Abstract

Improvement in the performance of a solar still is investigated with the integration of a geothermal cooling system and a vacuum pump. Geothermal cooling is simulated to provide a cold, effective underground water temperature, which could reach 15–25 °C below ambient. Cooling is achieved by circulating water underground. As a result of this circulation, the cold fluid from the ground flows into a counter flow shell and tube heat exchanger. A vacuum pump is used to keep the solar still at a certain vacuum pressure. The sizes of the geothermal system and solar still are designed in such a way that the water outlet temperature from the ground and its flow rate are capable of condensing the entire vapor produced by the still. An analytical model was developed and then solved using the Newton–Raphson method for solving non-linear equations. A prototype was built to validate the analytical model. The results were in close agreement. A 305% increase in daily water productivity resulted from the proposed enhancements. After experimental validation, the effects of various parameters such as vacuum pressure, ambient temperature, and wind speed on the yield of geothermal solar still were examined. It was found that the increase in vacuum pressure enhanced performance, whereas the increase in wind speed had a detrimental effect on the yield of the solar still. A higher ambient temperature increased the yield of the solar still. Finally, the design of the heat exchanger for condensing the distilled water using geothermal cooling water was also investigated in terms of the increase in UA (the product of overall heat transfer coefficient and the area of heat exchanger) with inlet cooling geothermal water temperature.

1. Introduction

The demand for fresh water is continuously increasing in line with population growth. In the current situation of rising oil prices along with concerns over declining oil reserves, the need to comply with the Kyoto Protocol has become vital for the reduction of greenhouse gases. Thus, it is of the utmost importance to find ways to use renewable energy sources for water desalination. The geographical location of the Kingdom of Saudi Arabia (KSA) gives it an advantage in utilizing solar energy to offset part of its domestic energy consumption. The abundance of freely available solar radiation, an average of 2200 thermal kilowatt hours (kWh) of solar energy per square meter of land area annually, is just waiting to be harnessed [1]. The combination of renewable energies such as solar and geothermal energy with desalination holds enormous potential for improving the potable water supply in the KSA.

Solar distillation is one of the oldest techniques to produce fresh water from brackish or saline water [2]. Numerous efforts have been made to enhance system performance so that the distillate output is obtained at a reasonable cost. These efforts include active solar distillation, in which the basin of the solar still is integrated with a panel of collectors through heat exchangers [3], enhancing the solar still performance by cooling the glass cover with water film [4], and using a thermal-electrical solar still in which the water vapor is removed from the basin by a low-power fan and then passed through an external condenser [5].

Other techniques involve the use of a double basin solar still [6], upward-type double-effect solar distillers [7], a double-basin solar still integrated with collectors [8], a solar still with an internal condenser [9], a multi-effect active distillation system [10], and a solar still with dye [11]. Karthikeyan and Natarajan [12] conducted a comprehensive review of the factors influencing the performance and productivity of solar stills. Al-Nimr and Haddad [13] investigated the capability of a radiative cooling system in condensing water vapor from humid air in a solar still. A so-called radiative condenser was introduced and analyzed to distill pure water from the vapor of humid air. Moreover, Haddad et al. [14] proposed a basin-type solar still integrated with a packed-bed storage tank, which was used as an external condenser for the still. The packed-bed condenser was cooled during the night using a radiative cooling panel by circulating pure water into the packed-bed condenser and radiative cooling panel. Other recent publications aim to modify the design of the solar still to increase its productivity or to investigate still performance under a wide range of design and operating conditions [15,16,17].

A cool underground temperature is utilized in space-cooling applications [18,19]. The difference between ambient hot or cold temperatures and an underground fixed temperature is approximately 10–20 °C, depending on the time and location [20,21]. This allows for use either as a heat sink (in summer) or a heat source (in winter). In summer, the soil temperature in a hot and arid region at a few meters deep is lower than the mean daily outdoor air temperature and is significantly lower than the usual outdoor daytime air temperature. Thus, it can be used as a heat sink to cool the exterior warm air. A ground source heat pump (GSHP) is a heat pump system that uses the ground as a heat source or sink. The geothermal system connects a heat pump underground and permits the rejection of heat into the ground for cooling purposes [22]. A large number of modifications have been proposed to improve the performance of solar stills. These modifications have been classified into six types based on still design guidelines [23]. Sivakumar et al. [24] summarized the different techniques that have been applied to increase solar still efficiency. Different modifications, including cooling techniques, have been proposed by Ayoub et al. [25] to increase solar still productivity.

The literature review reveals that various options to improve the performance of solar stills have been investigated. However, a geothermal system integrated with a vacuumed solar still has yet to be explored in detail, especially for KSA conditions. In this study, a closed-loop geothermal cooling system will be integrated with a solar still to reject heat from the distilled water vapor into the ground to improve still performance. Geothermal cooling is used to provide a cold, effective underground water temperature, which could reach 15–25 °C below ambient. Cooling is achieved by circulating water underground. As a result of this circulation, the cold fluid from the ground flows into a counter flow shell and tube heat exchanger. The outer shell contains water vapor from the water still, whereas the inner tube contains the cold water pumped from the ground. The heat exchanger is used to condense the vapor produced by the still. The sizes of the geothermal system and solar still are designed in such a way that the water outlet temperature from the ground and its flow rate are capable of condensing all of the vapor produced by the still. The temperature of water exiting the ground is much lower than that attained in conventional condensers that utilize cold water from ambient conditions. In addition, geothermal energy is considered a renewable energy, which does not depend on conventional sources of energy. Using the above-modified still, four goals are expected to be achieved: (i) The vapor pressure and temperature inside the still can be reduced with a vacuum and, as a result, thermal losses from the vapor are reduced and the solar still can still produce condensed water even with low intensity of solar radiation; (ii) the vapor partial pressure inside the still can be reduced, which enhances the evaporation rate from the still; and (iii) the low-temperature water exiting from the ground can enhance the condensation rate inside the condenser.

