Design of a Single-Phase BLDC Motor for a Cordless Vacuum Cleaner Considering the Efficiency of Airflow

Abstract

:1. Introduction

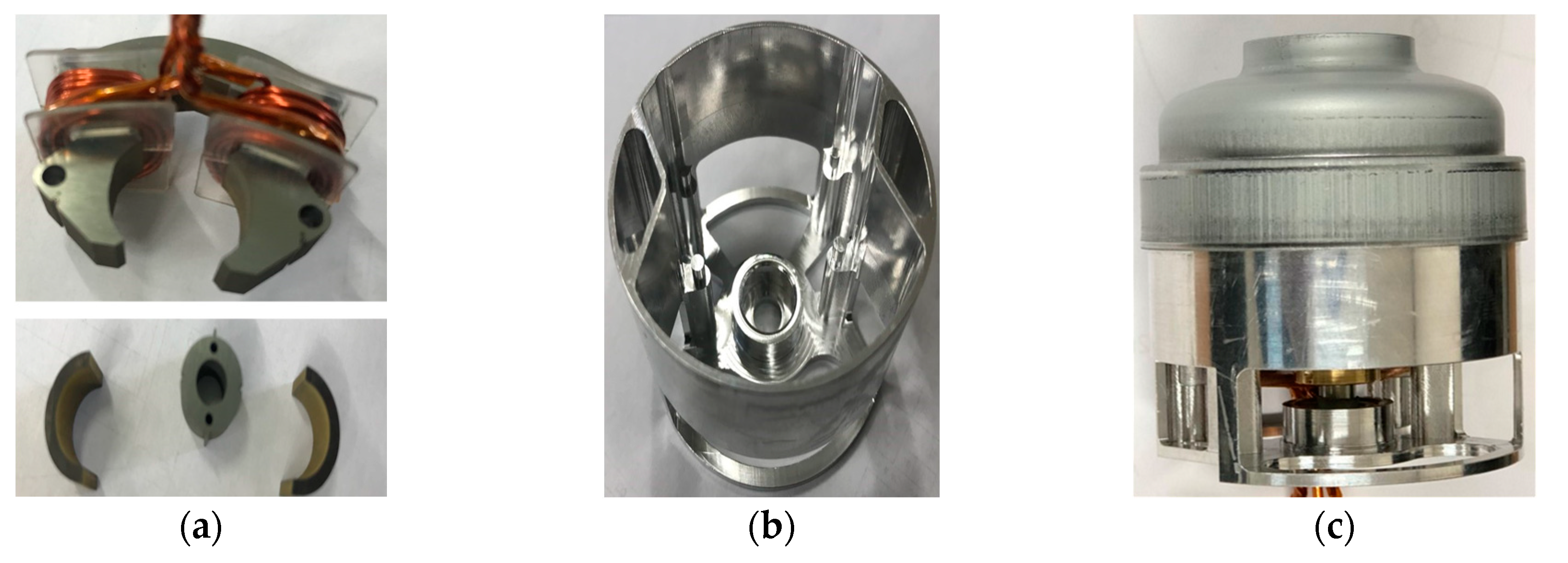

2. Inverter-Driven Single-Phase BLDC Motor

3. Analysis of Proposed Single-Phase BLDC Motor

3.1. Torque Production of a Single-Phase BLDC Motor

3.2. Design of Asymmetric Air Gap

3.3. Control of Single-Phase BLDC Motor

3.4. Electrical Dynamics of Single-Phase BLDC Motor

3.5. Fluid Dynamics of Single-Phase BLDC Motor

3.6. Experimental Verification of Efficiency in Airflow

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jang, K.B.; Won, S.H.; Kim, T.H.; Lee, J. Starting and high-speed driving of single-phase flux-reversal motor for vacuum cleaner. IEEE Trans. Magn. 2005, 41, 3967–3969. [Google Scholar] [CrossRef]

- Bentouati, S.; Zhu, Z.Q.; Howe, D. Permanent magnet brushless DC motors for consumer products. In Proceedings of the Ninth International Conference on Electrical Machines and Drives, Canterbury, UK, 1–3 September 1999; Volume 468, pp. 118–122. [Google Scholar]

- Sashidhar, S.; Fernandes, B.G. Comparison of a ferrite based single, three-phase spoke and surface permanent magnet BLDC motor for a PV submersible water pump. In Proceedings of the IEEE International Conference on Industrial Technology, Seville, Spain, 17–19 March 2015; pp. 671–676. [Google Scholar]

- Chiu, C.-L.; Chen, Y.-T.; Liang, Y.-L.; Liang, R.-H. Optimal driving efficiency design for the single-phase brushless DC fan motor. IEEE Trans. Magn. 2010, 46, 1123–1130. [Google Scholar] [CrossRef]

- Fazil, M.; Rajagopal, K.R. A novel air-gap profile of single-phase permanent-magnet brushless DC motor for starting torque improvement and cogging torque reduction. IEEE Trans. Magn. 2010, 46, 3928–3932. [Google Scholar] [CrossRef]

- Kale, P.P.L.; Patil, M.B.; Korade, D.N.; Jagtap, K.R. Experimental and CFD analysis of vacuum cleaner exhaust muffler. J. Mech. Civ. Eng. 2016, 13, 21–27. [Google Scholar]

- Li, H. Fluid flow analysis of a single-stage centrifugal fan with a ported diffuser. Eng. Appl. Comput. Fluid Mech. 2009, 2, 147–163. [Google Scholar] [CrossRef]

