Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer

Abstract

:1. Introduction

2. Materials and Methods

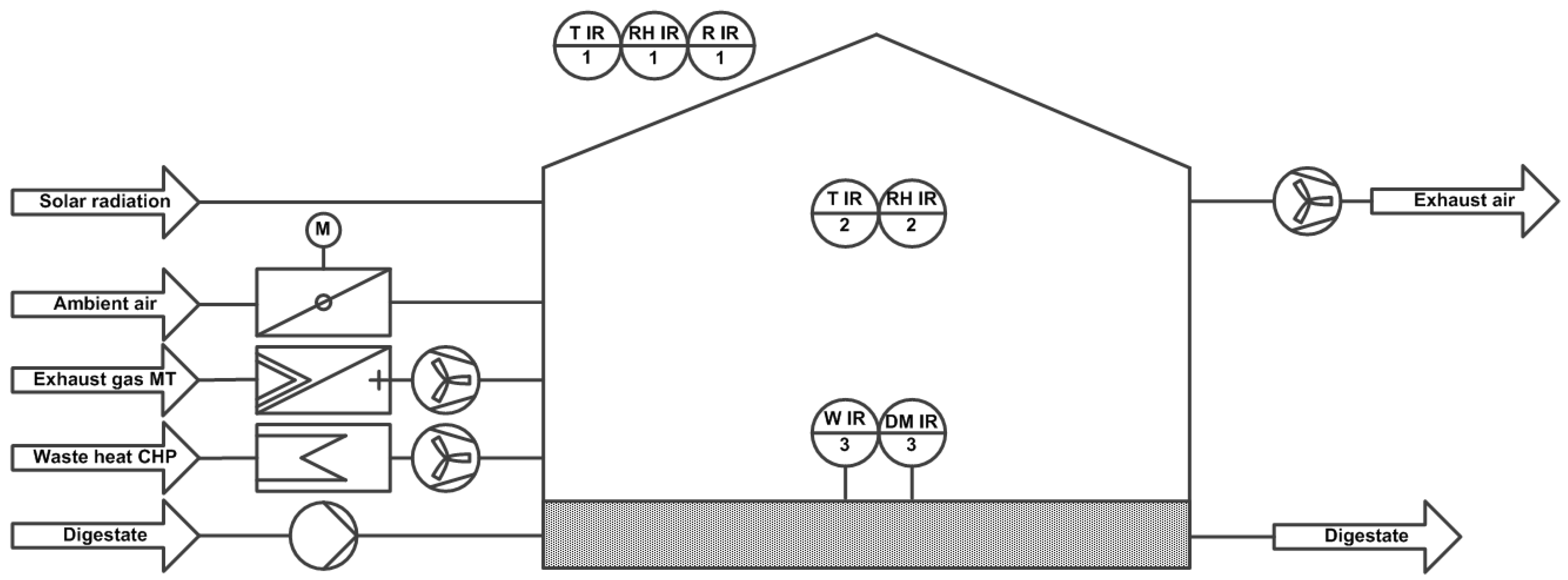

2.1. Description of the Drying System

2.2. Description of the Drying Process

3. Results and Discussion

3.1. Dying Characteristics and Energy Input

3.2. Drying Performance of Biogas Digestate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- German Biogas Association. German Biogas Market Data for 2017 and Forecast for 2018. Available online: https://www.biogas.org/edcom/webfvb.nsf/id/EN-German-biogas-market-data-for-2016-and-forecast-for-2017 (accessed on 6 December 2018).

- IRENA. Renewable Capacity Statistics 2018; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2018. [Google Scholar]

- Lootsma, A.; Raussen, T. Aktuelle Verfahren zur Aufbereitung und Verwertung von Gärresten. In Bio- und Sekundärrohstoffverwertung III stofflich energetisch; Wiemer, K., Kern, M., Eds.; Witzenhausen-Institut für Abfall, Umwelt und Energie: Witzenhausen, Germany, 2008; pp. 559–576. ISBN 3-928673-54-8. [Google Scholar]

- Möller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef] [Green Version]

- Möller, K.; Stinner, W.; Deuker, A.; Leithold, G. Effects of different manuring systems with and without biogas digestion on nitrogen cycle and crop yield in mixed organic dairy farming systems. Nutr. Cycl. Agroecosyst. 2008, 82, 209–232. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef]

- Sensel, K.; Wragge, V. Pflanzenbauliche Verwertung von Gärrückständen aus Biogasanlagen unter besonderer Berücksichtigung des Inputsubstrats Energiepflanzen; Institut für Agrar- und Stadtökologische Projekte an der Humboldt-Universität: Berlin, Germany, 2008. [Google Scholar]

- Döhler, H.; Schliebner, P. Verfahren und Wirtschaftlichkeit der Gärrestaufbereitung. In Verwertung von Wirtschafts- und Sekundärrohstoffdüngern in der Landwirtschaft–Nutzen und Risiken; KTBL: Darmstadt, Germany, 2006; pp. 199–212. ISBN 978-3939371-05-2. [Google Scholar]

- Döhler, H.; Wulf, S. Aktueller Stand bei der Gärrestaufbereitung. In Gülzower Fachgespräche Gärrestaufbereitung Für Eine Pflanzenbauliche Nutz.-Stand Und F+E-Bedarf; Fachagentur Nachwachsende Rohstoffe (FNR): Lauenburg, Germany, 2009; pp. 15–28. ISBN 978-3-9803927-5-4. [Google Scholar]

- Drosg, B.; Fuchs, W.; Al Seadi, T.; Madsen, M.; Linke, B. Nutrient Recovery by Biogas Digestate Processing; Baxter, D., Ed.; International Energy Agency (IEA Bioenergy): Paris, France, 2015; Available online: http://task37.ieabioenergy.com/files/daten-redaktion/download/Technical%20Brochures/NUTRIENT_RECOVERY_RZ_web2.pdf (accessed on 6 December 2018).