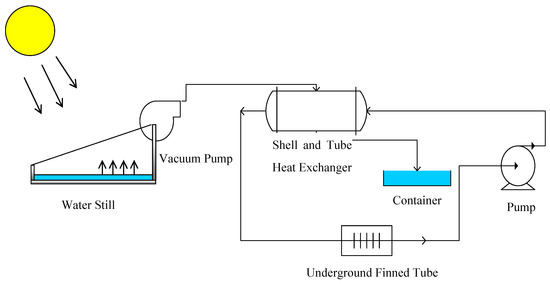

2. Modeling of Solar Still

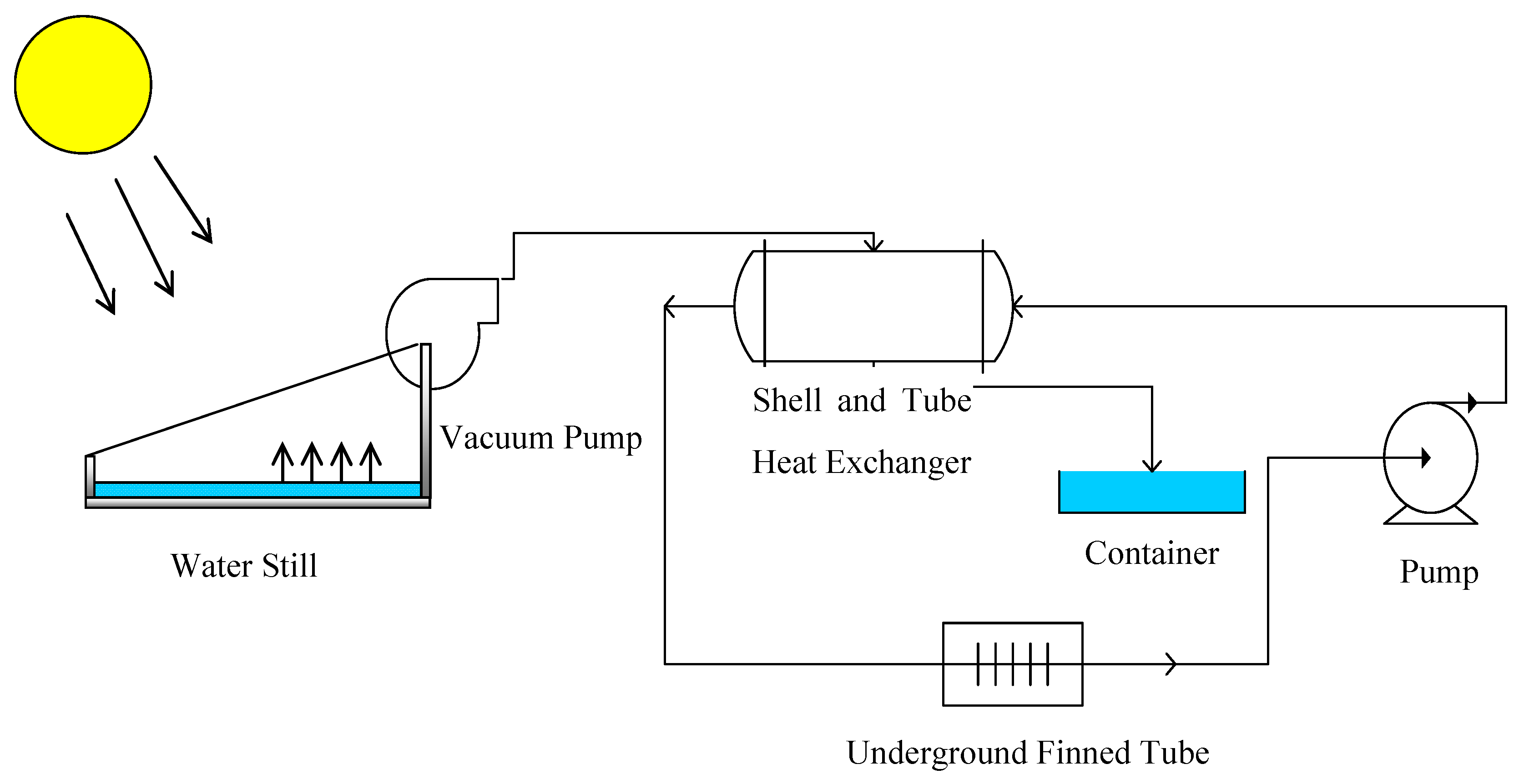

The proposed system consists of a basic solar still. The schematic diagram is shown in Figure 1. The still contains water that is heated by the sun to the point of evaporation. The water evaporates and fills the still. A vacuum pump is installed at the top corner of the still to withdraw the vapor from the still. This vapor is directed into the outer shell of a shell-and-tube heat exchanger. Cold brine water flows into the inner tube of the heat exchanger, which causes condensation of vapor on the outer surface of the inner tube. This condensed water is collected in a container.

Figure 1.

Proposed solar-geothermal still.

Geothermal energy is used to supply cold water to the inner tube. This is accomplished by passing the inner tube through the ground to a depth of 2–3 m. At this depth, the ground temperature is at least 20–25 °C below ambient temperature in most areas of the KSA [26]. At the lowest depth, fins are attached to the inner tube to enhance heat transfer from the inner tube to the ground. At the ground level, a pump is installed to withdraw cold water from the ground and circulate it to the shell-and-tube heat exchanger.

As shown in Figure 1, the vacuum pump will create suction (vacuum pressure Po) inside the still to enhance vaporization and drive the vapor to the condenser to prevent it from condensing on the glass. This will also reduce the glass temperature Tg.

The energy balance on the water side at a certain instant of time is

The energy balance on the glass is

where is the solar radiation at the tilted surface, τg is the glass transmissivity, αg is the glass absorptivity, Tw is the water temperature, and Tg is the glass temperature. hrw is the radiation heat transfer coefficient from the water given as [27]

where is the emissivity and is the Stefan–Boltzmann constant. hg is the glazing heat transfer coefficient given as [27]

where V is the wind speed at the location and εg is the glass emissivity. hcv is the convection heat transfer coefficient from the water given as [28]

where C = 0.075; ρm, km, μm, and αm are the density, thermal conductivity, viscosity, and thermal diffusivity, respectively, of the mixture corresponding to saturated mixture properties at approximately 50 °C. Ma and Mw are the molar masses of air and water, respectively. Po is the pressure inside the still (less than 101 kPa), which depends on the vacuum pump used, ranging from 50 to 101 kPa. P(T) represents saturated vapor pressure at temperature T, g is the gravity, and β can be defined as .

he is the evaporative mass heat transfer coefficient given as [29]

where Cpa is the specific heat capacity of dry air, hfg is the heat of evaporation, and Ra and Rw are the gas constants.

After simultaneously solving Equations (1)–(6), we will get Ta and Tg. The condensation rate will then be calculated from [27]

This needs a condenser to fully condense the vapor. Thus, an analysis is performed to calculate UA; then, , the geothermal water flow rate required to condense vapor, is calculated. The heat transfer from the condensing fluid side is

The heat transfer from the cooling water side is

where is the specific heat of cooling water, and and represent the outlet and inlet temperature of the cooling fluid, respectively. It is assumed that the available water temperature from the geothermal source is 15–25 °C below ambient temperature.

The heat transfer may also be calculated as

where is the effectiveness of the heat exchanger given by

NTU is the number of transfer units

where is the overall heat transfer coefficient of the condenser, and A is the area of the heat exchanger. It is assumed that the vapor has the same temperature as the water in the basin (). c is defined as

and can be obtained by solving Equations (8)–(13). The model developed above is a set of twelve non-linear equations. A computer simulation program based on these equations was developed in FORTRAN (IBM, Armonk, NY, USA), which uses the Newton-Raphson method for non-linear equations. The program solves the model by an iterative procedure in which the user has to provide realistic guesses of all the variables in the model.

3. Experimental Set-Up

Solar radiation measurements were conducted at the metrological station located at the top of the Mechanical Engineering Department’s building at King Saud University (KSU), as shown in Figure 2. The station is equipped with an Eppley Normal Incidence Pyrheliometer, Eppley rotating shadow band radiometer set-up, and a Precision Spectral Pyranometer. The discussion of the conversion of horizontal and diffuse radiation into was omitted for brevity; however, the analysis reported in reference [4] was used for this purpose.

Figure 2.

Solar radiation measurement station at King Saud University.

Figure 3 shows the solar still during testing and in its manufacturing phase. The main body was built with 3 mm galvanized steel. The still was built with a length, width, and height of 1 m, 1 m, and 0.6 m, respectively. The system was constructed mainly from a galvanized steel absorber plate (of thickness 0.04 m) that was painted black to increase the absorptivity. A Perspex sheet (6 mm) was used as the transparent top cover because of its low thermal conductivity and high transmissivity, compared with glass and lexan. Glass wool was used as insulation material because of its low density and cost. The tilt angle was set at 24.4° facing south based on the optimum calculations for Riyadh [30]. The inside was painted black to enhance the heat transfer. Geothermal energy was simulated using a cooler to maintain the water temperatures within the controlled range of 20–40 °C. A heat exchanger with 316 Stainless Steel Shell and Tube, 0.85 m2 surface area, and 17.3 m3/hr flow capacity (35185K45, McMaster) was used. Temperature measurements were taken by various calibrated K-type thermocouples (OMEGA 5TC-GG-K-20-36), which were installed to measure the glass cover temperature, the absorber plate temperature, the ambient temperature, and the air-vapour mixture temperature. A 30-channel data acquisition system (OMB-DAQ-54, Omega) was installed to get the thermocouple data in real time. The output distillate water was collected using a calibrated tube. The experiment was carried out between 9:00 and 18:00 during the months from January to June 2018 at King Saud University under the climatic conditions of Riyadh, Saudi Arabia. Two identical solar stills were manufactured. One of the solar stills was tested with the addition of a geothermal system and vacuum pump (called enhanced solar still) and the other one was tested in parallel without those enhancements (called conventional solar still).

Figure 3.

