1. Introduction

With the increasing environmental concerns, solar energy has been widely used because of its inexhaustible and environmentally friendly advantages [

1]. Under complex and changeable climate conditions, operational faults in a photovoltaic (PV) system have always been one of the important factors affecting its power-generation efficiency [

2,

3]. However, faults in the direct current (DC) side of a PV system, such as open-circuit, short-circuit, degradation and shading faults, are often difficult to avoid and can result in system energy loss, PV module lifespan reduction, or even serious safety concerns. Hence, the development of a fault detection method for the PV array faults is particularly significant for improving the energy conversion efficiency of the PV system, increasing the service life of the PV modules, and reducing maintenance cost [

4,

5].

Existing fault-detection methods include those based on thermal infrared detection, time domain reflectometry, artificial intelligence algorithm, mathematical model analysis methods, and so on. The thermal infrared detection method detects and identifies faults by an infrared scanner to measure the surface temperature of the PV modules for abnormal heat caused by faults. Nian et al. [

6] utilizes the principles of the semiconductor’s electroluminescence to design image acquisition devices that can obtain infrared image of PV modules. The devices can detect the faults including black pieces, fragmentation, broken grid and crack for the PV modules. Peizhen and Shicheng [

7] propose a method that can automatically analyze and recognize the working status of the PV arrays based on infrared image analysis. The method can accurately identify the normal, shading and degradation status of the PV modules. However, the thermal infrared detection method mainly focuses on the detection of hot spot faults inside a PV array.

The time domain reflectometry method needs to inject a pulse signal into the series PV modules circuits of a PV array, and then identifies the fault status of the PV array by comparing the input pulse signal with the feedback output signal. Takashima et al. [

8,

9] applies the time domain reflectometry method to detect degradation faults and locate fault positions of the PV module in a PV array by the change of response waveform. However, when utilizing the time domain reflectometry method to detect faults, the PV system must be turned off, which will critically affect the system’s productivity.

In recent years, artificial intelligence algorithms have attracted the attention of scholars. The artificial intelligence algorithms include mainly artificial neural network and machine learning methods to detect PV array faults. Chine et al. [

10] and Mekki et al. [

11] use an artificial neural network method to detect short circuit faults and partial shading faults of a PV array. Dhimish et al. [

12,

13] introduce a method to distinguish short circuit faults and partial shading faults of a PV array based on fuzzy logic. Dhimish et al. [

14] propose a statistical method to detect and locate accurately different faults types including a PV module fault, the PV strings faults, and a faulty maximum power point tracker (MPPT) unit. Harrou et al. [

15] present a statistical monitoring approach to discriminate short-circuit, open-circuit and shading faults of a PV array. However, these algorithms need to consume longer computation time and larger memory size in the process of fault detection.

The mathematical model analysis method compares actually measuring output values with analytically computing output values to detect the fault status of a PV array. There are some mathematical modeling approaches for fault detection. For instance, references [

16,

17,

18] use the one-diode model approaches to detect faults for a PV array. Kang et al. [

19] propose a novel method to diagnose output power lowering in a PV array based on using the Kalman-filter algorithm. But the effectiveness of these mathematical model-based fault detection methods depends heavily on the accuracy of the models. Silvestre et al. [

20] and Yahyaoui and Segatto [

21] present a new procedure for automatic fault detection in grid-connected PV systems based on the evaluation of current and voltage indicators where the computational complexity is reduced through minimizing the number of monitoring sensors. However, this method cannot distinguish between degradation faults and partial shading faults of the PV modules in a PV array.

In the literature, in order to detect the potential faults and fault types of the PV array under various climate conditions, a fault-detection method based on voltage and current observation and evaluation is proposed. This method can not only distinguish the open-circuit, short-circuit, degradation and shading faults in the potential faults of the PV array, but can also recognize the variable shading faults in some special situation. Furthermore, the computational procedures of the adopted strategy have been reduced and the number of monitoring sensors have been minimized. Simulink work has been carried out to show the effectiveness of the proposed method.

The paper is structured as follows.

Section 2 introduces the modeling of the PV module. In

Section 3, a PV array configuration and its fault characteristics analysis are described.

Section 4 completes the design of the fault-detection approach for the PV array in a PV system. The implementation of the fault detection in the PV array is provided with

Section 5. Simulation results are explained in

Section 6. Finally,

Section 7 draws conclusions from the paper and suggests future research directions.

