Wood Chip Drying through the Using of a Mobile Rotary Dryer

Abstract

1. Introduction

2. Materials and Methods

2.1. Rotary Dryer Prototype

2.2. Characterization of the Biomass

2.3. Experimental Procedure and Characterization of the Airflow

2.4. Energy Analysis

2.5. Statistical Analysis

3. Results and Discussion

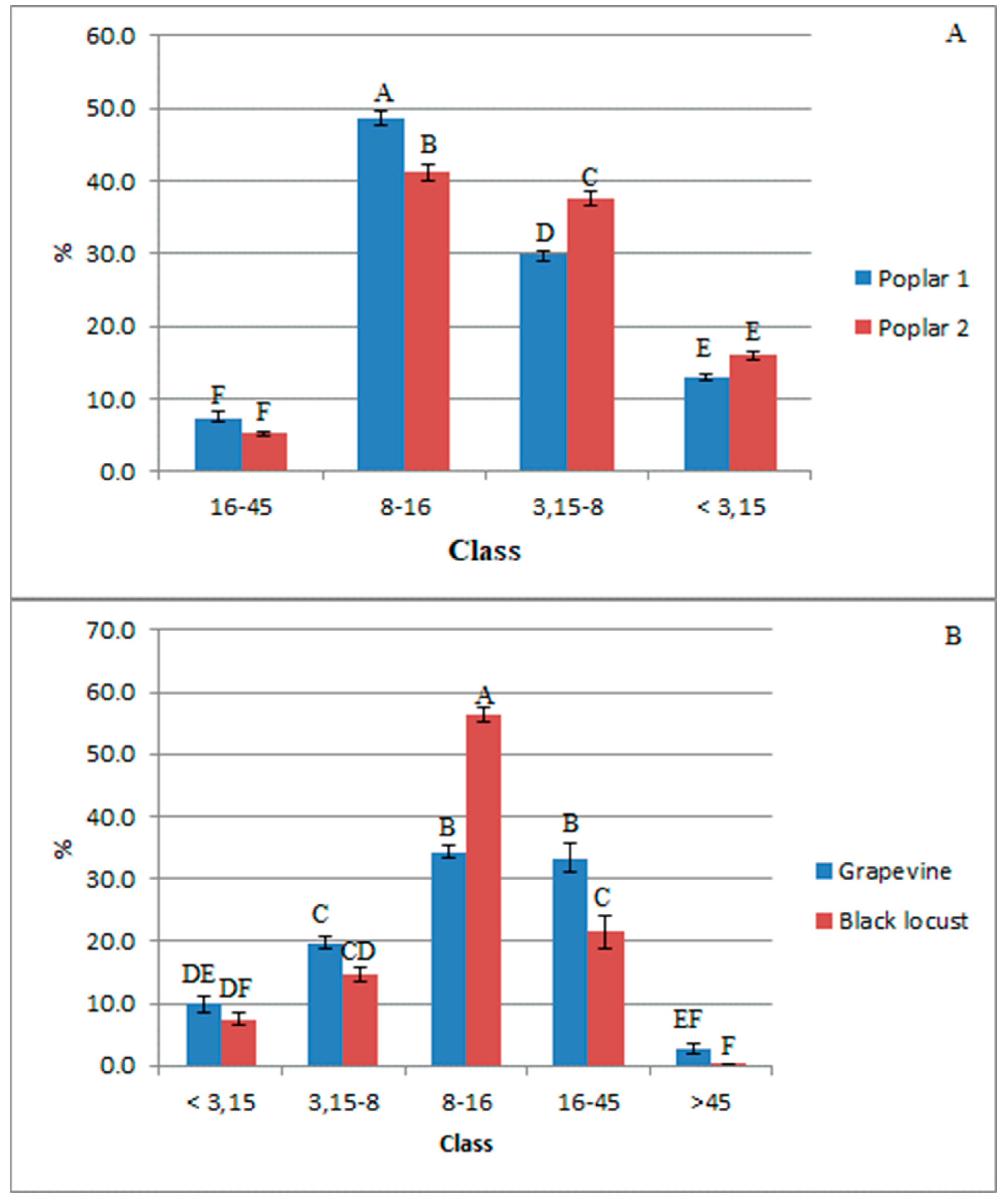

3.1. Biomass Characterization

