Induction Motor Broken Rotor Bar Detection Based on Rotor Flux Angle Monitoring

Abstract

:1. Introduction

2. Model of IM with a Faulty Rotor

3. Analysis of Healthy and Faulty Motors’ Behavior

3.1. Healthy Motor

- Case 1:

- A healthy motor with a constant load:As expected, in a healthy motor with a constant load (Tl = 30 Nm), magnetizing current imR and slip frequency ωsl remain constant (Figure 3a).

- Case 2:

- A healthy motor with a superimposed oscillating load:When a sinusoidal load torque is superimposed on a constant load, e.g., Tl = 30 ± 0.3 Nm at 2.7 Hz, denoted with LO1 (see Table A2 in Appendix A for various applied oscillating load conditions), only the magnetizing current remains practically constant, while ωsl (thus iSq) oscillates with the load torque frequency (Figure 3b).

3.2. Faulty Motor

- Case 3:

- A faulty motor with a constant load:In Equation (4) the magnetizing current contains the oscillation caused by the fault (factor f(β)). The same applies to Equation (5), where the term with factor h(β) can be neglected, as it is much smaller than the first part. Nevertheless, the slip frequency contains oscillations, caused by the fault (factor g(β)), as shown in Figure 4a.

- Case 4:

- A faulty motor with a superimposed oscillating load:In this case (LO1) the magnetizing current in Equation (4) oscillates due to the load oscillation (iSq) and the oscillation caused by the fault (factor f(β)). The same applies to Equation (5), where the term with factor h(β) can be neglected, as imR tracks iSd. Again, the slip frequency contains non-sinusoidal oscillations that are caused by the fault (factor g(β)) and by the load (iSq), as shown in Figure 4b.

3.3. Two Cases of Misinterpreted MCSA

3.3.1. False Positive BRB Detection

3.3.2. False Negative BRB Detection

4. Robust Detection of BRBs

- Example 1:

- A healthy motor: the actual rotor time constant τR changes due to the motor heating (τR < τR0, Ctemp > 1),

- Example 2:

- A faulty motor: the motor has two different time constants (τRD and τRQ), which is the case of our special interest. Additionally, Ctemp may or may not vary.

