Research on Energy Storage Optimization for Large-Scale PV Power Stations under Given Long-Distance Delivery Mode

Abstract

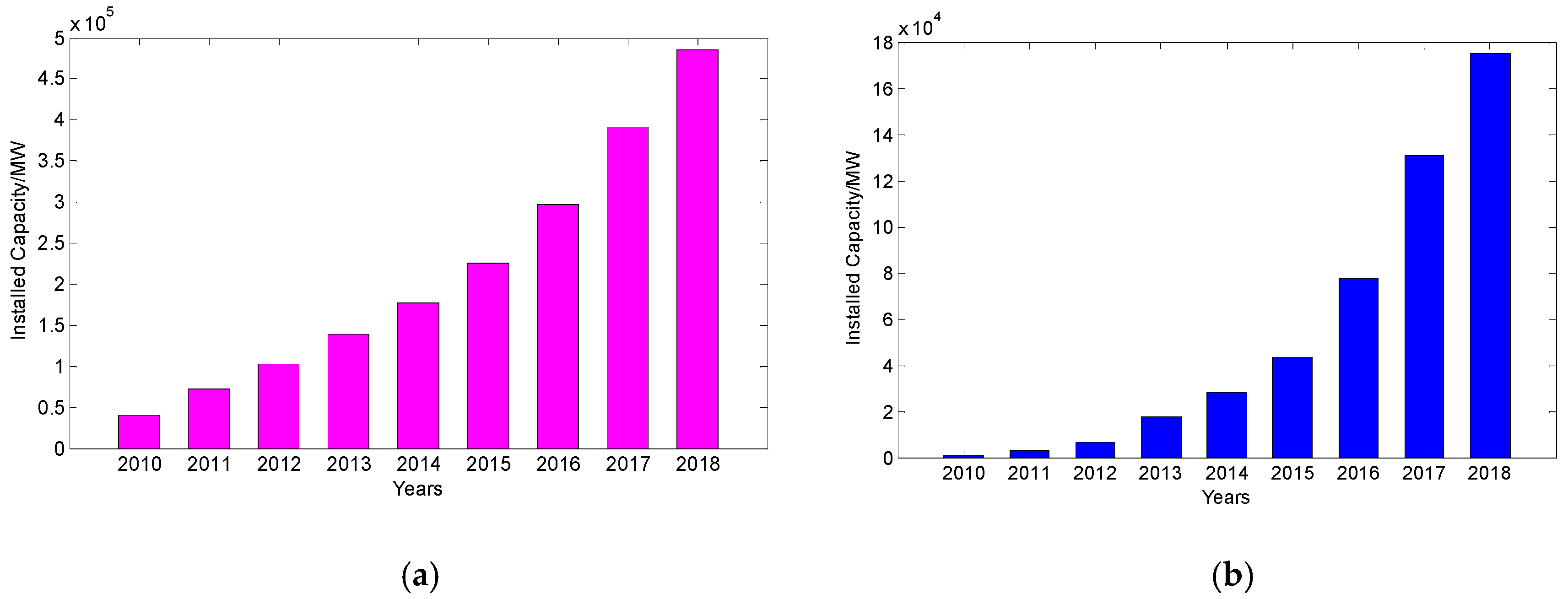

:1. Introduction

2. Methodologies

2.1. Long-Distance Delivery Mode

2.2. Energy Storage Optimization Model

2.2.1. Energy Dispatch Optimization Model

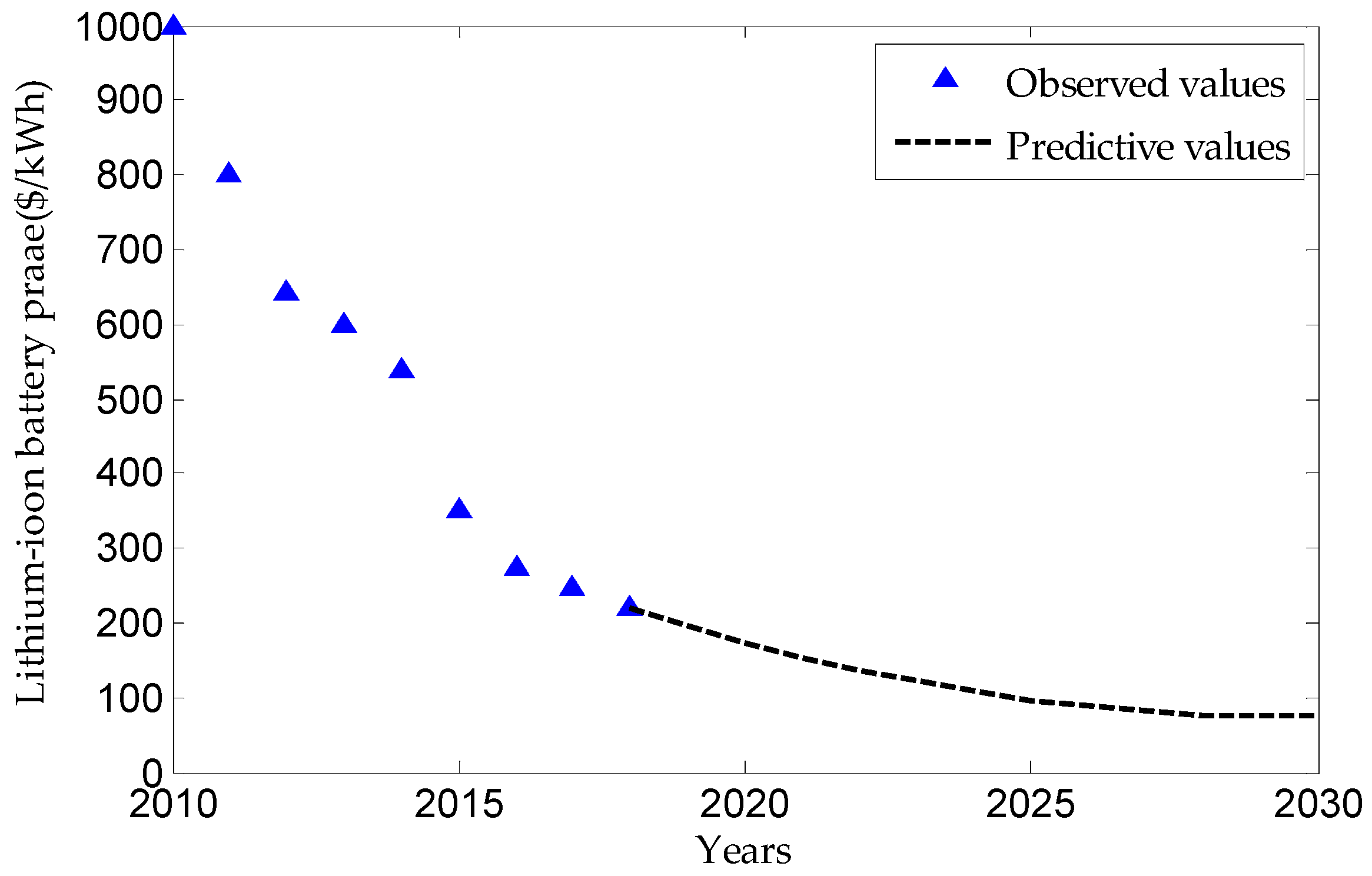