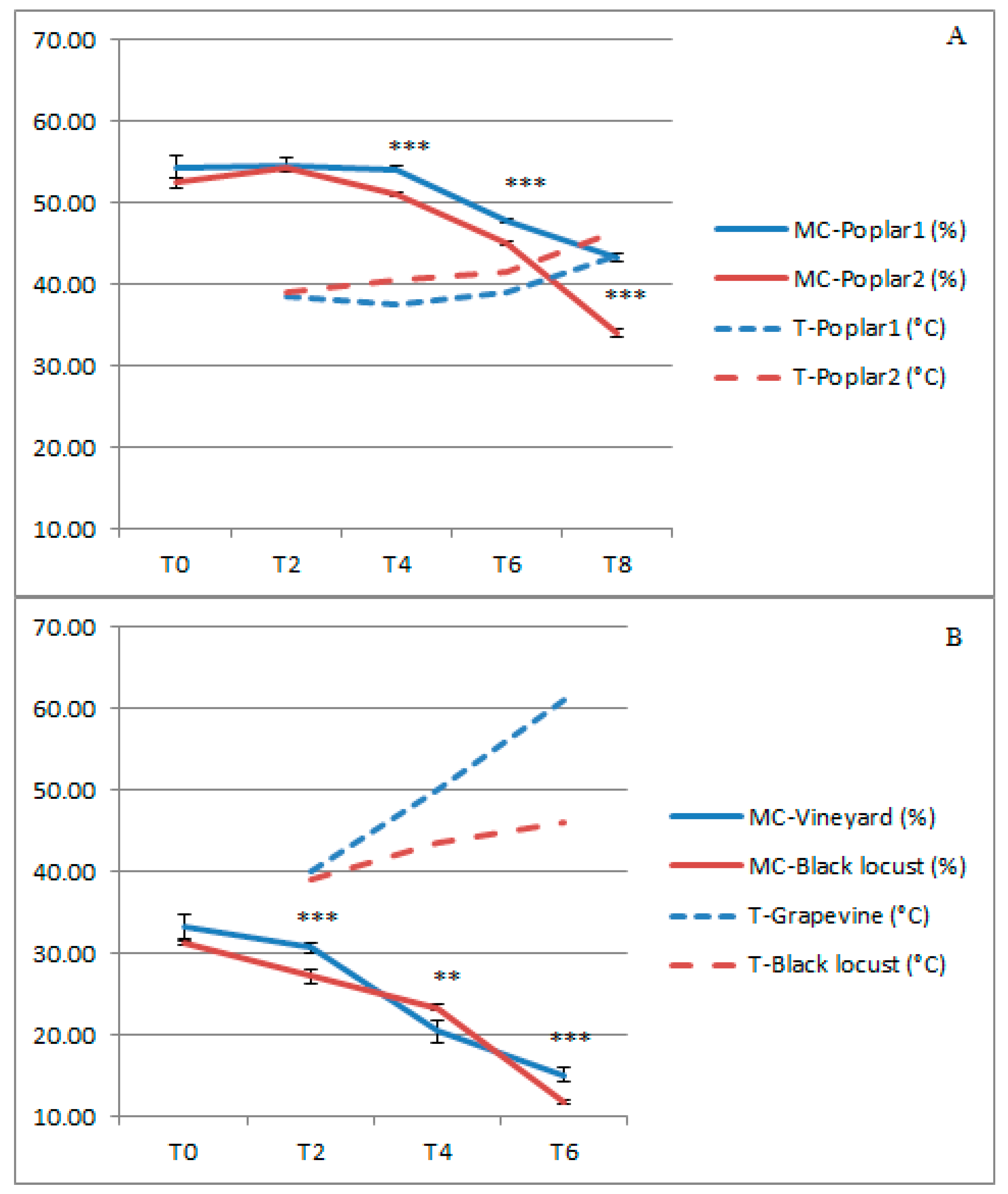

3.2. Drying Process

3.3. Characteristics of the Airflow

3.4. Energy Balance

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Colantoni, A.; Longo, L.; Gallucci, F.; Monarca, D. Pyro-Gasification of hazelnut using a downdraft gasifier for concurrent production of syngas and biochar. Contemp. Eng. Sci. 2016, 9, 1339–1348. [Google Scholar] [CrossRef]

