Flexible Modern Power System: Real-Time Power Balancing through Load and Wind Power

Abstract

:1. Introduction

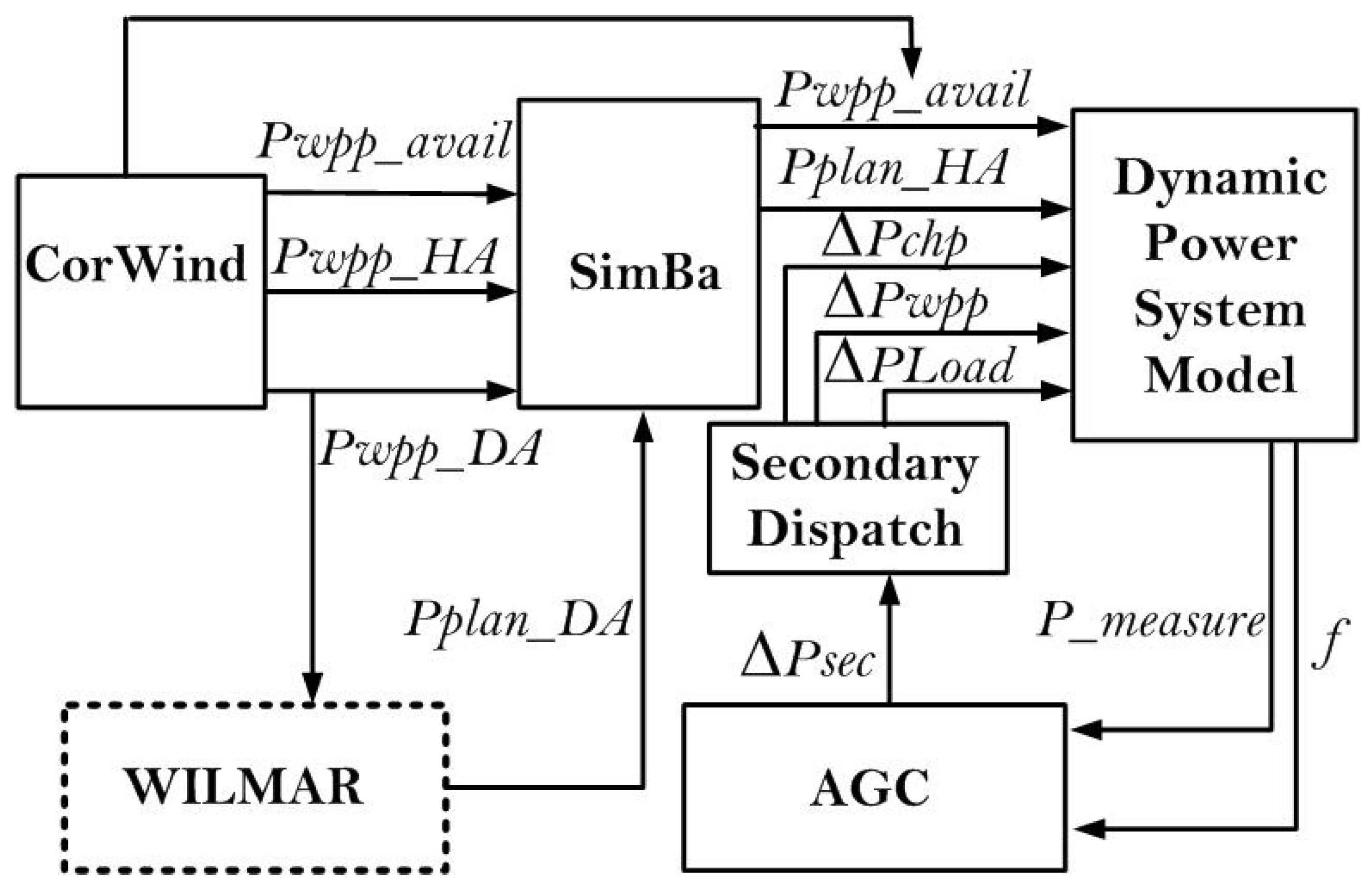

2. System Modeling

2.1. Modeling of the Flexible Loads

2.2. Modeling of Generating Units

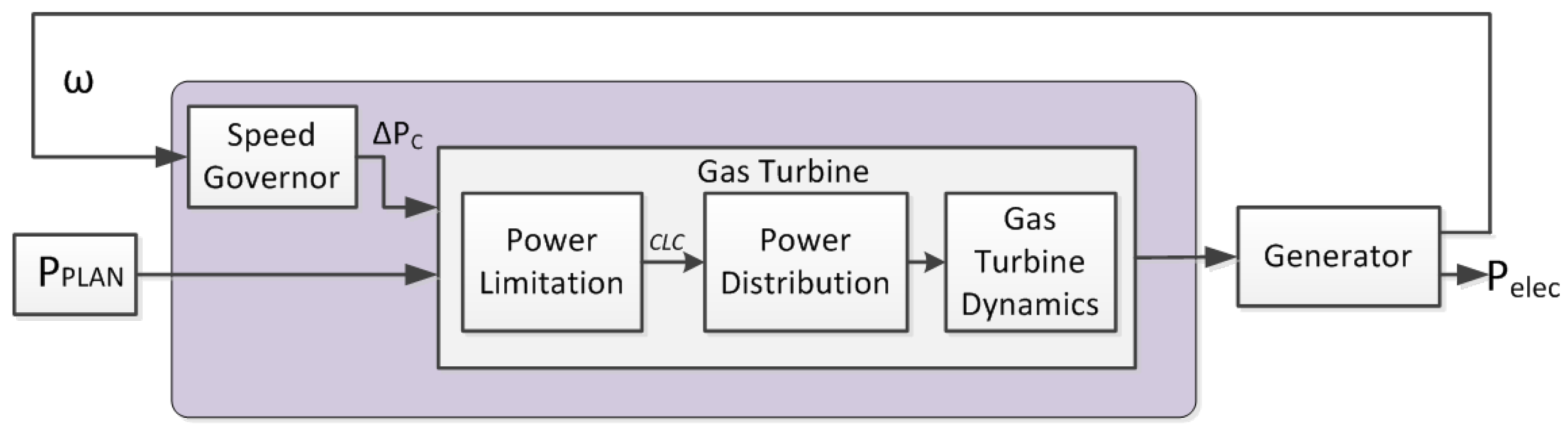

2.2.1. Combined Heat and Power Plant Model

2.2.2. Decentralized Combined Heat and Power Plant

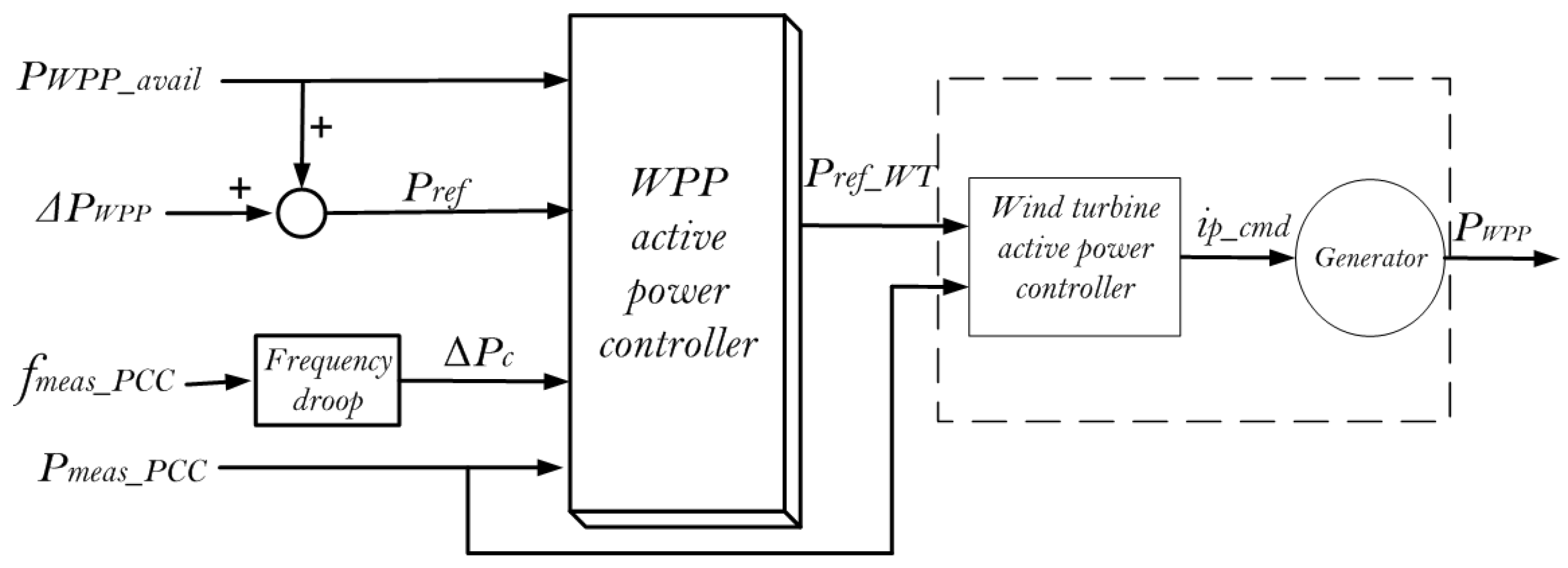

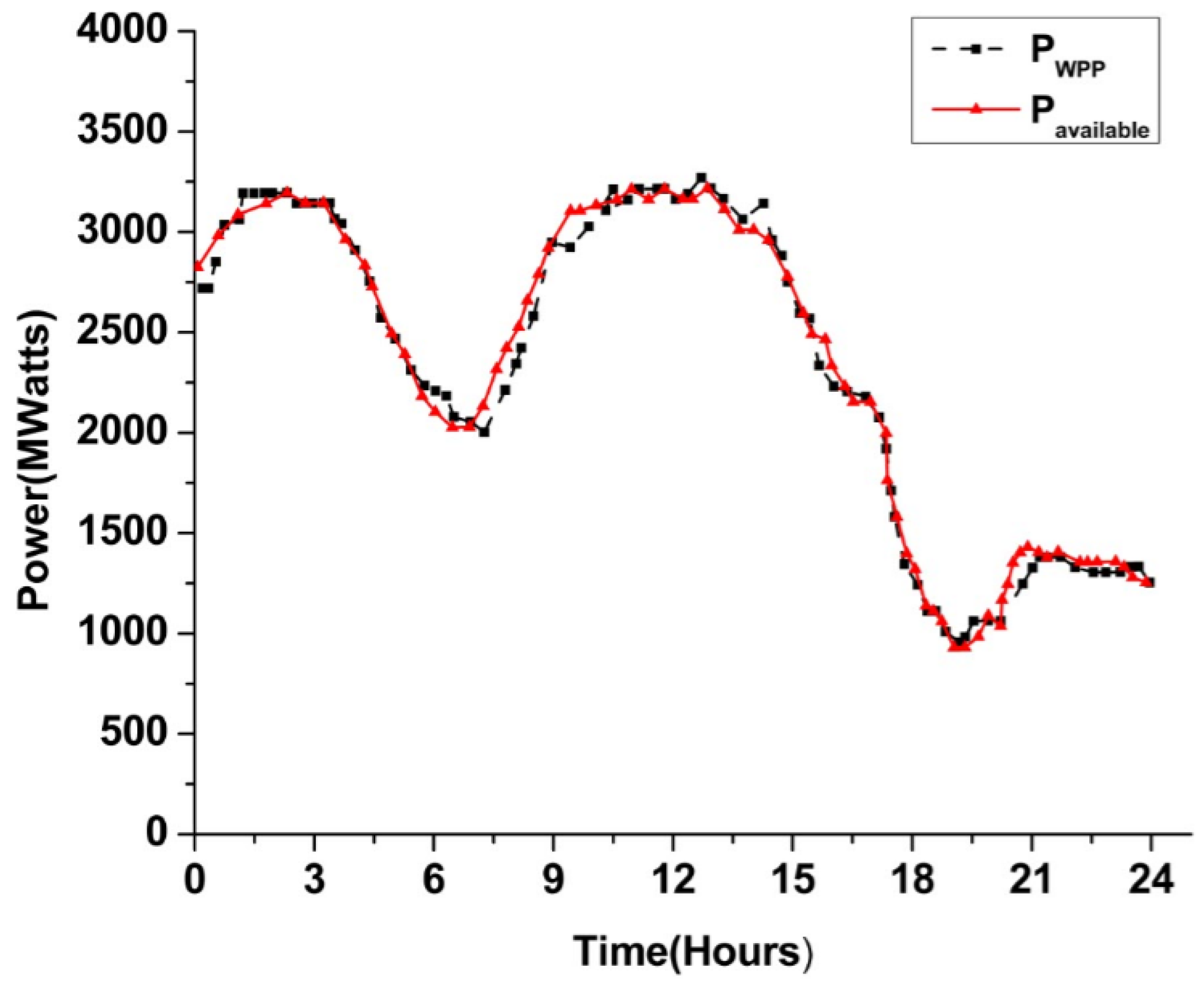

2.2.3. Wind Power Plant

2.3. Regulating Power Plan

2.4. Automatic Generation Control

3. Performance Analysis through Case Studies