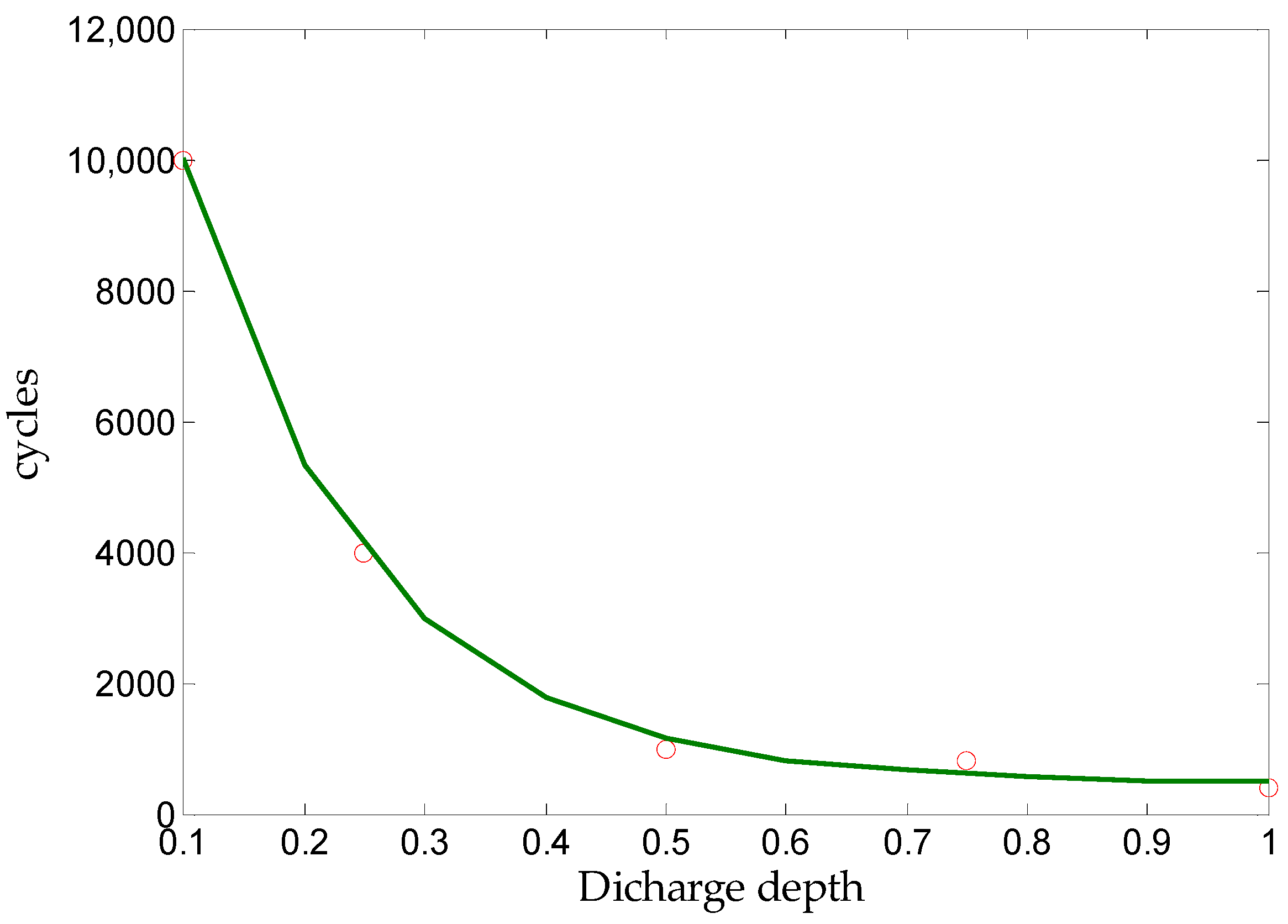

2.2.2. Lithium Battery Performance Model

2.2.3. Economic Evaluation System

3. Results and Discussion

3.1. Energy Dispatch Optimization Model Output

3.2. Capacity-Abandoned Electricity Analysis

3.3. Optimal Energy Storage Capacity

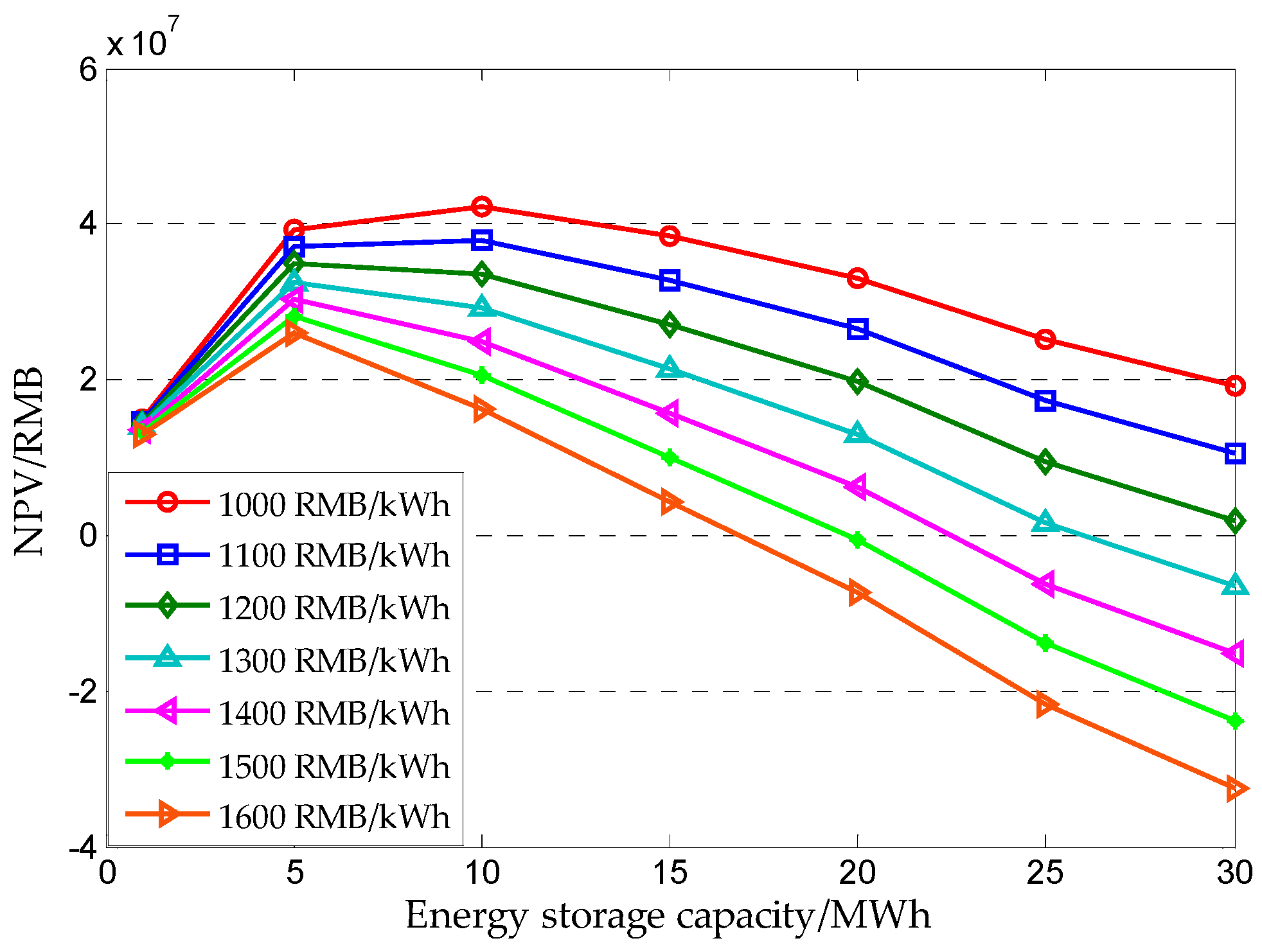

3.4. Battery Attenuation Variation Law and Replacement Cycle

4. Conclusions

- (1)

- Five-segment long-distance delivery mode was proposed to meet the power stability requirements for UHV transmission of large-scale PV power stations.

- (2)

- Energy storage capacity optimization system included energy dispatch optimization model, lithium battery performance model, and economic evaluation system, considering technology, economy, and energy storage battery performance.

- (3)

- The optimal capacity of energy storage was 5 MWh in the case study, according to the values of NPV in the unified life cycle (i.e., five years) with different unit prices and capacities of energy storage battery.