2. Photovoltaic (PV) Module Modeling

Numerous models of a solar cell that predict energy production have been reported in the literature. The single diode model of a solar cell is the most common model used to simulate energy production [

22]. This model is based on simulating the solar cell as a photo-generated current source connected in parallel with a diode. Taking into account the resistance characteristics and loss of solar cell materials, the serial internal resistance of the solar cell consists of recombination of carriers in the junction region of the PN junction, material resistance and contact resistance, and the parallel internal resistance of the solar cell consists of the leakage current at the edge. The equivalent circuit of the single diode model of the solar cell is shown in

Figure 1.

The equation that mathematically describes the current and voltage characteristic of the solar cell is given by [

23]:

where

and

are the output current and voltage of the solar cell, respectively;

is the photocurrent of the solar cell;

is the reverse saturation current of the diode;

is the diode’s ideality factor;

is the cell’s temperature;

is the electron charge (

);

is the Boltzmann constant (

);

and

are the series and parallel internal resistance, respectively.

However, a PV module is generally composed of solar cells connected by series connection. According to Equation (1), the current and voltage characteristic of a PV module can be given as [

23]:

where

and

are the output current and voltage of the PV module,

and

;

are the series connection number of solar cells;

is the photocurrent of the PV module,

;

is the reverse saturation current of the diode,

;

is the thermal voltage,

;

and

are series and parallel equivalent resistance,

and

.

3. PV Array Configuration and Its Fault Characteristics Analysis

In order to reduce hot spot effect effectively, the PV module is composed of solar cells connected by series and a bypass diode connected by parallel under the condition of partial shading [

24]. In this paper, the improved PV modules are connected by series to constitute a PV string, then all the similar PV strings are connected in parallel to form a PV array. The simple configuration structure of the PV array comprised by two parallel connection PV strings is shown in

Figure 2. In

Figure 2, the main function of the series diode (named as blocking diode) in each PV string is to prevent reverse current flowing in the PV string.

Four well-known faults that have occurred in the DC side of PV systems (short circuit, open circuit, partial shading and degradation faults) are studied in reference [

25] and [

26]. An open-circuit fault may occur due to a break in wires between the solar cells by series. An open-circuit fault is shown at point ‘F1’ of the PV array in

Figure 2a. A short-circuit fault is mainly due to bad wiring in a PV string or between PV strings. Additionally, aging, vibration and abrasion of PV modules are also the significant sources of short-circuit faults. ‘F2’ represents the short-circuit fault of the PV array in

Figure 2a. Partial shading is the phenomenon that a PV array receives uneven irradiation and temperature caused by passing clouds, adjacent buildings and towering trees and so on [

27,

28]. A shading fault occurs when the part of the PV array is shaded while the other part is normally exposed to the solar irradiance with resulting output power reduction. A shading fault is indicated at point ‘F3 ’in the PV array in

Figure 2b. A degradation fault appears attributed to the failure of the bond between different layers of the module leading to delamination, some tiny cracks on the solar cell and frequent changes in temperature of the module with increasing internal series resistance. ‘F4’ stands for the degradation fault in the PV array in

Figure 2b.

When different faults emerge in a PV array, the corresponding output characteristics of the PV array are entirely different. The output characteristic curves of the PV array under fault types set in

Figure 2 are shown as

Figure 3. As shown in

Figure 3, when an open circuit fault occurs, the short-circuit current of the PV array decreases significantly; when a short circuit fault appears, the open-circuit voltage of the PV array reduces rapidly; when the PV array is partially shaded, the MPP current of the PV array declines obviously, but the short-circuit current and the open-circuit voltage of the PV array are basically invariant; when a degradation fault emerges, the MPP current and voltage of the PV array are reduced compared with the PV array fault-free status, and it is worth noting that the short-circuit current and the open-circuit voltage of the PV array remain unchanged. According to the above analysis, the output variables of the voltage and current at the MPP, the short-circuit current and the open-circuit voltage of the PV array happen corresponding to changes under different fault conditions. Hence, in order to achieve PV array fault detection, the voltage and current at the MPP, the short-circuit current and the open-circuit voltage of the PV array are selected as fault characteristic quantities in the paper.

