Elementary Pore Network Models Based on Complex Analysis Methods (CAM): Fundamental Insights for Shale Field Development

Abstract

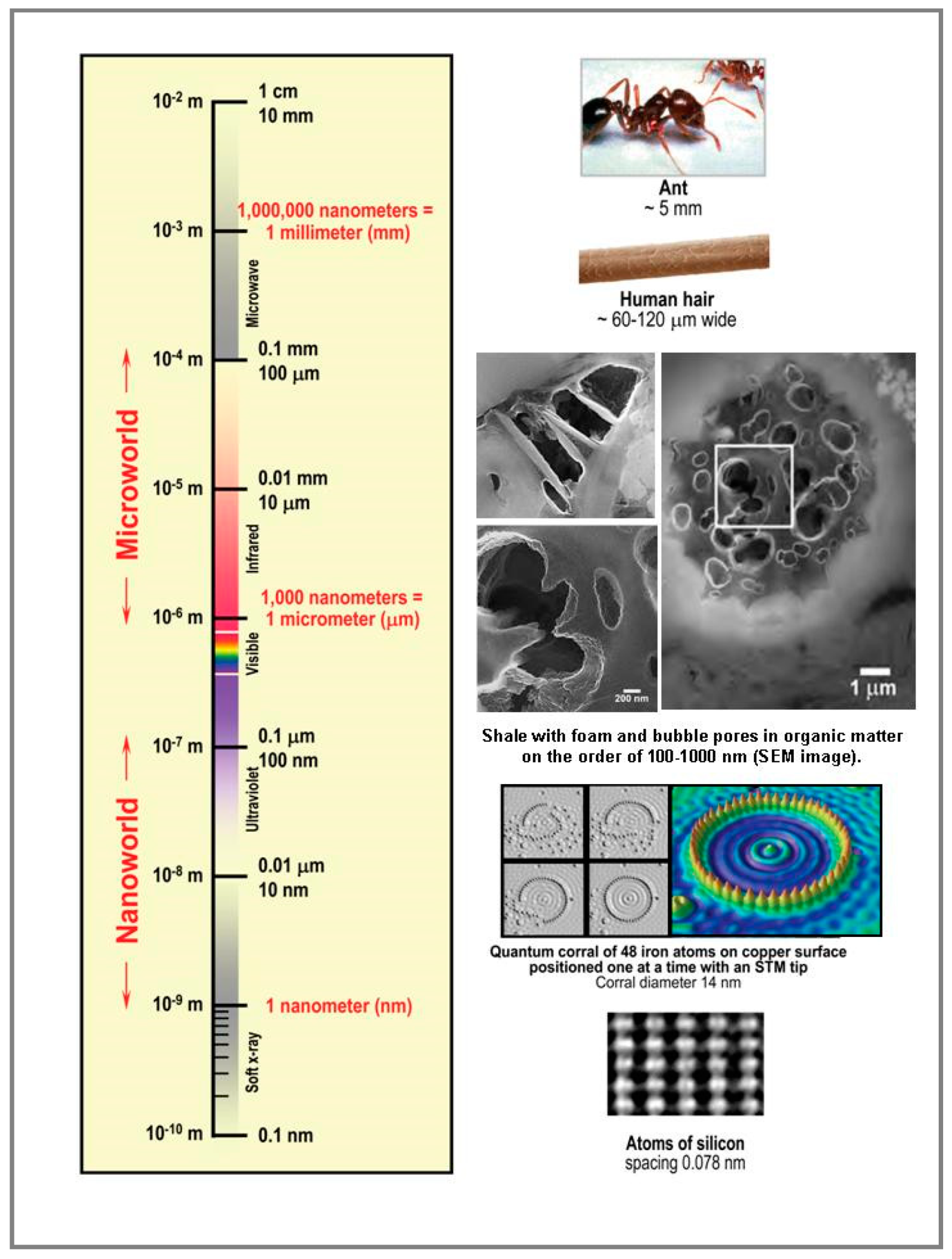

:1. Introduction

2. Modeling Approach

2.1. Prior Modeling Efforts

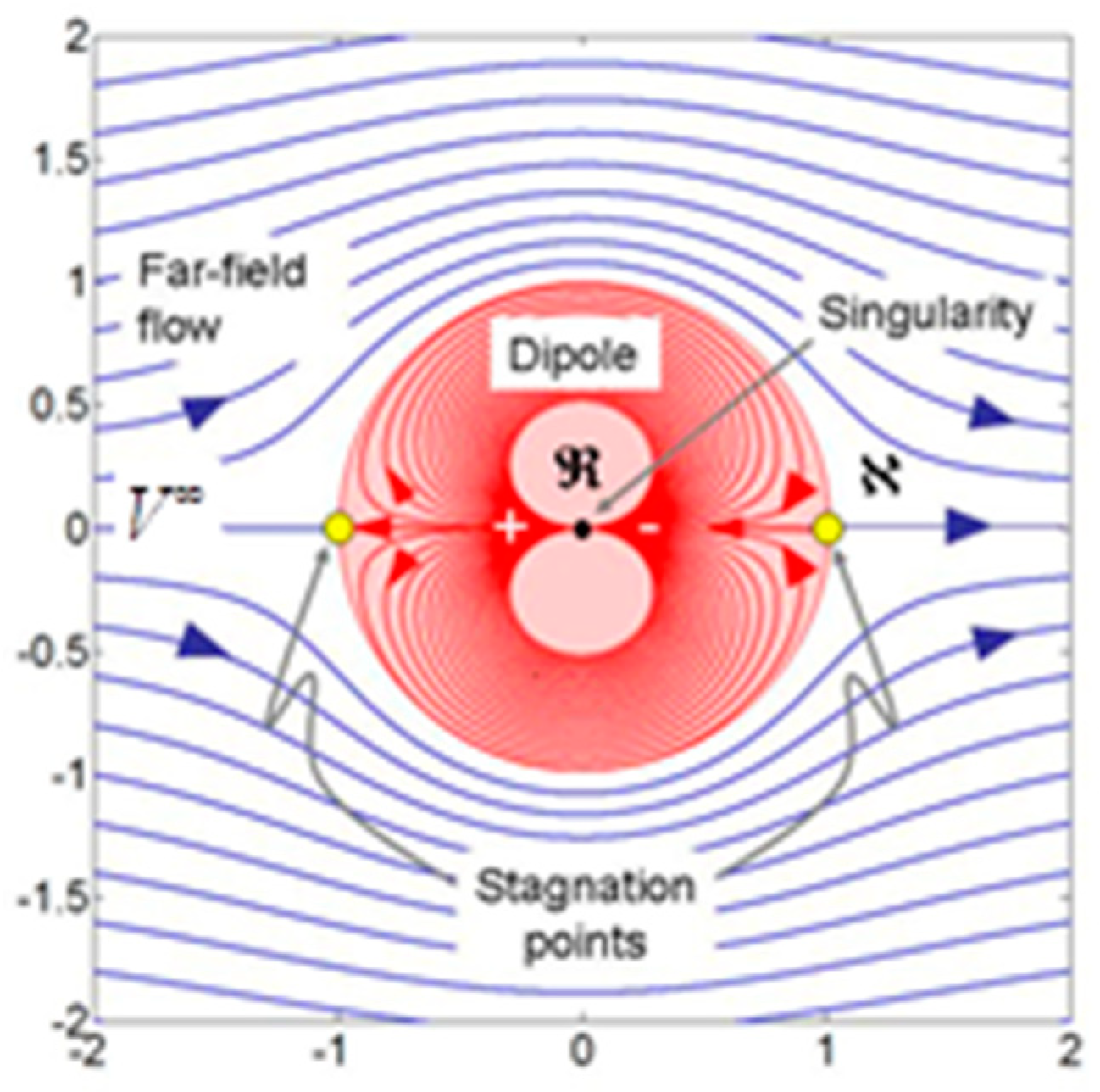

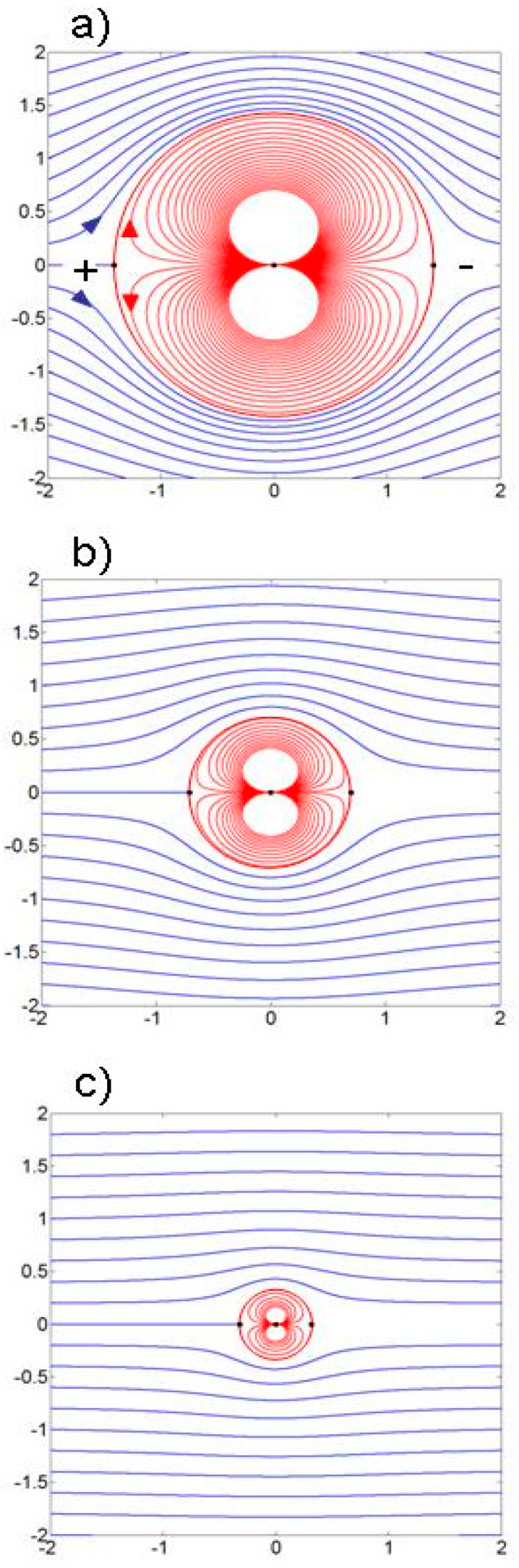

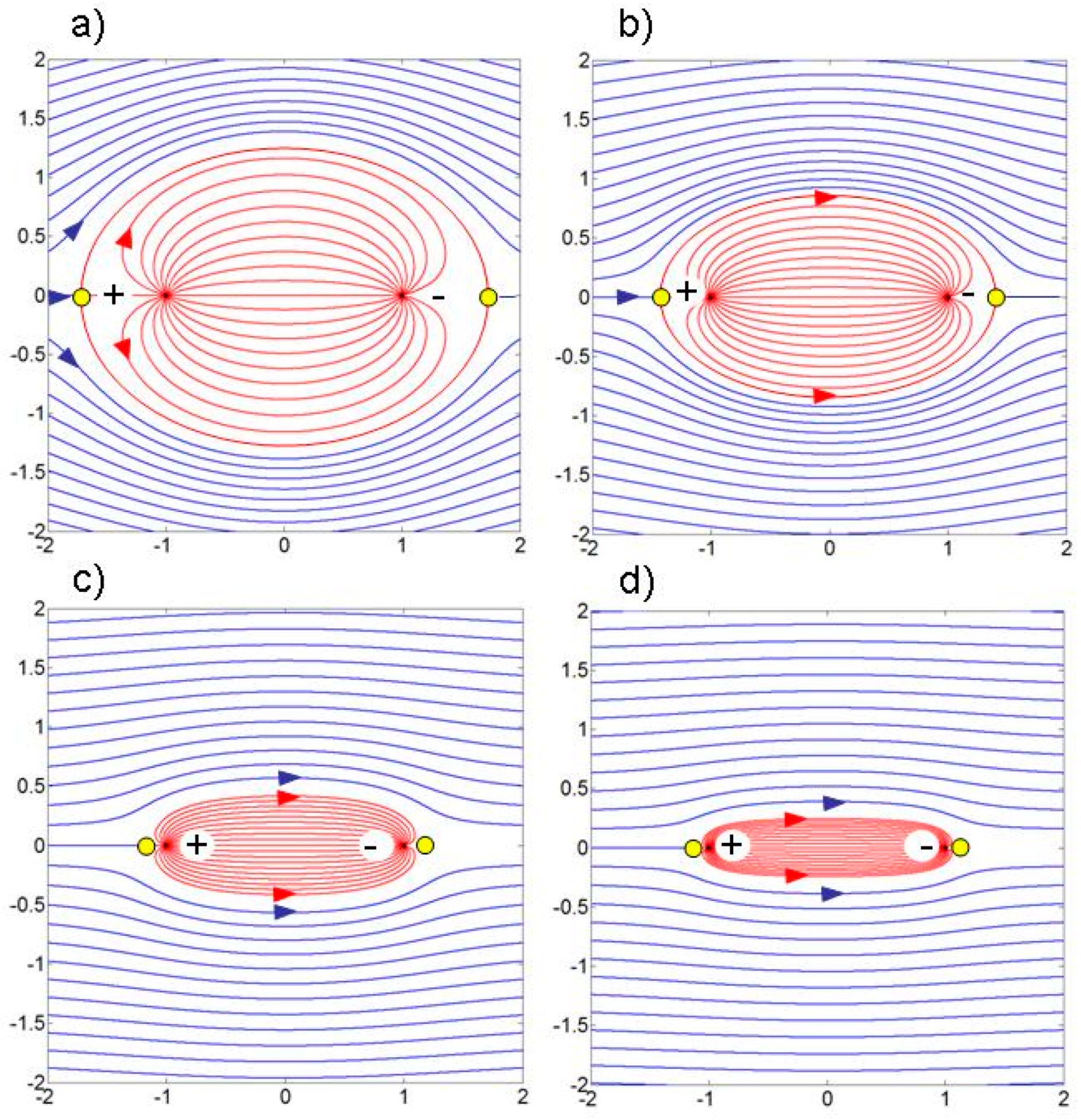

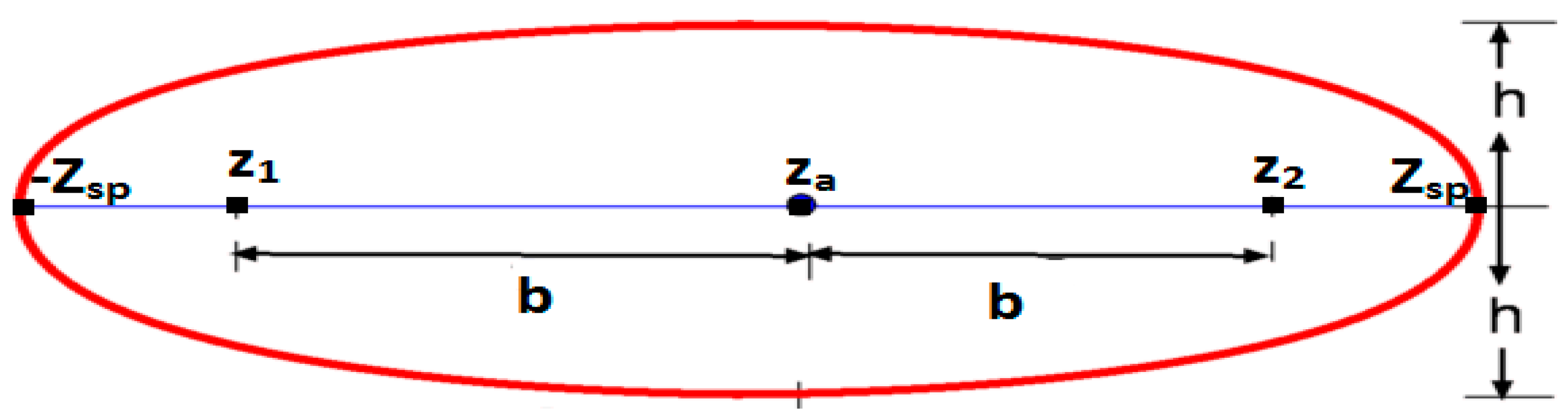

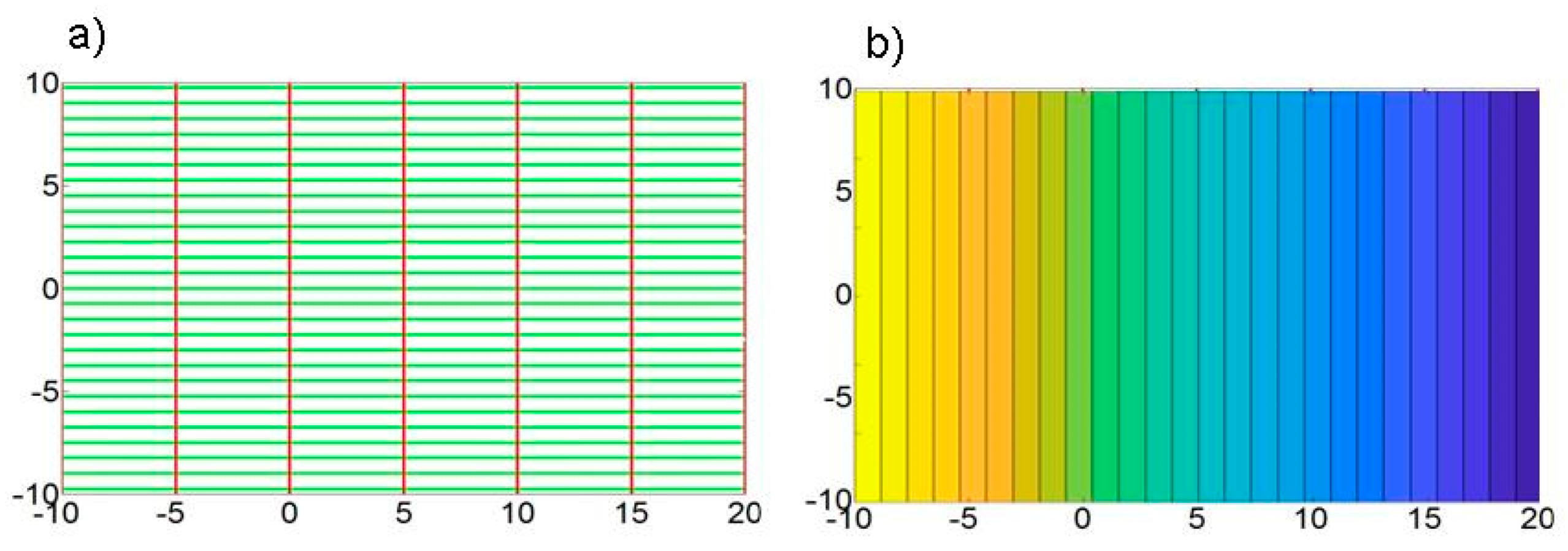

2.2. Complex Analysis Method (CAM)

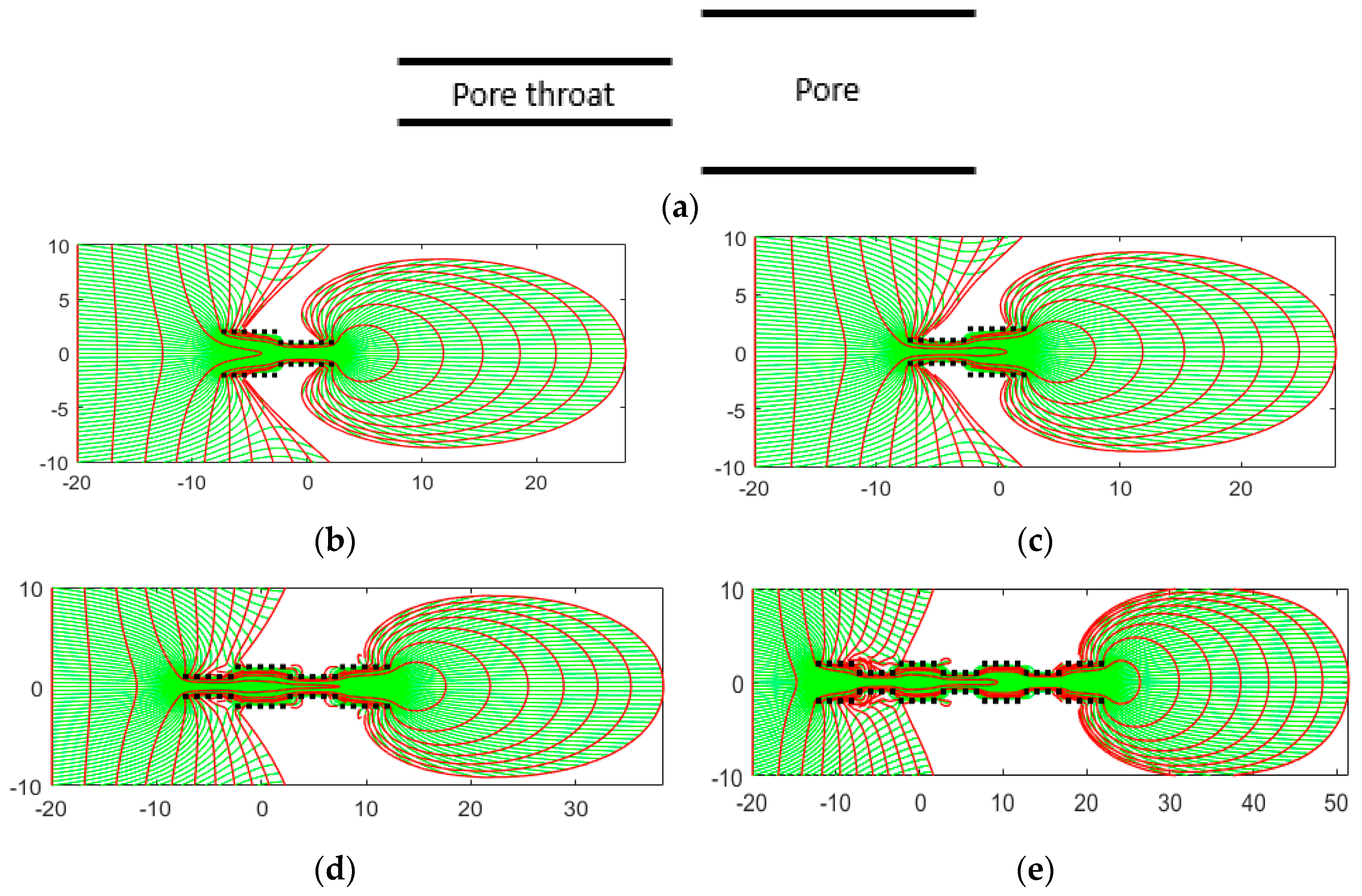

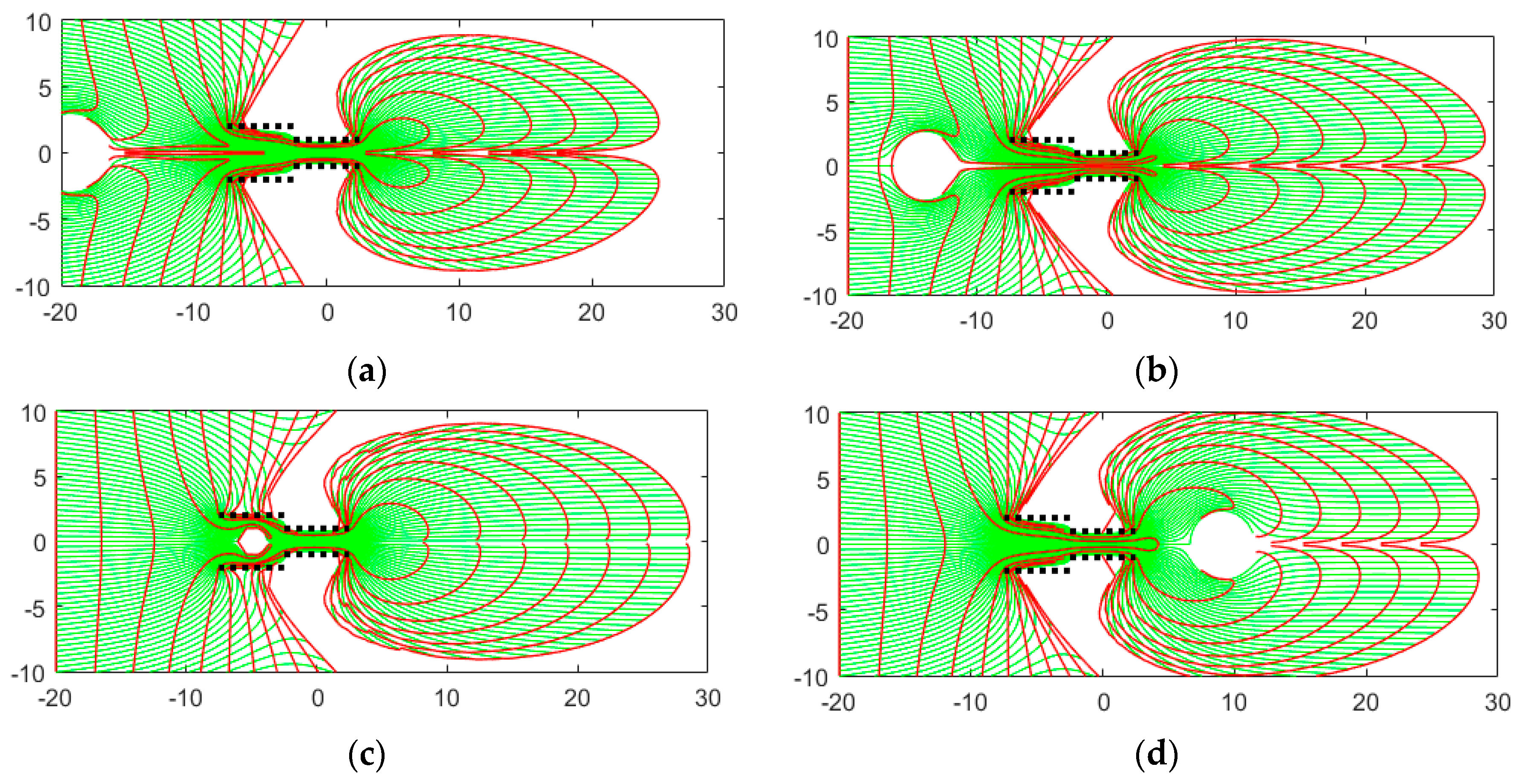

2.2.1. Single Pore Throat Channel Example

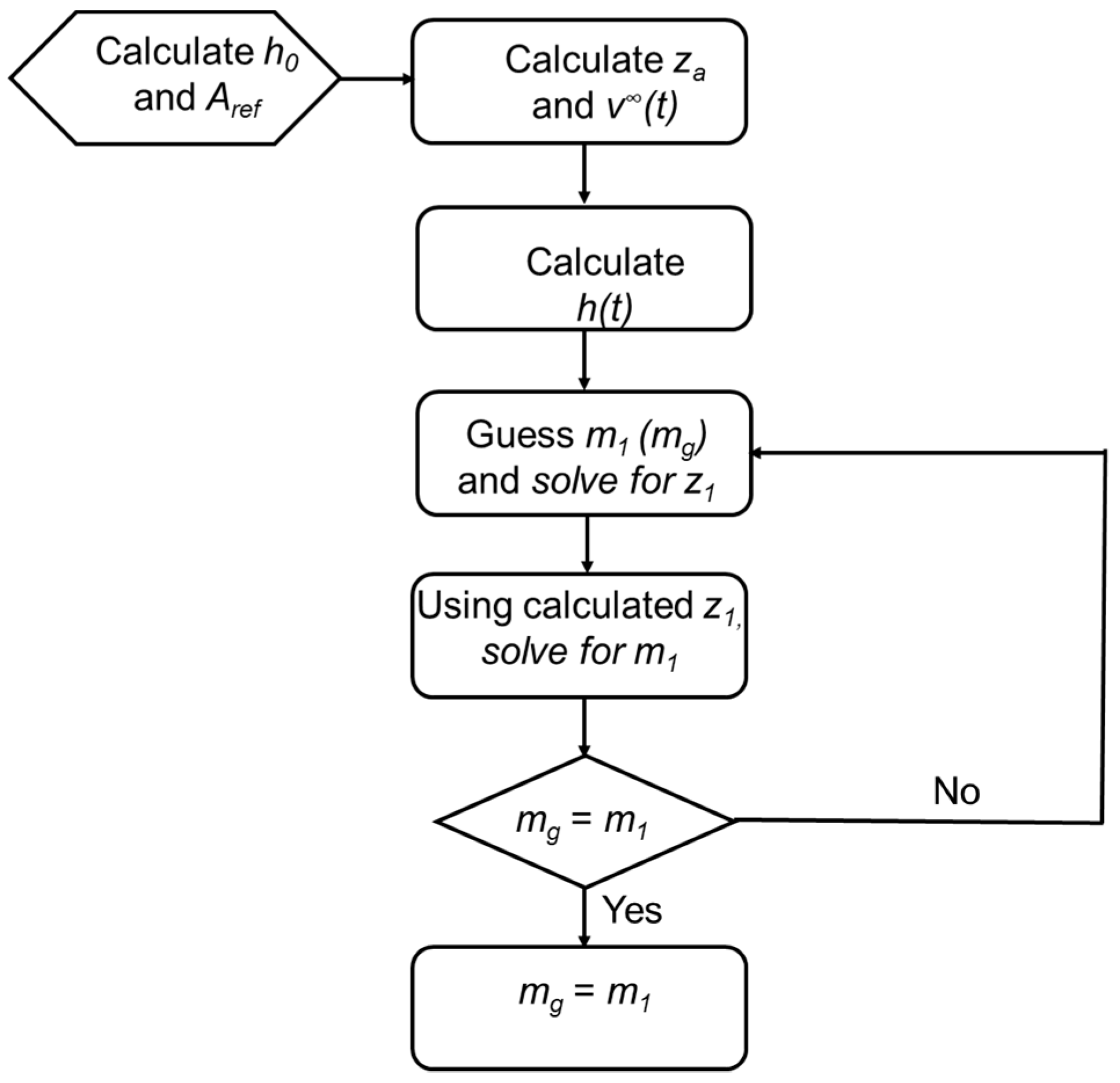

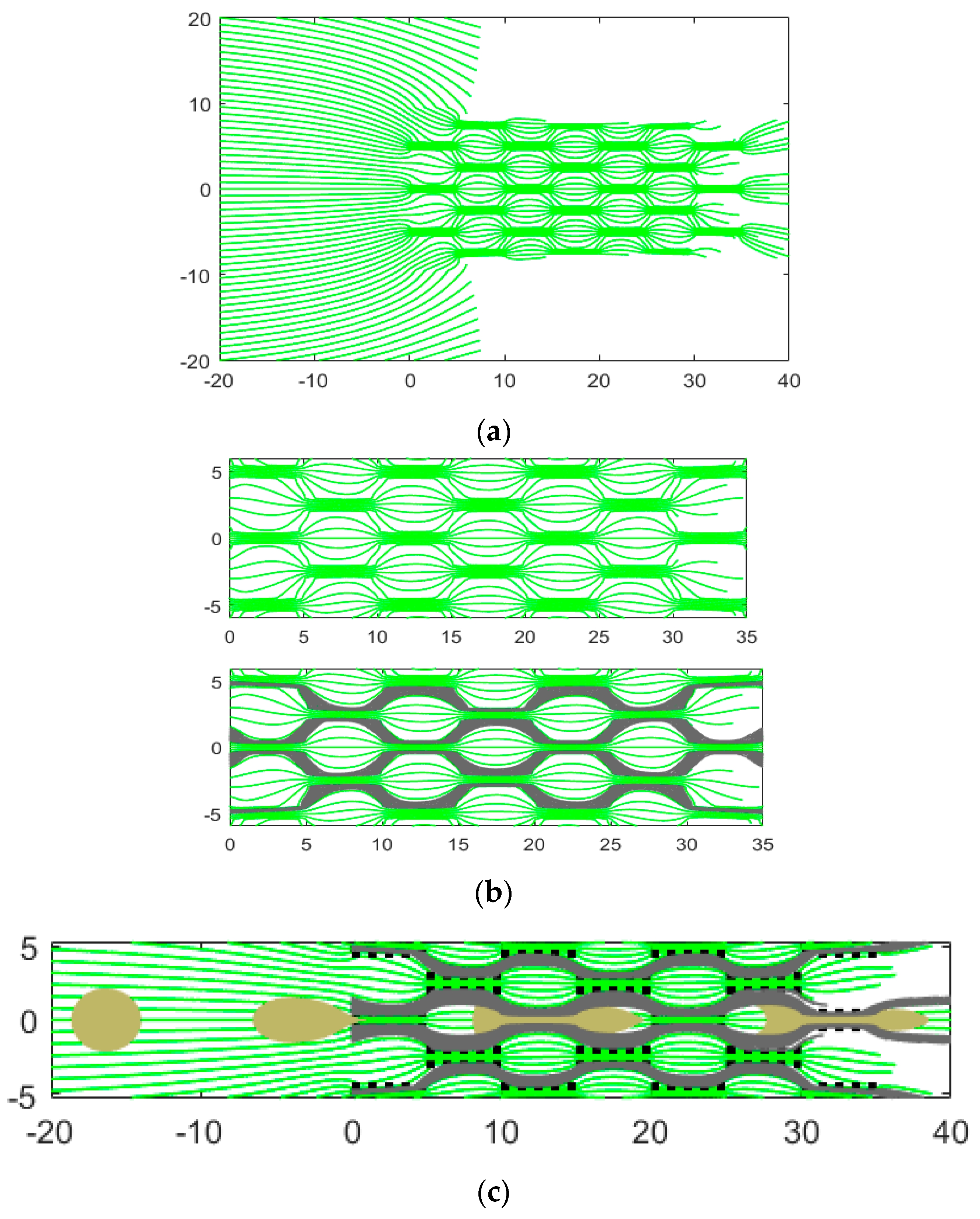

