Reduction of Heat Losses Using Quadruple Heating Pre-Insulated Networks: A Case Study

Abstract

:1. Introduction

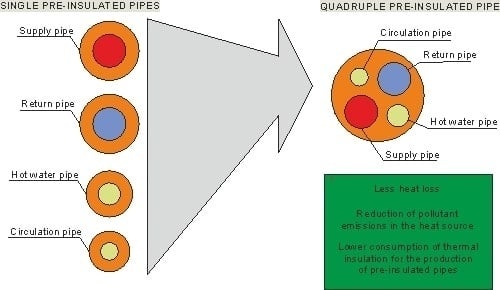

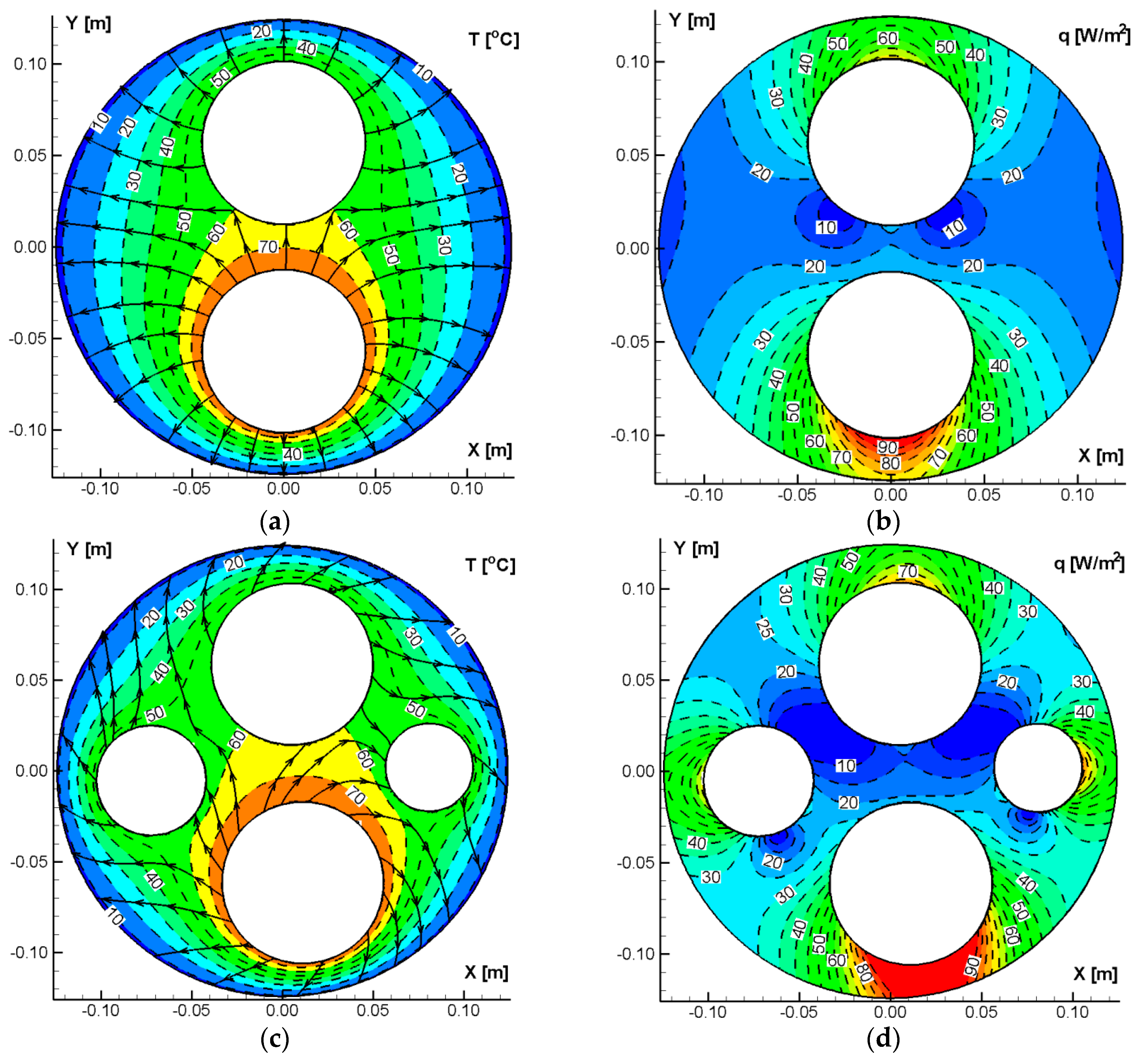

2. Description of the Model for Determining Heat Loss in Pre-Insulated Quadruple Pipes

3. Analysis of Heat Losses of Pre-Insulated Quadruple Networks on the Basis of Operating Parameters of the Existing Pre-Insulated Single Network and the Adopted Twin Pipe Network