5. Application of the Proposed Approach in the PV Array Fault Detection

In this research, the fault detection approach for a PV array is tested in a PV system and its control scheme is shown as

Figure 4. The PV system includes a PV array, a DC/DC converter, a MPPT controller and a load (described in reference [

29]). Application of the proposed method in fault detection for the PV array is implemented in the following process.

Step1 Initialization parameters: the number of the PV strings of the PV array (); the number of the PV modules of a PV string (); The PV modules receiving irradiation (); the receiving maximum irradiation of the PV modules in partial shading conditions (); the PV modules temperature ().

Step2 Calculation of fault characteristic quantities: the open-circuit voltage and the short-circuit current of the PV array (); the output voltage and current at the MPP of the PV array during fault-free condition (); the output voltage and current at the MPP of the PV array under partial shading with receiving the maximum irradiation ().

Step 3 Calculation of fault detection thresholds: first, evaluation the current indicator with an open fault existed in the PV array (), the voltage indicator with a short fault had been present in one of the PV strings (), the current indicator with a partial shading fault provided within the PV array (); Then, according to Equations (13), (16) and (21), calculation fault detection thresholds , and .

Step 4 Evaluation of the real-time voltage and current indicators: first, the PV system performs the MPPT strategy (proposed in [

29]) and extracts the output voltage and current of the PV array (

); Then evaluation the real-time voltage and current indicators (

).

Step 5 Faults detection: according to the fault detection principles defined in

Section 4.2,

will be respectively compared with

,

and

is compared with

at the same time so that this goal can be achieved to detect faults and identify the types of detected faults.

Step 6 Fault alarm: if the mentioned above fault happened in the PV array, the fault alarm will be sent out. Flowchart of the proposed fault detection method is shown in

Figure 5.

6. Results and Discussion

In order to inspect the performance of the proposed method for PV array fault detection, a PV system including a fault detection unit is modelled on the MATLAB/Simulink platform. The configuration structure of the PV array is shown in

Figure 6 and the key parameters of the PV modules comprising the PV array are reported in

Table 1 [

22]. The inputs of the fault detection unit are the real-time output voltage and current values of the PV array, and its outputs include the voltage and current indicators under fault-free conditions, the fault detection thresholds and the real-time voltage and current indicators. Then the voltage and current indicators are compared with the corresponding thresholds to detect PV array faults. The proposed scheme can not only detect the potential faults of the PV array under a test condition (receiving a certain irradiation), but identify the type of detected faults. To assess the strength of the fault detection method in the paper, eight fault types are performed in the PV array and are set as

Figure 6. In the first case, the PV array shown in

Figure 6 is monitored in fault-free fault. In the second case, a PV string of the PV array is opened (seen as F1 in

Figure 6). In the third and fourth cases, it is assumed that the PV array contain the short-circuit faults in a PV string and between the PV strings (seen as F2 and F3 in

Figure 6). In the fifth and sixth cases, degradation faults in a PV string or both two PV strings are considered (seen as F4 and F5 in

Figure 6). In the seventh case, the PV array is exposed to a partial shading condition (seen as F6 in

Figure 6). Under changeable climate conditions, the PV array usually experiences dynamic shading. Hence, the performance of the proposed method is also tested and verified under variable irradiation conditions in the paper.