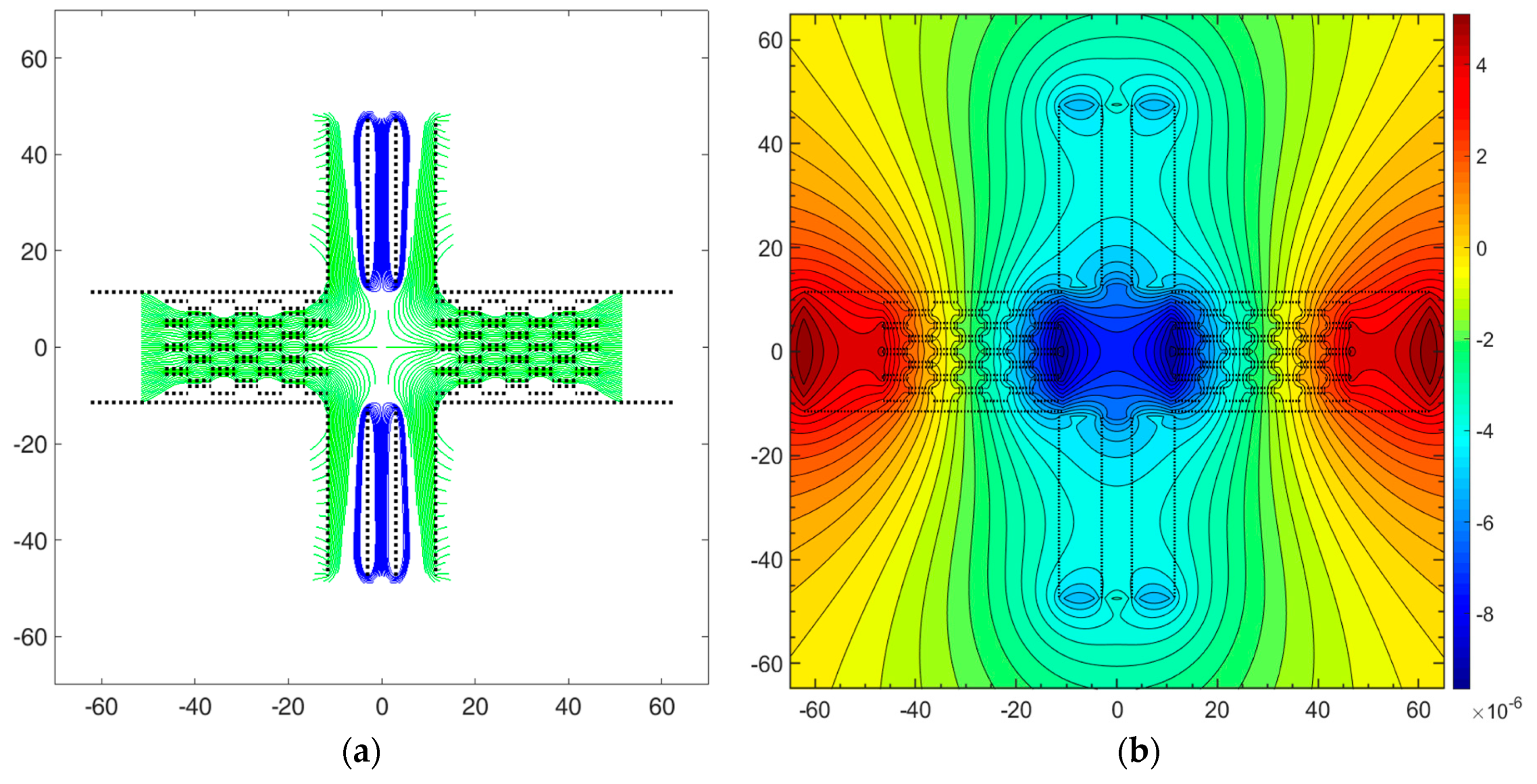

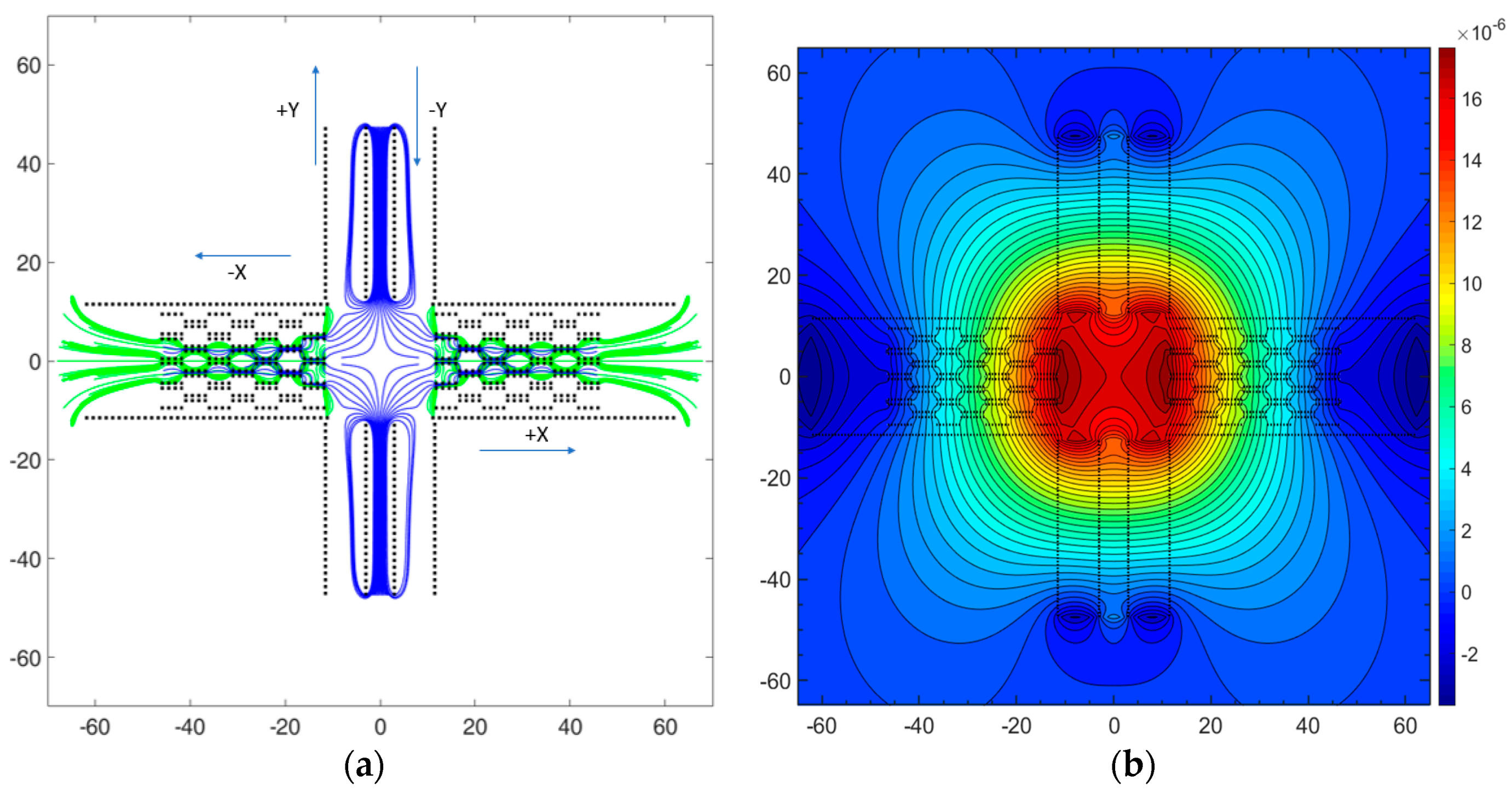

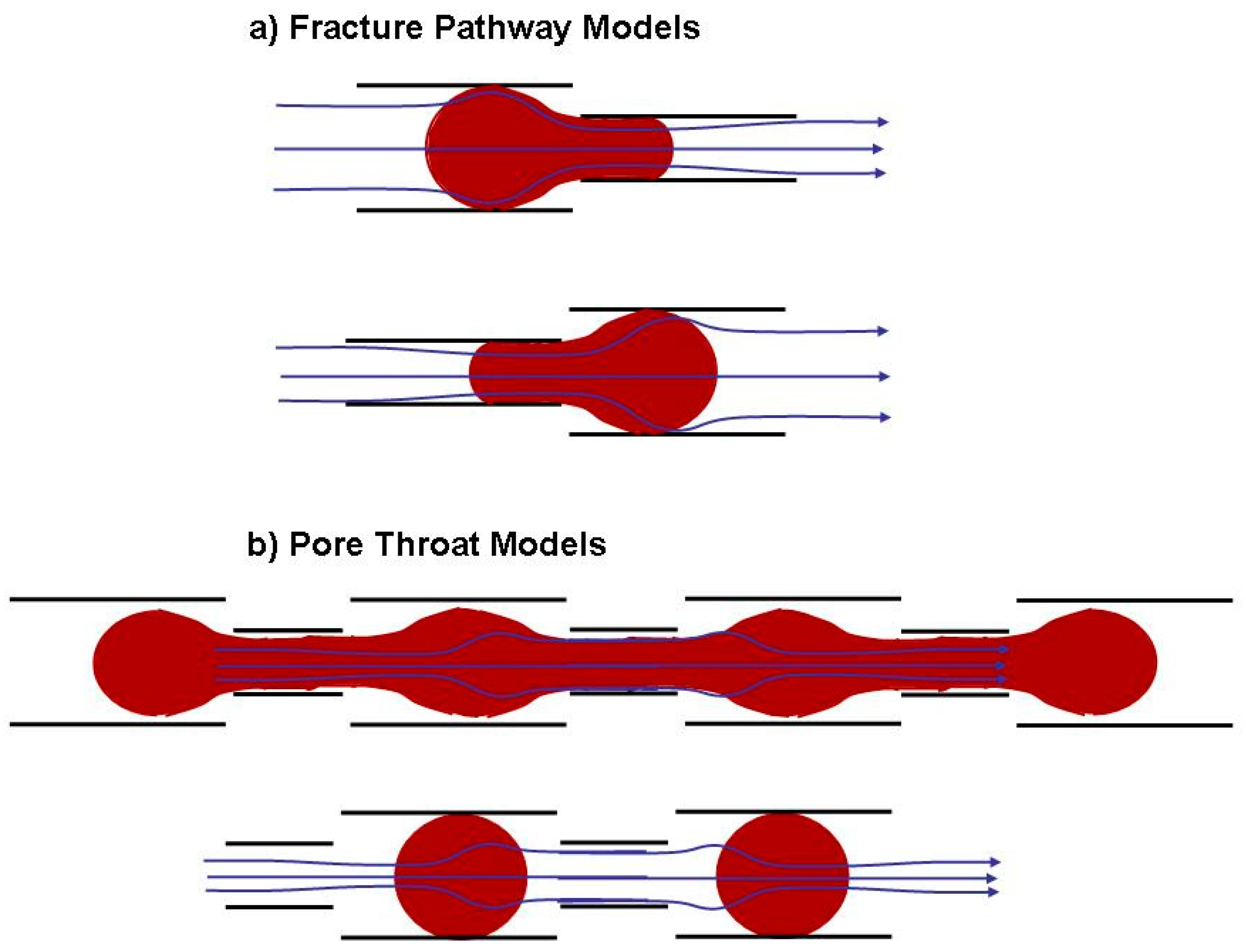

2.2.2. Movement of a Passive Ganglion through an Elementary Pore-Network

2.3. Multi-Pore Network Model

3. Dynamic Bottomhole Pressure Profiles

3.1. Model Design

3.2. Producer and Injection Wells

3.3. Wellbore Pressures during Drilling

4. Multi-Phase Flow Effects

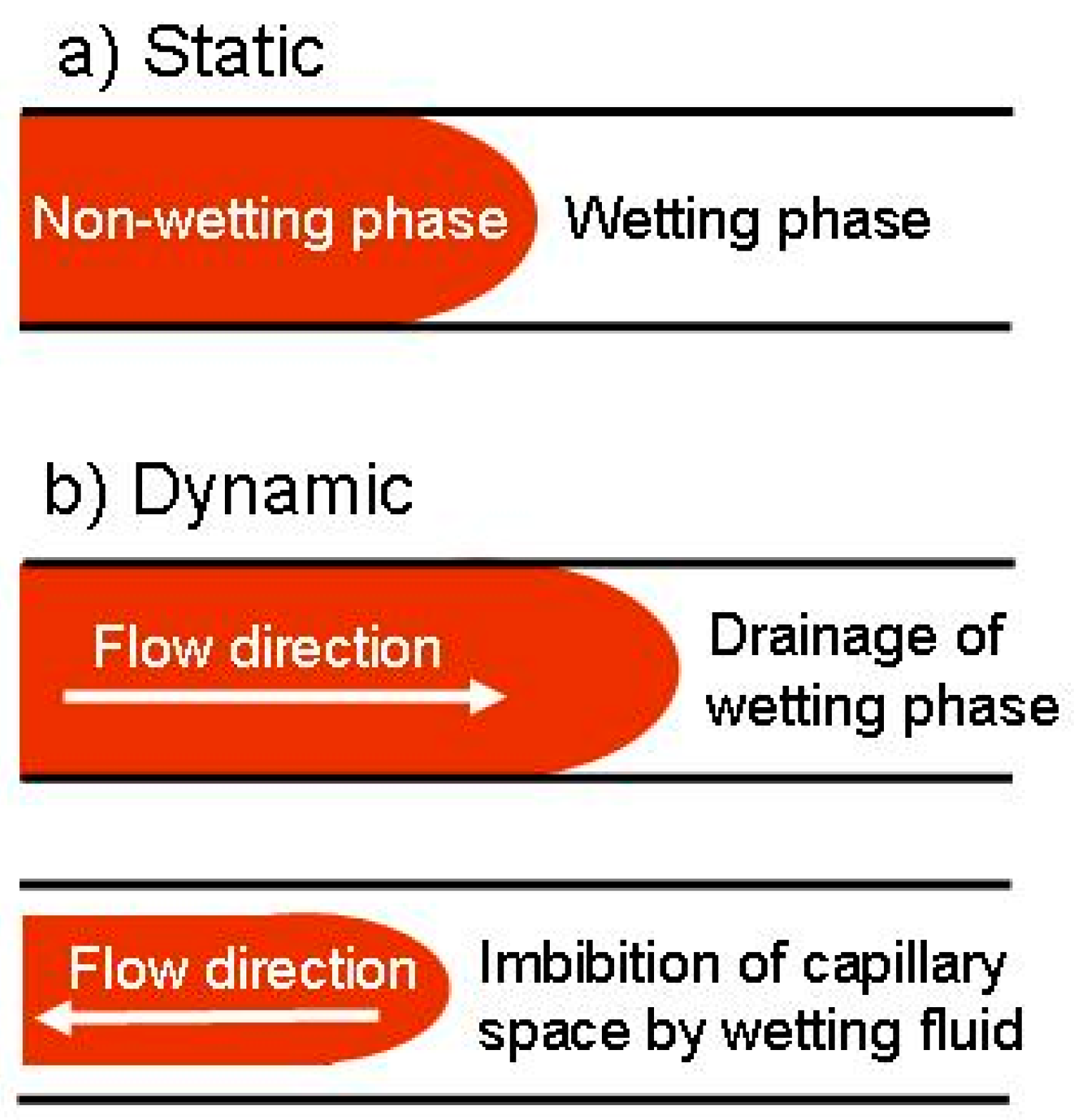

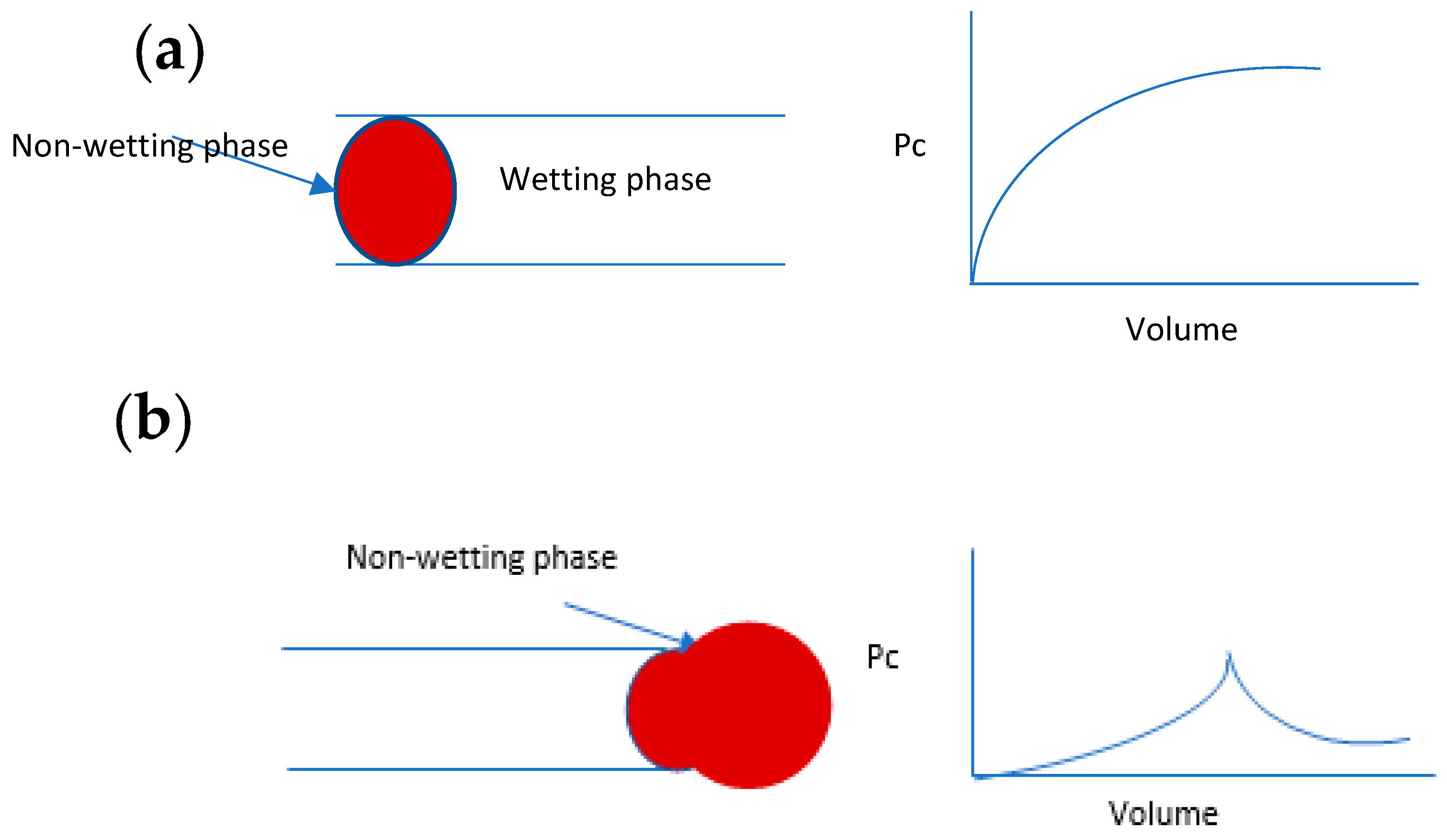

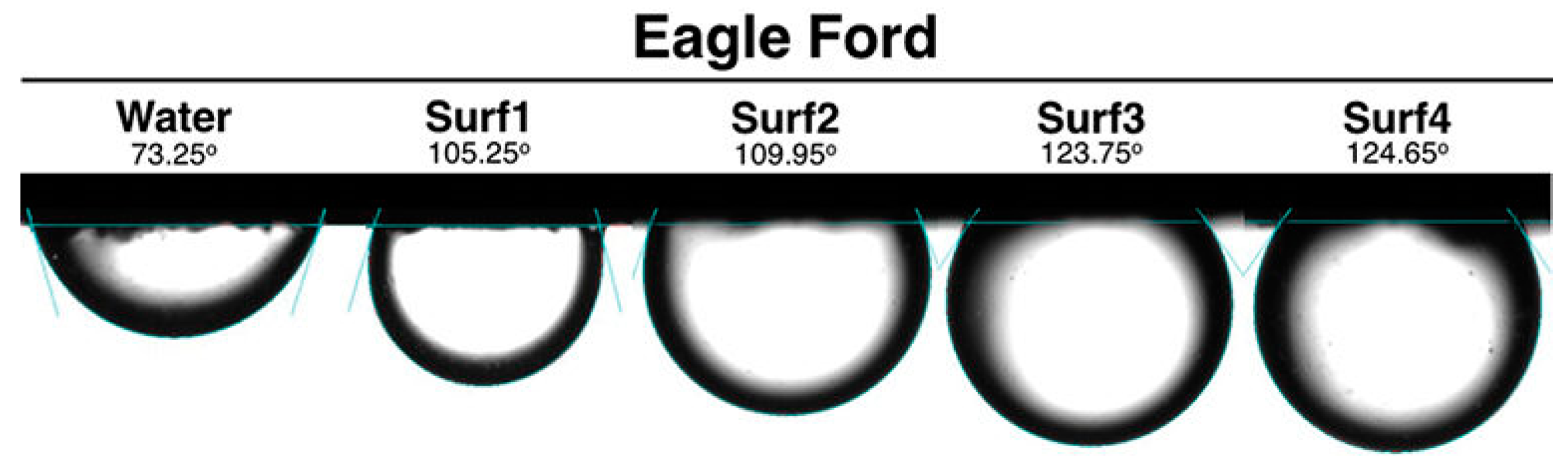

4.1. Capillary Pressure Effects

4.2. Movement of an Active Ganglion through an Elementary Pore-Network

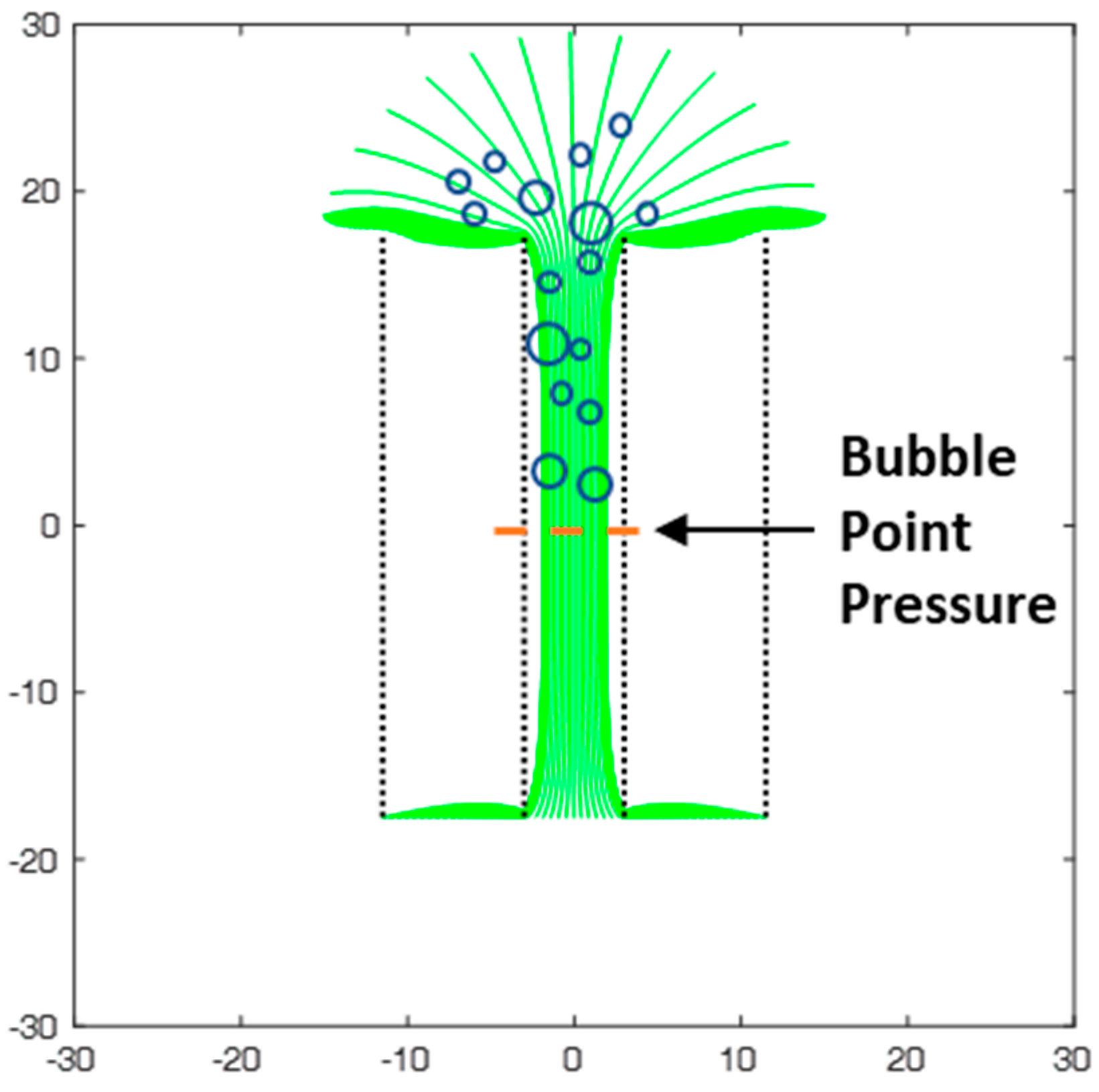

4.3. Bubble Point Delay Due to Capillarity