(a) Solar still during manufacturing and (b) vacuumed solar still during testing.

The experimental error analysis indicated the implication of the error in measured parameters on the uncertainty of the results. Detailed analysis of the various experimental parameters was carried out using the differential method according to Moffat [31]. Summary of the uncertainty values of the experimental parameters is listed in Table 1.

Table 1.

Uncertainty values of the experimental set-up.

The power requirement for running the vacuum and geothermal pumps was about 150 W on average. There are plans to fulfill the electrical energy demand by using solar panels so that the system can also be used effectively in arid zones where grid connectivity is not available. In future studies, the authors plan to connect a number of stills through a single line for a geothermal water and vacuum generation that will make it a more attractive solution for the given water productivity.

4. Results and Discussion

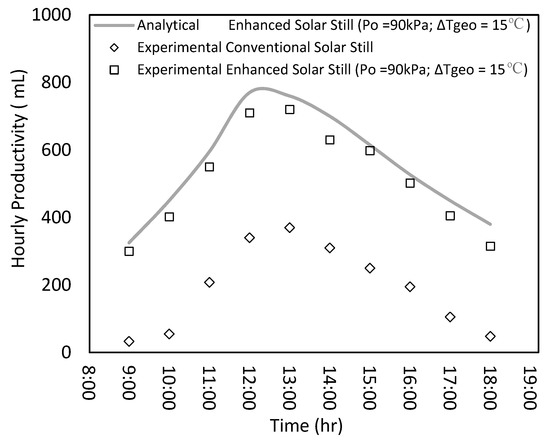

4.1. Comparison of Experimental and Analytical Results

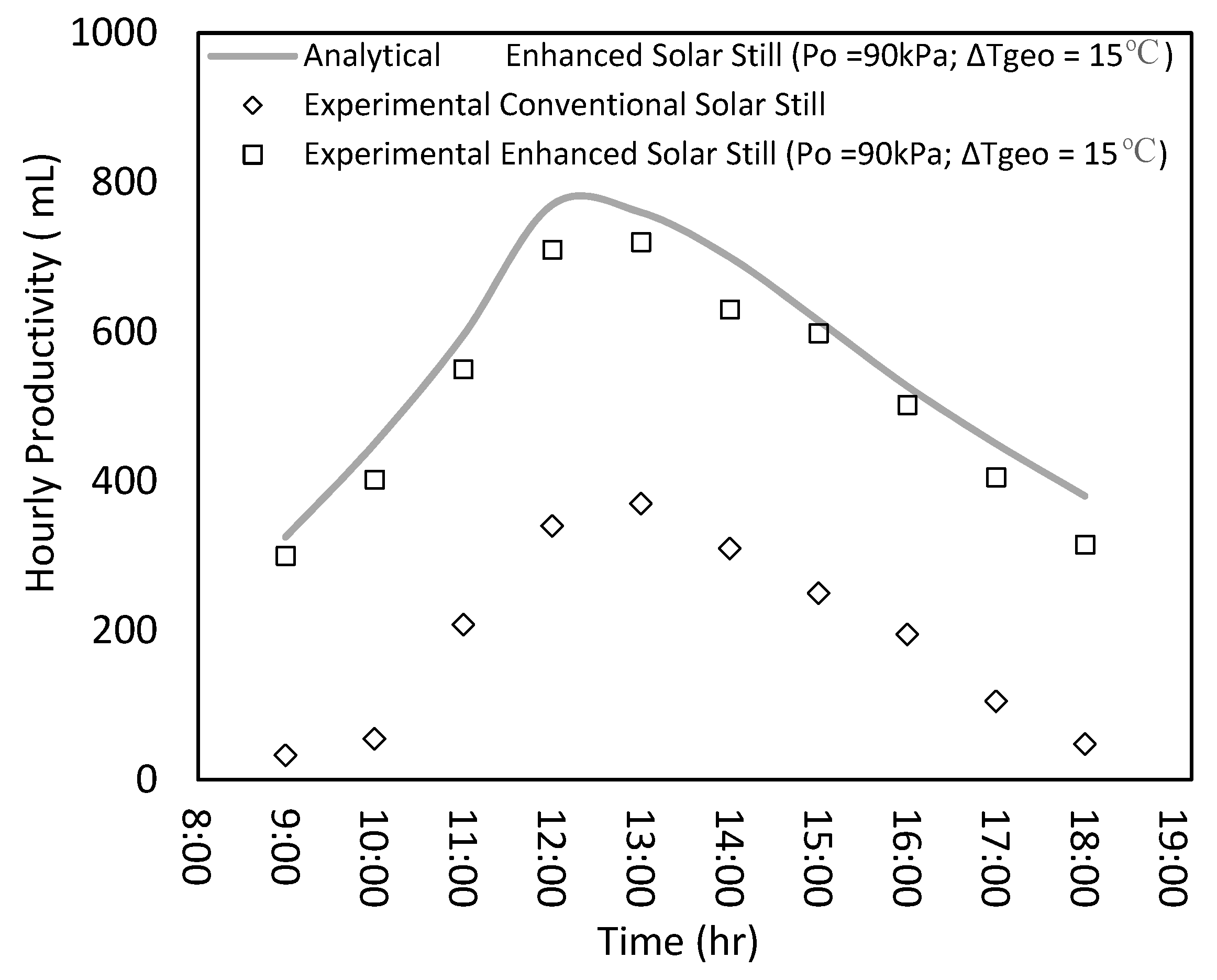

Figure 4 shows the comparison of the analytical and experimental results. The result of the analytical model for the enhanced solar still at the vacuum pressure of 90 kPa and geothermal temperature difference of 15 °C is shown along with the identical experimental result. The figure also shows the experimental result for a conventional solar still. It is evident that the analytical result is in close agreement with the experimental data. Comparison of the experimental result of the conventional still and enhanced still showed major improvement in hourly productivity. An average increase of 305% in hourly productivity is evident.

Figure 4.

Comparison of analytical and experimental results.