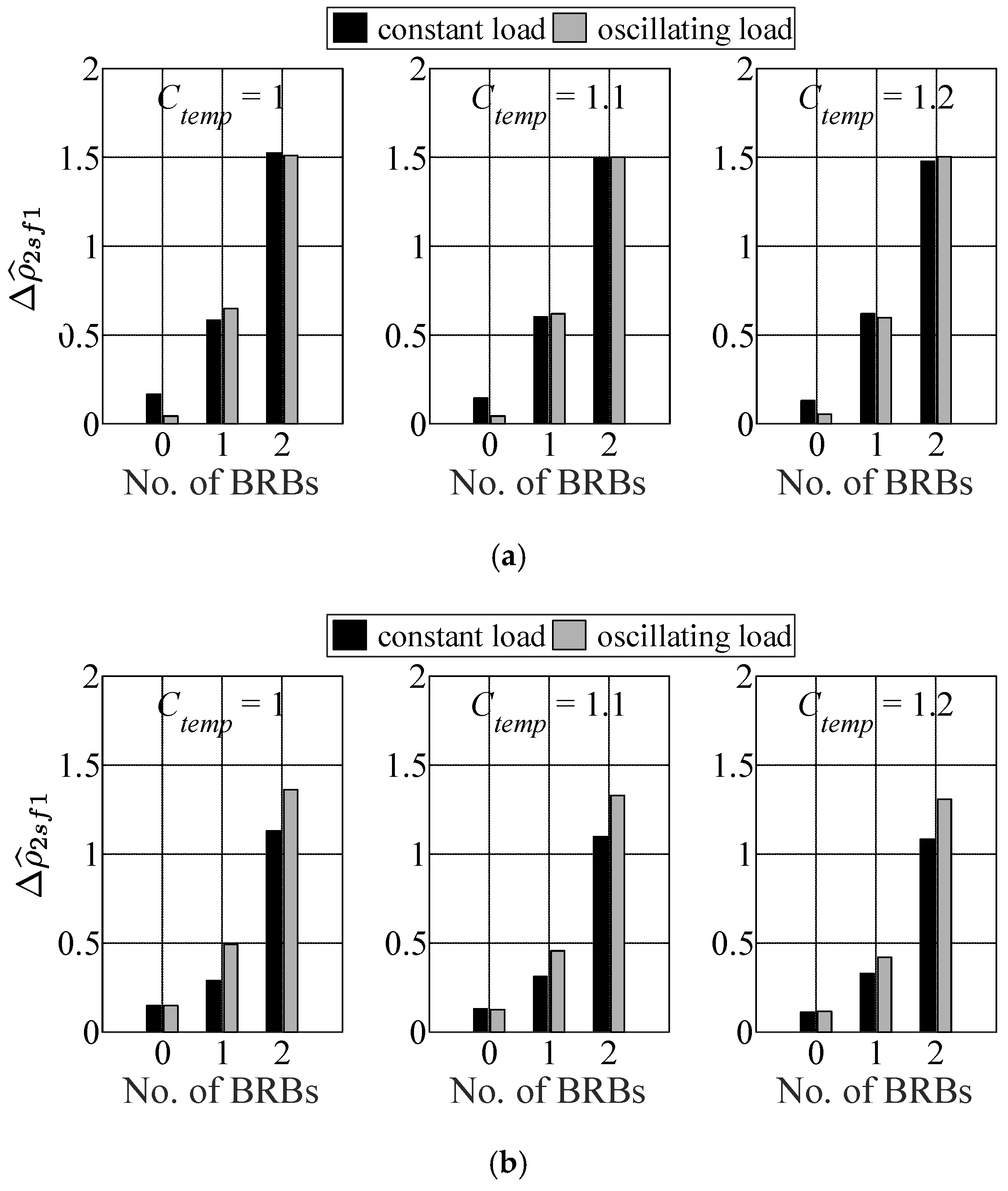

4.1. BRBs Detection—Simulations

4.2. BRBs Detection—Experiments