5. Discussion

5.1. Scaling BHP Models and Flow Velocities

5.2. Upscaling of Capillarity Effects

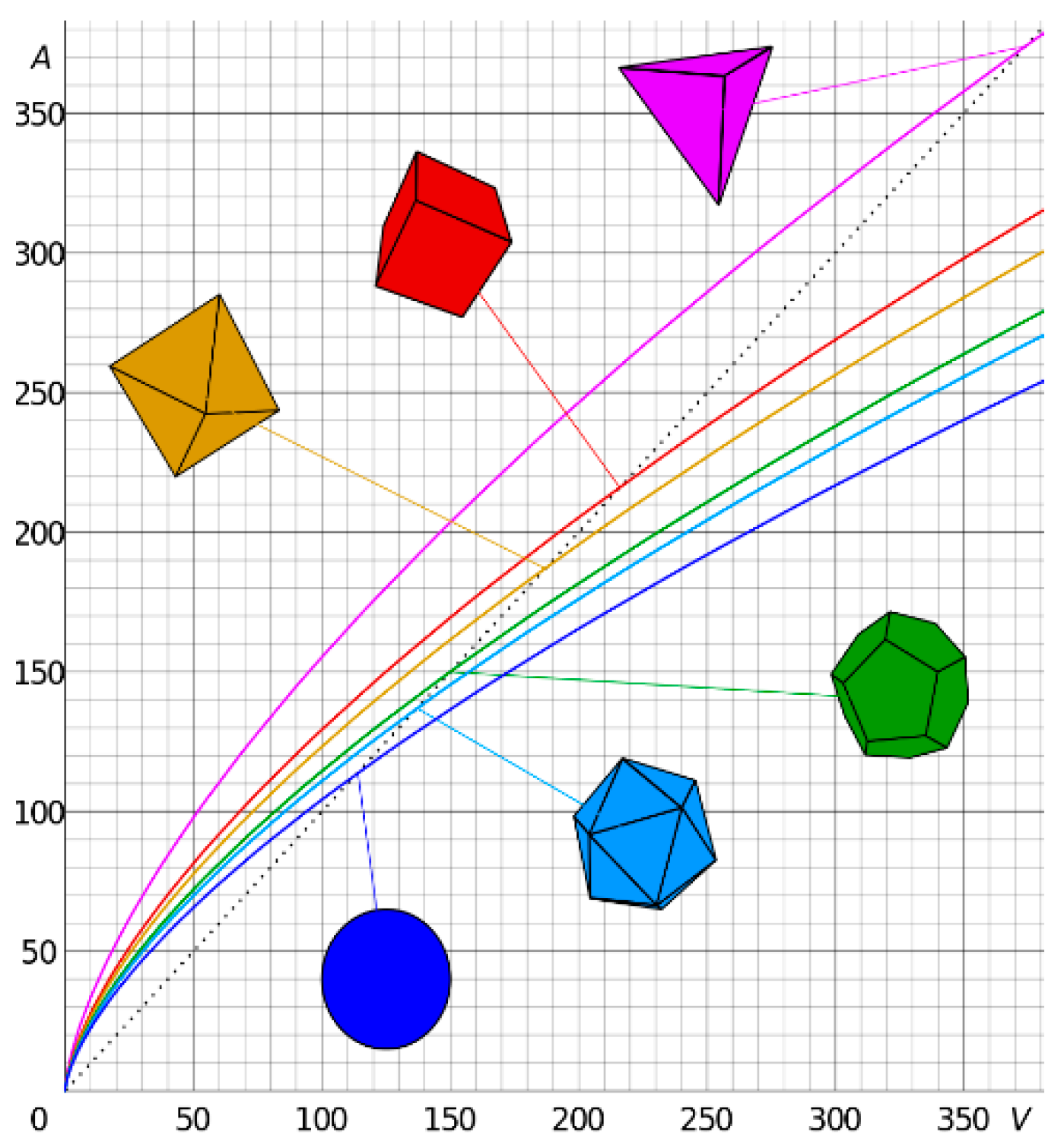

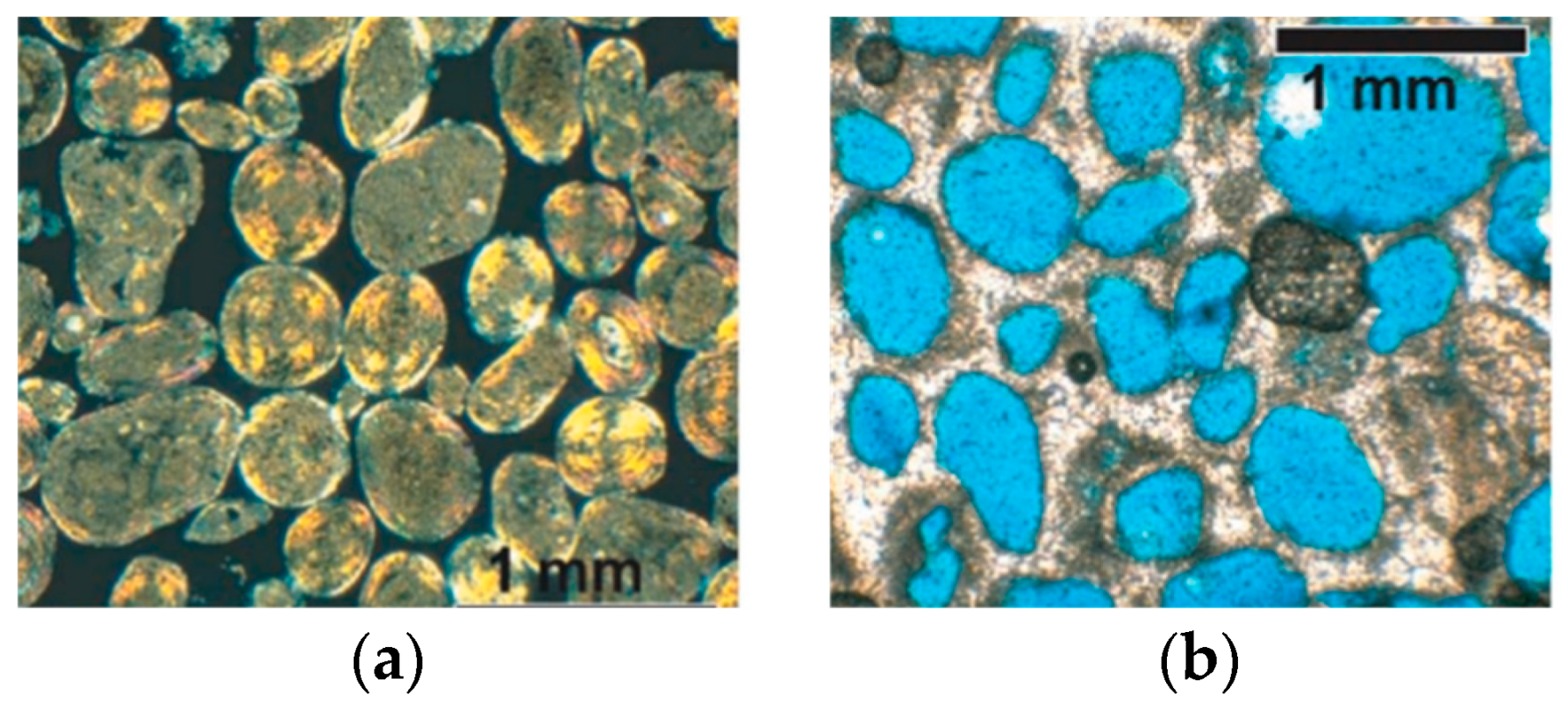

5.3. Multi-Phase Flow and Geometry of Pore Space

5.4. Future of Pore Network Models

6. Conclusions

- For a reservoir pressure that is underbalanced by the mud weight in the well, estimation of lateral pressure gradients in the BHP may help the operators to adjust any deficit in the density of the drilling fluids to prevent reservoir fluid reaching the surface via the annulus. The pressure of the fluid flowing in a wellbore can be effectively modeled by using a combination of a pore network model with a wellbore flow model. If the well models are properly scaled, the time for reservoir fluid to reach the surface can be predicted using time-of-flight contours. Ultra-fast rise of reservoir fluid is accompanied by a pressure kick, which may lead to the loss of well control (and is termed a blow-out when catastrophic).

- For reservoir pressure that is overbalanced by the mud weight in the well, the estimation of lateral pressure gradients in the BHP may assist the operators to select the appropriate combination of mud weight and circulation rate that will prevent an unwarranted invasion of the reservoir space by drilling fluid, which may lead to the loss of costly drilling mud. The mud not only provides pressure balance in the well, but is also a lubricant for the cutter which may wear, break, and get stuck when lost circulation occurs.

- Traditional wellbore stability models focus on the prevention of failure of the wellbore rock using geo-mechanical properties (elastic moduli and brittle failure criteria for certain stress concentrations). The simple models presented here show that mud circulation during drilling and pressure gradients at the transition of the reservoir to the wellbore may cause fluid flow which poses a drilling hazard if incompletely captured in concurrent geo-mechanical wellbore stability models, which focus on the elastic limit and brittle failure of the wellbore.

