Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining

Abstract

1. Introduction

2. Experimental and Numerical Simulation Methods

2.1. Engineering Background

2.2. Selection of Mining and Backfilling Methods

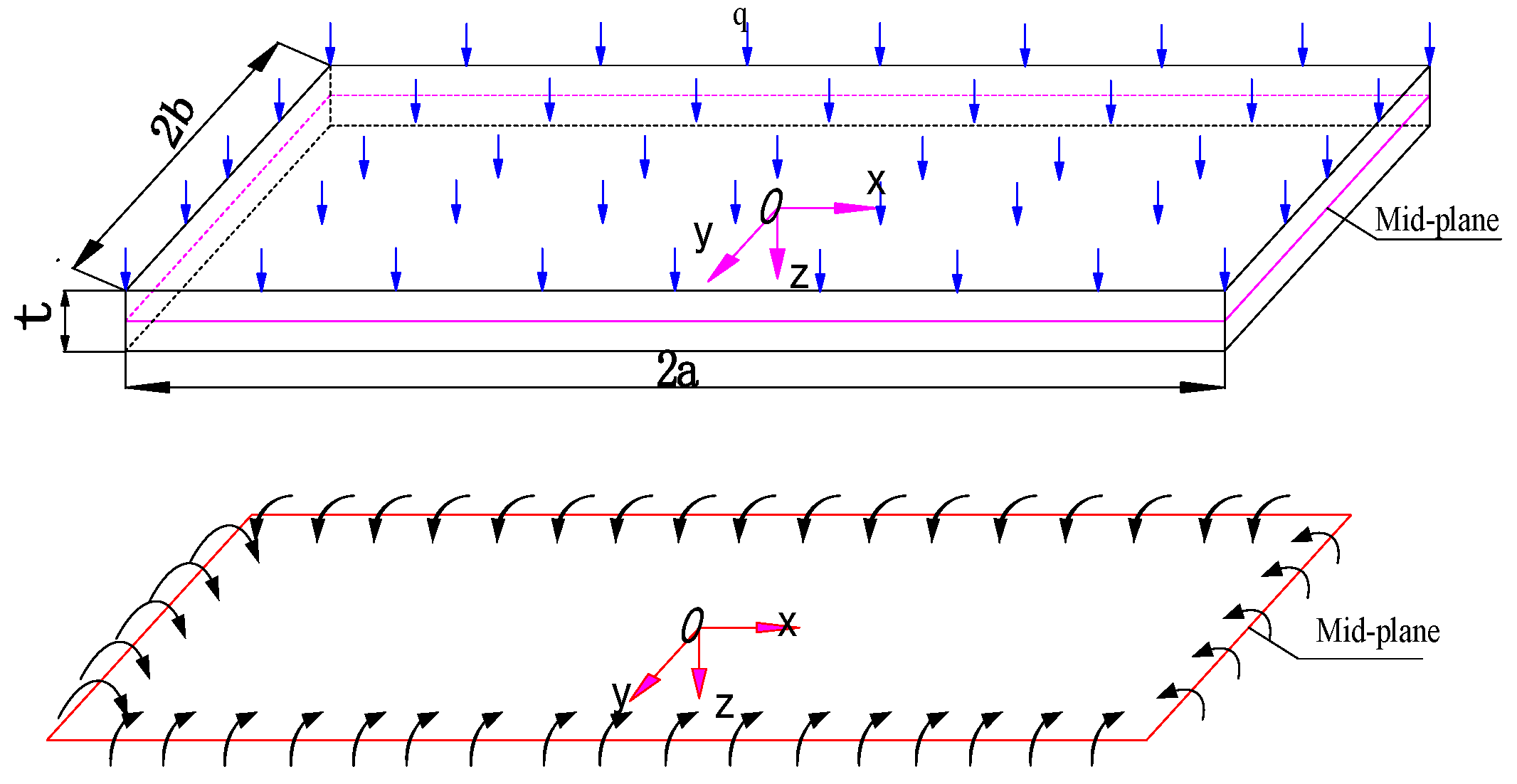

2.3. Calculation of Strip Mining Parameters

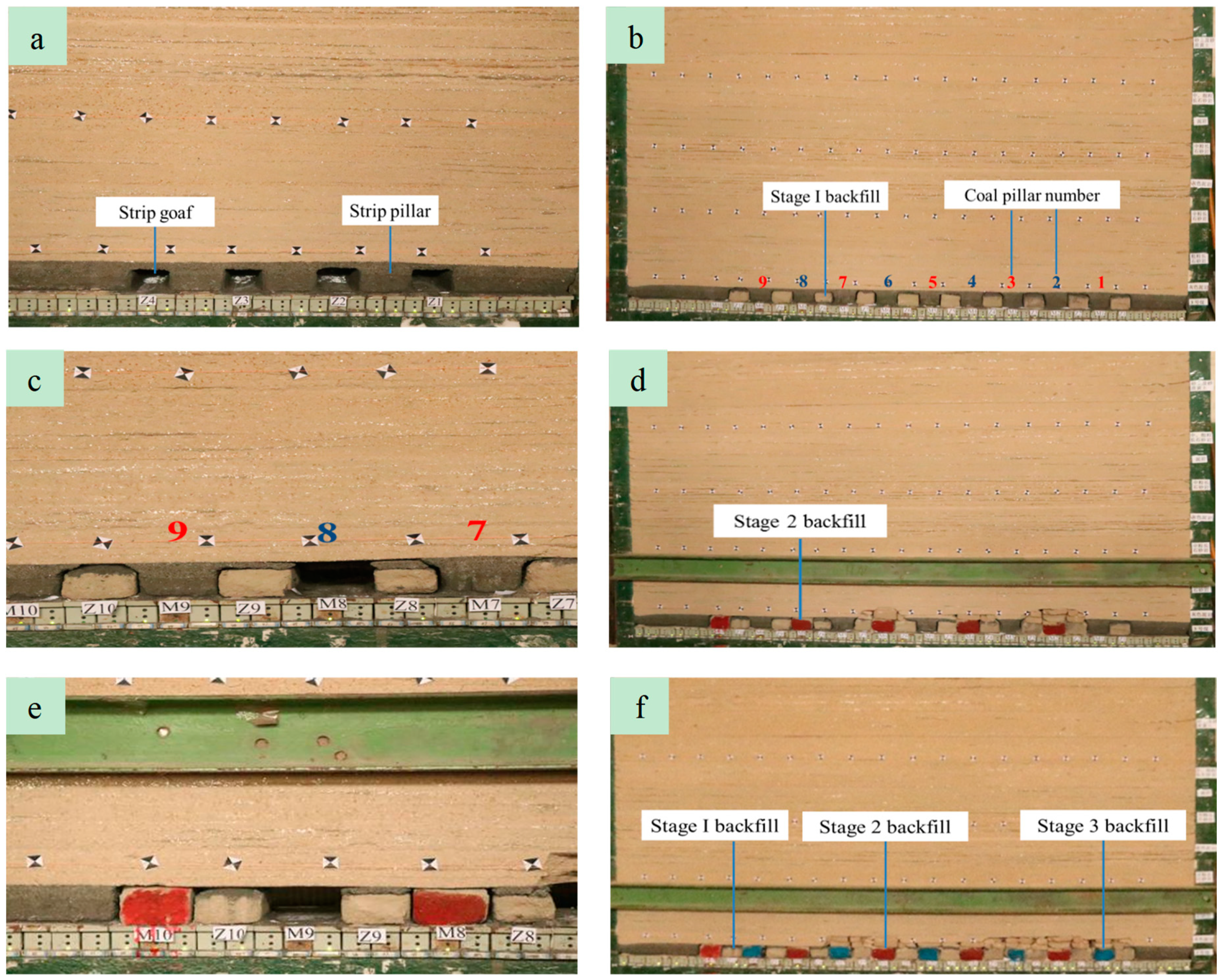

2.4. Construction of a Physical Model