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pirouti, M.; Bagdanavicius, A.; Ekanayake, J.; Wu, J.; Jenkins, N. Energy consumption and economic analyses of a district heating network. Energy 2013, 57, 149–159. [Google Scholar] [CrossRef]

- Neirotti, F.; Noussan, M.; Riverso, S.; Manganini, G. Analysis of different strategies for lowering the operation temperature in existing district heating networks. Energies 2019, 12, 321. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Wen, F.; Wang, K.; Huang, Y.; Salam, M.A. Modeling of a district heating system and optimal heat-power flow. Energies 2018, 11, 929. [Google Scholar] [CrossRef] [Green Version]

- Dalla Rosa, A.; Li, H.; Svendsen, S. Method for optimal design of pipes for low-energy district heating with focus on heat losses. Energy 2011, 36, 2407–2418. [Google Scholar] [CrossRef]

- Boysen, C.; Kaldemeyer, C.; Hilpert, S.; Tuschy, I. Integration of flow temperatures in unit commitment models of future district heating systems. Energies 2019, 12, 1061. [Google Scholar] [CrossRef] [Green Version]

- Krawczyk, D.A. Theoretical and real effect of the school’s thermal modernization—A case study. Energy Build. 2014, 81, 30–37. [Google Scholar] [CrossRef]

- Song, S.H.; Cheing, T. Pattern-based set partitioning algorithm for the integrated sustainable operation of a district heating network. Sustainability 2018, 10, 2774. [Google Scholar] [CrossRef] [Green Version]

- Kontu, K.; Vimpari, J.; Penttinen, P.; Junnila, S. City scale demand side management in three different-sized district heating systems. Energies 2018, 11, 3370. [Google Scholar] [CrossRef] [Green Version]

- Kudela, L.; Chylek, R.; Pospisil, J. Performant and simple numerical modeling of district heating pipes with heat accumulation. Energies 2019, 12, 633. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Shan, Y. An influencing parameters analysis of district heating network time delays based on the CFD method. Energies 2019, 12, 1297. [Google Scholar] [CrossRef] [Green Version]

- Salo, S.; Hast, A.; Jokisalo, J.; Kosonen, R.; Syri, S.; Hirvonen, J.; Martin, K. The impact of optimal demand response control and thermal energy storage on a district heating system. Energies 2019, 12, 1678. [Google Scholar] [CrossRef] [Green Version]

- Oclon, P.; Nowak-Oclon, M.; Vallati, A.; Quintino, A.; Corcione, M. Numerical determination of temperature distribution in heating network. Energy 2019, 183, 880–891. [Google Scholar] [CrossRef]

- Sun, G.; Wang, W.; Wu, Y.; Hu, W.; Yang, Z.; Wei, Z.; Zang, H.; Chen, S. A nonlinear analytical algorithm for predicting the probabilistic mass flow of a radial district heating network. Energies 2019, 12, 1215. [Google Scholar] [CrossRef] [Green Version]

- Danielewicz, J.; Śniechowska, B.; Sayegh, M.A.; Fidorów, N.; Jouhara, H. Three-dimensional numerical model of heat losses from district heating network pre-insulated pipes buried in the ground. Energy 2016, 108, 172–184. [Google Scholar] [CrossRef] [Green Version]

- Bøhm, B.; Kristjansson, H. Single, twin and triple buried heating pipes: On potential savings in heat losses and costs. Int. J. Energy Res. 2005, 29, 1301–1312. [Google Scholar] [CrossRef]

- Khosravi, M.; Arabkoohsar, A. Thermal-hydraulic performance analysis of twin-pipes for various future district heating schemes. Energies 2019, 12, 1299. [Google Scholar] [CrossRef] [Green Version]

- Teleszewski, T.J.; Zukowski, M. Modification of the shape of thermal insulation of a twin-pipe pre-insulated network. AIP Conf. Proc. 2019, 2078, 020030. [Google Scholar]