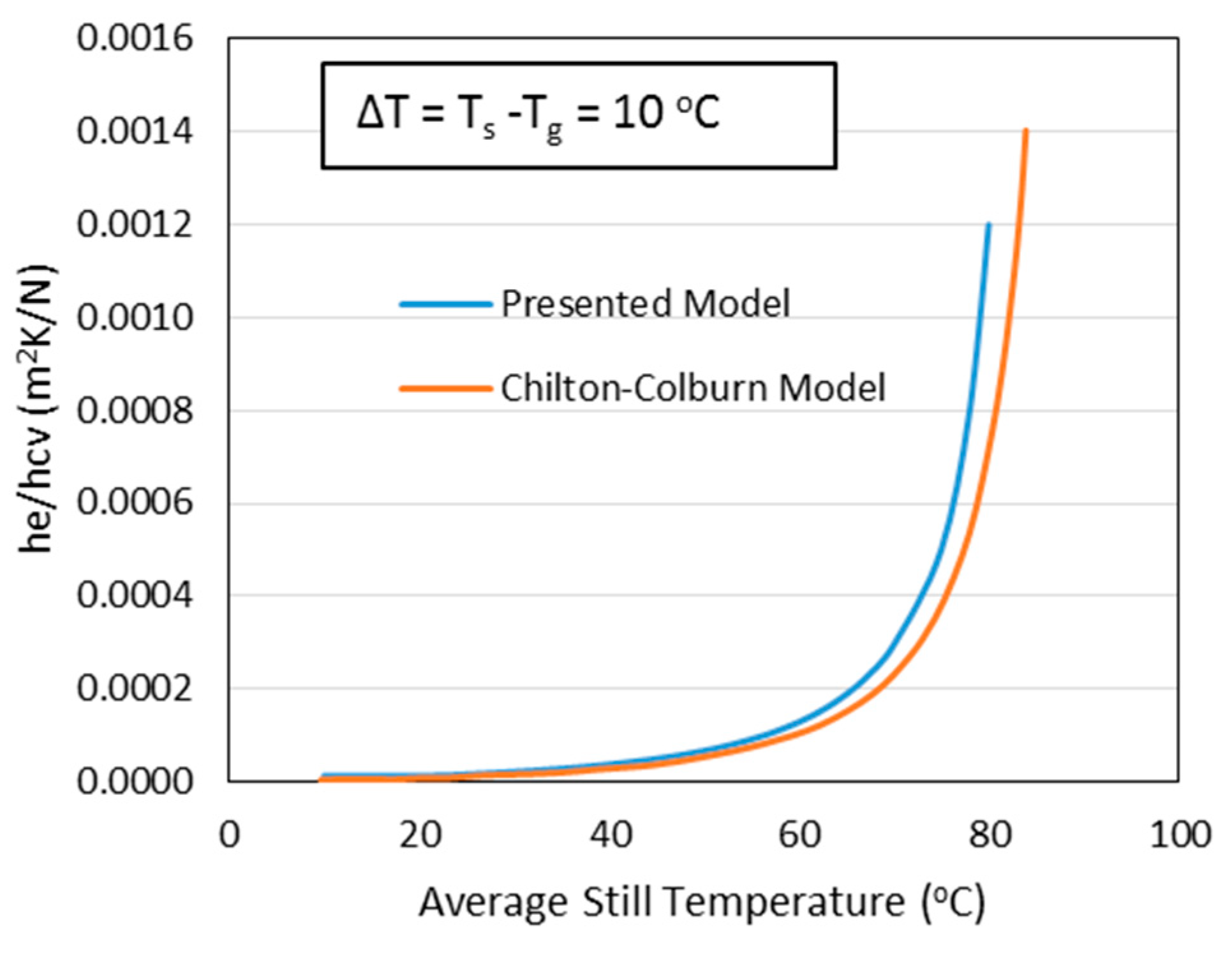

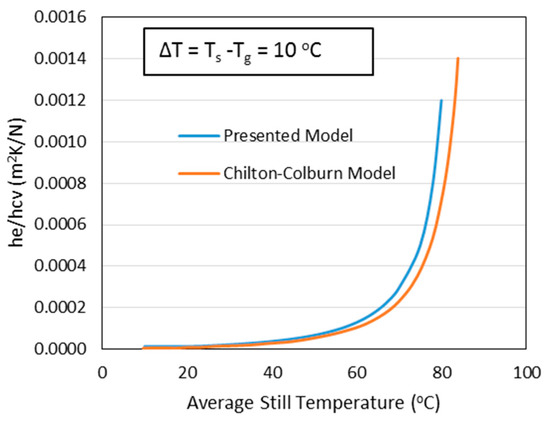

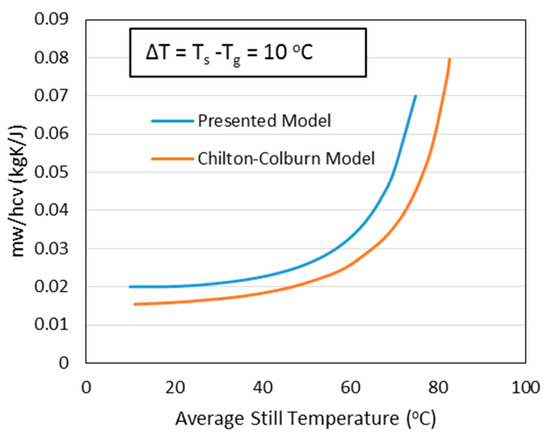

In Figure 5, the calculated numerical values of the he/hcv ratio corresponding to the Chilton-Colburn model [32] are shown as a function of the average still temperature for a typical temperature difference fixed at ΔT = Ts − Tg = 10 °C. The Chilton-Colburn model was selected for comparison as it is a well-known numerical model for solar stills, which has been validated with experimental results with impressive accuracy even at very high mass flow rate yields corresponding to the higher range of solar still operating temperatures. Figure 5 clearly demonstrates the significance of enforcing a vacuum in the solar still, as the he/hcv ratio of the presented model is higher than that of conventional solar stills based on the Chilton-Colburn model. The difference in ratios is insignificant at low average still temperatures of up to 40 °C. The difference increases substantially at higher still temperatures.

Figure 5.

he/hcv corresponding to Chilton-Colburn model.

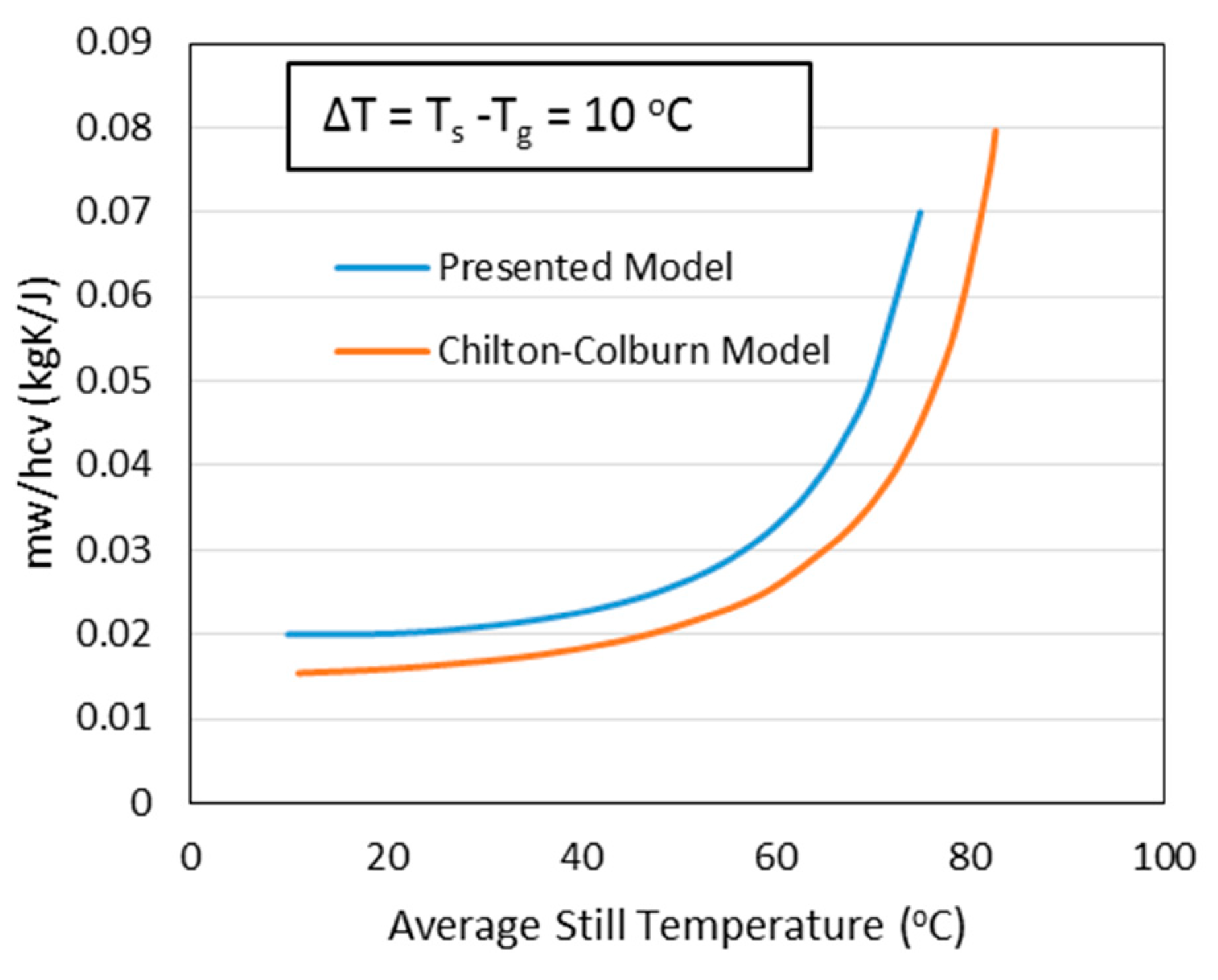

Figure 6 presents the ratio of the mass flow rate per unit still area and convective heat transfer versus the average still temperature for the proposed model compared with that of the Chilton-Colburn model for a typical temperature difference fixed at ΔT = Ts − Tg = 10 °C. Again, performance improvement is evident with the presented model as the ratios are higher at all still temperature ranges. Apparently, the he/hcv ratio for a fixed value of ΔT increases dramatically at higher operational temperatures, whereas for a fixed average still temperature, the corresponding deviation between both models grows as the temperature difference increases.