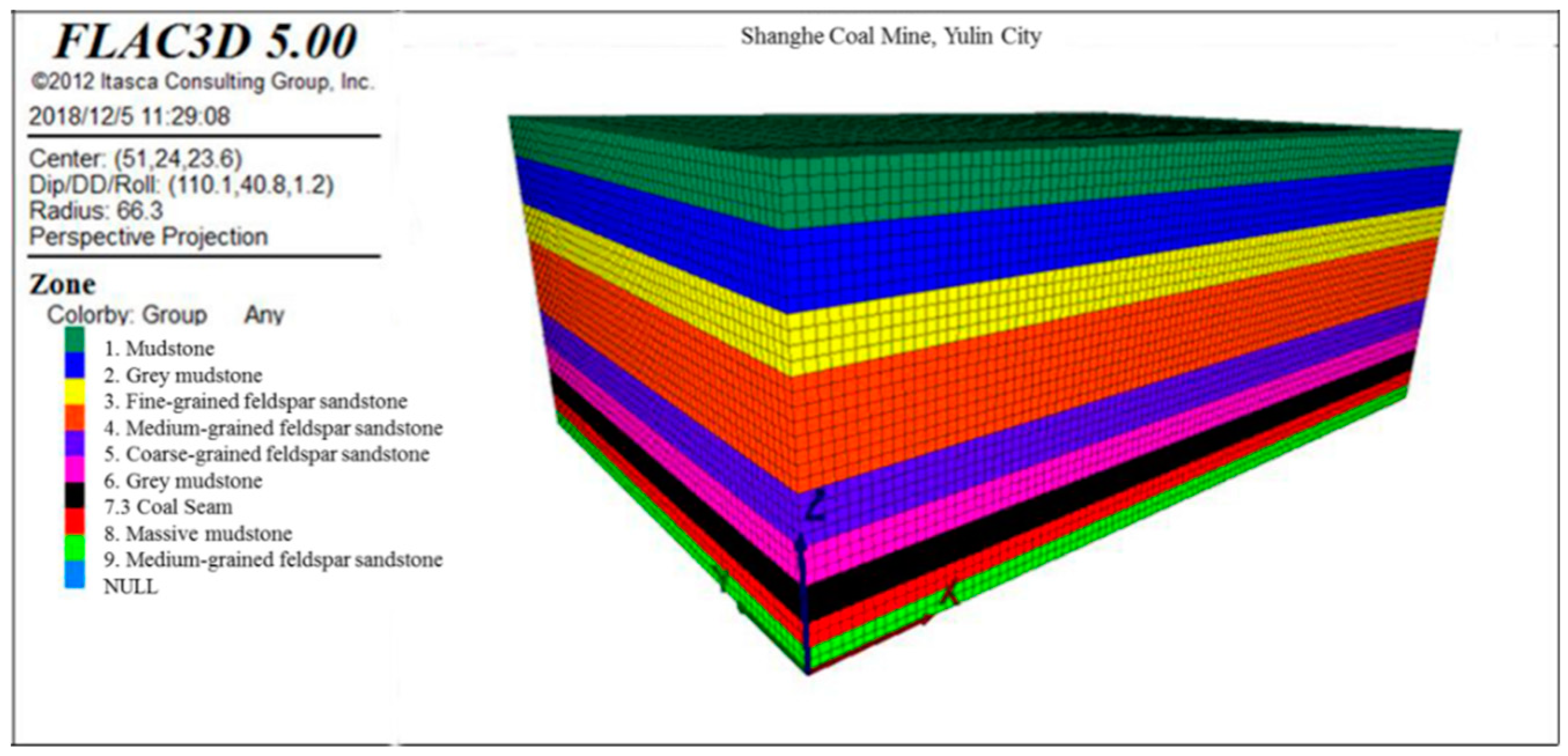

2.5. Numerical Modeling

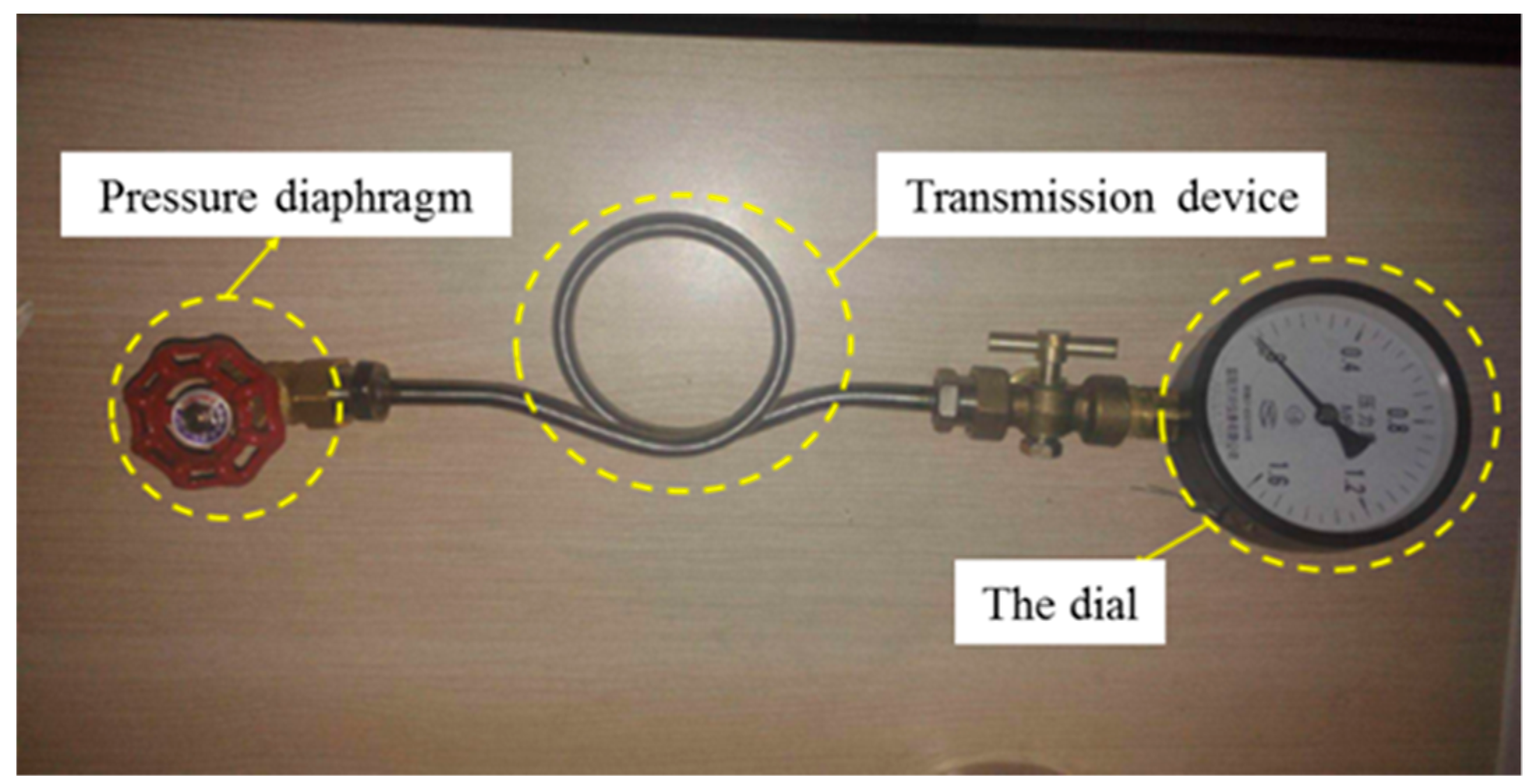

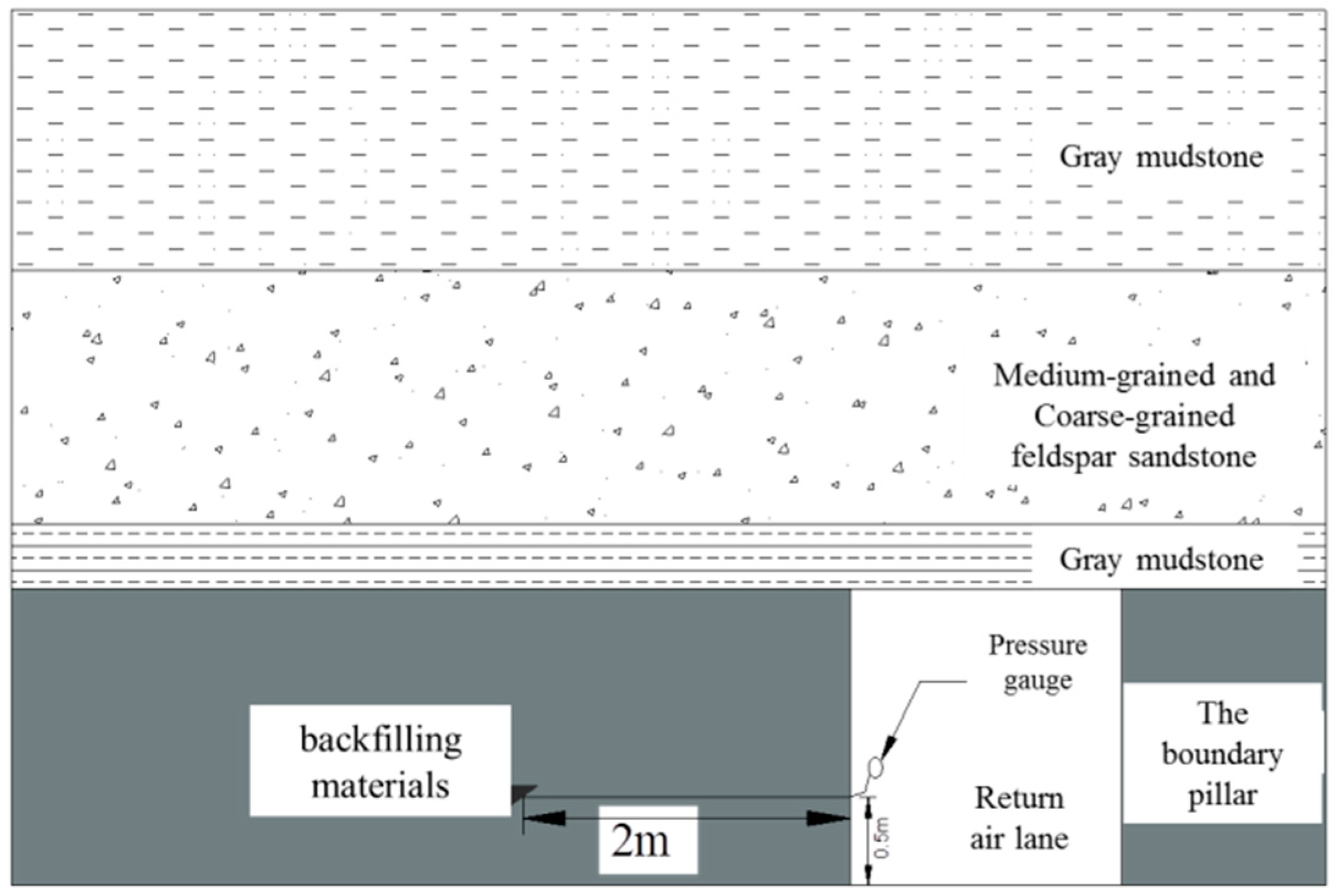

2.6. Field Measurement Methods

3. Results and Discussions

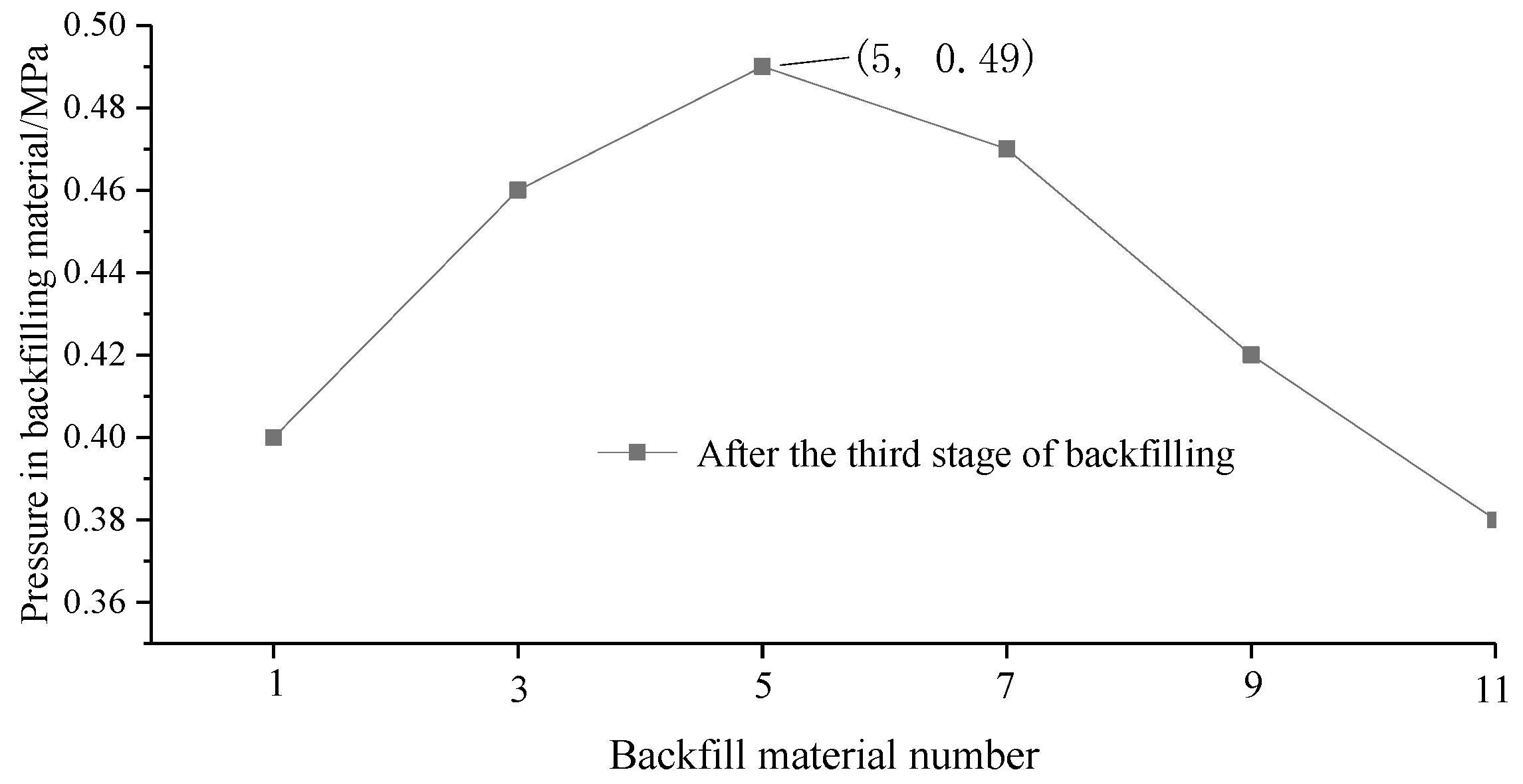

3.1. Results of Experimental Works

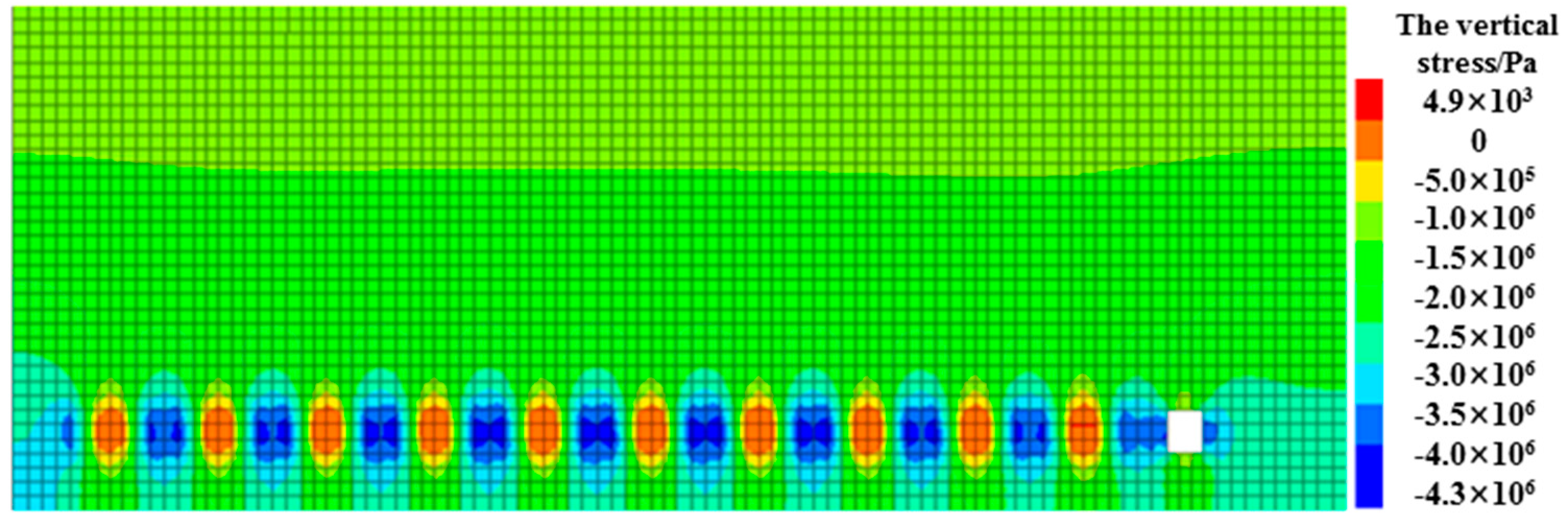

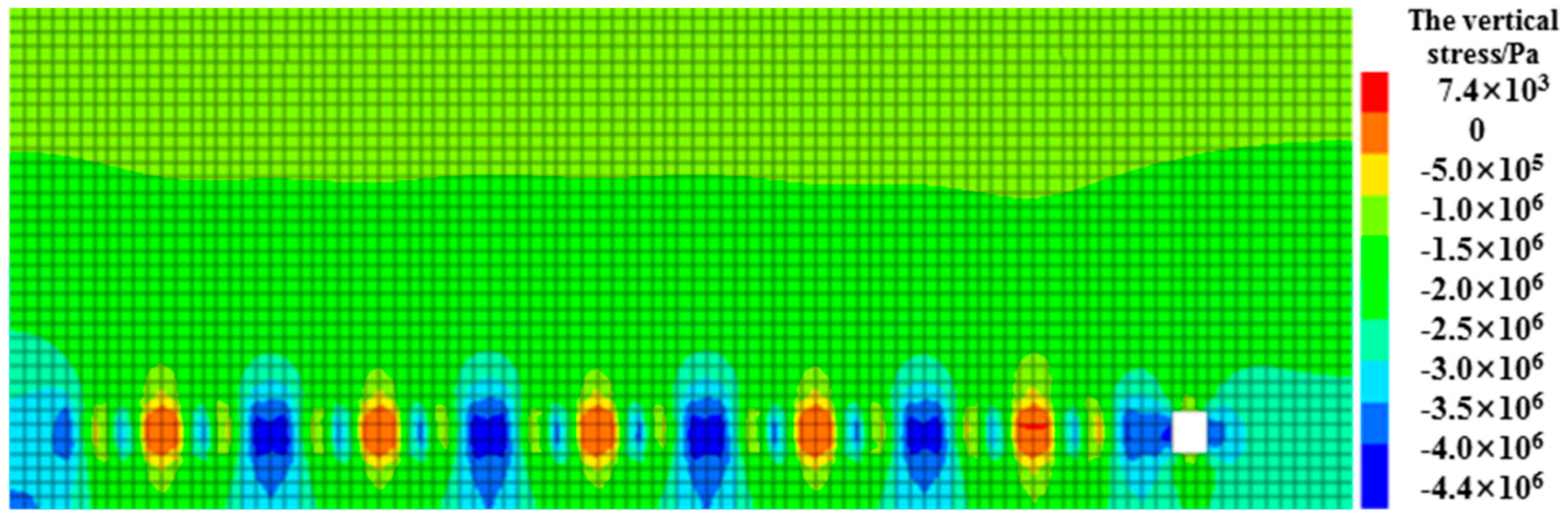

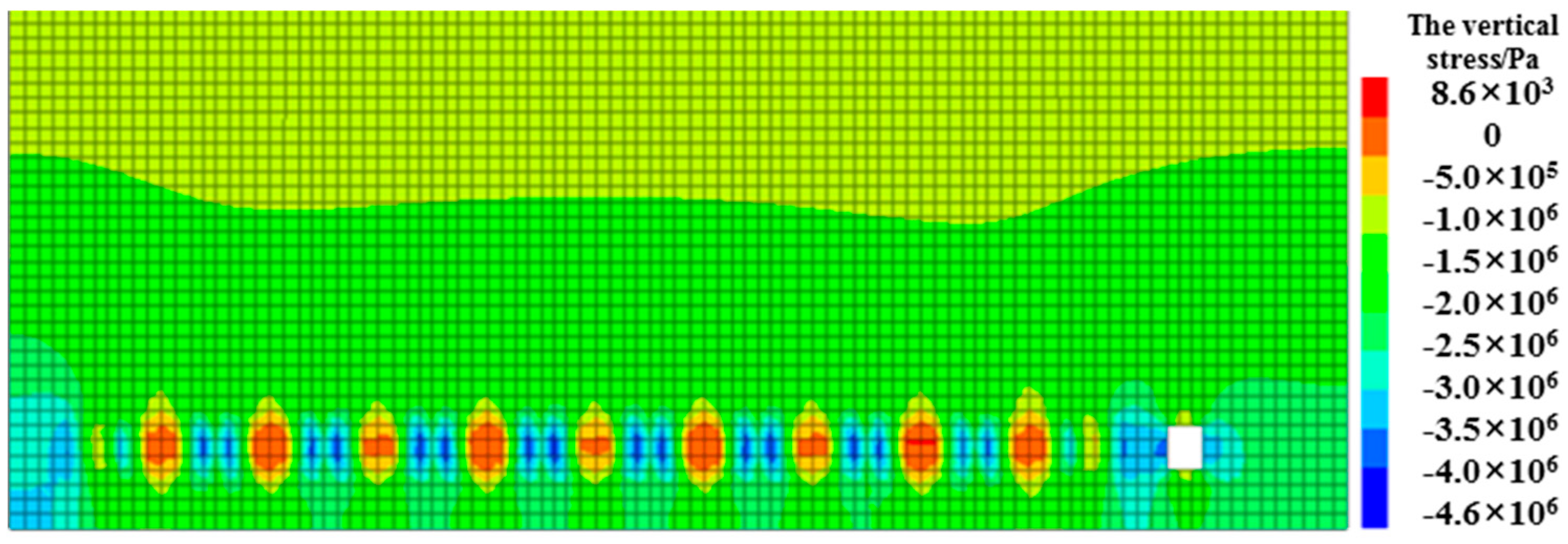