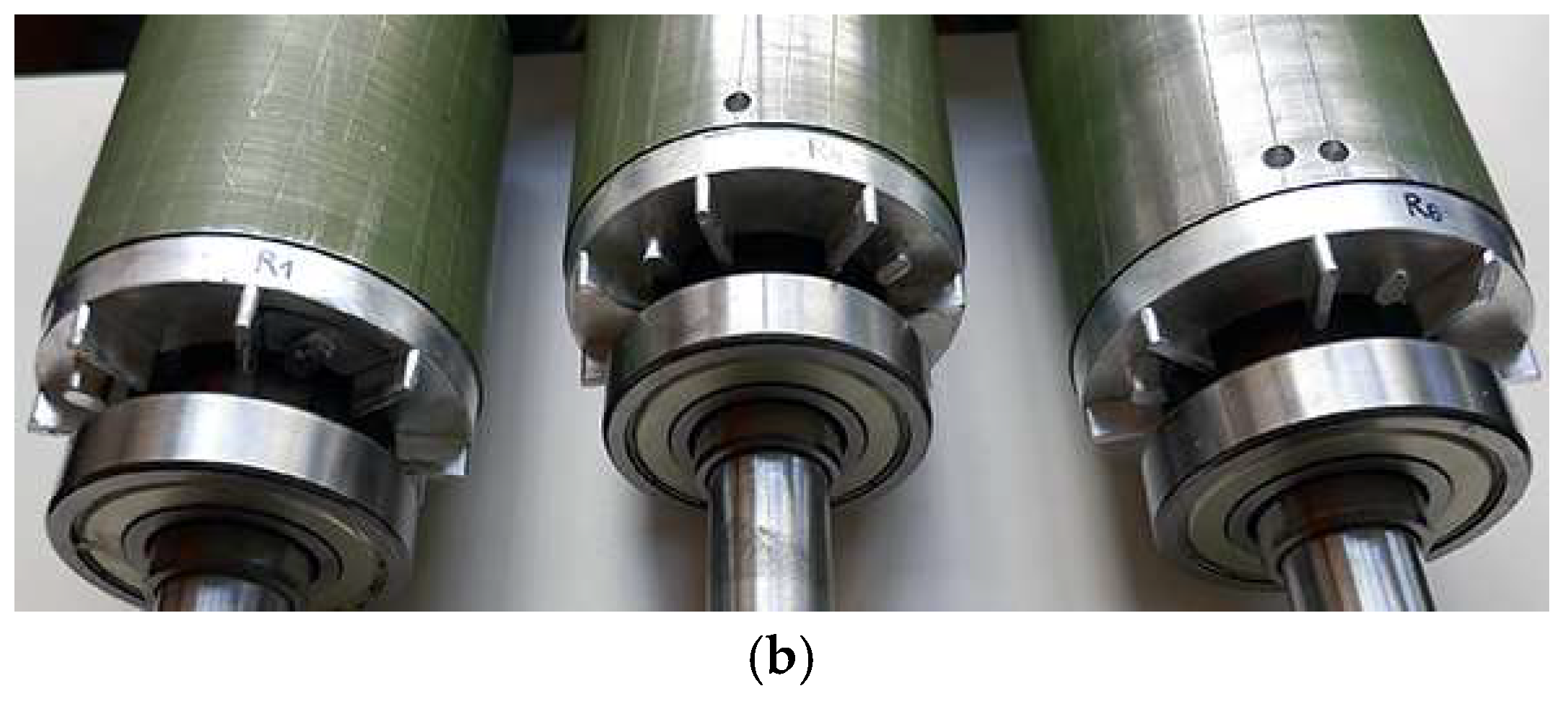

- numbers of BRBs (0: healthy rotor; 1 BRB; 2 adjacent BRBs—see tested rotors in Figure 12b),