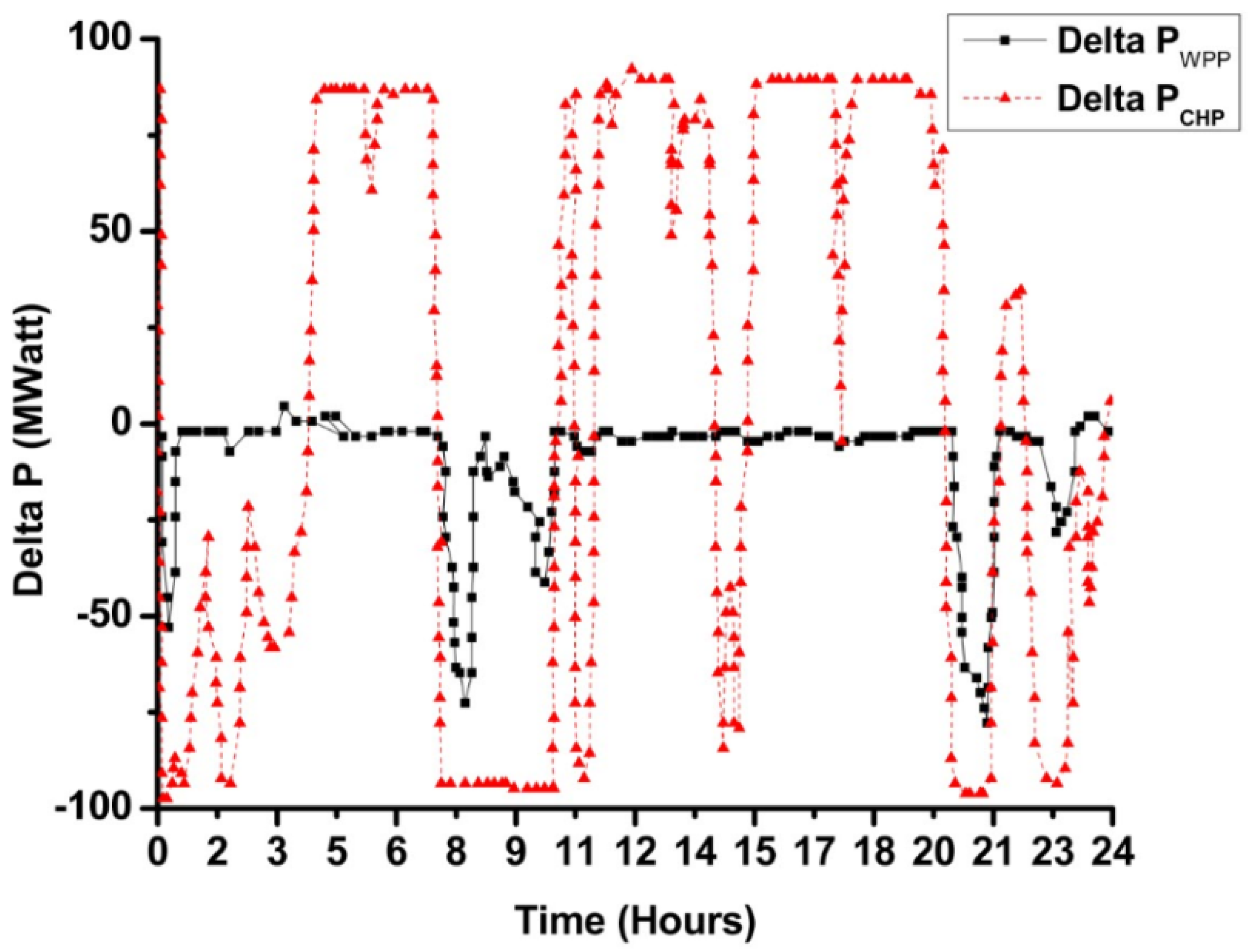

3.1. Case Study 1: Power Balance Control through WPPs and CHPs

- = WPP generation cost

- = CHP generation cost

- = Secondary dispatch from WPP

- = Secondary dispatch from CHP

- = Minimum generational level of WPP

- = Maximum generational level of WPP

- = Minimum generation of CHP

- = Maximum generation of CHP

- = Upper dispatch limit of CHP

- = Lower dispatch limit of CHP

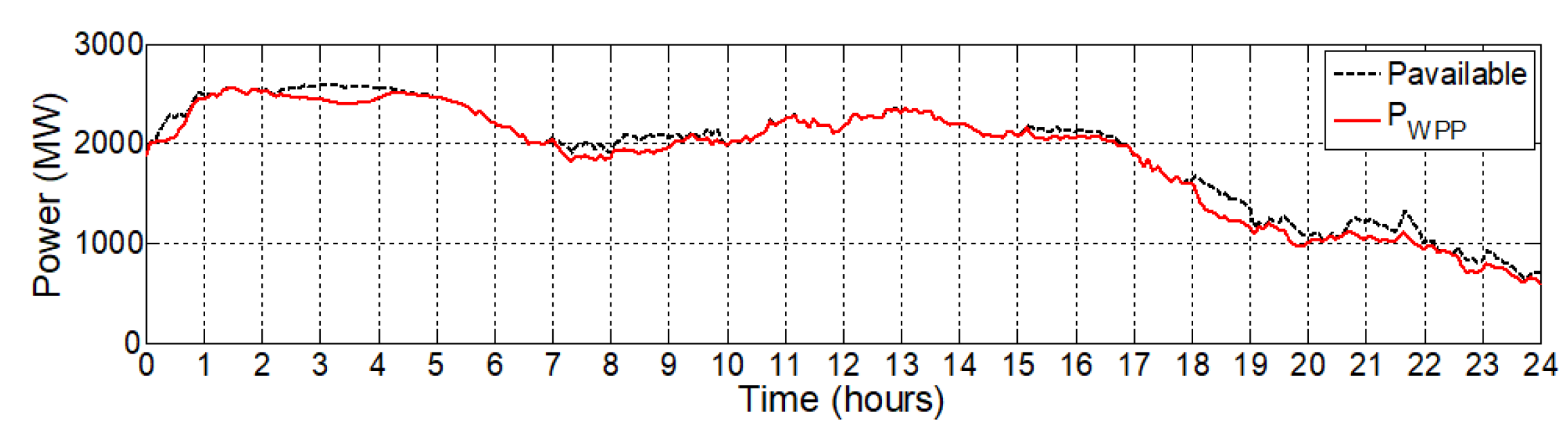

3.2. Case Study 2: Power Balance Control through WPPs and Flexible Loads

- = Cost of power generation from WPP

- = Cost of power generation from CHP