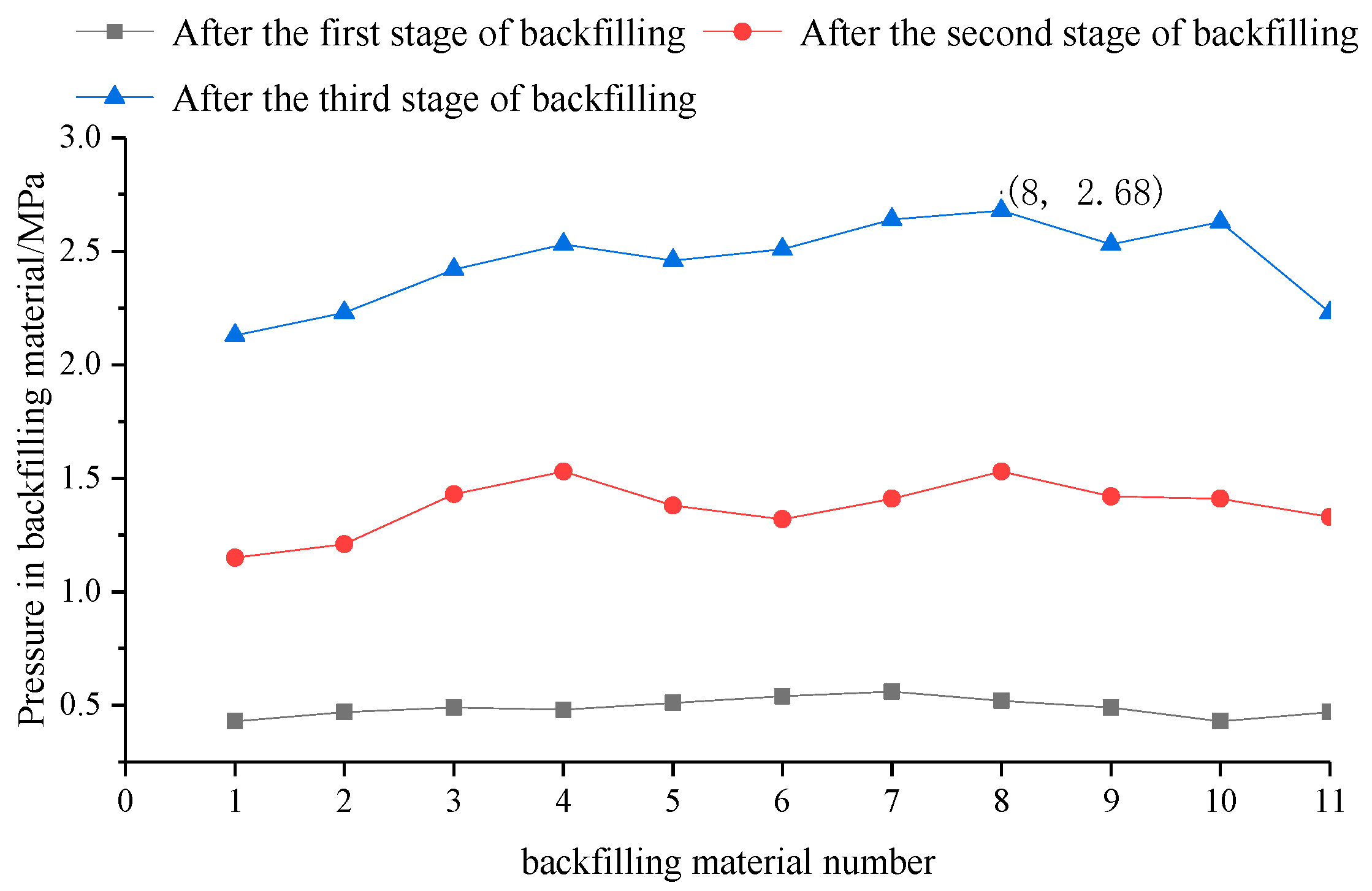

3.2. Numerical Modelling Results and Analysis

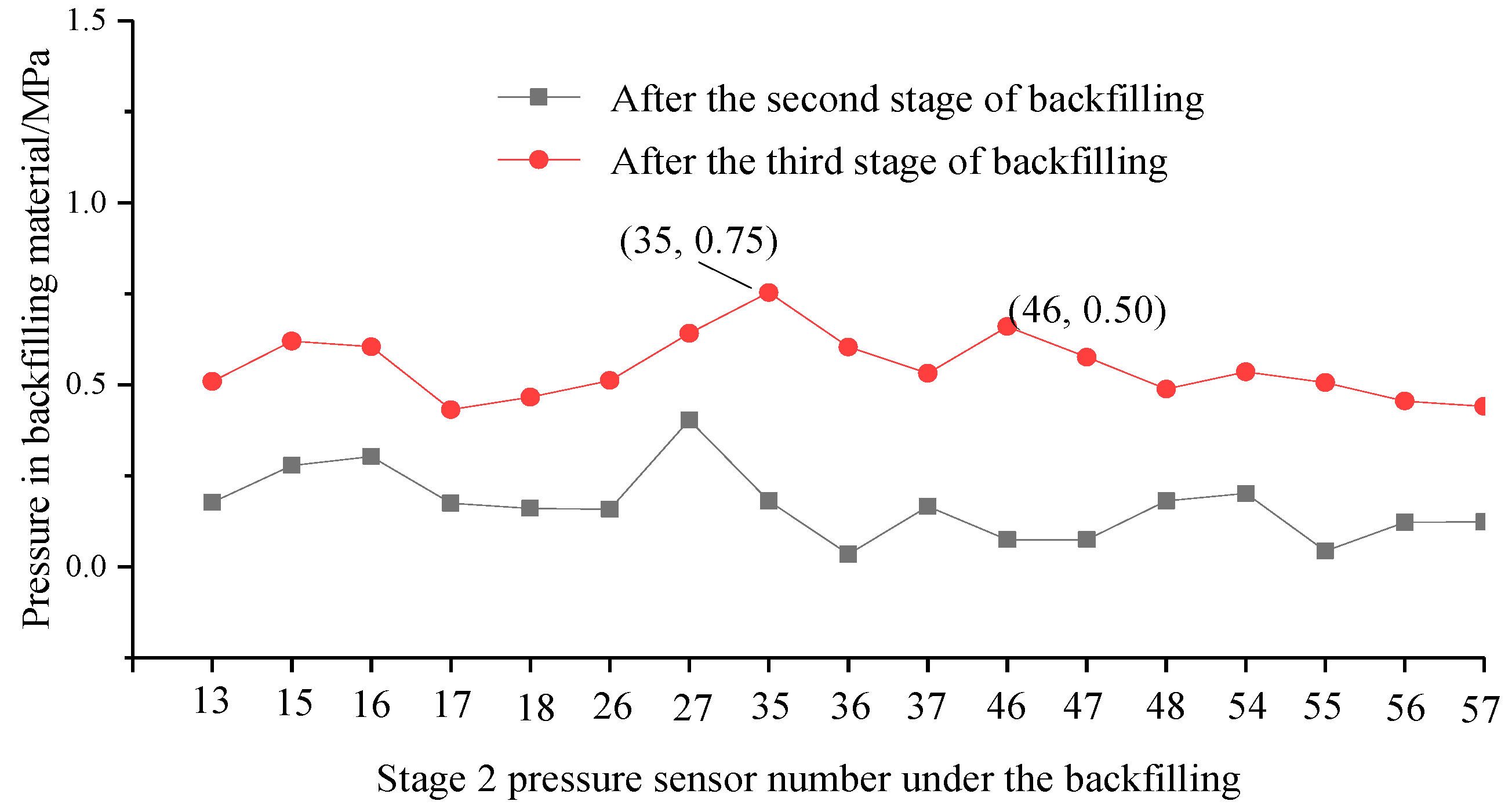

3.3. Analysis of Field Measurement Results in Field Backfill Materials

3.4. Comparison of Experimental Results with Numerical Simulation Results and Field Measurement Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, X.Z. Study on the