Figure 6.

me/hcv Corresponding to Chilton-Colburn Model.

4.2. Parametric Studies Based on the Analytical Model

Once the analytical model was proved to be reliable, an extensive parametric study was done to see the effect of vacuum pressure, ambient temperature, and wind speed. This study was important to select the best location for such systems within KSA.

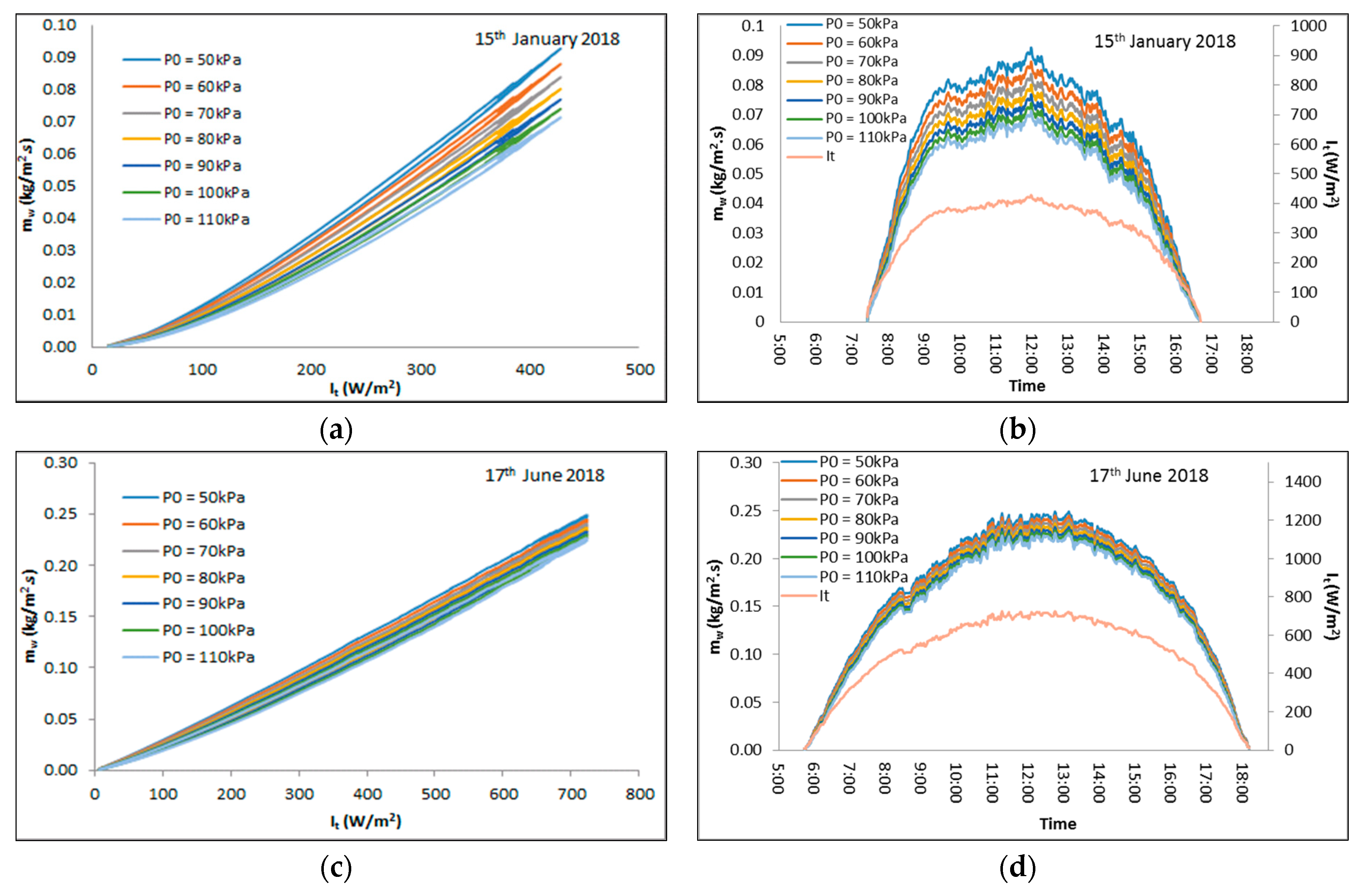

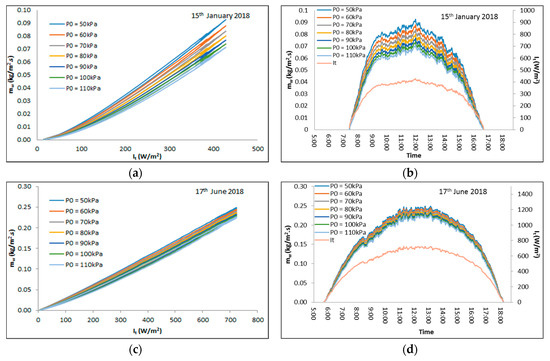

The effect of vacuum pressure on the production of desalinated water is presented in Figure 7. Real-time values of wind velocity and ambient temperature were obtained from the meteorological station. Two representative days for the winter and summer were considered for discussion. Figure 7 shows that the water yield of the solar still increases with the increase in vacuum pressure. The yield increased by approximately 19% at noon when the pressure inside the still decreased from 110 kPa to 50 kPa.

Figure 7.

Effect of vacuum pressure on the production of a geothermal solar still. (a,b) represent the analysis for a winter’s day on 15 January 2018. (c,d) represent the analysis for a summer’s day on 17 June 2018.