- (4)

- Based on attenuation variation law and annual abandoned electricity rate during the actual operation period, actual replacement cycle of the battery was proposed.

- (5)

- In the case study, the energy storage battery with the optimal capacity (i.e., 5 MWh) was suggested to be replaced once in two years.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| PV | photovoltaic |

| UHV | ultra-high voltage |

| NPV | net present value |

| SOC | state of charge |

| DOD | depth of discharge |

References

- Khatib, T.; Mohamed, A.; Sopian, K. Optimal sizing of hybrid pv/wind systems for malaysia using loss of load probability. Energy Sources Part A 2015, 37, 687–695. [Google Scholar] [CrossRef]

- Dujardin, J.; Kahl, A.; Kruyt, B. Interplay between photovoltaic, wind energy and storage hydropower in a fully renewable Switzerland. Energy 2017, 135, 513–525. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, Y.; Zhou, Y. Roles of wind and solar energy in China’s power sector: Implications of intermittency constraints. Appl. Energy 2018, 213, 22–30. [Google Scholar] [CrossRef]

- Heide, D.; Von Bremen, L.; Greiner, M. Seasonal optimal mix of wind and solar power in a future, highly renewable Europe. Renew. Energy 2010, 35, 2483–2489. [Google Scholar] [CrossRef]

- Heide, D.; Greiner, M.; Von Bremen, L. Reduced storage and balancing needs in a fully renewable European power system with excess wind and solar power generation. Renew. Energy 2011, 36, 2515–2523. [Google Scholar] [CrossRef] [Green Version]

- Ataei, A.; Nedaei, M.; Rashidi, R. Optimum design of an off-grid hybrid renewable energy system for an office building. J. Renew. Sustain. Energy 2015, 7, 053123. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. 2018. Available online: https://www.irena.org/ (accessed on 4 December 2018).

- Sun, H.; Zhi, Q.; Wang, Y. China’s solar photovoltaic industry development: The status quo, problems and approaches. Appl. Energy 2014, 118, 221–230. [Google Scholar] [CrossRef]

- Hua, Y.; Oliphant, M.; Hu, E.J. Development of renewable energy in Australia and China: A comparison of policies and status. Renew. Energy 2016, 85, 1044–1051. [Google Scholar] [CrossRef]

- Liu, L.Q.; Wang, Z.X.; Zhang, H.Q. Solar energy development in China—A review. Renew. Sustain. Energy Rev. 2010, 14, 301–311. [Google Scholar] [CrossRef]

- Zhang, S.F. Analysis of DSPV (distributed solar PV) power policy in China. Energy 2016, 98, 92–100. [Google Scholar] [CrossRef]

- Ge, X.; Jiang, Z.; Li, C. Social and ecological effects of biomass utilization and the willingness to use clean energy in the eastern Qinghai–Tibet plateau. Energy Policy 2012, 51, 828–833. [Google Scholar]

- Zeng, M.; Li, H.; Mingjuan, M. Review on transaction status and relevant policies of southern route in China’s West–East Power Transmission. Renew. Energy 2013, 60, 454–461. [Google Scholar]

- Jamal, T.; Urmee, T.; Calais, M. Technical challenges of PV deployment into remote Australian electricity networks: A review. Renew. Sustain. Energy Rev. 2017, 77, 1309–1325. [Google Scholar] [CrossRef]

- Lin, S.; Li, C.; Xu, F. Risk identification and analysis for new energy power system in China based on D numbers and decision-making trial and evaluation laboratory (DEMATEL). J. Clean. Prod. 2018, 180, 81–96. [Google Scholar] [CrossRef]

- Shu, Y.; Chen, W. Research and application of UHV power transmission in China. High Volt. 2018, 3, 1–13. [Google Scholar] [CrossRef]

- Jurasz, J.; Ciapała, B. Solar–hydro hybrid power station as a way to smooth power output and increase water retention. Sol. Energy 2018, 173, 675–690. [Google Scholar] [CrossRef]