characteristics of strata behavior in shallow seam longwall mining under the room-and-pillar mining goaf. J. China Coal Soc. 2012, 37, 898–902. [Google Scholar]

- Zhu, W.B.; Xu, J.L.; Chen, L.; Li, Z.; Liu, W.T. Mechanism of disaster induced by dynamic instability of coal pillar group in room-and-pillar mining of shallow and close coal seams. J. China Coal Soc. 2019, 44, 358–366. [Google Scholar]

- Zhu, W.B.; Xu, J.M.; Xu, J.L.; Chen, D.Y.; Shi, J.X. Pier-column backfill mining technology for controlling surface subsidence. Int. J. Rock Min. 2017, 96, 58–65. [Google Scholar] [CrossRef]

- Guan, Y.W.; Wei, Y.Q.; Yang, Z.J.; Li, Z.J.; Jun, W. Failure mechanism of the key strata-pillar system in room and pillar goaf based ona numerieal simulation. Chin. J. Geol. 2017, 28, 59–63. [Google Scholar]

- Jan, S.; Petr, K.; Milan, S. Seismological Activity During Room and Pillar Hard Coal Extraction at Great Depth. Procedia Eng. 2017, 191, 67–73. [Google Scholar]

- Fan, L.M.; Ma, X.D.; Ji, R.J. Progress in engineering practice of water-preserved coal mining in western eco-environment frangible area. J. China Coal Soc. 2015, 40, 1711–1717. [Google Scholar]