- Krawczyk, D.A.; Teleszewski, T.J. Optimization of geometric parameters of thermal insulation of pre-insulated double pipes. Energies 2019, 12, 1012. [Google Scholar] [CrossRef] [Green Version]

- Kristjansson, H.; Bøhm, B. Advanced and Traditional Pipe Systems Optimum Design of Distribution and Service Pipes; Technical Paper; Euroheat and Power: Brussels, Belgium, 2006; pp. 34–42. [Google Scholar]

- Krawczyk, D.A.; Teleszewski, T.J. Reduction of heat losses in a pre-insulated network located in central Poland by lowering the operating temperature of the water and the use of egg-shaped thermal insulation: A case study. Energies 2019, 12, 2104. [Google Scholar] [CrossRef] [Green Version]

- Van der Heijde, B.; Aertgeerts, A.; Helsen, L. Modelling steady-state thermal behaviour of double thermal network pipes. Int. J. Therm. Sci. 2017, 117, 316–327. [Google Scholar] [CrossRef] [Green Version]

- Babiarz, B.; Zięba, B. Heat losses in the preinsulated district heating systems. Civ. Environ. Eng. 2012, 283, 5–19. [Google Scholar]

- Bennet, J.; Claesson, J.; Hellström, G. Multipole method to compute the conductive heat flows to and between pipes in a composite cylinder. LUTVDGf (TVBH-7094)/1-42/(1987). Notes Heat Transfer 1987, 3, 1–44. [Google Scholar]

- Ravina, M.; Panepinto, D.; Zanetti, M.C.; Genon, G. Environmental analysis of a potential district heating network powered by a large-scale cogeneration plant. Environ. Sci. Pollut. Res. 2017, 24, 13424–13436. [Google Scholar] [CrossRef] [PubMed]

- Guelpa, E.; Mutani, G.; Todeschi, V.V. Reduction of CO2 emissions in urban areas through optimal expansion of existing district heating networks. J. Clean. Prod. 2018, 204, 117–129. [Google Scholar] [CrossRef]

- Brebbia, C.A.; Telles, J.C.F.; Wrobel, L.C. Boundary Element Techniques-Theory and Applications in Engineering; Springer: Berlin/Heidelberg, Germany; New York, NY, USA; Tokyo, Japan, 1984; Chapter 2. [Google Scholar]

- Teleszewski, T.J.; Sorko, S.A. Effect of viscous dissipation on forced convection for laminar flow through a straight regular polygonal duct using BEM method. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 220–238. [Google Scholar] [CrossRef]

- Zukowski, M. Forced convection heat transfer in square duct with heated and adiabatic walls at constant axial heat flux. AIP Conf. Proc. 2019, 2078, 020028. [Google Scholar]

- Teleszewski, T.J. Effect of viscous dissipation in stokes flow between rotating cylinders using BEM. Int. J. Numer. Methods Heat Fluid Flow. in press. [CrossRef]

- Jarfelt, U.; Ramnas, O. Thermal conductivity of polyurethane foam—Best performances. Heat distribution—pipe properties. Sektion 6a. In Proceedings of the 10th International Symposium of District Heating and Cooling, Hanover, Germany, 3–5 September 2006; pp. 1–11. [Google Scholar]

- BING Federation of European Rigid Polyurethane Foam Associations. Thermal Insulation Materials Made of Rigid Polyurethane Foam (PUR/PIR); Report N1; BING Federation of European Rigid Polyurethane Foam Associations: Brussels, Belgium, 2006; Available online: http://highperformanceinsulation.eu/wp-content/uploads/2016/08/Thermal_insulation_materials_made_of_rigid_polyurethane_foam.pdf (accessed on 2 October 2019).

- Krawczyk, D.A.; Teleszewski, T.J. Effects of some geometric parameters in energy-efficient heat distribution of pre-insulated double pipes. Proceedings 2018, 2, 1520. [Google Scholar] [CrossRef] [Green Version]

- Google Maps. Available online: https://www.google.pl/maps (accessed on 1 October 2019).