- Nystrom, J.; Dahlquist, E. Methods for determination of moisture continent in wood chip for power plant—A review. Fuel 2003, 83, 773–779. [Google Scholar] [CrossRef]

- Maltoni, A.; Mariotti, B.; Tani, A. La Robinia in Toscana. La Gestione dei Popolamenti, L’impiego in Impianti Specializzati, il Controllo della Diffusione, Regione Toscana—DEISTAF: Dipartimento di Economia, Ingegneria, Scienze e Tecnologie Agrarie e Forestali Università di Firenze; Regione Toscana: Firenze, Italy, 2012. [Google Scholar]

- Wimmerstedt, R. Recent advances in biofuel drying. Chem. Eng. Prog. 1999, 38, 441–447. [Google Scholar] [CrossRef]

- Kaplan, O.; Celik, C. An experimental research on woodchip drying using a screw conveyor dryer. Fuel 2018, 215, 468–473. [Google Scholar] [CrossRef]

- Meza, J.; Gil, A.; Cortés, C.; González, A. Drying cost of wood biomass in a semi-industrial exsperimental rotary dryer. In Proceedings of the 16th European Conference & Exhibition on Biomass for Energy, Biomass Resources, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Svoboda, K.; Martinec, J.; Pohorely, M.; Baxter, D. Integration of biomass drying with combustion/gasification technologies and minimalization of organic compounds. Chem. Pap. 2009, 63, 15–25. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N. Il cippato forestale. In Foresta, Legno, Energia. Linee guida per lo sviluppo di un modello di utilizzo del cippato forestale a fini energetici; Press Service Firenze: Florence, Italy, 2007; pp. 69–103. [Google Scholar]

- Spinelli, R. Cippato: La raccolta della materia prima. Mondo Macchina 2008, 2, 56–59. [Google Scholar]

- Cuevas, M.; Martínez-Cartas, M.L.; Perez-Villarejo, L.; Hernandez, L.; García-Martín, J.F.; Sanchez, S. Drying kinetics and effective water diffusivities in olive stone and olive-tree pruning. Renew. Energy 2019, 132, 911–920. [Google Scholar] [CrossRef]

- McIlveen-Wright, D.R.; Williams, B.C.; McMullan, J.T. A re-appraisal of wood-fired combustion. Bioresour. Technol. 2001, 76, 183–190. [Google Scholar] [CrossRef]

- Schuster, G.; Löffler, G.; Weigl, K.; Hofbauer, H. Biomass steam gasification—An extensive parametric modelling study. Bioresour. Technol. 2001, 77, 71–79. [Google Scholar] [CrossRef]

- Belis, C.A.; Cancelinha, J.; Duanea, M.; Forcina, V.; Pedronia, V.; Passarella, R.; Tanet, G.; Douglas, K.; Piazzalunga, A.; Bolzacchini, E.; et al. Sources for PM air pollution in the Po Plain, Italy: I. Critical comparison of methods for estimating biomass burning contributions to benzo(a)pyrene. Atmos. Environ. 2011, 45, 7266–7275. [Google Scholar] [CrossRef]

- Petracchini, F.; Romagnoli, P.; Paciucci, L.; Vichi, F.; Imperiali, A.; Paolini, V.; Liotta, F.; Cecinato, A. Influence of transport from urban sources and local biomass combustion on the air quality of a mountain area. Environ. Sci. Pollut. Res. 2017, 24, 4741–4754. [Google Scholar] [CrossRef] [PubMed]

- Barontini, M.; Crognale, S.; Scarfone, A.; Gallo, P.; Gallucci, F.; Petruccioli, M.; Pesciaroli, L.; Pari, L. Airborn fungi in biofuel wood chip storage sites. Int. Biodeter. Biodegr. 2014, 90, 17–22. [Google Scholar] [CrossRef]