- Bai, E.H.; Guo, W.B.; Tan, Y.; Yang, D.M. Green coordinated mining technology of strip mining roadway backfilling method. J. China Coal Soc. 2018, 43, 21–27. [Google Scholar]

- Guo, G.L.; Feng, W.K.; Zha, J.F.; Liu, Y.X.; Wang, Q. Subsidence control and farmland conservation by solid backfilling mining technology. Trans. Nonferr. Metals Soc. 2011, 21, s665–s669. [Google Scholar] [CrossRef]

- Huang, Q.X.; He, Y.P.; Cao, J. Experimental Investigation on Crack Development Characteristics in Shallow Coal Seam Mining in China. Energies 2019, 12, 1302. [Google Scholar] [CrossRef]

- Sun, X.K.; Zhao, Q.M.; Shi, X.Y. Research and application on the technology of paste backfilling fully mechanized in residual strip pillar. J. Min. Saf. Eng. 2017, 34, 650–654. [Google Scholar]

- Du, X.J.; Feng, G.R.; Zhang, Y.J.; Wang, Z.H.; Guo, Y.X.; Qi, T.Y. Bearing mechanism and stability monitoring of cemented gangue-fly ash backfill column with stirrups in partial backfill engineering. Eng. Struct. 2019, 188, 603–612. [Google Scholar] [CrossRef]

- Liu, J.; Sui, W.; Zhao, Q. Environmentally sustainable mining: A case study of intermittent cut-and-fill mining under sand aquifers. Environ. Earth Sci. 2017, 76, 562. [Google Scholar] [CrossRef]

- Tang, W.J.; Sun, X.K.; Wang, H.; Shi, X.Y.; Li, X.Y.; Li, Y. Study on effect of overlying strata stability during strip coal pillar excavation with paste backfilling. Coal Sci. Technol. 2017, 45, 109–115. [Google Scholar]

- Du, X.J.; Feng, G.R.; Qi, T.Y.; Guo, Y.X.; Zhang, Y.J.; Wang, Z.H. Failure characteristics of large unconfined cemented gangue backfill structure in partial backfill mining. Constr. Build. Mater. 2019, 194, 257–265. [Google Scholar] [CrossRef]

- Mu, W.Q.; Li, L.C.; Guo, Z.P.; Du, Z.W.; Wang, S.X. Novel Segmented Roadside Plugging-Filling Mining Method and Overlying Rock Mechanical Mechanism Analyses. Energies 2019, 12, 2073. [Google Scholar] [CrossRef]

- Cao, W.H.; Wang, X.F.; Li, P.; Zhang, D.S.; Sun, C.D.; Qin, D.D. Wide Strip Backfill Mining for Surface Subsidence Control and Its Application in Critical Mining Conditions of a Coal Mine. Sustainability 2018, 10, 700. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Sun, Q. Theory and technique of greening mining integrating mining, separating and backfilling in deep coal resources. J. China Coal Soc. 2018, 43, 377–389. [Google Scholar]

- Sun, Q.; Zhang, J.X.; Yin, W.; Zhou, N.; Liu, Y. Study of stability of surrounding rock and characteristic of overburden strata movement with longwall roadway backfill coal mining. J. China Coal Soc. 2017, 42, 404–412. [Google Scholar]

- Fan, D.Y.; Liu, X.S.; Tan, Y.L.; Song, S.L.; Gu, Q.H.; Yan, L.; Xu, Q. Roof Cutting Parameters Design for Gob-Side Entry in Deep Coal Mine: A Case Study. Energies 2019, 12, 2032. [Google Scholar] [CrossRef]

- Han, J.H.; Zou, J.Q.; Hu, C.C.; Yang, W.H. Study on Size Design of Shaft Protection Rock/Coal Pillars in Thick Soil and Thin Rock Strata. Energies 2019, 12, 2553. [Google Scholar] [CrossRef]

- Ju, F.; Huang, P.; Guo, S.; Xiao, M.; Lan, L.X. A roof model and its application in solid backfilling mining. Int. J. Min. Sci. Technol. 2017, 27, 139–143. [Google Scholar] [CrossRef]

- Huang, Q.X.; He, Y.P. Research on Overburden Movement Characteristics of Large Mining Height Working Face in Shallow Buried Thin Bedrock. Energies 2019, 12, 4208. [Google Scholar] [CrossRef]

- Zhu, X.J.; Guo, G.L.; Liu, H.; Chen, T.; Yang, X.Y. Experimental research on strata movement characteristics of backfill–strip mining using similar material modeling. Bull. Eng. Geol. Environ. 2019, 78, 2151–2167. [Google Scholar] [CrossRef]

- Kong, P.; Jiang, L.S.; Shu, J.M.; Wang, L. Mining Stress Distribution and Fault-Slip Behavior: A Case Study of Fault-Influenced Longwall Coal Mining. Energies 2019, 12, 2494. [Google Scholar] [CrossRef]

- Zhu, W.B.; Yu, S.C.; Xuan, D.Y.; Shan, Z.J.; Xu, J.L. Experimental study on excavating strip coal pillars using caving zone backfill technology. Arab. J. Geosci. 2018, 11, 554. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Zhang, W.Q. Practice and technique of green mining with integration of mining, dressing, backfilling and X in coal resources. J. China Coal Soc. 2019, 44, 64–73. [Google Scholar]

- Chang, Q.L.; Zhou, H.Q.; Bai, J.B.; Duan, C.R.; Li, Y.W. Stability Study and Practice of Overlying Strata with Paste Backfilling. J. Min. Saf. Eng. 2011, 28, 279–282. [Google Scholar]

- Kostecki, T.; Spearing, A.J.S. Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Xu, J.L. Strata control and scientific coal mining—A celebration of the academic thoughts and achievements of Academician Ming gao Qian. J. Min. Saf. Eng. 2019, 36, 1–6. [Google Scholar]

- Zhang, J.X.; Li, M.; Abbas, T.; Zhang, W.Q.; Wu, Z.Y.; Song, W.J. Properties and application of backfill materials in coal mines in China. Minerals 2019, 9, 53. [Google Scholar] [CrossRef]

- Khaldoun, A.; Ouadif, L.; Baba, K.; Bahi, L. Valorization of mining waste and tailings through paste backfilling solution, Imiter operation, Morocco. Int. J. Min. Sci. Technol. 2016, 26, 146–151. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Ju, F.; Zhou, N.; Zhang, Q. Laws and mechanism of strata behaviors in backfill mining. J. Min. Saf. Eng. 2017, 34, 310–316. [Google Scholar]

- Xiapeng, P.; Fall, M.; Haruna, S. Sulphate induced changes of rheological properties of cemented paste backfill. Miner. Eng. 2019, 141, 105849. [Google Scholar] [CrossRef]

