurements from experimental trials show that the co-ordinated scheduling of refrigerators allows energy savings of between 19% and 29% compared to their traditional isolated (non-co-operative) operation. Moreover, by adaptively changing the hysteresis bands of individual fridges in response to changes in thermal behaviour, a further 20% of savings in energy are possible at the local refrigerator level, thereby providing benefits to both network suppliers and individual consumers. Importantly, manufacturers do not need to make any significant hardware changes to reap these benefits, as the control methodology uses only sensor and actuation mechanisms already present in modern domestic refrigerators.

It should be noted that whilst the proposed methodology has been specifically directed towards the co-ordinated operation of refrigerators, the underlying techniques are more widely applicable, for instance, for the preferential charging of a multiple electric vehicles with constrained total aggregate power availability, or HVAC systems in large buildings.

Author Contributions

Conceptualization, C.B.; methodology, C.B., M.R.Z.S.; software, M.R.Z.S.; validation, C.B., M.R.Z.S.; formal analysis, C.B., M.R.Z.S.; investigation, M.R.Z.S.; resources, C.B.; data curation, M.R.Z.S.; writing—original draft preparation, C.B., M.R.Z.S.; writing—review and editing, C.B., M.R.Z.S.; visualization, M.R.Z.S.; supervision, C.B.; project administration, C.B.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbols | |

| A | System matrix |

| a | Thermal characteristics of refrigerator inner temperature parameter |

| Ac | Overall thermal insulation (W/°C) |

| B | Input matrix |

| b | Impact of the energy transfer from the compressor due to the operation of the system parameter |

| C | Output matrix |

| c | Impact of ambient temperature parameter |

| i | Refrigerators identifier |

| J | Binary Quadratic cost function |

| K(t) | Kalman gain at time t |

| mc | Thermal mass (J/°C) |

| minoff | Minimum off-time per cycle for each refrigerator |

| minon | Minimum on-time per cycle for each refrigerator |

| N1 | Minimum prediction horizons |

| N2 | Maximum prediction horizons |

| Nu | Control horizon |

| n | Number of outputs |

| P(t) | Electrical power required at time t (W) |

| Maximum power consumption at a given time (W) | |

| Q | Weighting factor for control increments |

| R | Weighting factors for predicted error |

| r | Number of inputs |

| s(t) | state of device at time t (a binary ON (1) /OFF (0)) |

| ST | Sample time |

| T(t) | Estimated internal temperature of the refrigerator at the time t (°C) |

| Tamb (t) | Ambient temperature at time t (°C) |

| Tfinish | Experimental test length (Sec) |

| Internal temperature references for each refrigerator which should be kept within upper and lower bounds (°C) | |

| u(t) | Input vector |

| x | State vector |

| ɳ | Coefficient of performance |

| Set of indices in the scheduling horizon | |

| Regression vector at time t | |

| Parameters vector at time t | |

| Abbreviations | |

| BQP | Binary Quadratic Programming |

| DSM | Demand Side Management |

| DSR | Demand Side Response |

| FFR | Firm Frequency Response |

| HVAC | Heating, ventilation, and air conditioning |

| IoT | Internet of Things |

| MPC | Model Predictive Control |

| RLS | Recursive Least Squares |

| TCL | Thermostatically Controlled Load |

Appendix A

The hardware test facility comprises of three domestic refrigerators, see Figure A1. A detailed summary of the appliances is given in Table A1. Each refrigerator is instrumented with a DS18B20 waterproof sensor to measure the internal temperature. The sensors have a −55 °C to +125 °C temperature range and a ±0.5 °C accuracy. During the tests, the ambient temperature is measured with an accuracy of ±0.5 °C from −40 °C to +125 °C by a TMP102 module. The real-time power usage of each refrigerator is measured using TP-Link Smart Wi-Fi Plug (HS110) with an accuracy of ± 0.2 W. The smart plug is also used to provide ON-OFF control of the refrigerator. The network connection is established using a NodeMCU which is an open-source IoT platform that includes integrated support for Wi-Fi. The experimental setup uses ThingSpeak for data acquisition and monitoring in the cloud.

The procedure to obtain the scheduled operation of domestic Refrigerators using MPC can be described as follows:

| Algorithm 1. Model predictive control (MPC) with binary quadratic programming (BQP) for the scheduled operation of domestic refrigerators |

| 1: Input: |

| 2: N1, N2, Nu and ST For each appliance i: |

| 3: |

| 4: Minoff(i) Minon(i) |

| 5: Q(i) R(i) |

| 6: |

| 7: for t = 0: ST: Tfinish |

| 8: Receive the measured Ti(t), Pi(t) and Tamb(t) from ThingSpeak Calculate the A, B and C matrices using (3)–(10) |

| 9: Receive from ThingSpeak |

| 10: Minimize J considering the constraints (12)–(14) and calculate , using opti and solve commands in MATLAB |

| 11: Send to ThingSpeak |

| end |

Table A1.