- Chapela, S.; Porteiro, J.; Gómez, M.A.; Patiño, D.; Míguez, J.L. Comprehensive CFD modeling of the ash deposition in a biomass packed bed burner. Fuel 2018, 234, 1099–1122. [Google Scholar] [CrossRef]

- Klavinia, K.; Cinis, A.; Zandeckis, A. A study of pressure drops in an experimental low temperature wood chip dryer. Agron. Res. 2014, 12, 511–518. [Google Scholar]

- Li, H.; Chen, Q.; Zhang, X.; Finney, K.N.; Sharifi, V.N.; Swithenbank, J. Evaluation of a biomass drying process using waste heat from process industries: A case study. Appl. Therm. Eng. 2012, 35, 71–80. [Google Scholar] [CrossRef]

- Fredrikson, R.W. Utilisation of Wood Waste as Fuel for Rotary and Flash Tube Wood Dryer Operation. In Proceedings of the Biomass Fuel Drying Conference Proceedings, Superior, WN, USA, 8 August 1984; Office of Special Programs, University of Minnesota: Minneapolis, MN, USA, 1984; pp. 1–16. [Google Scholar]

- Hulkkonen, S.; Parvio, E.; Raiko, M. An Advanced Fuel Drying Technology for Fluidized Bed Boilers. In Proceedings of the 13th International Conference on Fluidized Bed Combustion, Orlando, FL, USA, 7–10 May 1995; pp. 399–403. [Google Scholar]

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.D.; Roskilly, A.P. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 233–234, 367–385. [Google Scholar] [CrossRef]

- Ozollapins, M.; Kakitis, A.; Nulle, I. Stalk biomass drying rate evaluation. In Proceedings of the 12th International Scientific Conference Enginering for Rural Development, Jelgava, Latvia, 23–24 May 2013. [Google Scholar]

- Pang, S.; Mujumdar, A.S. Drying of woody biomass for bioenergy: Drying technologies and optimization for an integrated bioenergy plant. Dry. Technol. 2010, 28, 690–701. [Google Scholar] [CrossRef]

- Vigants, E.; Vigants, G.; Veidenbergs, I.; Lauka, D.; Klavina, K.; Blumberga, D. Analysis of Energy Consumption for Biomass Drying Process. In Proceedings of the 10th International Scientific and Practical Conference on Environment, Technology and Resources, Rezekne, Latvia, 18–20 June 2015; Volume II, pp. 317–322. [Google Scholar]

- AIEL. Sistemi di essiccazione. In Legna, Cippato e Pellet, Produzione, Requisiti Qualitativi, Compravendita; Associazione Italiana Energie Agroforestali (AIEL): Legnaro (PD), Italy, 2012; pp. 93–100. [Google Scholar]

- Kocsis, L.; Herdovics, M.; Deákvári, J.; Fenyvesi, L. Corn drying experiments by pilot dryer. Agron. Res. Biosyst. Eng. Special Iss. 2011, 1, 91–97. [Google Scholar]

- Grimm, D.; Elustondo, M.; Mäkelä, M.; Segerström, G.; Kalén, L.; Fraikin, A.; Léonard, S.; Larsson, H. Drying recycled fiber rejects in a bench-scale cyclone: Influence of device geometry and operational parameters on drying mechanisms. Fuel Process. Technol. 2017, 167, 631–640. [Google Scholar] [CrossRef]

- Gu, C.; Yuanb, Z.; Sunb, S.; Guanb, L.; Wub, K. Simulation investigation of drying characteristics of wet filamentous biomass particles in a rotary kiln. Fuel Process. Tchnol. 2018, 178, 344–352. [Google Scholar] [CrossRef]

- Zuccarello, B. La co-densificazione di sanse e residui di potature: Fattibilità tecnico-economica e sviluppo. In Proceedings of the Conference Progetto ECODENS—Ecostabilizzazione delle sanse mediante densificazione, Misura 124-PSR Sicilia, 2007–2013, Università degli Studi di Palermo, Palermo, Italy, 30 January 2014. [Google Scholar]