- Jiang, F.X.; Weng, J.L.; Bai, W.S.; Wang, G.L.; Li, M. Rock burst risk in surrounding abscission layer of overlying high key strata in deep strip mining mines. J. China Univ. Min. Technol. 2018, 47, 40–47. [Google Scholar]

- Yu, Y.; Deng, K.Z.; Chen, S.E. Mine Size Effects on Coal Pillar Stress and Their Application for Partial Extraction. Sustainability 2018, 10, 792. [Google Scholar] [CrossRef]

- Sada, H.; Mamadou, F. Time- and temperature-dependent rheological properties of cemented paste backfill that contains super plasticizer. Powder Technol. 2019, 360, 731–740. [Google Scholar]

- Yin, Y.C.; Zhao, T.B.; Zhang, Y.B.; Tan, Y.L.; Qiu, Y.; Taheri, A.; Jing, Y. An Innovative Method for Placement of Gangue Backfilling Material in Steep Underground Coal Mines. Minerals 2019, 9, 107. [Google Scholar] [CrossRef]

- Chen, S.J.; Du, Z.W.; Zhang, Z.; Zhang, H.W.; Xia, Z.G.; Feng, F. Effects of chloride on the early mechanical properties and microstructure of gangue-cemented paste backfill. Constr. Build. Mater. 2020, 235, 117504. [Google Scholar] [CrossRef]

- Huang, Y.C.; Wu, Y.; Chang, J. Application and Technology of Coal Mining with Paste like Roadway Backfill. Coal Sci. Technol. 2014, 342, 253–2336. [Google Scholar]

- Li, J.M.; Huang, Y.L.; Chen, Z.W.; Zhang, J.X.; Jiang, H.Q.; Zhang, Y.C. Characterizations of macroscopic deformation and particle crushing of crushed gangue particle material under cyclic loading: In solid backfilling coal mining. Powder Technol. 2019, 343, 159–169. [Google Scholar] [CrossRef]

- Liu, K.; Zhou, H.Q.; Zheng, L.J.; Li, L. Strip Mining Technology with Paste Backfilling. Coal Sci. Technol. 2010, 38, 10–14. [Google Scholar]

- Wang, F.; Jiang, B.Y.; Chen, S.J.; Ren, M.Z. Surface collapse control under thick unconsolidated layers by backfilling strip mining in coal mines. Int. J. Rock Mech. Min. 2019, 113, 268–277. [Google Scholar] [CrossRef]

- Xu, Z.L. A Concise Course on Elasticity; Higher Education Press: Beijing, China, 2013; pp. 197–198. [Google Scholar]

- Shao, X.P. Basic Research on Control of Surrounding Rock in Big Section Safety Mining in Steep Seams; Xi’an University of Science and Technology: Xi’an, China, 2008; pp. 73–75. [Google Scholar]

- Qian, M.G. Mining Pressure and Strata Control; University of Mining and Technology Press: Xuzhou, China, 2010; pp. 79–80. [Google Scholar]

- Huang, Q.X.; Cao, J. Research on Coal Pillar Malposition Distance Based on Coupling Control of Three-Field in Shallow Buried Closely Spaced Multi-Seam Mining, China. Energies 2019, 12, 462. [Google Scholar] [CrossRef]

| Name | Layer Thickness (m) | Model Layer Thickness (cm) | Match Ratio Number | Consumables (kg) | |||

|---|---|---|---|---|---|---|---|

| Sand | Gypsum | Calcium Carbonate | Coal Ash | ||||

| Sandy loess | 47.81 | 48 | 928 | 5.76 | 0.13 | 0.51 | |

| Mudstone | 10.93 | 11 | 646 | 5.48 | 0.36 | 0.56 | |

| Gray mudstone | 12.99 | 13 | 728 | 5.6 | 0.16 | 0.64 | |

| Fine-grained feldspar sandstone | 7.26 | 7 | 737 | 5.6 | 0.24 | 0.56 | |

| Medium-grained feldspar sandstone | 15.23 | 15 | 746 | 5.6 | 0.32 | 0.48 | |

| Coarse-grained feldspar sandstone | 9.19 | 9 | 846 | 5.69 | 0.28 | 0.43 | |

| Gray mudstone | 4.53 | 5 | 728 | 5.6 | 0.16 | 0.64 | |

| 3# Coal | 6.34 | 6 | 21:1:2:21 | 2.99 | 0.14 | 0.28 | 2.99 |

| Name | Layer Thickness (m) | Bulk Density (kN/m3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Tensile Strength (MPa) | Cohesion (MPa) | Angle of Internal Friction (°) |

|---|---|---|---|---|---|---|---|

| Mudstone | 10.93 | 24.9 | 3.68 | 2.1 | 1.2 | 1.5 | 25 |

| Gray mudstone | 12.99 | 25.8 | 3.56 | 2.1 | 1.2 | 1.3 | 35 |

| Fine-grained feldspar sandstone | 7.26 | 25.6 | 8.82 | 4.84 | 2.9 | 3.0 | 31 |

| Medium-grained feldspar sandstone | 15.23 | 24.8 | 8.82 | 4.84 | 2.9 | 3.0 | 31 |

| Coarse-grained feldspar sandstone | 9.19 | 27.8 | 7.87 | 3.83 | 2.5 | 2.8 | 33 |

| Gray mudstone | 4.53 | 26.5 | 3.56 | 2.1 | 0.9 | 1.2 | 27 |

| 3# Coal | 6.34 | 14.3 | 2.35 | 1.47 | 1.1 | 1.7 | 30 |

| Massive mudstone | 4.29 | 26.5 | 3.63 | 2.2 | 1.2 | 1.4 | 31 |

| Medium-grained feldspar sandstone | 7.32 | 23.6 | 8.82 | 4.84 | 2.9 | 3.1 | 29 |

| Backfill materials | 5.5 | 21.0 | 4.3 | 2.3 | 1.2 | 4.2 | 37 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, X.; Li, X.; Wang, L.; Fang, Z.; Zhao, B.; Liu, E.; Tao, Y.; Liu, L. Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining. Energies 2020, 13, 211. https://doi.org/10.3390/en13010211

Shao X, Li X, Wang L, Fang Z, Zhao B, Liu E, Tao Y, Liu L. Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining. Energies. 2020; 13(1):211. https://doi.org/10.3390/en13010211

Chicago/Turabian StyleShao, Xiaoping, Xin Li, Long Wang, Zhiyu Fang, Bingchao Zhao, Ershuai Liu, Yeqing Tao, and Lang Liu. 2020. "Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining" Energies 13, no. 1: 211. https://doi.org/10.3390/en13010211

APA StyleShao, X., Li, X., Wang, L., Fang, Z., Zhao, B., Liu, E., Tao, Y., & Liu, L. (2020). Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining. Energies, 13(1), 211. https://doi.org/10.3390/en13010211