- = Energy activated through secondary response

- = Energy extracted through flexible units

- = Secondary dispatch from WPP

- = Secondary dispatch from CHP

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AGC | Automatic Generation Control |

| WPPs | Wind Power Plants |

| CPL | Cold Storage Power Plants |

| EV | Electric Vehicles |

| HP | Heat Pumps |

| CHP | Centralized Combined Heat and Power plant |

| DCHP | De-centralized Combined Heat and Power plant |

| HA | Hour-Ahead |

| TSO | Transmission System Operator |

References

- Basit, A.; Hansen, A.D.; Sørensen, P.E.; Giannopoulos, G. Real-time impact of power balancing on power system operation with large scale integration of wind power. J. Mod. Power Syst. Clean Energy 2017, 5, 202–210. [Google Scholar] [CrossRef]

- Aziz, A.; Shafiullah, G.; Stojcevski, A.; Mto, A. Participation of DFIG based wind energy system in load frequency control of interconnected multigeneration power system. In Proceedings of the IEEE 2014 Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 28 September–1 October 2014; pp. 1–6. [Google Scholar]

- Basit, A.; Hansen, A.D.; Altin, M.; Sørensen, P.E.; Gamst, M. Compensating active power imbalances in power system with large-scale wind power penetration. J. Mod. Power Syst. Clean Energy 2016, 4, 229–237. [Google Scholar] [CrossRef]

- Basit, A.; Hansen, A.D.; Altin, M.; Sørensen, P.E.; Gamst, M. Wind power integration into the automatic generation control of power systems with large-scale wind power. J. Eng. 2014, 2014, 538–545. [Google Scholar] [CrossRef] [Green Version]

- Basit, A.; Hansen, A.D.; Altin, M.; Sørensen, P. Analysis of Highly Wind Power Integrated Power System model performance during Critical Weather conditions. In Proceedings of the Wind Integration Workshop (WIW14), Berlin, Germany, 11–13 November 2014. [Google Scholar]