Specification of appliances.

Table A1.

Specification of appliances.

| iGENIX | VonShef | Russell Hobbs | |

|---|---|---|---|

| Model | IG 3920 | 13/291 | RHCLRF17B |

| Type | Compressor | Compressor | Thermoelectric |

| Energy rating | A+ | A+ | A+ |

| Total storage capacity (L) | 90 | 47 | 17 |

| Power (W) | 55 | 50 | 50 |

| Voltage (V) | 220–240 | 220–240 | 220–240 |

| Frequency (Hz) | 50 | 50 | 50 |

Figure A1.

The hardware setup used in the measurement tests.

References

- Department for Business, Energy and Industrial Strategy. UK Energy Statistics, 2018 & Q4 2018; HM Government: London, UK, 2018. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/791297/Press_Notice_March_2019.pdf (accessed on 25 October 2019).

- Department for Business, Energy and Industrial Strategy. Energy Consumption in the UK 1970 to 2018; HM Government: London, UK, 2018. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/820843/Energy_Consumption_in_the_UK__ECUK__MASTER_COPY.pdf (accessed on 25 October 2019).

- Leading Fridge & Fridge/Freezer Brands in the UK. 2018. Available online: https://www.statista.com/statistics/437582/leading-brands-of-fridges-and-fridge-freezers-in-the-uk/ (accessed on 20 October 2019).

- Barther, C.; Götz, T. The Overall Worldwide Saving Potential from Domestic Refrigerators and Freezers; Wuppertal Institute for Climate, Environment and Energy: Wuppertal, Germany, 2012. [Google Scholar]

- International Energy Agency. Key World Energy Statistics 2019; OECD: Paris, France, 2019; ISBN 9789264847880. [Google Scholar]

- Schweppe, F.; Tabors, R.; Kirtley, J.; Outhred, H.; Pickel, F.; Cox, A. Homeostatic Utility Control. IEEE Trans. Power Appar. Syst. 1980, PAS-99, 1151–1163. [Google Scholar] [CrossRef]

- Malhame, R.; Chong, C.-Y. Electric load model synthesis by diffusion approximation of a high-order hybrid-state stochastic system. IEEE Trans. Autom. Contr. 1985, 30, 854–860. [Google Scholar] [CrossRef]

- Stadler, M.; Krause, W.; Sonnenschein, M.; Vogel, U. Modelling and evaluation of control schemes for enhancing load shift of electricity demand for cooling devices. Environ. Model. Softw. 2009, 24, 285–295. [Google Scholar] [CrossRef]

- Angeli, D.; Kountouriotis, P.-A. A Stochastic Approach to “Dynamic-Demand” Refrigerator Control. IEEE Trans. Control Syst. Technol. 2012, 20, 581–592. [Google Scholar] [CrossRef]

- Borsche, T.S.; de Santiago, J.; Andersson, G. Stochastic control of cooling appliances under disturbances for primary frequency reserves. Sustain. Energy Grids Netw. 2016, 7, 70–79. [Google Scholar] [CrossRef]

- Aunedi, M.; Kountouriotis, P.-A.; Calderon, J.E.O.; Angeli, D.; Strbac, G. Economic and Environmental Benefits of Dynamic Demand in Providing Frequency Regulation. IEEE Trans. Smart Grid 2013, 4, 2036–2048. [Google Scholar] [CrossRef]

- Tindemans, S.H.; Trovato, V.; Strbac, G. Decentralized Control of Thermostatic Loads for Flexible Demand Response. IEEE Trans. Control Syst. Technol. 2015, 23, 1685–1700. [Google Scholar] [CrossRef]

- Saleh, I.; Postnikov, A.; Arsene, C.; Zolotas, A.; Bingham, C.; Bickerton, R.; Pearson, S. Impact of Demand Side Response on a Commercial Retail Refrigeration System. Energies 2018, 11, 371. [Google Scholar] [CrossRef]

- Niro, G.; Salles, D.; Alcântara, M.V.P.; da Silva, L.C.P. Large-scale control of domestic refrigerators for demand peak reduction in distribution systems. Electr. Power Syst. Res. 2013, 100, 34–42. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Ledesma, S.; Rodríguez-Valderrama, D.A.; Hernández-Fusilier, D. Energy optimization of a domestic refrigerator controlled by a fuzzy logic system using the status of the door. Int. J. Refrig. 2019, 104, 1–8. [Google Scholar] [CrossRef]