Author Contributions

Funding

Conflicts of Interest

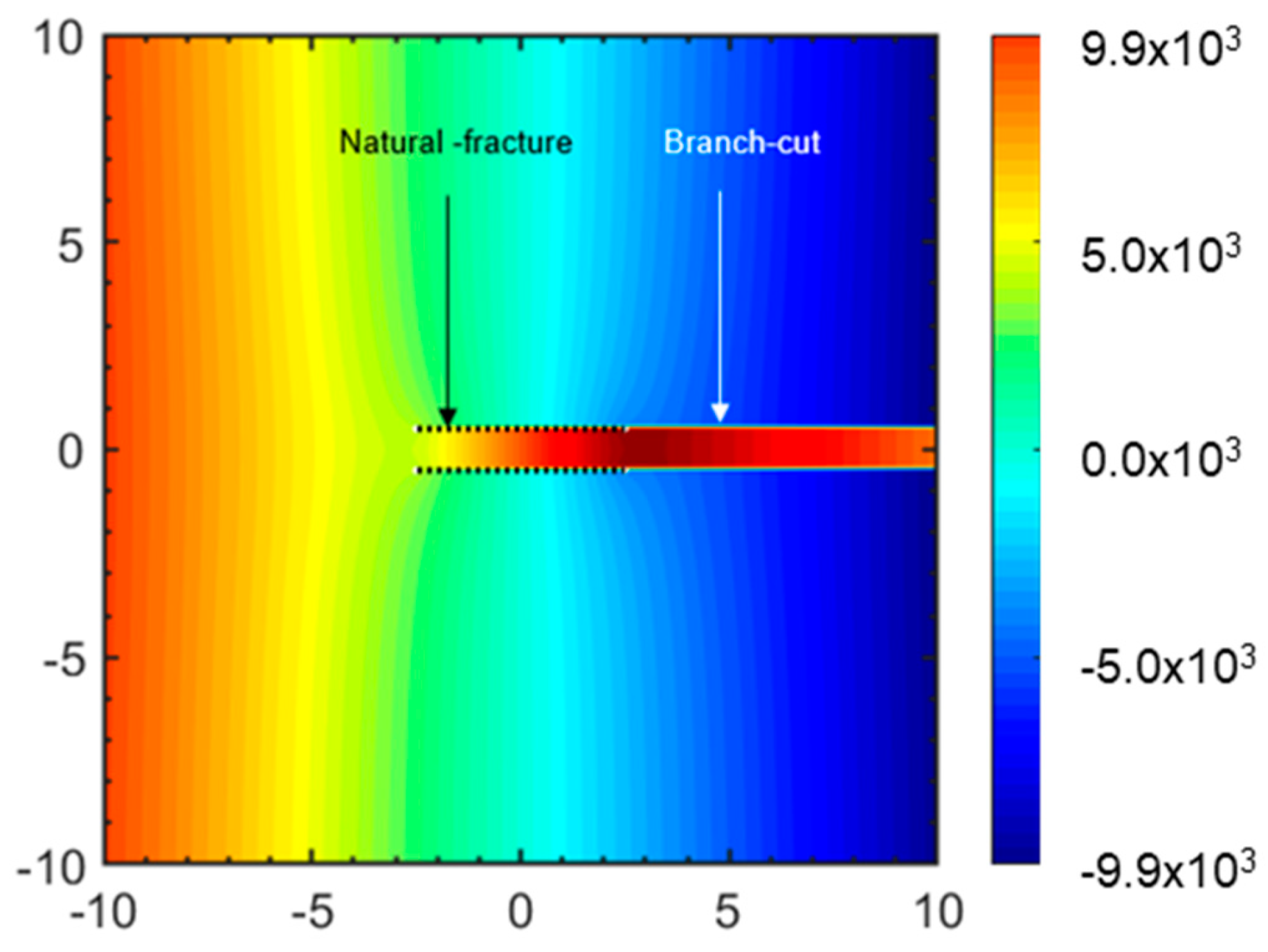

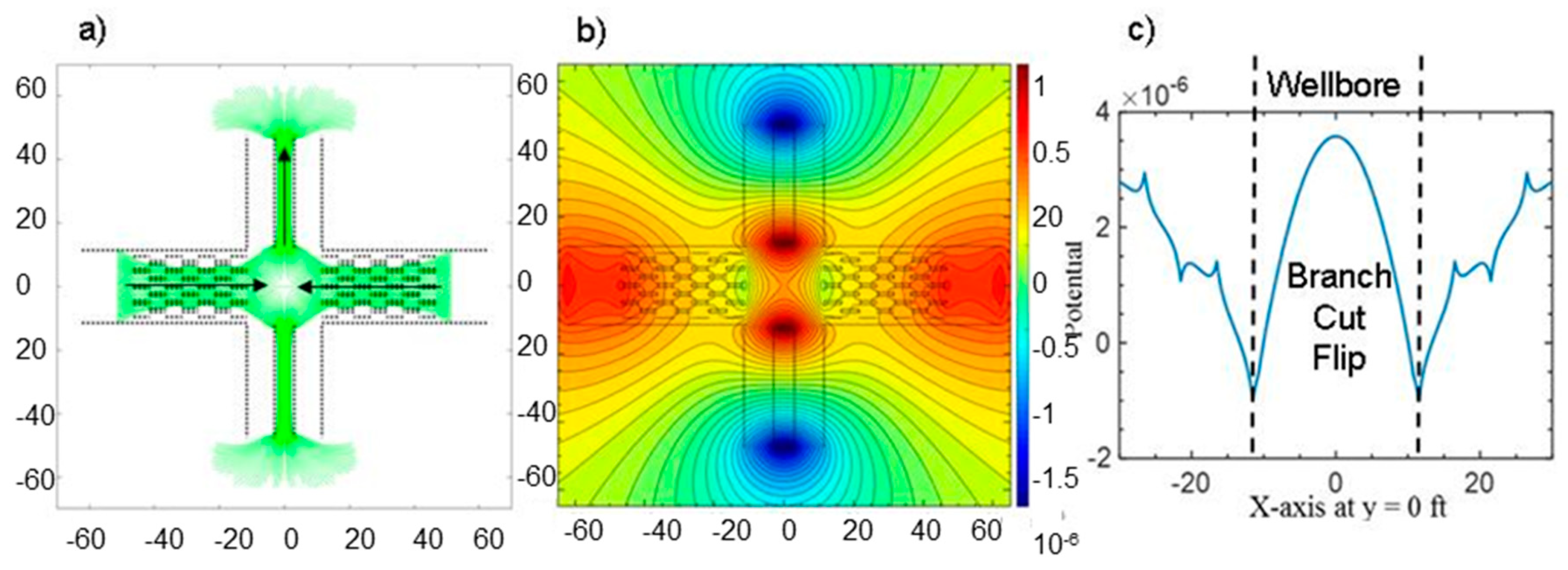

Appendix A. Branch Cuts in Pressure Plot

Appendix A.1. Background

Appendix A.2. Demonstration of Branch Cut for a Simple Case

Appendix A.3. Proposed Solution to the Branch Cut Placement

| Physical Quantity | Symbol | Value | Units |

|---|---|---|---|

| Depth | h | 1 | m |

| Porosity | n | 20 | % |

| Permeability | k | 9.87 × 10−16 | m2 |

| Viscosity | µ | 0.01 | Pa·s |

| Far-field velocity | ux | 9.5 × 10−9 | m·s−1 |

| Angle of far-field flow | α | 0 | ° |

| Fracture center | zc | 0 | m |

| Fracture length | L | 5 | m |

| Fracture width | W | 1 | m |

| Angle | γ | 0 | ° |

| Angle between the corner points | β | 90 | ° |

| Strength of fracture | ν | 9.5 × 10−9 | m4·s−1 |

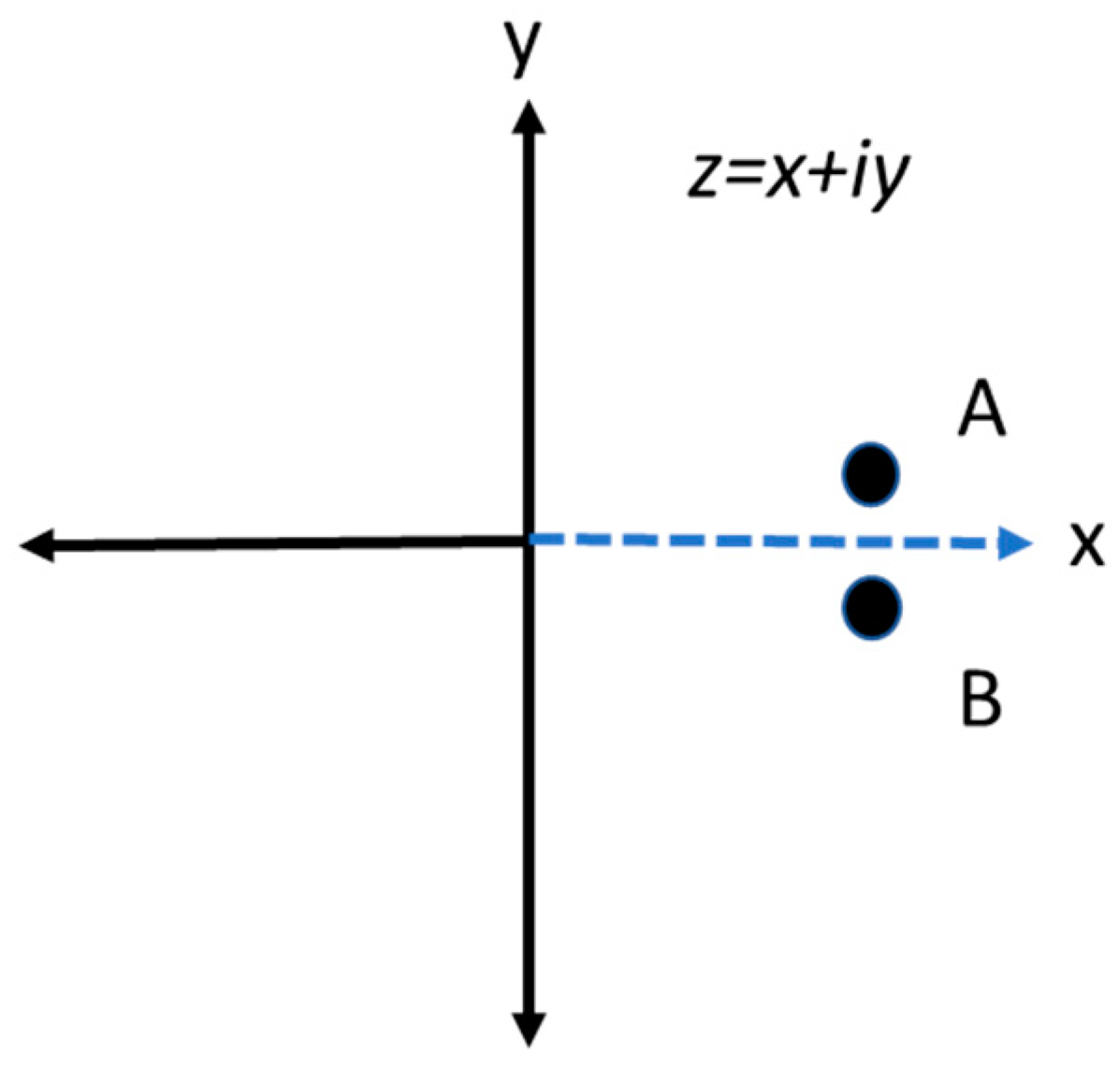

Appendix B. Dipole Strength and Relationship Radius with Far-Field Flow Rate

Appendix B.1. Velocity Potential

Appendix B.2. Dipole Radius and Revolution Time

Appendix B.3. Complex Potential and Velocities in Polar Coordinates

Appendix B.4. Velocities of Internal and External Domains

Appendix B.5. Volume Conservation in Local Domain

References

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sedimen. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Preliminary classification of matrix pores in mudrocks. Gulf Coast Assoc. Geol. Soc. Trans. 2010, 60, 435–441. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bulletin 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Pommer, M.; Milliken, K. Pore types and pore-size distributions across thermal maturity, Eagle Ford Formation, Southern Texas. In Proceedings of the 2014 AAPG Annual Convention and Exhibition, Houston, TX, USA, 6–9 April 2014. [Google Scholar]

- Alfi, M.; Chai, Z.; Yan, B.; Stimpson, B.C.; Barrufet, M.A.; Killough, J. Advances in simulation of hydrocarbon production from shale reservoirs. In Proceedings of the 2017 Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Alfi, M.; Banerjee, D.; Nasrabadi, H. Effect of confinement on the dynamic contact angle of hydrocarbons. Energy Fuels 2016, 30, 8962–8967. [Google Scholar] [CrossRef]

- Alfi, M.; Nasrabadi, H.; Banerjee, D. Experimental investigation of confinement effect on phase behavior of hexane, heptane and octane using lab-on-a-chip technology. Fluid Phase Equilibr. 2016, 423, 25–33. [Google Scholar] [CrossRef]

- Weijermars, R.; Alves, I.N. High-resolution visualization of flow velocities near frac-tips and flow interference of multi-fracked Eagle Ford wells, Brazos County, Texas. J. Petrol. Sci. Eng. 2018, 165, 946–961. [Google Scholar] [CrossRef]

- Khanal, A.; Weijermars, R. Pressure depletion and drained rock volume near hydraulically fractured parent and child wells. J. Pet. Sci. Eng. 2019, 172, 607–626. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. The development of organic porosity in the woodford shale as a function of thermal maturity. In Proceedings of the 2012 SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar] [CrossRef]

- Erdman, N.; Drenzek, N. Integrated preparation and imaging techniques for the microstructural and geochemical characterization of shale by scanning electron microscopy. AAPG Memoir 2013, 102, 7–14. [Google Scholar] [CrossRef]

- Bahadur, J.; Melnichenko, Y.B.; Mastalerz, M.; Furmann, A.; Clarkson, C.R. Hierarchical pore morphology of cretaceous shale: A small-angle neutron scattering and ultra-small-angle neutron scattering study. Energy Fuel 2014, 28, 6336–6344. [Google Scholar] [CrossRef]

- Zuo, L.; Weijermars, R. Rules for flight paths and time of flight for flows in porous media with heterogeneous permeability and porosity. Geofluids 2018, 3, 1–18. [Google Scholar] [CrossRef]

- Teklu, T.W.; Alharthy, N.; Kazemi, H.; Yin, X.; Graves, R.M. Hydrocarbon and non-hydrocarbon gas miscibility with light oil in shale reservoirs. In Proceedings of the 2014 SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014. [Google Scholar] [CrossRef]

- Li, J.; Yu, T.; Liang, X.; Zhang, P.; Chen, C.; Zhang, J. Insights on the gas permeability change in porous shale. Adv. Geo Energy Res. 2017, 1, 63–67. [Google Scholar] [CrossRef]

- Jin, L.; Ma, Y.; Jamili, A. Investigating The effect of pore proximity on phase behavior and fluid properties in shale formations. In Proceedings of the 2013 SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar] [CrossRef]

- Alharthy, N.S.; Nguyen, T.; Kazemi, H.; Teklu, T.; Graves, R. Multiphase compositional modeling in small-scale pores of unconventional shale reservoirs. In Proceedings of the 2013 SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar] [CrossRef]