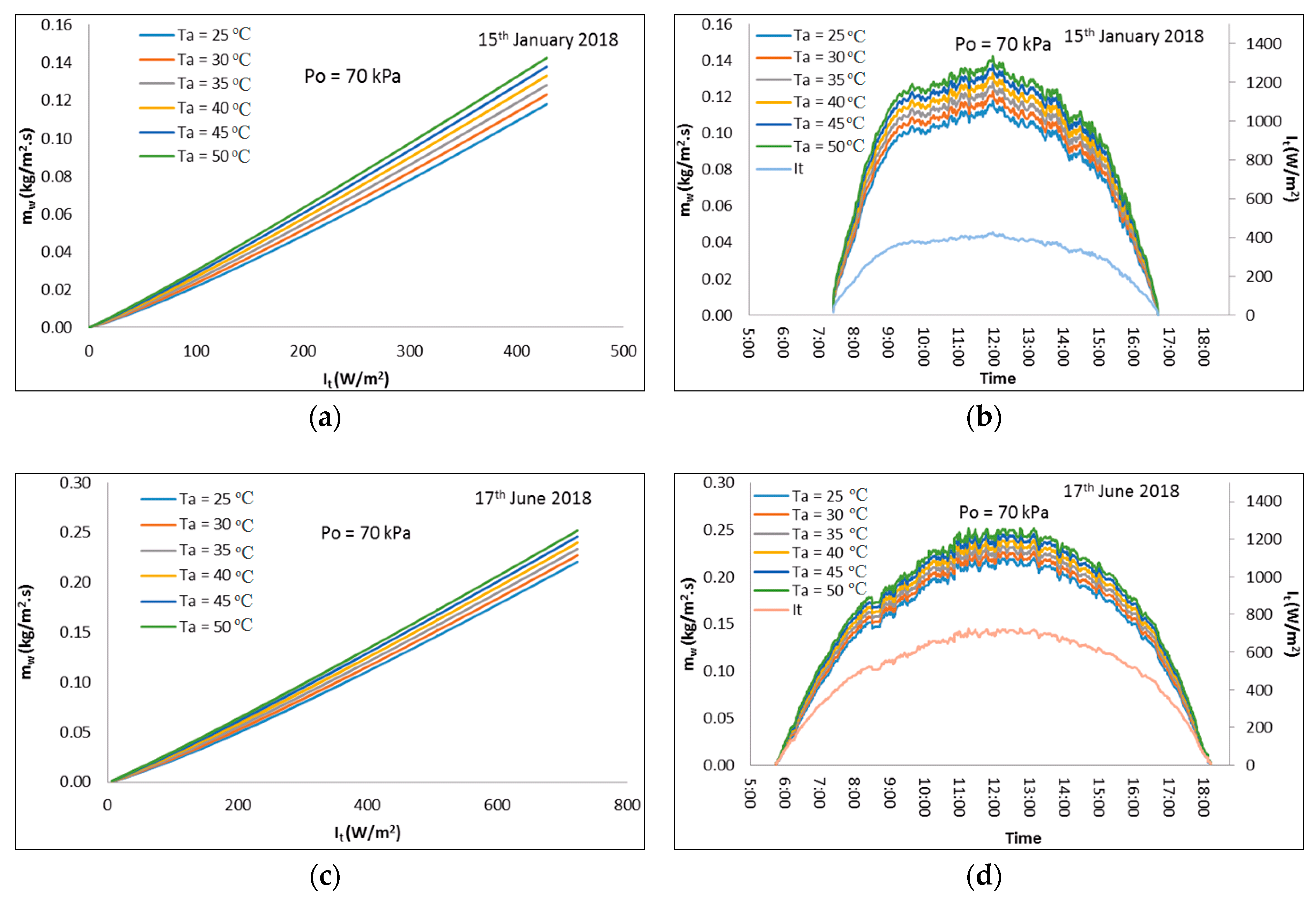

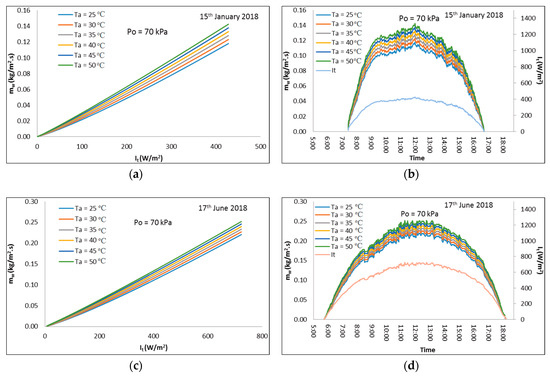

The effect of ambient temperature on the yield of desalinated water is presented in Figure 8. Real-time values of wind velocity were obtained from the meteorological station, and the vacuum pressure was kept at 70 kPa. Two representative days for the winter and summer were considered for discussion. It is clear from the figure that the water yield of the solar still increased with the increase in ambient temperature. There was an increase of approximately 17% yield at noon when the ambient temperature increased from 25 °C to 50 °C.

Figure 8.

Effect of ambient temperature on the production of a geothermal solar still. (a,b) represent analysis for a winter’s day on 15 January 2018. (c,d) represent analysis for a summer’s day on 17 June 2018.