- Mujumdar, A.S. Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Kaplan, O.; Celik, C. Woodchip drying in a screw conveyor dryer. J. Renew. Sustain. Energy 2012, 4, 063110. [Google Scholar] [CrossRef]

- Xu, Q.; Pang, S. Mathematical modeling of rotary drying of woody biomass. Dry. Technol. 2008, 26, 1344–1350. [Google Scholar] [CrossRef]

- Krokida, M.; Marinos-Kouris, D.; Mujumdar, A.S. Rotary drying. In Handbook of Industrial Drying; Mujumdar, A.S., Ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 151–172. [Google Scholar]

- Lazdāns, V.; Lazdiņš, A.; Zimelis, A. Technology of biofuel production from slash in clear-cuts of spruce stands. For. Sci. 2009, 19, 109–121. [Google Scholar]

- Williams-Gardner, A. Industrial Drying; Leonard Hill Books Ltd.: London, UK, 1971. [Google Scholar]

- Brammer, J.; Bridgwater, A. Drying technologies for an integrated gasification bio-energy plant. Renew. Sustain. Energy Rev. 1999, 3, 243–289. [Google Scholar] [CrossRef]

- Maciejewska, A.; Veringa, H.; Sanders, J.; Peteves, C. Co-Firing of Biomass with Coal: Constraints and Role of Biomass Pre-Treatment; JRC’s Institute for Energy: Petten, The Nederlands, 2006. [Google Scholar]

- UNI EN 14774-2. Solid Biofuels, Determination of Moisture Content—Oven Dry Method. Part 2: Total Moisture—Simplified Method; Italian Authority for Standardization: Milano, Italy, 2010. [Google Scholar]

- UNI EN 15103. Solid Biofuels, Determination of Bulk Density; Italian Authority for Standardization: Milano, Italy, 2010. [Google Scholar]

- UNI EN 14961-1. Solid Biofuels, Determination of Particle Size Distribution. Part 1: Oscillating Screen Method Using Sieve Apertures of 1 mm and Above; Italian Authority for Standardization: Milano, Italy, 2011. [Google Scholar]

- ISO 3310-2. Test Sieves e Technical Requirements and Testing-Part 1: Test Sieves of Metal Wire Cloth; Italian Authority for Standardization: Milano, Italy, 2000. [Google Scholar]

- Hartmann, H. Handbuch Bioenergie-Kleinanlagen; Sonderpublikation des Bundesministeriums für Verbraucherschutz, Ernährung und Landwirtschaft (BMVEL) und der Fachagentur Nachwachsende Rohstoffe (FNR): Gülzow, Germany, 2007. [Google Scholar]

- Manzone, M.; Balsari, P.; Spinelli, R. Small-scale storage techniques for fuel chips from short rotation forestry. Fuel 2013, 109, 687–692. [Google Scholar] [CrossRef]

- Pari, L.; Assirelli, A.; Acampora, A.; Del Giudice, A.; Santangelo, E. A new prototype for increasing the particle size of chopped Arundo donax (L.). Biomass Bioenergy 2015, 74, 288–295. [Google Scholar] [CrossRef]

- Garcia-Galindo, D.; Gomez-Palmero, M.; Lopez, E.; Sebastián, F.; Jirjis, R.; Gebresenbet, G.; Germer, S.; Pari, L.; Suardi, A.; Lapeña, A.; et al. Agricultural pruning harvesting demostrationns in Germany, France, and Spain. Lessons learned reccommendations. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1727–1733. [Google Scholar]

- Zhou, L.P.; Wang, B.X.; Peng, X.F.; Du, X.Z.; Yang, Y.P. On the Specific Heat Capacity of CuO Nanofluid. Adv. Mech. Eng. 2010, 1–4, 172085. [Google Scholar] [CrossRef]

- Tippayawong, N.; Tantakitti, S.; Thavornun, S. Energy efficiency improvements in longan drying practice. Energy 2008, 33, 1137–1143. [Google Scholar] [CrossRef]