- Rehl, T.; Müller, J. Life cycle assessment of biogas digestate processing technologies. Resour. Conserv. Recycl. 2011, 56, 92–104. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Golkowska, K.; Lebuf, V.; Vaneeckhaute, C.; Michels, E.; Meers, E.; Benetto, E.; Koster, D. Environmental assessment of digestate treatment technologies using LCA methodology. Waste Manag. 2015, 43, 442–459. [Google Scholar] [CrossRef]

- Delzeit, R.; Kellner, U. The impact of plant size and location on profitability of biogas plants in Germany under consideration of processing digestates. Biomass Bioenergy 2013, 52, 43–53. [Google Scholar] [CrossRef]

- Collard, M.; Teychené, B.; Lemée, L. Comparison of three different wastewater sludge and their respective drying processes: Solar, thermal and reed beds – Impact on organic matter characteristics. J. Environ. Manag. 2017, 203, 760–767. [Google Scholar] [CrossRef]

- Metcalf&Eddy. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Murray, A.; Horvath, A.; Nelson, K.L. Hybrid Life-Cycle Environmental and Cost Inventory of Sewage Sludge Treatment and End-Use Scenarios: A Case Study from China. Environ. Sci. Technol. 2008, 42, 3163–3169. [Google Scholar] [CrossRef] [Green Version]

- Baumann, R. Entwässerung und solare Trocknung von flüssigem Klärschlamm. Ph.D. Thesis, University of Hohenheim, Stuttgart, Germany, 2009. [Google Scholar]

- Krawczyk, P. Numerical Modeling of Simultaneous Heat and Moisture Transfer During Sewage Sludge Drying in Solar Dryer. Procedia Eng. 2016, 157, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Bux, M.; Starcevic, N. Stand der Technik solarer und solarunterstützter Trocknungsverfahren für Klärschlamm. GWF Wasser Abwasser 2005, 146, 504–509. [Google Scholar]

- German Institute for Standardization. Characterization of Sludges-Determination of Dry Residue and Water Content, German version DIN EN 12880; Beuth: Berlin, Germany, 2001. [Google Scholar]

- Awiszus, S.; Meissner, K.; Reyer, S.; Müller, J. Utilization of digestate in a convective hot air dryer with integrated nitrogen recovery. Landtechnik 2018, 73, 106–114. [Google Scholar] [CrossRef]

- Awiszus, S.; Meissner, K.; Reyer, S.; Müller, J. Ammonia and methane emissions during drying of dewatered biogas digestate in a two-belt conveyor dryer. Bioresour. Technol. 2018, 247, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Baumann, R.; Thermo-System Industrie- & Trocknungstechnik GmbH, Stuttgart, Baden-Württemberg, Germany. Personal communication, 2019.

- Neumann, H. Gärrest im “Treibhaus” trocknen. Energ. Pflanz. Das Fachmag. Für Nachwachsende Rohst. Erneuerbare Energien. 2007, 2–4. [Google Scholar]

- Jacobs, U. Kosten und Wirtschaftlichkeit der Klärschlammtrocknung. In Energie aus Abfall-Band 10; Thomé-Kosmiensky, K.J., Beckmann, M., Eds.; TK Verlag Karl Thomé-Kozmiensky: Neuruppin, Germany, 2013. [Google Scholar]

- Erneuerbare Energien Gesetz (EEG). Gesetz zur Neuregelung des Rechts der Erneuerbaren Energien im Strombereich und zur Änderung damit zusammenhängender Vorschriften; Bundesgesetzblatt (BGBl): Bonn, Germany, 2008; Volume Teil I Nr. 49. [Google Scholar]

| Performance Indicator | CHP | MT |

|---|---|---|

| Electric power, kW | 335 | 200 |

| Electrical efficiency (ηel), % | 35 | 33 |

| Thermal power, kW | 528 | 280 |

| Thermal efficiency (ηth), % | 55 | 46 |

| Total power, kW | 863 | 480 |

| Cogeneration efficiency, % | 90 | 79 |

| Variant | mini | t | MCini | MCfin | mevap | EP | Etotal | Espec. |

|---|---|---|---|---|---|---|---|---|

| t | d | % | % | t | kg m−² d−1 | MWh | MJ kg−1 | |

| S-CHP | 60 | 13 | 94.6 ± 0.1a | 10.9 ± 2.1a | 56.4 ± 1.3a | 9.0 ± 0.2a | 95.1 | 6.1± 0.0a |

| S-CHP-MT | 60 | 13 | 93.8 ± 0.6b | 10.5 ± 4.3a | 55.9 ± 2.8a | 8.9 ± 0.4a | 150.4 | 9.7 ± 0.0b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurer, C.; Müller, J. Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer. Energies 2019, 12, 1294. https://doi.org/10.3390/en12071294

Maurer C, Müller J. Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer. Energies. 2019; 12(7):1294. https://doi.org/10.3390/en12071294

Chicago/Turabian StyleMaurer, Claudia, and Joachim Müller. 2019. "Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer" Energies 12, no. 7: 1294. https://doi.org/10.3390/en12071294

APA StyleMaurer, C., & Müller, J. (2019). Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer. Energies, 12(7), 1294. https://doi.org/10.3390/en12071294