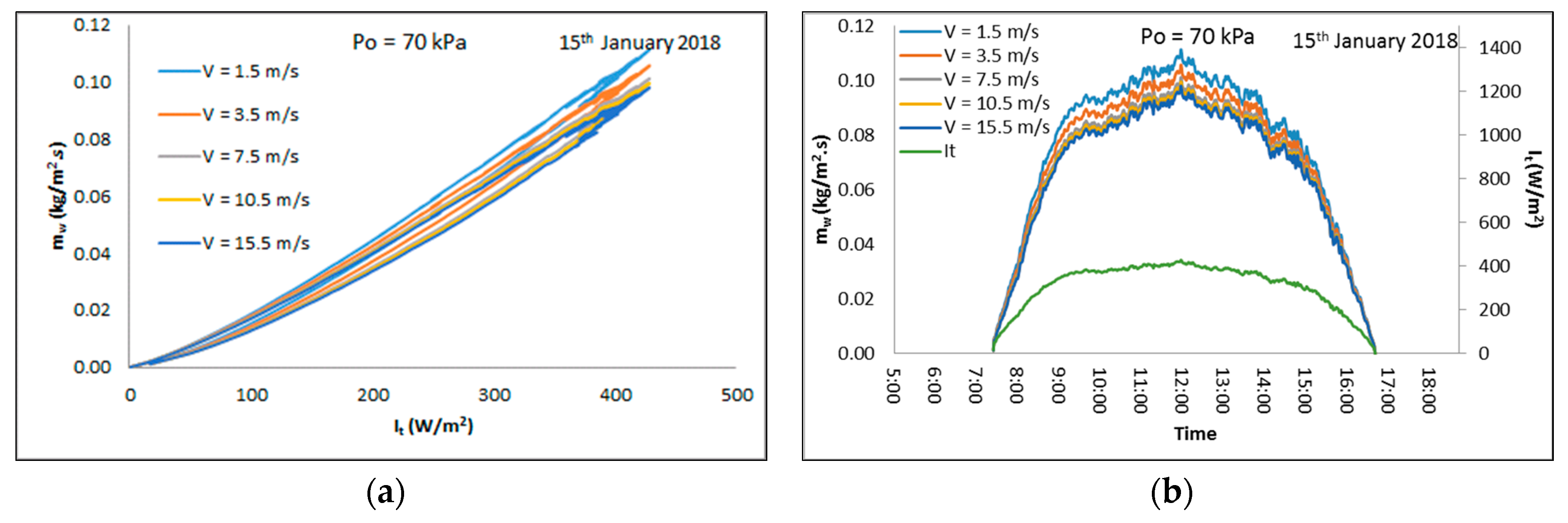

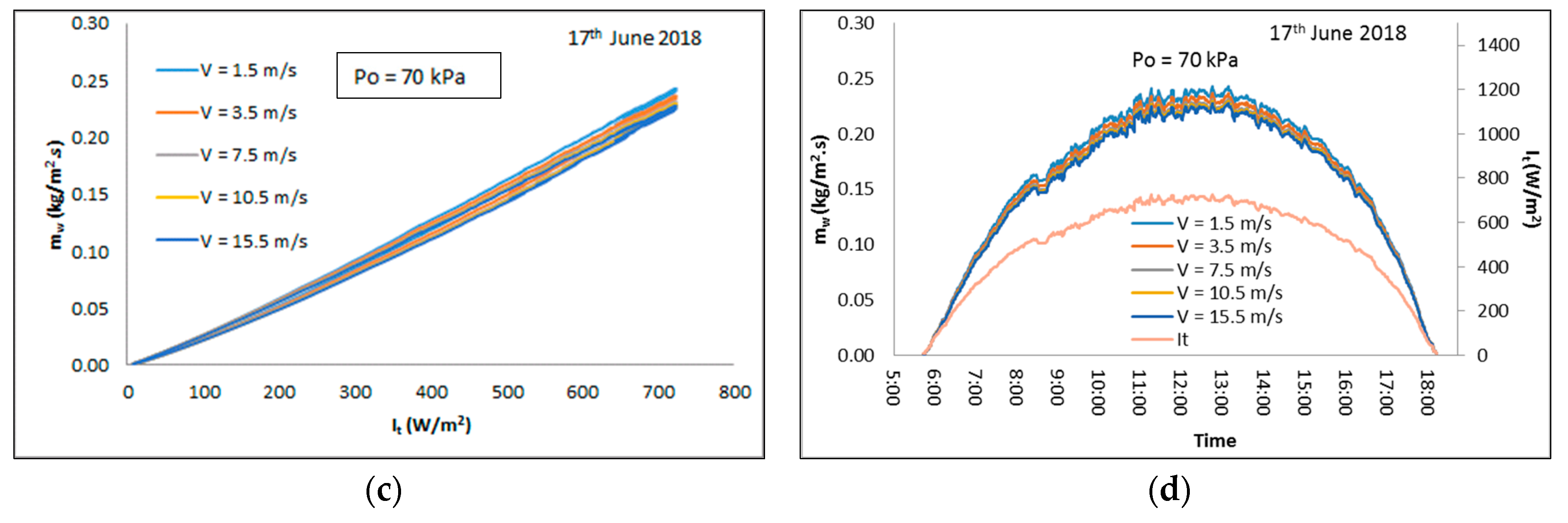

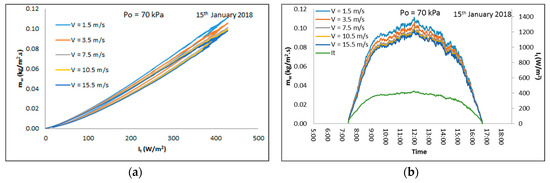

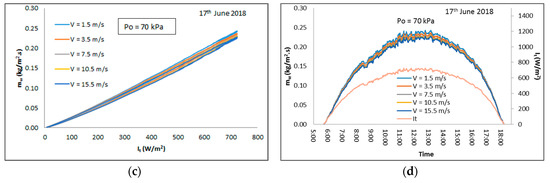

The effect of wind speed on the production of desalinated water is presented in Figure 9. Real-time ambient temperature was obtained from the meteorological station, and the vacuum pressure was kept at 70 kPa. It is obvious from the figure that the water yield of the solar still decreased with the increase in wind speed. This can be attributed to the increase in heat losses with the wind speed.

Figure 9.

Effect of wind speed on the production of a geothermal solar still. (a,b) represent analysis for a winter’s day on 15 January 2018. (c,d) represent analysis for a summer’s day on 17 June 2018.

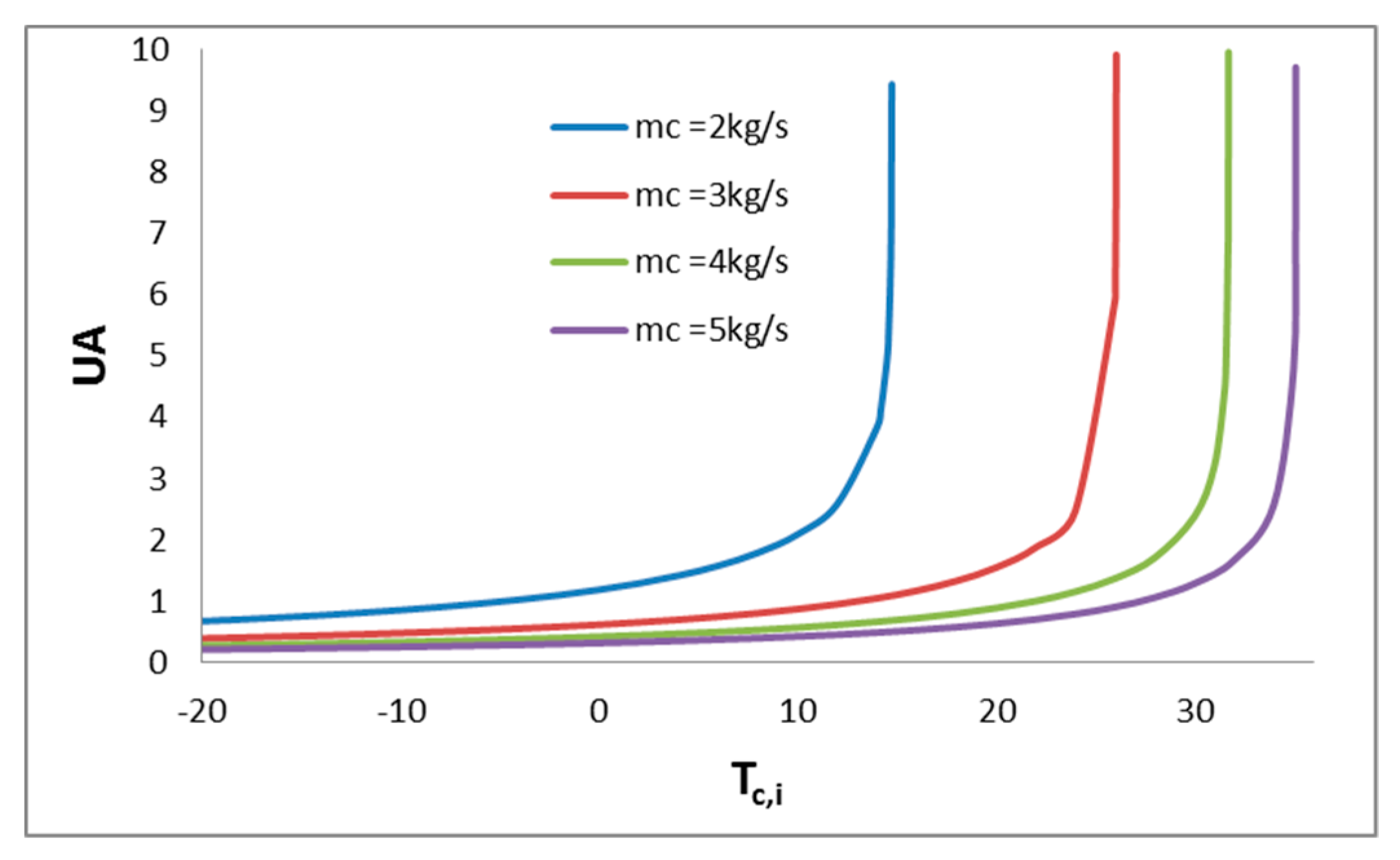

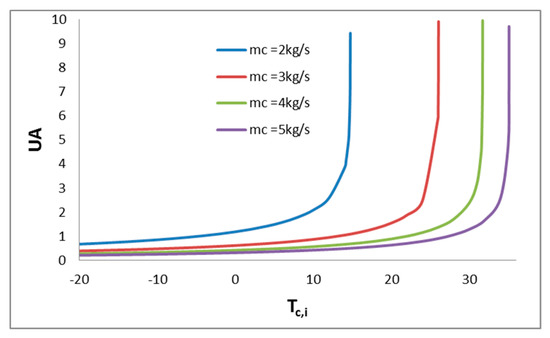

The effect of the inlet temperature of geothermal water on the heat exchanger design is presented in Figure 10. The UA for each mass flow rate increased with the increase in inlet temperature. Since the effectiveness is proportional to NTU (NTU = UA/Cmin), the optimum area of the heat exchanger should be selected in the design of the inlet mass flow rate of geothermal water.

Figure 10.

UA versus the inlet temperature of geothermal water.

5. Conclusions and Recommendations

A geothermal cooling system integrated with a solar still to improve the water still performance was investigated experimentally and analytically. A prototype was built to validate the analytical model. An analytical model was developed and then solved using the Newton-Raphson method for solving non-linear equations. The effects of various parameters such as vacuum pressure, ambient temperature, and wind speed on the yield of the geothermal solar still were examined. The following conclusions were drawn from the study:

- The analytical and experimental results were in close agreement;

- A 305% increase in daily water productivity resulted from the proposed enhancements;

- The increase in vacuum pressure enhanced the yield of the solar still;

- The increase in wind speed had a detrimental effect on the yield of the solar still;

- The increase in ambient temperature increased the yield of the solar still.

Finally, the design of the heat exchanger for condensing the distilled water using geothermal cooling water was also investigated in terms of the increase in UA with inlet cooling geothermal water temperature. The proposed model showed performance improvement when a vacuum pump was included in a hybrid solar-geothermal still.