- European Environment Agency, Publications Office of the European Union. EMEP/EEA Air Pollutant Emission Inventory Guidebook; European Environment Agency, Publications Office of the European Union: Luxemburg, 2016. [Google Scholar]

- Gómez, D.R.; Watterson, J.D.; Americano, B.B.; Ha, C.; Marland, G.; Matsika, E.; Namayanga, L.N.; Osman-Elasha, B.; Kalenga Saka, J.D.; Treanton, K.; et al. Intergovernmental Panel on Climate Change (IPCC) Guidelines for National Greenhouse Gas Inventories. Volume 2: Energy, Stationary Combustion. Institute for Global Environmental Strategies; Institute for Global Environmental Strategies (IGES) on behalf of the IPCC: Hayama, Kanagawa, Japan, 2006; Chapter 2. [Google Scholar]

| No. Pipes (Figure 2b) | Supply Pipe | Return Pipe | Hot Water Pipe | Circulation Pipe | Thermal Insulation Field 2 × A1 + A2 + A3 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | d1 | A1 | qIa | D1 | d1 | A1 | qIb | D2 | d2 | A2 | qIc | D3 | d3 | A3 | qId | ||

| mm | mm | m2 | W/m | mm | mm | m2 | W/m | mm | mm | m2 | W/m | mm | mm | m2 | W/m | m2 | |

| 1,2 | 200 | 114.3 | 0.0212 | 21.4 | 200 | 114.3 | 0.0212 | 15.5 | 140 | 76.1 | 0.0108 | 19.7 | 110 | 48.3 | 0.0077 | 14.6 | 0.0608 |

| 3 | 160 | 88.9 | 0.0139 | 20.4 | 160 | 88.9 | 0.0139 | 14.7 | 125 | 60.3 | 0.0094 | 16.4 | 110 | 48.3 | 0.0077 | 14.6 | 0.0449 |

| 4 | 160 | 88.9 | 0.0139 | 20.4 | 160 | 88.9 | 0.0139 | 14.7 | 110 | 48.3 | 0.0077 | 14.6 | 90 | 33.7 | 0.0055 | 12.2 | 0.0409 |

| 5,6 | 140 | 76.1 | 0.0108 | 19.7 | 140 | 76.1 | 0.0108 | 14.2 | 110 | 48.3 | 0.0077 | 14.6 | 90 | 33.7 | 0.0055 | 12.2 | 0.0348 |

| 7 | 140 | 76.1 | 0.0108 | 19.7 | 140 | 76.1 | 0.0108 | 14.2 | 110 | 42.4 | 0.0081 | 12.6 | 75 | 26.9 | 0.0038 | 11.7 | 0.0336 |

| 8,9 | 110 | 48.3 | 0.0077 | 14.6 | 110 | 48.3 | 0.0077 | 10.5 | 90 | 33.7 | 0.0055 | 12.2 | 75 | 26.9 | 0.0038 | 11.7 | 0.0247 |

| No. Pipes (Figure 2b) | Twin Pipe (Supply Pipe + Return Pipe) | Twin Pipe (Hot Water Pipe + Circulation Pipe) | Thermal Insulation Field A4 + A5 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D4 | d1 | s1 | A4 | qIIa | D5 | d2 | d3 | s2 | A5 | qIIb | ||

| mm | mm | mm | m2 | W/m | mm | mm | mm | mm | m2 | W/m | m2 | |

| 1,2 | 315 | 114.3 | 25 | 0.0574 | 23.4 | 225 | 76.1 | 48.3 | 20 | 0.0270 | 11.4 | 0.0844 |

| 3 | 250 | 88.9 | 25 | 0.0367 | 24.0 | 200 | 60.3 | 48.3 | 20 | 0.0220 | 11.0 | 0.0587 |

| 4 | 250 | 88.9 | 25 | 0.0367 | 24.0 | 160 | 48.3 | 33.7 | 19 | 0.0147 | 10.6 | 0.0513 |

| 5,6 | 225 | 76.1 | 20 | 0.0307 | 20.6 | 160 | 48.3 | 33.7 | 19 | 0.0147 | 10.6 | 0.0453 |

| 7 | 225 | 76.1 | 20 | 0.0307 | 20.6 | 160 | 42.4 | 26.9 | 19 | 0.0161 | 8.8 | 0.0468 |

| 8,9 | 160 | 48.3 | 19 | 0.0164 | 17.5 | 140 | 33.7 | 26.9 | 19 | 0.0125 | 8.9 | 0.0289 |

| No. Pipes (Figure 1) | Quadruple Pre-Insulated Pipe | |||||||

|---|---|---|---|---|---|---|---|---|

| D4 | d1 (S,R) | d2 | d3 | s1 | Thermal Insulation Field A6 | Heating Season (S+R+H+C) qIIIa | Out of the Heating Season (H+C) qIIIb | |