- Nikoobakht, A.; Aghaei, J. IGDT-based robust optimal utilisation of wind power generation using coordinated flexibility resources. IET Renew. Power Gener. 2016, 11, 264–277. [Google Scholar] [CrossRef]

- García-González, J.; Contreras, A.; Formozo, C.; Vallés, M.; Rivero, E.; Lobato, E.; Ramos, A.; Frías, P.; Egido, I.; Sánchez, P.; et al. Economic Impact Analysis of the Demonstrations in Task-Forces TF1 and TF3-Deliverable D15. 1: WP15. Economic Impacts of the Demonstrations, Barriers towards Scaling Up and Solutions; DTU Lyngby: Lyngby, Denmark, 2014. [Google Scholar]

- Aziz, A.; Oo, A.T.; Stojcevski, A. Analysis of frequency sensitive wind plant penetration effect on load frequency control of hybrid power system. Int. J. Electr. Power Energy Syst. 2018, 99, 603–617. [Google Scholar] [CrossRef]

- Lu, L.; Tu, J.; Chau, C.K.; Chen, M.; Lin, X. Online Energy Generation Scheduling for Microgrids with Intermittent Energy Sources and Co-Generation; ACM: New York, NY, USA, 2013; Volume 41. [Google Scholar]

- Narayanaswamy, B.; Garg, V.K.; Jayram, T. Online optimization for the smart (micro) grid. In Proceedings of the 3rd International Conference on Future Energy Systems: Where Energy, Computing and Communication Meet, Madrid, Spain, 9–11 May 2012; p. 19. [Google Scholar]

- Chang, T.H.; Alizadeh, M.; Scaglione, A. Real-time power balancing via decentralized coordinated home energy scheduling. IEEE Trans. Smart Grid 2013, 4, 1490–1504. [Google Scholar] [CrossRef]

- Sun, S.; Dong, M.; Liang, B. Real-time welfare-maximizing regulation allocation in dynamic aggregator-EVs system. IEEE Trans. Smart Grid 2014, 5, 1397–1409. [Google Scholar] [CrossRef]

- Sun, S.; Dong, M.; Liang, B. Real-time power balancing in electric grids with distributed storage. IEEE J. Sel. Top. Signal Process. 2014, 8, 1167–1181. [Google Scholar] [CrossRef]

- Huang, Y.; Mao, S.; Nelms, R.M. Adaptive electricity scheduling in microgrids. IEEE Trans. Smart Grid 2014, 5, 270–281. [Google Scholar] [CrossRef]

- Xiang, L.; Ng, D.W.K.; Lee, W.; Schober, R. Optimal storage-aided wind generation integration considering ramping requirements. In Proceedings of the 2013 IEEE International Conference on Smart Grid Communications (SmartGridComm), Vancouver, BC, Canada, 21–24 October 2013; pp. 648–653. [Google Scholar]

- Huang, L.; Walrand, J.; Ramchandran, K. Optimal power procurement and demand response with quality-of-usage guarantees. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–8. [Google Scholar]

- Chen, S.; Shroff, N.B.; Sinha, P. Heterogeneous delay tolerant task scheduling and energy management in the smart grid with renewable energy. IEEE J. Sel. Areas Commun. 2013, 31, 1258–1267. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, M.; Fang, Y.; Khargonekar, P.P. Decentralized coordination of energy utilization for residential households in the smart grid. IEEE Trans. Smart Grid 2013, 4, 1341–1350. [Google Scholar] [CrossRef]

- Sun, S.; Dong, M.; Liang, B. Distributed real-time power balancing in renewable-integrated power grids with storage and flexible loads. IEEE Trans. Smart Grid 2016, 7, 2337–2349. [Google Scholar] [CrossRef]

- Zhang, Y.; Gatsis, N.; Giannakis, G.B. Robust energy management for microgrids with high-penetration renewables. IEEE Trans. Sustain. Energy 2013, 4, 944–953. [Google Scholar] [CrossRef]

- Salinas, S.; Li, M.; Li, P.; Fu, Y. Dynamic energy management for the smart grid with distributed energy resources. IEEE Trans. Smart Grid 2013, 4, 2139–2151. [Google Scholar] [CrossRef]