- Haghi, E.; Farshidian, B.; Saboohi, Y. Developing a model for optimal sizing of a small hydropower/PV hybrid system for electrification. In Proceedings of the IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 14–17 August 2017; pp. 170–176. [Google Scholar]

- Zhang, Y.; Ma, C.; Lian, J. Optimal photovoltaic capacity of large-scale hydrophotovoltaic complementary systems considering electricity delivery demand and reservoir characteristics. Energy Convers. Manag. 2019, 195, 597–608. [Google Scholar] [CrossRef]

- Lata-García, J.; Reyes-Lopez, C.; Jurado, F. Sizing optimization of a small hydro/photovoltaic hybrid system for electricity generation in Santay Island, Ecuador by two methods. In Proceedings of the 2017 CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), Pucon, Chile, 18–20 October 2017; pp. 1–6. [Google Scholar]

- Apostolopoulou, D.; Mcculloch, M. Optimal Short-term Operation of a Cascaded Hydro-Solar Hybrid System: A Case Study in Kenya. IEEE Trans. Sustain. Energy 2018, 10, 1878–1889. [Google Scholar] [CrossRef]

- Overland, I.; Reischl, G. A place in the Sun? IRENA’s position in the global energy governance landscape. Int. Environ. Agreem. 2018, 18, 335–350. [Google Scholar] [CrossRef] [Green Version]

- Wei, M.; Smith, S.J.; Sohn, M.D. Experience curve development and cost reduction disaggregation for fuel cell markets in Japan and the US. Appl. Energy 2017, 191, 346–357. [Google Scholar] [CrossRef] [Green Version]

- Agudosi, E.S.; Abdullah, E.C.; Numan, A. A Review of the Graphene Synthesis Routes and its Applications in Electrochemical Energy Storage. Crit. Rev. Solid State Mater. Sci. 2019, 1–39. [Google Scholar] [CrossRef]

- Bloomberg New Energy Finance. New Energy Outlook 2018; Bloomberg New Energy Finance (BNEF): New York, NY, USA, 2018. [Google Scholar]

- Zhang, D.; Guo, J.; Li, J. Coordinated control strategy of hybrid energy storage to improve accommodating ability of PV. J. Eng. 2017, 2017, 1555–1559. [Google Scholar] [CrossRef]

- Ma, W.; Wang, W.; Wu, X. Control Strategy of a Hybrid Energy Storage System to Smooth PV Power Fluctuations Considering PV Output Power Curtailment. Sustainability 2019, 11, 1324. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, H.; Beguenane, R.; Merabet, A. Technical and financial benefits of electrical energy storage. In Proceedings of the 2012 IEEE Electrical Power and Energy Conference, London, ON, Canada, 10–12 October 2012; pp. 86–91. [Google Scholar]

- Lehmann, C.; Weeber, M.; Böhner, J. Techno-economical analysis of photovoltaic-battery storage systems for peak-shaving applications and self-consumption optimization in existing production plants. Procedia CIRP 2016, 48, 313–318. [Google Scholar] [CrossRef] [Green Version]

- Jones, R.; Haley, B.; Kwok, G. Electrification and the Future of Electricity Markets: Transitioning to a Low-Carbon Energy System. IEEE Power Energy Mag. 2018, 16, 79–89. [Google Scholar] [CrossRef]

- Akbari, H.; Browne, M.C.; Ortega, A. Efficient energy storage technologies for photovoltaic systems. Sol. Energy 2018, 192, 144–168. [Google Scholar] [CrossRef]

- Lucas, A.; Chondrogiannis, S. Smart grid energy storage controller for frequency regulation and peak shaving, using a vanadium redox flow battery. Int. J. Electr. Power Energy Syst. 2016, 80, 26–36. [Google Scholar] [CrossRef]

- Rodrigues, E.M.G.; Godina, R.; Santos, S.F. Energy storage systems supporting increased penetration of renewables in islanded systems. Energy 2014, 75, 265–280. [Google Scholar] [CrossRef]