| mm | mm | mm | mm | mm | m2 | W/m | W/m | |

| 1,2 | 315 | 114.3 | 76.1 | 48.3 | 25 | 0.0510 | 28.8 | 11.7 |

| 3 | 250 | 88.9 | 60.3 | 48.3 | 25 | 0.0320 | 33.6 | 14.8 |

| 4 | 250 | 88.9 | 48.3 | 33.7 | 25 | 0.0339 | 28.3 | 10.2 |

| 5,6 | 225 | 76.1 | 48.3 | 33.7 | 20 | 0.0279 | 25.7 | 10.0 |

| 7 | 225 | 76.1 | 42.4 | 26.9 | 20 | 0.0287 | 23.9 | 10.0 |

| 8,9 | 160 | 48.3 | 33.7 | 26.9 | 19 | 0.0150 | 23.7 | 11.6 |

| Unit Heat Losses During the Heating Season | Unit Heat Losses in the Off-Heating Season |

|---|---|

| Case I | |

| qIj = qIa + qIb + qIc + qId | qIj = qIc + qId |

| Case II | |

| qIIj = qIIa | qIIj = qIIb |

| Case III | |

| qIIIj = qIIIa | qIIIj = qIIIb |

| Heating Network Variant | Energy Consumed for Heat Losses During the Heating Season (255 Days) [GJ] | Energy Consumed for Heat Losses in the Off-Heating Season (110 Days) [GJ] | Annual Energy Consumed for Heat Losses (365 Days) [GJ] |

|---|---|---|---|

| Pre-insulated single heating network, current condition (S, R, H, C), Case I | 493.7 | 95.9 | 589.6 |

| Two pre-insulated twin pipe heating networks (S + R, H + C), Case II | 254 | 35.3 | 289.3 |

| Quadruple heating pre-insulated network (S + R + H + C), Case III | 214.7 | 38.2 | 252.8 |

| Pollutant | Ef [g/GJ] | EIEf [kg/year] | EIIEf [kg/year] | EIIIEf [kg/year] | ∆EI-II [kg/year] | ∆EI-III [kg/year] |

|---|---|---|---|---|---|---|

| NOx | 209.0 | 123.2 | 60.5 | 52.8 | 62.8 | 70.4 |

| CO | 8.7 | 5.130 | 2.517 | 2.200 | 2.612 | 2.930 |

| NMVOC | 1.0 | 0.590 | 0.289 | 0.253 | 0.300 | 0.337 |

| SOx | 820 | 483.5 | 237.3 | 207.3 | 246.2 | 276.2 |

| TSP | 11.4 | 6.722 | 3.298 | 2.882 | 3.423 | 3.839 |

| PM10 | 7.7 | 4.540 | 2.228 | 1.947 | 2.312 | 2.593 |

| PM2.5 | 3.4 | 2.005 | 0.984 | 0.860 | 1.021 | 1.145 |

| CO2 | 98,300 | 57,960.0 | 28,442.3 | 24,854.2 | 29,517.7 | 33,105.8 |

| CH4 | 1 | 0.590 | 0.289 | 0.253 | 0.300 | 0.337 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teleszewski, T.J.; Krawczyk, D.A.; Rodero, A. Reduction of Heat Losses Using Quadruple Heating Pre-Insulated Networks: A Case Study. Energies 2019, 12, 4699. https://doi.org/10.3390/en12244699

Teleszewski TJ, Krawczyk DA, Rodero A. Reduction of Heat Losses Using Quadruple Heating Pre-Insulated Networks: A Case Study. Energies. 2019; 12(24):4699. https://doi.org/10.3390/en12244699

Chicago/Turabian StyleTeleszewski, Tomasz Janusz, Dorota Anna Krawczyk, and Antonio Rodero. 2019. "Reduction of Heat Losses Using Quadruple Heating Pre-Insulated Networks: A Case Study" Energies 12, no. 24: 4699. https://doi.org/10.3390/en12244699

APA StyleTeleszewski, T. J., Krawczyk, D. A., & Rodero, A. (2019). Reduction of Heat Losses Using Quadruple Heating Pre-Insulated Networks: A Case Study. Energies, 12(24), 4699. https://doi.org/10.3390/en12244699