- constant load torques (Tl = 20 Nm and Tl = 30 Nm),

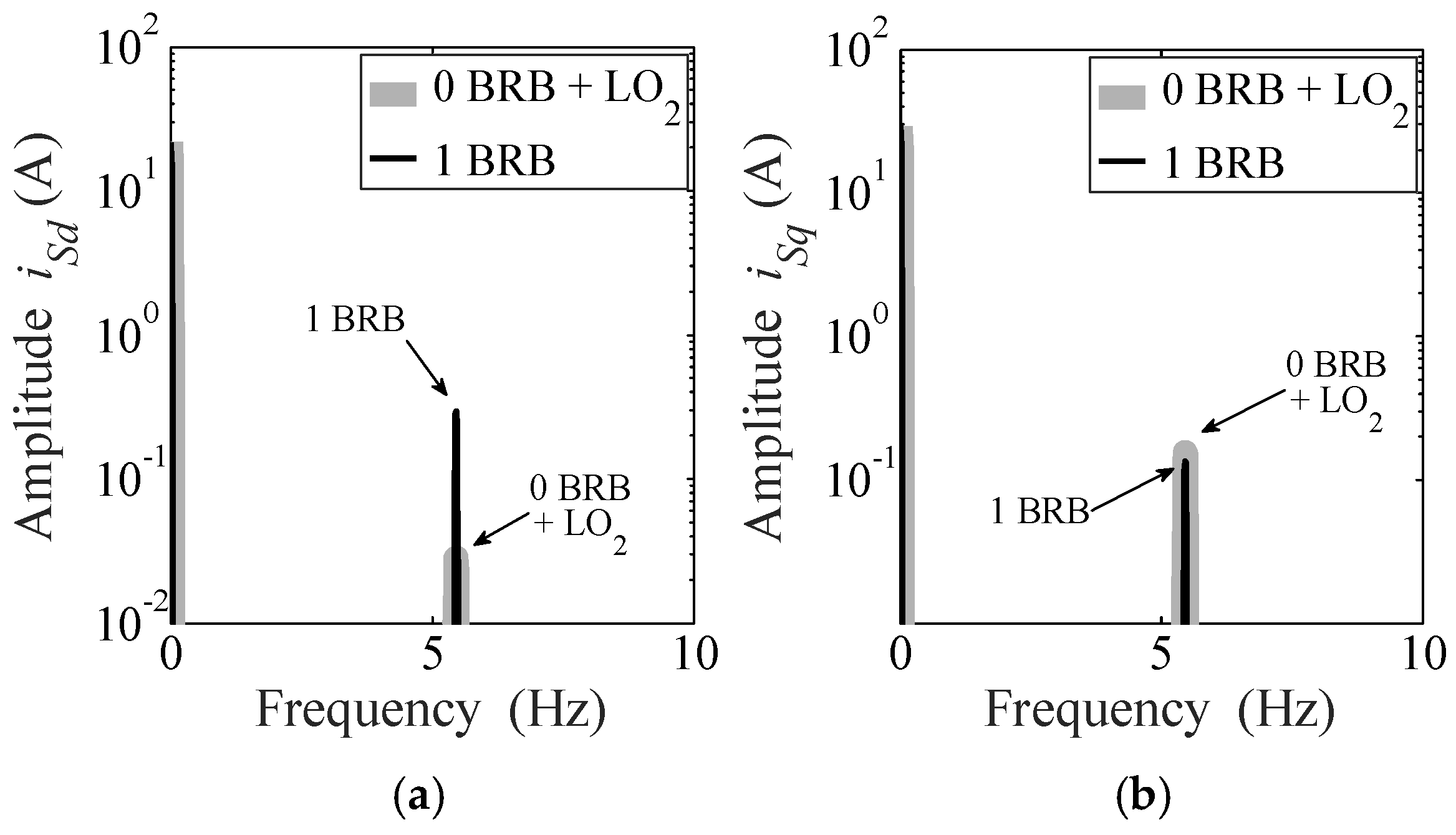

4.2.1. Spectral Signature of BRBs and Load Oscillation

4.2.2. On-line Implementation of Detection Algorithm

4.2.3. Detection Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Rated power (kW) | 3.0 | Rated current (A) | 13.0 | |

| Rated torque (Nm) | 30.0 | Rated voltage (V) | 236 | |

| Rated speed (min–1) | 1000 | Moment of inertia (kg·m2) | 0.019 | |

| Number of pole pairs | 3 | 0 BRB: τR0 = τR@75 °C (ms) | 79.8 | |

| Rated frequency (Hz) | 50 | τR0 = τR@25 °C (ms) | 97.1 | |

| Number rotor bars | 30 | 1 BRB: τRD (ms) | 77.6 | |

| Stator inductance (mH) | 48.9 | τRQ (ms) | 79.8 | |

| Mutual inductance (mH) | 45.0 | 2 BRB: τRD (ms) | 74.7 | |

| Stator resistance (Ω) | 0.65 | τRQ (ms) | 79.8 |

| Annotation | Constant Load (Nm) | Superimposed Oscillation (Nm) | Frequency of Oscillation (Hz) |

|---|---|---|---|

| LO1 | 30 | ±0.3 | 2.70 |

| LO2 | 30 | ±0.3 | 5.46 |

| LO3 | 20 | ±3.0 | 2.00 |

| LO4 | 30 | ±3.0 | 2.00 |

References

- Henao, H.; Capolino, G.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in Fault Diagnosis for Electrical Machines: A Review of Diagnostic Techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef] [Green Version]

- Capolino, G.A.; Antonino-Daviu, J.A.; Riera-Guasp, M. Modern Diagnostics Techniques for Electrical Machines, Power Electronics, and Drives. IEEE Trans. Ind. Electron. 2015, 62, 1738–1745. [Google Scholar] [CrossRef] [Green Version]

- Bellini, A.; Filippetti, F.; Franceschini, F.; Sobczyk, T.J.; Tassoni, C. Diagnosis of Induction Machines by d-q and i.s.c. Rotor Models. In Proceedings of the 2005 IEEE 5th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Vienna, Austria, 7–9 September 2005; pp. 1–6. [Google Scholar]

- Nandi, S.; Toliyat, H.A.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Zhang, P.; Du, Y.; Habetler, T.G.; Lu, B. A Survey of Condition Monitoring and Protection Methods for Medium-Voltage Induction Motors. IEEE Trans. Ind. Appl. 2011, 47, 34–46. [Google Scholar] [CrossRef]

- Culbert, I.; Letal, J. Signature Analysis for Online Motor Diagnostics: Early Detection of Rotating Machine Problems Prior to Failure. IEEE Ind. Appl. Mag. 2017, 23, 76–81. [Google Scholar] [CrossRef]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O. State of the Art and Trends in the Monitoring, Detection and Diagnosis of Failures in Electric Induction Motors. Energies 2017, 10, 1056. [Google Scholar] [CrossRef]