- Nojabaei, B.; Johns, R.T.; Chu, L. Effect of capillary pressure on phase behavior in tight rocks and shales. SPE Reserv. Eval. Eng. 2013, 16, 281–289. [Google Scholar] [CrossRef]

- Richardson, Y.; Drobek, M.; Julbe, A.; Blin, J.; Pinta, F. Biomass gasification to produce syngas. Recent Adv. Thermo Chem. Convers. Biomass 2015, 2015, 213–250. [Google Scholar]

- Civan, F.; Rai, C.S.; Sondergeld, C.H. Shale-gas permeability and diffusivity inferred by improved formulation of relevant retention and transport mechanisms. Transp. Porous Med. 2011, 86, 925. [Google Scholar] [CrossRef]

- Fairbrass, M.; Tanguy, D. The Scale of Things: Mind-Blowing Proportions, Remarkable Ratios, Extraordinary Facts; Quadrille Publishing: London, UK, 2017. [Google Scholar]

- Stimpson, B.C.; Barrufet, M.A. Constructing oil-gas capillary pressure and relative permeability curves from a distribution of pores in shale reservoirs. In Proceedings of the 2017 Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Stimpson, B.C.; Barrufet, M.A. Effects of confined space on production from tight reservoirs. In Proceedings of the 2016 SPE Annual Technical Conference and Exhibition, Dubai, UAE, 26–28 September 2016. [Google Scholar] [CrossRef]

- Khoshghadam, M.; Khanal, A.; Lee, W.J. Numerical study of impact of nano-pores on gas-oil ratio and production mechanisms in liquid-rich shale oil reservoirs. In Proceedings of the 2015 Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar] [CrossRef]

- Khoshghadam, M.; Khanal, A.; Yu, C.; Rabinejadganji, N.; Lee, W.J. Producing gas-oil ratio behavior of unconventional volatile-oil reservoirs, and its application in production diagnostics and decline curve analysis. In Proceedings of the 2017 Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Berg, S.; Ott, H.; Klapp, S.A.; Schwing, A.; Neiteler, R.; Brussee, N.; Makurat, A.; Leu, L.; Enzmann, F.; Schwarz, J.-O.; et al. Real-time 3D imaging of Haines jumps in porous media flow. Proc. Natl. Acad. Sci. USA 2013, 110, 3755–3759. [Google Scholar] [CrossRef] [Green Version]

- Berkowitz, B. Characterizing flow and transport in fractured geological media: A review. Adv. Water Resour. 2002, 25, 861–884. [Google Scholar] [CrossRef]

- Neuman, S.P. Trends, prospects and challenges in quantifying flow and transport through fractured rocks. Hydrogeol. J. 2005, 13, 124–147. [Google Scholar] [CrossRef]

- Geiger, S.; Dentz, M.; Neuweiler, I. A novel multi-rate dual-porosity model for improved simulation of fractured and multi-porosity reservoirs. In Proceedings of the 2011 SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, UAE, 9–11 October 2011. [Google Scholar] [CrossRef]

- Flemisch, B.; Berre, I.; Boon, W.; Fumagalli, A.; Schwenck, N.; Scotti, A.; Tatomir, A. Benchmarks for single-phase flow in fractured porous media. Adv. Water Resour. 2018, 111, 239–258. [Google Scholar] [CrossRef] [Green Version]

- Warren, J.E.; Root, P.J. The behavior of naturally fractured reservoirs. Soc. Petrol. Eng. J. 1963, 3, 1–11. [Google Scholar] [CrossRef]

- Lu, H.; Donato, G.D.; Blunt, M.J. General transfer functions for multiphase flow in fractured reservoirs. SPE J. 2008, 13, 289–297. [Google Scholar] [CrossRef]

- Al-Kobaisi, M.; Ozkan, E.; Kazemi, H. A hybrid numerical-analytical model of finite-conductivity vertical fractures intercepted by a horizontal well. SPE Res. Eval. Eng. 2006, 9, 345–355. [Google Scholar] [CrossRef]

- Mason, G.; Fischer, H.; Morrow, N.; Ruth, D. Correlation for the effect of fluid viscosities on counter-current spontaneous imbibition. J. Petrol. Sci. Eng. 2010, 72, 195–205. [Google Scholar] [CrossRef]

- Wtherspoon, P.; Wang, J.; Iwai, K.; Gale, J. Validity of cubic law for fluid flow in a deformable rock fracture. Tech. Inf. Rep. No. 23 1980. [Google Scholar] [CrossRef]

- Zimmerman, R.W.; Chen, D.; Cook, N.G. The effect of contact area on the permeability of fractures. J. Hydrol. 1992, 139, 79–96. [Google Scholar] [CrossRef] [Green Version]

- Zimmerman, R.; Kumar, S.; Bodvarsson, G. Lubrication theory analysis of the permeability of rough-walled fractures. Int. J. Rock Mech. Mining Sci. Geomech. Abstr. 1991, 28, 325–331. [Google Scholar] [CrossRef] [Green Version]

- Pyrak-Nolte, L.; Morris, J. Single fractures under normal stress: The relation between fracture specific stiffness and fluid flow. Int. J. Rock Mech. Mining Sci. 2000, 37, 245–262. [Google Scholar] [CrossRef]

- Sisavath, S.; Al-Yaarubi, A.; Pain, C.C.; Zimmerman, R.W. A simple model for deviations from the cubic law for a fracture undergoing dilation or closure. In Thermo-Hydro-Mechanical Coupling in Fractured Rock; Kümpel, H.-J., Ed.; Springer: Basel, Switzerland, 2003; pp. 1009–1022. [Google Scholar] [CrossRef]