6.1. Fault-Free Operation

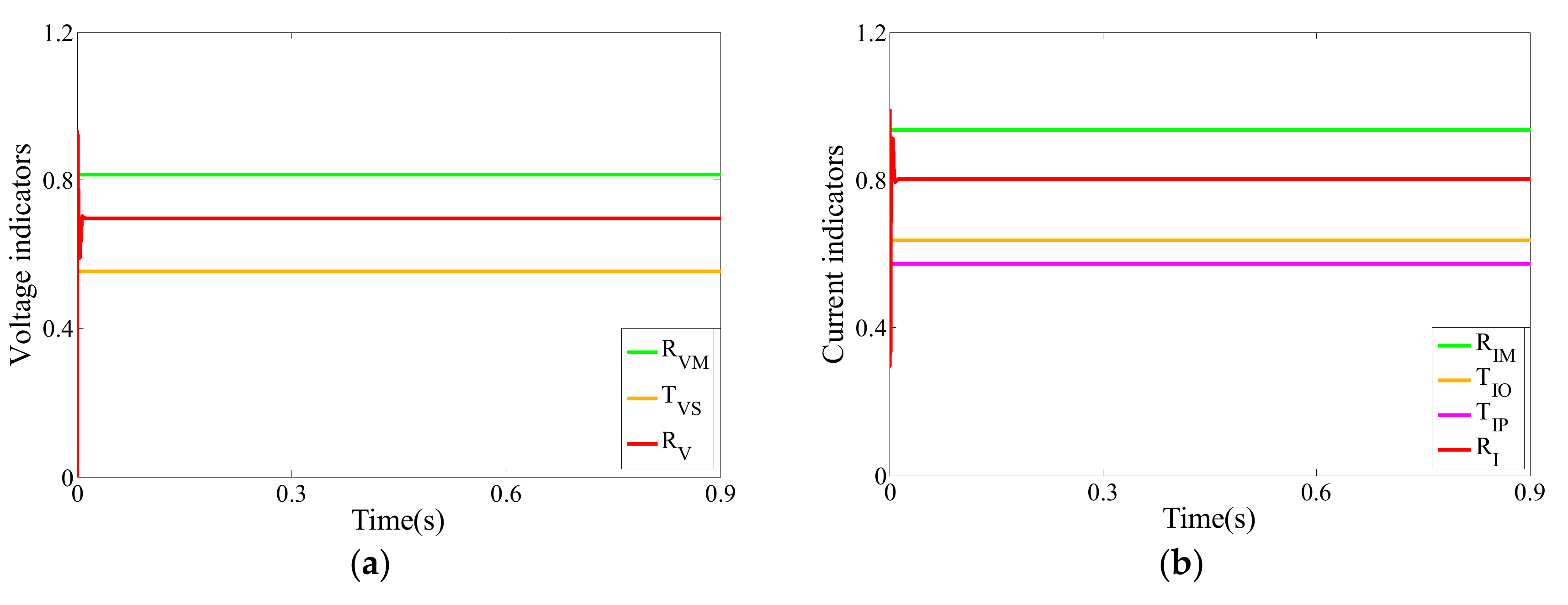

When the PV array of the PV system described above is monitored in fault-free operation, the voltage and current indicators of the PV system are shown as

Figure 7 among the PV modules temperature kept at

and receiving irradiation stabilized in

.

Figure 7a shows the voltage indicator in fault-free operation (

), the threshold of short circuit faults (

) and the real-time voltage indicator of the PV system (

). As can be seen in

Figure 7a,

exceeding

indicates that the PV system is not emerged short-circuit faults. At the same time,

Figure 7b shows the current indicator in fault-free operation (

), the threshold of open circuit faults (

), the threshold of partial shading faults (

) and the real-time current indicator of the PV system (

). As illustrated in

Figure 7b,

surpassing respectively

and

demonstrates that open-circuit and partial shading faults are not present in the PV system. Due to

and

several times being close to

and

, this means that degradation faults have not occurred in the PV system according to

Section 4.2.4 and shows the effectiveness of the fault-detection algorithm under fault-free operation.

6.2. Open-Circuit PV Strings

One of the PV strings is disconnected from the PV array, which makes the PV system provide an open circuit fault (shown as F1 in

Figure 6a). Under the PV array examined at standard test conditions, the voltage and current indicators of the PV system in an open circuit fault are shown as

Figure 8. On the one hand, the current indicator of

is below the open-circuit fault threshold given by

, on the other hand the voltage indicator of

exhibits the same characteristics with fault-free operation (seen in

Figure 8a,b). It is noteworthy to mention that when an open circuit fault emerged in one of the PV strings, the real-time current indicator of the PV system must be lower than the threshold of

and the real-time voltage indicator shows the same properties with fault-free operation.

6.3. Short-Circuit Faults

Two PV modules of a PV string are shorted, which makes the PV system present in short-circuit faults (shown as F2 in

Figure 6a). Under the PV array examined at standard test conditions, the voltage and current indicators of short circuit faults in a PV string are shown as

Figure 9. As the voltage of the short-circuited PV string decreased, the voltages of the fault-free PV strings drop to equal the voltage of the short-circuited PV string. Hence, the voltage indicator of

is far below the short-circuit fault threshold given by

(seen in

Figure 9a). According to the output current-voltage characteristic of the PV array, it can be seen that the output currents of the fault-free PV strings increase to equal the short current of the PV strings so that the value of

is slightly larger than the value of

(seen in

Figure 9b).