- Bouzid, M.B.K.; Champenois, G.; Bellaaj, N.M.; Signac, L.; Jelassi, K. An Effective Neural Approach for the Automatic Location of Stator Interturn Faults in Induction Motor. IEEE Trans. Ind. Electron. 2008, 55, 4277–4289. [Google Scholar] [CrossRef]

- Gandhi, A.; Corrigan, T.; Parsa, L. Recent Advances in Modeling and Online Detection of Stator Interturn Faults in Electrical Motors. Ind. Electron. IEEE Trans. 2011, 58, 1564–1575. [Google Scholar] [CrossRef]

- Maraaba, L.; Al-Hamouz, Z.; Abido, M. An Efficient Stator Inter-Turn Fault Diagnosis Tool for Induction Motors. Energies 2018, 11, 653. [Google Scholar] [CrossRef]

- Gritli, Y.; Bellini, A.; Rossi, C.; Casadei, D.; Filippetti, F.; Capolino, G.A. Condition monitoring of mechanical faults in induction machines from electrical signatures: Review of different techniques. In Proceedings of the 2017 IEEE 11th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Tinos, Greece, 29 August–1 September 2017; pp. 77–84. [Google Scholar]

- Jung, J.; Park, Y.; Lee, S.B.; Cho, C.H.; Kim, K.; Wiedenbrug, E.J.; Teska, M. Monitoring Journal-Bearing Faults: Making Use of Motor Current Signature Analysis for Induction Motors. IEEE Ind. Appl. Mag. 2017, 23, 12–21. [Google Scholar] [CrossRef]

- Stack, J.R.; Habetler, T.G.; Harley, R.G. Fault classification and fault signature production for rolling element bearings in electric machines. IEEE Trans. Ind. Appl. 2004, 40, 735–739. [Google Scholar] [CrossRef]

- Yahia, K.; Sahraoui, M.; Cardoso, A.J.M.; Ghoggal, A. The Use of a Modified Prony’s Method to Detect the Airgap-Eccentricity Occurrence in Induction Motors. IEEE Trans. Ind. Appl. 2016, 52, 3869–3877. [Google Scholar] [CrossRef]

- Ojaghi, M.; Aghmasheh, R.; Sabouri, M. Model-based exact technique to identify type and degree of eccentricity faults in induction motors. IET Electr. Power Appl. 2016, 10, 706–713. [Google Scholar] [CrossRef]

- Pezzani, C.; Donolo, P.; Bossio, G.; Donolo, M.; Guzmán, A.; Zocholl, S.E. Detecting Broken Rotor Bars with Zero-Setting Protection. IEEE Trans. Ind. Appl. 2014, 50, 1373–1384. [Google Scholar] [CrossRef]

- Hou, Z.; Huang, J.; Liu, H.; Wang, T.; Zhao, L. Quantitative broken rotor bar fault detection for closed-loop controlled induction motors. IET Electr. Power Appl. 2016, 10, 403–410. [Google Scholar] [CrossRef]

- Trachi, Y.; Elbouchikhi, E.; Choqueuse, V.; Benbouzid, M.E.H.; Wang, T. A Novel Induction Machine Fault Detector Based on Hypothesis Testing. IEEE Trans. Ind. Appl. 2017, 53, 3039–3048. [Google Scholar] [CrossRef]

- Fernandez-Cavero, V.; Morinigo-Sotelo, D.; Duque-Perez, O.; Pons-Llinares, J. A Comparison of Techniques for Fault Detection in Inverter-Fed Induction Motors in Transient Regime. IEEE Access 2017, 5, 8048–8063. [Google Scholar] [CrossRef]

- Jerkan, D.G.; Reljić, D.D.; Marčetić, D.P. Broken Rotor Bar Fault Detection of IM Based on the Counter-Current Braking Method. IEEE Trans. Energy Convers. 2017, 32, 1356–1366. [Google Scholar] [CrossRef]

- Yang, T.; Pen, H.; Wang, Z.; Chang, C.S. Feature Knowledge Based Fault Detection of Induction Motors Through the Analysis of Stator Current Data. IEEE Trans. Instrum. Meas. 2016, 65, 549–558. [Google Scholar] [CrossRef]