- Serale, G.; Fiorentini, M.; Capozzoli, A.; Bernardini, D.; Bemporad, A. Model Predictive Control (MPC) for Enhancing Building and HVAC System Energy Efficiency: Problem Formulation, Applications and Opportunities. Energies 2018, 11, 631. [Google Scholar] [CrossRef]

- Carrascal, E.; Garrido, I.; Garrido, A.; Sala, J. Optimization of the Heating System Use in Aged Public Buildings via Model Predictive Control. Energies 2016, 9, 251. [Google Scholar] [CrossRef]

- Baghina, N.; Lampropoulos, I.; Asare-Bediako, B.; Kling, W.L.; Ribeiro, P.F. Predictive control of a domestic freezer for real-time demand response applications. In Proceedings of the 2012 3rd IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Berlin, Germany, 14–17 October 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Sossan, F.; Lakshmanan, V.; Costanzo, G.T.; Marinelli, M.; Douglass, P.J.; Bindner, H. Grey-box modelling of a household refrigeration unit using time series data in application to demand side management. Sustain. Energy Grids Netw. 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Schné, T.; Jaskó, S.; Simon, G. Embeddable adaptive model predictive refrigerator control for cost-efficient and sustainable operation. J. Clean. Prod. 2018, 190, 496–507. [Google Scholar] [CrossRef]

- Constantopoulos, P.; Schweppe, F.C.; Larson, R.C. Estia: A real-time consumer control scheme for space conditioning usage under spot electricity pricing. Comput. Oper. Res. 1991, 18, 751–765. [Google Scholar] [CrossRef]

- Shirazi, E.; Zakariazadeh, A.; Jadid, S. Optimal joint scheduling of electrical and thermal appliances in a smart home environment. Energy Convers. Manag. 2015, 106, 181–193. [Google Scholar] [CrossRef]

- Bozchalui, M.C.; Hashmi, S.A.; Hassen, H.; Canizares, C.A.; Bhattacharya, K. Optimal Operation of Residential Energy Hubs in Smart Grids. IEEE Trans. Smart Grid 2012, 3, 1755–1766. [Google Scholar] [CrossRef]

- Kumar, K.N.; Vijayakumar, K.; Kalpesh, C. Virtual energy storage capacity estimation using ANN-based kWh modelling of refrigerators. IET Smart Grid 2018, 1, 31–39. [Google Scholar] [CrossRef]

- Ljung, L. System Identification: Theory for the User, 2nd ed.; Prentice Hall Information and System Sciences Series; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1999; ISBN 9780136566953. [Google Scholar]

- Camacho, E.F.; Bordons, C. Model Predictive Control; Advanced Textbooks in Control and Signal Processing; Springer: London, UK; New York, NY, USA, 2004; ISBN 9781852336943. [Google Scholar]

- Achterberg, T. SCIP: Solving constraint integer programs. Math. Prog. Comp. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Geppert, J.; Stamminger, R. Analysis of effecting factors on domestic refrigerators’ energy consumption in use. Energy Convers. Manag. 2013, 76, 794–800. [Google Scholar] [CrossRef]

- Harrington, L.; Aye, L.; Fuller, B. Impact of room temperature on energy consumption of household refrigerators: Lessons from analysis of field and laboratory data. Appl. Energy 2018, 211, 346–357. [Google Scholar] [CrossRef]

- Söylemez, E.; Alpman, E.; Onat, A. Experimental analysis of hybrid household refrigerators including thermoelectric and vapour compression cooling systems. Int. J. Refrig. 2018, 95, 93–107. [Google Scholar] [CrossRef]

- Zavvar Sabegh, M.R.; Bingham, C.M. Impact of Hysteresis Control and Internal Thermal Mass on the Energy Efficiency of IoT-Controlled Domestic Refrigerators. In Proceedings of the 2019 IEEE 7th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 12–14 August 2019; pp. 103–107. [Google Scholar] [CrossRef]

- Postnikov, A.; Albayati, I.M.; Pearson, S.; Bingham, C.; Bickerton, R.; Zolotas, A. Facilitating static firm frequency response with aggregated networks of commercial food refrigeration systems. Appl. Energy 2019, 251, 113357. [Google Scholar] [CrossRef]

- HOME—ICEAGE REFRIGERATION. Available online: http://www.iceage-hvac.com/Uploads/Product/2014-12-22/5497c67a7dc35.pdf (accessed on 25 October 2019).

- BITZER//us. Available online: https://www.bitzer.de/shared_media/documentation/kt-100-3.pdf (accessed on 25 October 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).