The PV system experiencing a short-circuit fault between the PV strings is given as F3 in

Figure 6a. The voltage and current indicators of the PV system are shown in

Figure 10 at standard test conditions. The voltage indicator of

is below the threshold given by

and the current indicator of

is slightly larger than the value of

, which manifests a short-circuit fault been present in the PV array (seen in

Figure 10a,b). The experimental result shows that the short circuit between the PV strings has less effect on the output voltage of the system than two short-circuited PV modules of a PV string.

6.4. Degradation Faults

In the PV system, a degradation fault occurring in a PV module of one of the PV strings or in two PV modules of different PV strings are separately given as F4 and F5 in

Figure 6b. For this purpose, degradation faults have been simulated by inserting a resistance of 5

to the degradation PV modules. Under the PV array examined at standard test conditions, the real-time voltage and current indicators of the PV system in degradation faults are shown as

Figure 11 and

Figure 12. The voltage indicator of

is more than the threshold given by

and is evidently less than the value of

. Similarly, the current indicator of

is more than the value of

and is obviously less than the value of

. Therefore, according to

Section 4.2.4, the proposed fault detection method can commendably distinguish the degradation faults of the PV modules.

6.5. Partial Shading Faults

The part of the PV array is shaded while the other part is entirely exposed to irradiance with

and the partial shading fault is set as F6 in

Figure 6b. Real-time working environment data for the PV system were collected in the day with fastest weather change in the local PV power station at Gansu, China. The number of irradiation hours were 12 with the average irradiation as

in the day. The receiving maximum irradiation of the PV modules under partial shading conditions (

) is taken as

in this paper. Therefore, if a PV module receiving irradiation lower than the value of

, the PV module is considered to existing a partial shading fault. Under the PV array temperature kept at

, the PV array receives simultaneously two different irradiations, which are respectively

and

. In this situation, the voltage and current indicators of the PV system in partial shading faults are shown as

Figure 13. The voltage indicator of

drops compared with the value of

, and the current indicator of

is far less than the partial shading faults threshold of

, which illustrates partial shading faults existed in the PV array.

Since the PV system receiving the irradiation often changes in the actual environment, the effectiveness of the fault detection algorithm under variable irradiation conditions is validated in this paper. Under the PV array temperature kept at

, the PV system only receives one irradiation with

at the beginning. After 1 s, the PV modules of each PV string obtains three different irradiation, which are set as

,

and

respectively. Based on this circumstance, the voltage and current indicators of the PV system in the variable shading condition are shown as

Figure 14. The PV array of the PV system is considered as fault-free operation because

and

are severally close to

and

in 0–1 s. However, the current indicator of

is less than the threshold of

and the voltage indicator of

drops distinctly compared with the value of

in 1–2 s. Hence, a partial shading fault of the PV system is detected in 1–2 s. According to

Figure 13 and

Figure 14, when the PV array of the PV system occurred partial shading faults, the current indicator of

is lower than the threshold of

. According to

Section 4.2.3, the effectiveness of the proposed method to detect partial shading faults is validated.

7. Conclusions

In the work, a fault-detection method based on voltage and current observation and evaluation has been employed to identify faults of the PV array in a PV system. This proposed method can distinguish degradation, static shading and variable shading faults under changeable climatic conditions, which is the most prominent feature of this article. Furthermore, the simple structure and low complexity of the proposed method are the key merits to implement fault detection for the PV array. The performance of the proposed method is validated based on the MATLAB/Simulink platform under all experimental protocols (fault-free operation, an open-circuit string of the PV array, short-circuit faults in a PV string, short-circuit fault between the PV strings, a degradation fault in a PV string, degradation faults in two PV strings, partial shading and variable shading of the PV array). Results show that the proposed method can accurately detect potential faults and fault types for the PV array. Although this proposed method has successfully achieved the expected fault-detection objective, an improved fault-detection method will need to be proposed when photovoltaic arrays receive continuously changing irradiation in a certain period of time. Furthermore, in order to deal with the faults that exist in PV arrays in time, we need to further solve the problem of fault locations.