- Uslu, U.; Zhang, B.; Pillai, J.R.; Chaudhary, S.K.; Bak-Jensen, B.; de Cerio Mendaza, I.D. Participation of flexible loads in load frequency control to support high wind penetration. In Proceedings of the 2016 IEEE Innovative Smart Grid Technologies-Asia (ISGT-Asia), Melbourne, Australia, 28 November–1 December 2016; pp. 442–447. [Google Scholar]

- Pillai, J.R.; Bak-Jensen, B. Integration of vehicle-to-grid in the western Danish power system. IEEE Trans. Sustain. Energy 2011, 2, 12–19. [Google Scholar] [CrossRef]

- Basit, A.; Hansen, A.D.; Sørensen, P. Dynamic model of frequency control in Danish power system with large scale integration of wind power. In Proceedings of the 2013 China Wind Power Conference (CPW’13), Beijing, China, 16–18 October 2013; pp. 16–18. [Google Scholar]

- Hovgaard, T.G.; Larsen, L.F.; Skovrup, M.J.; Jørgensen, J.B. Power consumption in refrigeration systems-modeling for optimization. In Proceedings of the 2011 International Symposium on Advanced Control of Industrial Processes (ADCONIP), Hangzhou, China, 23–27 May 2011; pp. 234–239. [Google Scholar]

- Basit, A.; Hansen, A.; Altin, M.; Sørensen, P. Balancing modern Power System with large scale of wind power. In Proceedings of the China Wind Power (CWP2014), Beijing, China, 22–24 October 2014. [Google Scholar]

- Basit, A.; Altin, M. Wind Power Plant System Services. Ph.D. Thesis, DTU Wind Energy, Roskilde, Denmark, 2014. [Google Scholar]

- Report, I.C. Dynamic models for steam and hydro turbines in power system studies. IEEE Trans. Power Appar. Syst. 1973, PAS-92, 1904–1915. [Google Scholar] [CrossRef]

- CIGRE. Modeling of Gas Turbines and Steam Turbines in Combined Cycle Power Plants; CIGRE Technical Brochure 238; CIGRE: Paris, France, April 2003. [Google Scholar]

- Draft, I.C. Electrical Simulation Models for Wind Power Generation Wind Turbines; IEC Std. Committee Draft (CD) 88/424/CD; IEC: Geneva, Switzerland, 2012. [Google Scholar]

- ENTSOE. Continental Europe Operation Handbook P1 Load-Frequency Control and Performance; ENSTO-E: Brussels, Belgium, 2003. [Google Scholar]

- Rebours, Y.G.; Kirschen, D.S.; Trotignon, M.; Rossignol, S. A survey of frequency and voltage control ancillary services Technical features. IEEE Trans. Power Syst. 2007, 22, 350–357. [Google Scholar] [CrossRef]

- Singh, B.; Singh, S. Wind power interconnection into the power system: A review of grid code requirements. Electr. J. 2009, 22, 54–63. [Google Scholar] [CrossRef]

| Power System Model | Generating Units | System Interconnections | ||||

|---|---|---|---|---|---|---|

| CHP (MW) | DCHP (MW) | WPP (MW) | Sweden (MW) | Great Belt Link (MW) | Germany (MW) | |

| Capacities | 1754 | 220 | 2800 | 1700 | 600 | 600 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basit, A.; Ahmad, T.; Yar Ali, A.; Ullah, K.; Mufti, G.; Hansen, A.D. Flexible Modern Power System: Real-Time Power Balancing through Load and Wind Power. Energies 2019, 12, 1710. https://doi.org/10.3390/en12091710

Basit A, Ahmad T, Yar Ali A, Ullah K, Mufti G, Hansen AD. Flexible Modern Power System: Real-Time Power Balancing through Load and Wind Power. Energies. 2019; 12(9):1710. https://doi.org/10.3390/en12091710

Chicago/Turabian StyleBasit, Abdul, Tanvir Ahmad, Asfand Yar Ali, Kaleem Ullah, Gussan Mufti, and Anca Daniela Hansen. 2019. "Flexible Modern Power System: Real-Time Power Balancing through Load and Wind Power" Energies 12, no. 9: 1710. https://doi.org/10.3390/en12091710

APA StyleBasit, A., Ahmad, T., Yar Ali, A., Ullah, K., Mufti, G., & Hansen, A. D. (2019). Flexible Modern Power System: Real-Time Power Balancing through Load and Wind Power. Energies, 12(9), 1710. https://doi.org/10.3390/en12091710