- Elkasabgy, N.M.; Eastham, A.R.; Dawson, G.E. Detection of broken bars in the cage rotor on an induction machine. IEEE Trans. Ind. Appl. 1992, 28, 165–171. [Google Scholar] [CrossRef]

- Mirafzal, B.; Demerdash, N.A.O. On innovative methods of induction motor interturn and broken-bar fault diagnostics. IEEE Trans. Ind. Appl. 2006, 42, 405–414. [Google Scholar] [CrossRef]

- Lee, S.; Hong, J.; Lee, S.B.; Wiedenbrug, E.J.; Teska, M.; Kim, H. Evaluation of the Influence of Rotor Axial Air Ducts on Condition Monitoring of Induction Motors. IEEE Trans. Ind. Appl. 2013, 49, 2024–2033. [Google Scholar] [CrossRef]

- Yang, C.; Kang, T.J.; Hyun, D.; Lee, S.B.; Antonino-Daviu, J.A.; Pons-Llinares, J. Reliable Detection of Induction Motor Rotor Faults Under the Rotor Axial Air Duct Influence. IEEE Trans. Ind. Appl. 2014, 50, 2493–2502. [Google Scholar] [CrossRef]

- Park, Y.; Jeong, M.; Lee, S.B.; Antonino-Daviu, J.A.; Teska, M. Influence of Blade Pass Frequency Vibrations on MCSA-Based Rotor Fault Detection of Induction Motors. IEEE Trans. Ind. Appl. 2017, 53, 2049–2058. [Google Scholar] [CrossRef]

- Climente-Alarcon, V.; Antonino-Daviu, J.A.; Haavisto, A.; Arkkio, A. Diagnosis of Induction Motors Under Varying Speed Operation by Principal Slot Harmonic Tracking. IEEE Trans. Ind. Appl. 2015, 51, 3591–3599. [Google Scholar] [CrossRef]

- Faiz, J.; Ghorbanian, V.; Ebrahimi, B.M. EMD-Based Analysis of Industrial Induction Motors with Broken Rotor Bars for Identification of Operating Point at Different Supply Modes. IEEE Trans. Ind. Inform. 2014, 10, 957–966. [Google Scholar] [CrossRef]

- Drif, M.; Kim, H.; Kim, J.; Lee, S.B.; Cardoso, A.J.M. Active and Reactive Power Spectra-Based Detection and Separation of Rotor Faults and Low-Frequency Load Torque Oscillations. IEEE Trans. Ind. Appl. 2017, 53, 2702–2710. [Google Scholar] [CrossRef]

- Schoen, R.R.; Habetler, T.G. Evaluation and implementation of a system to eliminate arbitrary load effects in current-based monitoring of induction machines. IEEE Trans. Ind. Appl. 1997, 33, 1571–1577. [Google Scholar] [CrossRef]

- Wu, L.; Habetler, T.G.; Harley, R.G. A Reliable Rotor Eccentricity Detection Scheme for Induction Machines in the Presence of a Position Dependent Load Torque Oscillation. In Proceedings of the 2007 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cracow, Poland, 6–8 September 2007; pp. 83–88. [Google Scholar]

- Bossio, G.R.; Angelo, C.H.D.; Bossio, J.M.; Pezzani, C.M.; Garcia, G.O. Separating Broken Rotor Bars and Load Oscillations on IM Fault Diagnosis Through the Instantaneous Active and Reactive Currents. IEEE Trans. Ind. Electron. 2009, 56, 4571–4580. [Google Scholar] [CrossRef]

- Angelo, C.H.D.; Bossio, G.R.; Garcia, G.O. Discriminating broken rotor bar from oscillating load effects using the instantaneous active and reactive powers. IET Electr. Power Appl. 2010, 4, 281–290. [Google Scholar] [CrossRef]

- Wu, L.; Habetler, T.G.; Harley, R.G. A Review of Separating Mechanical Load Effects from Rotor Faults Detection in Induction Motors. In Proceedings of the 2007 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cracow, Poland, 6–8 September 2007; pp. 221–225. [Google Scholar]

- Sun, L.; Xu, B. An Improved Method for Discerning Broken Rotor Bar Fault and Load Oscillation in Induction Motors. Energies 2018, 11, 3130. [Google Scholar] [CrossRef]