- Langsrud, Ø.; JØrgensen, K.; Ofstad, R.; Næs, T. Analyzing designed experiments with multiple responses. J. Appl. Stat. 2007, 34, 1275–1296. [Google Scholar] [CrossRef]

- Jakob, K. Black locust (Robinia pseudoacacia L.). In Energy Plant Species, Their Use And impact on Environment and Development; James & James (Science Publishers) Ltd.: London, UK, 1998; pp. 98–103. [Google Scholar]

- Kraszkiewicz, A. Chemical composition and selected energy proprieties of Black locust bark (Robinia pseudoacacia L.). Agric. Eng. 2016, 20, 117–124. [Google Scholar]

- Hellrigl, B. Elementi di Xiloenergetica. Definizioni, Formule e Tabelle; AIEL-Italian Agriforestry Energy Association: Padova, Italy, 2006. [Google Scholar]

- Civitarese, V.; Del Giudice, A.; Suardi, A.; Santangelo, E.; Pari, L. Study on the effect of a new rotor designed for chipping short rotation woody crops. Croat. J. For. Eng. 2015, 36, 101–108. [Google Scholar]

- Anderson, J.-O.; Westerlund, L. Improved energy efficiency in sawmill drying system. Appl. Energy 2014, 113, 891–901. [Google Scholar] [CrossRef]

- Johansson, L.; Westerlund, L. An open absorption system installed at a sawmill description of pilot plant used for timber and bio-fuel drying. Energy 2000, 25, 1067–1079. [Google Scholar] [CrossRef]

- Chua, K.J.; Mujumdar, A.S.; Hawlader, M.N.A.; Chou, S.K.; Ho, J.C. Batch drying of banana pieces—Effect of stepwise change in drying air temperature on drying kinetics and product color. Food Res. Int. 2001, 34, 721–731. [Google Scholar] [CrossRef]

- Ogura, H.; Yamamoto, T.; Otsubo, Y.; Ishida, H.; Kage, H.; Mujumdar, A.S. A control strategy for chemical heat pump dryer. Dry. Technol. 2005, 23, 1189–1203. [Google Scholar] [CrossRef]

- De Fusco, L.; Jeanmart, H.; Blondeau, J. A modelling approach for the assessment of an air-dryer economic feasibility for small-scale biomass steam boilers. Fuel Process. Technol. 2015, 134, 251–258. [Google Scholar] [CrossRef]

| Biomass | Amount (kg) | Moisture Content (%) | Calorific Value (MJ·kg−1) | Bulk Density (kg/m3) |

|---|---|---|---|---|

| Poplar 1 | 250.0 | 54.4 ± 1.4 | 7.1 ± 0.3 | 280.6 ± 8.4 |

| Poplar 2 | 250.0 | 52.5 ± 0.6 | 7.5 ± 0.1 | 285.2 ± 3.2 |

| Grapevine | 143.7 | 33.3 ± 1.5 | 11.5 ± 0.3 | 199.3 ± 8.2 |

| Black locust | 207.0 | 31.2 ± 0.3 | 12.0 ± 0.1 | 358.5 ± 10.5 |

| Biomass | Mean Particle Size (mm) | A |

|---|---|---|

| Poplar 1 | 64.0 ± 8.7 B | 511.1 ± 68.9 B |

| Poplar 2 | 39.2 ± 6.0 C | 786.0 ± 100.2 A |

| Grapevine | 145.0 ± 45.4 A | 263.9 ± 78.8 C |

| Black locust | 68.3 ± 7.8 B | 480.4 ± 46.6 B |

| Source of Variation | Temperature | Rate | Speed | |||

|---|---|---|---|---|---|---|

| F | p | F | p | F | p | |

| Species | 1.72 | 0.184 | 39.86 | 0.000 | 48.66 | 0.000 |

| ChP | 147.30 | 0.000 | 145.60 | 0.000 | 8.81 | 0.001 |

| Species X ChP | 4.33 | 0.003 | 0.68 | 0.666 | 4.34 | 0.003 |

| Variable | ChP | Poplar 1 | Poplar 2 | Grapevine | Black Locust |

|---|---|---|---|---|---|

| Temperature (°C) | 1 | 73.75 ± 4.22 A | 76.85 ± 1.14 A | 60.40 ± 9.69 AC | 64.30 ± 11.97 AB |