- Park, Y.-U.; Cho, J.-H.; Kim, D.-K. Cogging torque reduction of single-phase brushless DC motor with a tapered air-gap using optimizing notch size and position. IEEE Trans. Ind. Appl. 2015, 51, 4455–4463. [Google Scholar] [CrossRef]

- Dunkl, S.; Muetze, A.; Schoener, G. Design constraints of small single-phase permanent magnet brushless DC drives for fan applications. IEEE Trans. Ind. Appl. 2015, 51, 3178–3186. [Google Scholar] [CrossRef]

- Kimr, H.-C.; Han, J.-H.; Jung, T.-U. Analysis of torque characteristic according to the asymmetrical airgap of the BLDC motor for cooling-fan. In Proceedings of the International Conference on Electrical Machines and Systems, Busan, Korea, 26–29 October 2013; pp. 1277–1280. [Google Scholar]

- Bentouati, S.; Zhu, Z.Q.; Howe, D. Influence of design parameters on the starting torque of a single-phase PM brushless DC motor. IEEE Trans. Magn. 2000, 36, 3533–3536. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.Q.; Bentouati, S.; Howe, D. Control of single-phase permanent magnet brushless dc drives for high-speed applications. In Proceedings of the 8th International Conference on Power Electronics and Variable Speed Drives, London, UK, 18–19 September 2000; pp. 327–332. [Google Scholar]

- Son, I.-H.; Noh, Y.; Choi, E.-H.; Choi, J.Y.; Ji, Y.J.; Lim, K. Optimization of the flow path efficiency in a vacuum cleaner fan. J. Mech. Eng. 2018, 64, 258–268. [Google Scholar]

| Angular Ratio | ||||||

|---|---|---|---|---|---|---|

| 1:1:1 | 2:1:3 | 2:3:1 | 2:1:1 | 3:1:2 | 3:2:1 | |

| 34.0 | 34.0 | 34.0 | 51.0 | 51.0 | 51.0 | |

| 34.0 | 17.0 | 51.0 | 25.5 | 17.0 | 34.0 | |

| 34.0 | 51.0 | 17.0 | 25.5 | 34.0 | 17.0 | |

| Parameters | Tapered Air Gap | Stepped Air Gap | |||

|---|---|---|---|---|---|

| stack length | mm | 9.0 | 9.0 | ||

| gap ratio | - | 2.0 | 2.0 | ||

| turns/pole | turns | 26 | 24 | ||

| resistance | ohm | 0.020 | 0.017 | ||

| rotor speed | r/min | 100,000 | 100,000 | ||

| battery | volts | 20 | 26 | 20 | 26 |

| torque | mNm | 56.2 | 55.5 | 55.8 | 55.1 |

| current | Arms | 41.7 | 40.3 | 43.4 | 43.2 |

| copper loss | watts | 34.3 | 32.0 | 28.9 | 31.0 |

| core loss | watts | 5.6 | 5.8 | 5.4 | 6.0 |

| output | watts | 588.1 | 581.0 | 584.7 | 577.2 |

| efficiency | % | 93.7 | 93.9 | 94.1 | 94.0 |

| torque ripple | % | 168.0 | 240.4 | 182.9 | 254.5 |

| Parameters | With Capacitors | Stepped Air Gap |

|---|---|---|

| Pressure, Pa | 12,714 | 12,717 |

| , L/s | 12.2 | 12.2 |

| T, mNm | 30.1 | 30.0 |

| , W | 160.4 | 155.1 |

| , W | 283.7 | 282.7 |

| Efficiency, % | 54.7 | 54.9 |

| Parameters | Speed of Operation, r/min | |||

|---|---|---|---|---|

| 84,468 | 97,542 | 100,020 | ||

| input power | watts | 283.0 | 420.2 | 451.2 |

| air flow | /min | 0.648 | 0.738 | 0.753 |

| vacuum | kPa | 151.0 | 196.0 | 204.0 |

| suction power | watts | 120.0 | 176.9 | 188.4 |

| current | Arms | 20.3 | 27.0 | 28.6 |

| copper loss | watts | 9.0 | 16.0 | 18.0 |

| core loss | watts | 6.0 | 6.0 | 6.0 |

| motor output | watts | 258.5 | 384.1 | 412.2 |

| motor efficiency | % | 95.5 | 94.6 | 94.5 |

| inverter efficiency | % | 96.7 | 96.7 | 96.7 |

| airflow efficiency | % | 46.4 | 46.1 | 45.7 |

| system efficiency | % | 42.4 | 42.1 | 41.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, H.; Cho, J.; Hwang, S.-H.; Choi, J.Y.; Lee, C. Design of a Single-Phase BLDC Motor for a Cordless Vacuum Cleaner Considering the Efficiency of Airflow. Energies 2019, 12, 465. https://doi.org/10.3390/en12030465

Hwang H, Cho J, Hwang S-H, Choi JY, Lee C. Design of a Single-Phase BLDC Motor for a Cordless Vacuum Cleaner Considering the Efficiency of Airflow. Energies. 2019; 12(3):465. https://doi.org/10.3390/en12030465

Chicago/Turabian StyleHwang, Hongsik, Jeonghyun Cho, Seon-Hwan Hwang, Ju Yong Choi, and Cheewoo Lee. 2019. "Design of a Single-Phase BLDC Motor for a Cordless Vacuum Cleaner Considering the Efficiency of Airflow" Energies 12, no. 3: 465. https://doi.org/10.3390/en12030465

APA StyleHwang, H., Cho, J., Hwang, S.-H., Choi, J. Y., & Lee, C. (2019). Design of a Single-Phase BLDC Motor for a Cordless Vacuum Cleaner Considering the Efficiency of Airflow. Energies, 12(3), 465. https://doi.org/10.3390/en12030465