- Goktas, T.; Arkan, M. Discerning broken rotor bar failure from low-frequency load torque oscillation in DTC induction motor drives. Trans. Inst. Meas. Control 2018, 40, 279–286. [Google Scholar] [CrossRef]

- Kral, C.; Kapeller, H.; Pirker, F.; Pascoli, G. Discrimination of Rotor Faults and Low Frequency Load Torque Modulations of Squirrel Cage Induction Machines by means of the Vienna Monitoring Method. In Proceedings of the IEEE 36th Conference on Power Electronics Specialists, Recife, Brazil, 16 June 2005; IEEE: Aachen, Germany, 2005; pp. 2861–2866. [Google Scholar]

- Kral, C.; Pirker, F.; Pascoli, G.; Kapeller, H. Robust Rotor Fault Detection by Means of the Vienna Monitoring Method and a Parameter Tracking Technique. IEEE Trans. Ind. Electron. 2008, 55, 4229–4237. [Google Scholar] [CrossRef]

- Luo, X.; Liao, Y.; Toliyat, H.A.; El-Antably, A.; Lipo, T.A. Multiple coupled circuit modeling of induction machines. IEEE Trans. Ind. Appl. 1995, 31, 311–318. [Google Scholar]

- Leonhard, W. Control of Electrical Drives; Springer: Berlin, Germany, 2001; ISBN 978-3-540-41820-7. [Google Scholar]

- Cruz, S.M.A.; Stefani, A.; Filippetti, F.; Cardoso, A.J.M. A New Model-Based Technique for the Diagnosis of Rotor Faults in RFOC Induction Motor Drives. IEEE Trans. Ind. Electron. 2008, 55, 4218–4228. [Google Scholar] [CrossRef]

- Nemec, M.; Drobnič, K.; Fišer, R.; Ambrožič, V. Simplified model of induction machine with broken rotor bars. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016; pp. 1085–1090. [Google Scholar]

- Makuc, D.; Drobnič, K.; Ambrožič, V.; Miljavec, D.; Fišer, R.; Nemec, M. Parameters estimation of induction motor with faulty rotor. Przegląd Elektrotechniczny 2012, 88, 41–46. [Google Scholar]

- Vas, P. Sensorless Vector and Direct Torque Control; Oxford University Press: New York, NY, USA, 1998; ISBN 0-19-856465-1. [Google Scholar]

- Hinkkanen, M.; Luomi, J. Modified integrator for voltage model flux estimation of induction motors. IEEE Trans. Ind. Electron. 2003, 50, 818–820. [Google Scholar] [CrossRef] [Green Version]

- Secrest, C.W.; Pointer, J.S.; Buehner, M.R.; Lorenz, R.D. Improving Position Sensor Accuracy through Spatial Harmonic Decoupling, and Sensor Scaling, Offset, and Orthogonality Correction Using Self-Commissioning MRAS Methods. IEEE Trans. Ind. Appl. 2015, 51, 4492–4504. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemec, M.; Ambrožič, V.; Fišer, R.; Nedeljković, D.; Drobnič, K. Induction Motor Broken Rotor Bar Detection Based on Rotor Flux Angle Monitoring. Energies 2019, 12, 794. https://doi.org/10.3390/en12050794

Nemec M, Ambrožič V, Fišer R, Nedeljković D, Drobnič K. Induction Motor Broken Rotor Bar Detection Based on Rotor Flux Angle Monitoring. Energies. 2019; 12(5):794. https://doi.org/10.3390/en12050794

Chicago/Turabian StyleNemec, Mitja, Vanja Ambrožič, Rastko Fišer, David Nedeljković, and Klemen Drobnič. 2019. "Induction Motor Broken Rotor Bar Detection Based on Rotor Flux Angle Monitoring" Energies 12, no. 5: 794. https://doi.org/10.3390/en12050794

APA StyleNemec, M., Ambrožič, V., Fišer, R., Nedeljković, D., & Drobnič, K. (2019). Induction Motor Broken Rotor Bar Detection Based on Rotor Flux Angle Monitoring. Energies, 12(5), 794. https://doi.org/10.3390/en12050794