Author Contributions

S.N.D. and A.E.-L. conceived the idea, developed the mathematical model and performed the experiments; S.N.D., A.E.-L. and M.A. developed the methodology and analyzed the data; A.E.-L. and H.A.-A. contributed in analysis tools, project administration and funding acquisition; S.N.D. wrote the paper.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding this work through research group No. RG-1440-087.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| A | Area of Heat Exchanger (m2) |

| C | Constant |

| Cp | Specific Heat (kJ/kgK) |

| Cc | Specific Heat of Geothermal Water (kJ/kgK) |

| ΔTgeo | Difference between Ambient Temperature and Geothermal Water Temperature |

| Exp. | Experimental |

| h | Heat Transfer Coefficient (W/m2K) |

| hfg | Heat of Evaporation (kJ/kg) |

| g | Gravity (m/s2) |

| I | Solar Radiation (W/m2) |

| k | Thermal Conductivity(W/mK) |

| M | Molar Mass (kg/mol) |

| Mass Flow Rate of Water (kg/s) | |

| Mass Flow Rate of Geothermal Water (kg/s) | |

| NTU | Number of Transfer Units |

| P | Pressure (kPa) |

| P(T) | Saturated Vapor Pressure at T (kPa) |

| R | Gas Constant (kJ/kgK) |

| T | Temperature (K) |

| U | Overall Heat Transfer Coefficient (W/m2K) |

| V | Wind Speed (m/s) |

| Greek | |

| α | Absorptivity |

| β | Constant |

| Emissivity | |

| Effectiveness of Heat Exchanger | |

| τ | Transmisivity |

| Stefan-Boltzman Constant | |

| ρ | Density (kg/m3) |

| μ | Viscosity (Ns/m2) |

| Subscript | |

| a | Air |

| c | Convection |

| e | Evaporation |

| g | Glass |

| m | Mixture |

| o | Vacuum |

| r | Radiation |

| t | Tilted surface |

| w | Water |

References

- Saleh, H.A. Evaluation of solar energy research and its applications in Saudi Arabia—20 years of experience. Renew. Sustain. Energy Rev. 2001, 5, 59–77. [Google Scholar]

- Nebbia, G.; Mennozi, G. A short history of water desalination. In Proceedings of the International Symposium, Milano, Italy, 18–19 April 1966; pp. 129–172. [Google Scholar]

- Tiwari, G.N.; Saxena, P.; Thakur, K. Thermal analysis of active solar distillation system. Energy Convers. Manag. 1994, 35, 51–59. [Google Scholar] [CrossRef]

- Abu-Hijleh, B. Enhanced solar still performance using water film cooling of the glass cover. Desalination 1996, 107, 233–242. [Google Scholar] [CrossRef]

- Nijegorodov, N.; Jain, P.; Carlsson, S. Thermal-electrical, high efficiency solar stills. Renew. Energy 1994, 4, 123–127. [Google Scholar] [CrossRef]

- Yadav, Y. Parametric studies on a double basin solar still. Int. J. Sol. Energy 1994, 16, 137–150. [Google Scholar] [CrossRef]

- Yeh, H.; Chen, Z. Energy balances for upward-type, double-effect solar distillers with air flow through the second-effect unit. Energy 1994, 19, 619–626. [Google Scholar] [CrossRef]

- Yadav, Y. Transient analysis of double basin solar still integrated with collector. Desalination 1989, 71, 151–164. [Google Scholar] [CrossRef]

- Ahmed, S.T. Study of single-effect solar still with an internal condenser. Sol. Wind Technol. 1988, 5, 637–643. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Singh, A.K.; Saxena, P.; Rai, S. The performance of multi-effect active distillation system. Int. J. Sol. Energy 1993, 13, 277–287. [Google Scholar] [CrossRef]

- Lawrence, S.A.; Gupta, S.P.; Tiwari, G.N. Experimental validation of thermal analysis of solar still with dye. Int. J. Sol. Energy 1988, 6, 291–305. [Google Scholar] [CrossRef]

- Selvaraj, K.; Natarajan, A. Factors influencing the performance and productivity of solar stills—A review. Desalination 2018, 435, 181–187. [Google Scholar] [CrossRef]

- Al-Nimr, M.; Haddad, O. Water Distiller/Condenser by radiative cooling of ambient air. Renew. Energy 1998, 13, 323–331. [Google Scholar] [CrossRef]

- Haddad, O.; Al-Nimr, M.; Maqableh, A. Enhanced solar still performance using a radiative cooling system. Renew. Energy 2000, 12, 459–469. [Google Scholar] [CrossRef]

- Saadi, Z.; Rahmani, A.; Lachtar, S.; Soualmi, H. Performance evaluation of a new stepped solar still under the desert climatic conditions. Energy Convers. Manag. 2018, 171, 1749–1760. [Google Scholar] [CrossRef]

- Al-harahsheh, M.; Abu-Arabi, M.; Mousa, H.; Alzghoul, Z. Solar desalination using solar still enhanced by external solar collector and PCM. Appl. Therm. Eng. 2018, 128, 1030–1040. [Google Scholar] [CrossRef]

- Nayi, K.H.; Modi, K.V. Pyramid solar still: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 81, 136–148. [Google Scholar] [CrossRef]

- Gao, J.; Li, A.; Xu, X.; Gang, W.; Yan, T. Ground heat exchangers: Applications, technology integration and potentials for zero energy buildings. Renew. Energy 2018, 128, 337–349. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Philippe, M.; Murugesan, K.; Verma, V.; Hu, P. Experimental thermal performance analysis of ground heat exchangers for space heating and cooling applications. Renew. Energy 2017, 113, 1168–1181. [Google Scholar] [CrossRef]

- Ground-Coupled Heat Exchanger. Available online: https://en.wikipedia.org/wiki/Ground-coupled_heat_exchanger (accessed on 1 November 2018).

- US Department of Energy. Geothermal Heat Pumps. Available online: http://www.energysavers.gov/your_home/space_heating_cooling (accessed on 1 November 2018).

- Bose, J.E.; Ledbetter, C.W.; Partin, J.R. Experimental results of a low-cost solar-assisted heat pump system using earth coil and geo-thermal well storage. In Proceedings of the 4th Annual Heat Pump Technology Conference, Stillwater, OK, USA, 9–10 April 1979. [Google Scholar]

- Xiao, G.; Wang, X.; Ni, M.; Wang, F.; Zhu, W.; Luo, Z.; Cen, K. A review on solar stills for brine desalination. Appl. Energy 2013, 103, 642–652. [Google Scholar] [CrossRef]

- Sivakumar, V.; Sundaram, G.E. Improvement techniques of solar still efficiency: A review. Renew Sustain. Energy Rev. 2013, 28, 246–264. [Google Scholar] [CrossRef]

- Ayoub, G.M.; Malaeb, L.; Saikaly, P.E. Critical variables in the performance of a productivity-enhanced solar still. Sol. Energy 2013, 98, 472–484. [Google Scholar] [CrossRef]

- Nabil, E.; Alaboodi, A. Implementing of Desalination System Utilizing Solar and Subsurface Condensation of Humid Air in Arid Regions. J. Innov. Eng. 2014, 2, 6. [Google Scholar]

- Al-Hussaini, H.; Smith, I.K. Enhancing of solar still productivity using vacuum technology. Energy Convers. Manag. 1995, 36, 1047–1051. [Google Scholar] [CrossRef]

- Tsilingiris, P.T. Combined heat and mass transfer analyses in solar distillation systems—The restrictive conditions and a validity range investigation. Sol. Energy 2012, 86, 3288–3300. [Google Scholar] [CrossRef]

- Tsilingiris, P.T. The influence of binary mixture thermophysical properties in the analysis of heat and mass transfer processes in solar distillation systems. Sol. Energy 2007, 81, 1482–1491. [Google Scholar] [CrossRef]

- Tamimi, A.; Sowayan, A. Optimum Tilt Angles of Flat-plate Solar Collectors at Riyadh, Kingdom of Saudi Arabia. Energy Sources Part A Recov. Util. Environ. Effects 2012, 34, 1213–1221. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the Uncertainties in Experimental Results Experimental Thermal and Fluid Science; Elsevier Science Pub Co., Inc.: New York, NY, USA, 1988. [Google Scholar]

- Chilton, T.H.; Colburn, A.P. Mass transfer (absorption) coefficients—Prediction from data on heat transfer and fluid friction. Ind. Eng. Chem. 1934, 26, 1183–1187. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).