- Zimmerman, R.W. A simple model for coupling between the normal stiffness and the hydraulic transmissivity of a fracture. In Proceedings of the 42nd US Rock Mechanics, 2nd US–Canada Rock Mechanics Symposium, San Francisco, CA, USA, 29 June–2 July 2008. [Google Scholar]

- Zimmerman, R.W.; Al-Yaarubi, A.H.; Pain, C.C.; Grattoni, C.A. Nonlinear regimes of fluid flow in rock fractures. Int. Rock Mech. 2004, 41, 384. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Koyama, T.; Neretnieks, I.; Jing, L. Shear-induced flow channels in a single rock fracture and their effect on solute transport. Transp. Porous Media 2010, 87, 503–523. [Google Scholar] [CrossRef]

- Chen, Z.; Qian, J.; Qin, H. Experimental study of the non-darcy flow and solute transport in a channeled single fracture. J. Hydrodyn. Ser. B 2011, 23, 745–751. [Google Scholar] [CrossRef]

- Yasuhara, H.; Polak, A.; Mitani, Y.; Grader, A.; Halleck, P.; Elsworth, D. Evolution of fracture permeability through fluid–rock reaction under hydrothermal conditions. Earth Plan. Sci. Lett. 2006, 244, 186–200. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Rajaram, H.; Viswanathan, H.; Zyvoloski, G.; Stauffer, P. Buoyant convection resulting from dissolution and permeability growth in vertical limestone fractures. Geophys. Res. Lett. 2009, 36, L03401. [Google Scholar] [CrossRef]

- Lake, L.W.; Johns, R.T.; Rossen, W.R.; Pope, G.A. Fundamentals of Enhanced Oil Recovery; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Blunt, M.J. Multiphase Flow in Permeable Media: A Pore-Scale Perspective; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Melrose, J.C. Thermodynamic aspects of capillarity. Ind. Eng. Chem. 1968, 60, 53–70. [Google Scholar] [CrossRef]

- Melrose, J. Role of capillary forces in determining microscopic displacement efficiency for oil recovery by waterflooding. J. Can. Petrol. Technol. 1974, 13, 1–13. [Google Scholar] [CrossRef]

- Chatzis, I.; Morrow, N.R.; Lim, H.T. Magnitude and detailed structure of residual oil saturation. Soc. Petrol. Eng. J. 1983, 23, 311–326. [Google Scholar] [CrossRef]

- Mandal, A.; Achinta, B. Modeling of flow of oil-in-water emulsions through porous media. Petrol. Sci. 2015, 12, 273–281. [Google Scholar] [CrossRef] [Green Version]

- Thiele, M.R.; Batycky, R.P.; Blunt, M.J. A streamline-based 3d field-scale compositional reservoir simulator. In Proceedings of the 1997 SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar] [CrossRef]

- Alpak, F.O.; Riviere, B.; Frank, F. A phase-field method for the direct simulation of two-phase flows in pore-scale media using a non-equilibrium wetting boundary condition. Comput. Geosci. 2016, 20, 881–908. [Google Scholar] [CrossRef]

- Frank, F.; Liu, C.; Alpak, F.O.; Riviere, B. A finite volume/discontinuous Galerkin method for the advective Cahn–Hilliard equation with degenerate mobility on porous domains stemming from micro-CT imaging. Comput. Geosci. 2018, 22, 543–563. [Google Scholar] [CrossRef]

- Frank, F.; Liu, C.; Alpak, F.O.; Berg, S.; Riviere, B. Direct numerical simulation of flow on pore-scale images using the phase-field method. SPE J. 2018, 23, 1833–1850. [Google Scholar] [CrossRef]

- Frank, F.; Liu, C.; Scanziani, A.; Alpak, F.O.; Riviere, B. An energy-based equilibrium contact angle boundary condition on jagged surfaces for phase-field methods. J. Colloid Interface Sci. 2018, 523, 282–291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riewchotisakul, S.; Akkutlu, I.Y. Adsorption enhanced transport of hydrocarbons in organic nanopores. SPE J. 2015, 21, 1–10. [Google Scholar] [CrossRef]

- Blunt, M.J.; Jackson, M.D.; Piri, M.; Valvatne, P.H. Detailed physics, predictive capabilities and macroscopic consequences for pore-network models of multiphase flow. Adv. Water Resour. 2002, 25, 1069–1089. [Google Scholar] [CrossRef]

- Xiong, Q.; Baychev, T.G.; Jivkov, A.P. Review of pore network modelling of porous media: Experimental characterisations, network constructions and applications to reactive transport. J. Contam. Hydrol. 2016, 192, 101–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weijermars, R.; Van Harmelen, A.; Zuo, L.H. Controlling flood displacement fronts using a parallel analytical streamline simulator. J. Petrol. Sci. Eng. 2016, 139, 23–42. [Google Scholar] [CrossRef]

- Weijermars, R.; van Harmelen, A. Breakdown of doublet re-circulation and direct line drives by far-field flow: Implications for geothermal and hydrocarbon well placement. Geophys. J. Int. 2016, 206, 19–47. [Google Scholar] [CrossRef]

- Weijermars, R.; Van Harmelen, A. Advancement of sweep zones in waterflooding: Conceptual insight and flow visualizations of oil-withdrawal contours and waterflood time-of-flight contours using complex potentials. J. Petrol. Explor. Prod. Technol. 2017, 7, 785–812. [Google Scholar] [CrossRef]

- Weijermars, R.; van Harmelen, A.; Zuo, L.; Nascentes Alves, I.; Yu, W. High resolution visualization of flow interference between frac clusters (Part 1): Model verification and basic cases. In Proceedings of the 2017 SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Weijermars, R.; van Harmelen, A.; Zuo, L. Flow interference between frac clusters (Part 2): Field example from the midland basin (wolfcamp formation, spraberry trend field) with implications for hydraulic fracture design. In Proceedings of the 2017 SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Weijermars, R.; Harmelen, A.V.; Zuo, L.; Alves, I.N.; Yu, W. Flow interference between hydraulic fractures. SPE Reserv. Eval. Eng. 2018, 21, 942–960. [Google Scholar] [CrossRef]

- Van Harmelen, A.; Weijermars, R. Complex analytical solutions for flow in hydraulically fractured hydrocarbon reservoirs with and without natural fractures. Appl. Math. Model. 2018, 56, 137–157. [Google Scholar] [CrossRef]

- Khanal, A.; Weijermars, R. Modeling flow and pressure fields in porous media with discrete fractures and smart placement of branch cuts for variant and invariant complex potentials. Appl. Math. Model. 2019. In Review. [Google Scholar]

- Khanal, A.; Weijermars, R. Visualization of drained rock volume (DRV) in hydraulically fractured reservoirs with and without natural fractures using complex analysis methods (CAM). Petrol. Sci. 2019. [Google Scholar] [CrossRef]

- Parsegov, S.G.; Nandlal, K.; Schechter, D.S.; Weijermars, R. Physics-driven optimization of drained rock volume for multistage fracturing: Field example from the Wolfcamp Formation, Midland Basin. In Proceedings of the 2018 Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar] [CrossRef]

- Weijermars, R.; Van Harmelen, A. Shale Reservoir Drainage Visualized for a Wolfcamp Well (Midland Basin, West Texas, USA). Energies 2018, 11, 1665. [Google Scholar] [CrossRef]

- Kahan, W. Branch Cuts for Complex Elementary Functions, or Much Ado about Nothing’S Sign Bit. In The State of the Art in Numerical Analysis; Iserles, A., Powell, M.J.D., Eds.; Clarendon Press: Oxford, UK, 1987. [Google Scholar]

- Holzbecher, L. Streamline visualization of potential flow with branch cuts, with applications to groundwater. J. Flow Vis. Image Process. 2018, 25, 119–144. [Google Scholar] [CrossRef]

- Wang, J.; Weijermars, R. New interface for assessing potential instability at Critical Wellbore Pressure with deviatoric stress distributions and various failure criteria. Rock Mech. Rock Eng. 2019. In Review. [Google Scholar]

- Weijermars, R.; Zhang, X.; Schultz-Ela, D. Geomechanics of fracture caging in wellbores. Geophys. J. Int. 2013, 193, 1119–1132. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Javadpour, F.; Feng, Q. Confinement correction to mercury intrusion capillary pressure of shale nanopores. Sci. Rep. 2016, 6, 20160. [Google Scholar] [CrossRef]

- Jansen, J.D. Nodal Analysis of Oil and Gas Production Systems; Society of Petroleum Engineers: Richardson, TX, USA, 2017. [Google Scholar]

- Weijermars, R.; Schmeling, H. Scaling of Newtonian and non-Newtonian fluid dynamics without inertia for quantitative modelling of rock flow due to gravity (including the concept of rheological similarity). Phys. Earth Planet. Inter. 1986, 43, 316–330. [Google Scholar] [CrossRef]

- Nandlal, K.; Weijermars, R. Drained rock volume around hydraulic fractures in porous media: planar fractures versus fractal networks. Petrol. Sci. 2019. In Press. [Google Scholar]

- Eberli, G.P.; Baechle, G.T.; Anselmetti, F.S.; Incze, M.L. Factors controlling elastic properties in carbonate sediments and rocks. The Lead. Edge 2003, 22, 654–660. [Google Scholar] [CrossRef] [Green Version]

- Goudarzi, A.; Delshad, M.; Sepehrnoori, K. A chemical EOR benchmark study of different reservoir simulators. Comput. Geosci. 2016, 94, 96–109. [Google Scholar] [CrossRef]

- Juanes, R.; Lie, K. A front-tracking method for efficient simulation of miscible gas injection processes. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 31 January–2 February 2005. [Google Scholar] [CrossRef]

- Juanes, R.; Blunt, M.J. Impact of viscous fingering on the prediction of optimum WAG ratio. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006. [Google Scholar] [CrossRef]

- LaForce, T.C.; Jessen, K. Analytical and numerical investigation of multicomponent multiphase WAG displacements. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar] [CrossRef]

- Seto, C.J.; Orr, F.M. Analytical solutions for multicomponent, two-phase flow in porous media with double contact discontinuities. Transp. Porous Med. 2009, 78, 161–183. [Google Scholar] [CrossRef]

- Pires, A.P.; Bedrikovetsky, P.G.; Shapiro, A.A. A splitting technique for analytical modelling of two-phase multicomponent flow in porous media. J. Pet. Sci. Eng. 2006, 51, 54–67. [Google Scholar] [CrossRef] [Green Version]

- Rankine Oval. 2005. Available online: http://www-mdp.eng.cam.ac.uk/web/library/enginfo/aerothermal_dvd_only/aero/fprops/poten/node36.html (accessed on 26 January 2019).

- Kundu, P.K.; Cohen, I.M. Fluid Mechanics; Academic Press: San Diego, CA, USA, 2002. [Google Scholar]

| Physical Quantity | Producer Case 4 | Injector Case 5 | Underbalanced Case 3 | Overbalanced Case 6 |

|---|---|---|---|---|

| Pore Strength (cm4·s−1) | 5 × 10−6 | 5 × 10−6 | 5 × 10−6 | 5 × 10−6 |

| Pore-throat Strength (cm4·s−1) | 1 × 10−5 | 1 × 10−5 | 1 × 10−5 | 1 × 10−5 |

| Pore Width (cm) | 4 | 4 | 4 | 4 |

| Pore-throat Width (cm) | 1 | 1 | 1 | 1 |

| Reservoir Boundary Strength (cm4·s−1) | 6 × 10−4 | 6 × 10−4 | 6 × 10−4 | 6 × 10−4 |

| Annulus Strength (cm4·s−1) | 6 × 10−4 | 6 × 10−4 | 6 × 10−4 | 1.20 × 10−3 |

| Tubing Strength (cm4·s−1) | 6 × 10−4 | 6 × 10−4 | 6 × 10−4 | 6 × 10−4 |

| Reservoir Boundary Width (cm) | 23 | 23 | 23 | 23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weijermars, R.; Khanal, A. Elementary Pore Network Models Based on Complex Analysis Methods (CAM): Fundamental Insights for Shale Field Development. Energies 2019, 12, 1243. https://doi.org/10.3390/en12071243

Weijermars R, Khanal A. Elementary Pore Network Models Based on Complex Analysis Methods (CAM): Fundamental Insights for Shale Field Development. Energies. 2019; 12(7):1243. https://doi.org/10.3390/en12071243

Chicago/Turabian StyleWeijermars, Ruud, and Aadi Khanal. 2019. "Elementary Pore Network Models Based on Complex Analysis Methods (CAM): Fundamental Insights for Shale Field Development" Energies 12, no. 7: 1243. https://doi.org/10.3390/en12071243

APA StyleWeijermars, R., & Khanal, A. (2019). Elementary Pore Network Models Based on Complex Analysis Methods (CAM): Fundamental Insights for Shale Field Development. Energies, 12(7), 1243. https://doi.org/10.3390/en12071243