| 2 | 71.23 ± 4.23 A | 72.15 ± 2.85 A | 60.27 ± 10.00 AC | 67.47 ± 48.79 AB | |

| 3 | 28.58 ± 1.15 D | 31.10 ± 0.84 D | 41.97 ± 10.31 BD | 34.87 ± 2.99 CD | |

| Airflow rate (m3·h−1) | 1 | 1035.99 ± 47.64 | 1004.40 ± 70.59 | 809.52 ± 155.50 | 811.80 ± 49.98 |

| 2 | 948.24 ± 16.13 | 978.03 ± 47.06 | 734.88 ± 139.58 | 775.80 ± 26.82 | |

| 3 | 659.79 ± 49.67 | 625.41 ± 36.56 | 332.88 ± 54.05 | 396.31 ± 6.64 | |

| Speed (m·s−1) | 1 | 5.79 ± 0.33 A | 5.70 ± 0.37 A | 4.63 ± 0.91 AC | 4.59 ± 0.28 AC |

| 2 | 5.28 ± 0.05 AB | 5.49 ± 0.26 A | 4.08 ± 0.73 AC | 4.52 ± 0.11 AC | |

| 3 | 5.76 ± 0.41 A | 5.53 ± 0.36 A | 2.95 ± 0.46 C | 3.48 ± 0.02 C |

| Parameter | Poplar 2 | Grapevine | Black Locust |

|---|---|---|---|

| Biomass fuel used (kg) | 80 | 60 | 52 |

| Dried biomass (kg) | 208.3 | 98.8 | 142.2 |

| Quantity of H2O evaporated (kg) | 41.7 | 44.9 | 64.8 |

| Heating value * (MJ·Kg−1) | |||

| - wet basis | 7.50 | 11.53 | 11.96 |

| - dry basis | 11.34 | 15.35 | 17.10 |

| Parameter | Poplar 2 | Grapevine | Black Locust |

|---|---|---|---|

| Item | Thermal Energy Utilization | ||

| Energy input (MJ·kgdry solid −1) | 4.35 | 6.88 | 4.14 |

| Heat for drying Q (MJ·kgdry solid−1) | 1.61 | 0.86 | 1.12 |

| Losses (MJ·kgdry solid−1) | 2.74 | 6.02 | 3.02 |

| Drying efficiency η (%) | 37 | 12 | 27 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Giudice, A.; Acampora, A.; Santangelo, E.; Pari, L.; Bergonzoli, S.; Guerriero, E.; Petracchini, F.; Torre, M.; Paolini, V.; Gallucci, F. Wood Chip Drying through the Using of a Mobile Rotary Dryer. Energies 2019, 12, 1590. https://doi.org/10.3390/en12091590

Del Giudice A, Acampora A, Santangelo E, Pari L, Bergonzoli S, Guerriero E, Petracchini F, Torre M, Paolini V, Gallucci F. Wood Chip Drying through the Using of a Mobile Rotary Dryer. Energies. 2019; 12(9):1590. https://doi.org/10.3390/en12091590

Chicago/Turabian StyleDel Giudice, Angelo, Andrea Acampora, Enrico Santangelo, Luigi Pari, Simone Bergonzoli, Ettore Guerriero, Francesco Petracchini, Marco Torre, Valerio Paolini, and Francesco Gallucci. 2019. "Wood Chip Drying through the Using of a Mobile Rotary Dryer" Energies 12, no. 9: 1590. https://doi.org/10.3390/en12091590

APA StyleDel Giudice, A., Acampora, A., Santangelo, E., Pari, L., Bergonzoli, S., Guerriero, E., Petracchini, F., Torre, M., Paolini, V., & Gallucci, F. (2019). Wood Chip Drying through the Using of a Mobile Rotary Dryer. Energies, 12(9), 1590. https://doi.org/10.3390/en12091590