- Hajiaghasi, S.; Salemnia, A.; Hamzeh, M. Hybrid energy storage system for microgrids applications: A review. J. Energy Storage 2019, 21, 543–570. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, H.; Yang, Y. Improved coordinated control strategy of hybrid energy storages in PV Power Smoothing. Energy Procedia 2018, 145, 151–156. [Google Scholar] [CrossRef]

- Aktas, A.; Erhan, K.; Ozdemir, S. Experimental investigation of a new smart energy management algorithm for a hybrid energy storage system in smart grid applications. Electr. Power Syst. Res. 2017, 144, 185–196. [Google Scholar] [CrossRef]

- Li, B.; Roche, R.; Paire, D. Sizing of a stand-alone microgrid considering electric power, cooling/heating, hydrogen loads and hydrogen storage degradation. Appl. Energy 2017, 205, 1244–1259. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Dong, S.; Lian, J. Multi-Objective Sizing of Hybrid Energy Storage System for Large-Scale Photovoltaic Power Generation System. Sustainability 2019, 11, 5441. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Xin, J.; Yu, Y. Optimization of energy storage system capacity for wind farms based on cost-benefit analysis. In Proceedings of the 2016 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Xi’an, China, 25–28 October 2016; pp. 1513–1517. [Google Scholar]

- Yu, M.; Huang, W.; Tai, N. Optimal reserve provision regulation for wind farms equipped with energy storage systems. Int. Trans. Electr. Energy Syst. 2019, 29, e2718. [Google Scholar] [CrossRef]

- Khaki, B.; Das, P. Sizing and Placement of Battery Energy Storage Systems and Wind Turbines by Minimizing Costs and System Losses. arXiv 2019, arXiv:1903.12029. [Google Scholar]

- Varshosaz, F.; Moazzami, M.; Fani, B. Day-Ahead Capacity Estimation and Power Management of a Charging Station based on Queuing Theory. IEEE Trans. Ind. Inform. 2019, 15, 5561–5574. [Google Scholar] [CrossRef]

- Muttaqi, K.M.; Islam, M.R.; Sutanto, D. Future Power Distribution Grids: Integration of Renewable Energy, Energy Storage, Electric Vehicles, Superconductor, and Magnetic Bus. IEEE Trans. Appl. Supercond. 2019, 29, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Engels, J.; Claessens, B.; Deconinck, G. Techno-Economic Analysis and Optimal Control of Battery Storage for Frequency Control Services, Applied to the German Market. Appl. Energy 2019, 242, 1036–1049. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Neathery, J.K.; Remias, J.E. Method for Energy Storage to Utilize Intermittent Renewable Energy and Low-Value Electricity for CO2 Capture and Utilization. U.S. Patent No. 9,285,112, 15 March 2016. [Google Scholar]

- Hong, N.N.; Nakanishi, Y. Optimal Scheduling of an Isolated Wind-Diesel-Energy Storage System Considering Fast Frequency Response and Forecast Error. Energies 2019, 12, 843. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, M.A.; Eltamaly, A.M. Modeling of Hybrid Renewable Energy System. Modeling and Simulation of Smart Grid Integrated with Hybrid Renewable Energy Systems; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Ban, M.; Jilai, Y.U.; Shahidehpour, M. Optimal sizing of PV and battery-based energy storage in an off-grid nanogrid supplying batteries to a battery swapping station. J. Mod. Power Syst. Clean Energy 2019, 7, 309–320. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Chen, Y.; Fu, M. Multi-Objective Optimization-Based Real-Time Control Strategy for Battery/Ultracapacitor Hybrid Energy Management Systems. IEEE Access 2019, 7, 11640–11650. [Google Scholar] [CrossRef]

- Peng, K.; Feng, G.; Guan, X. Stochastic predictive control of battery energy storage for wind farm dispatching: Using probabilistic wind power forecasts. Renew. Energy 2015, 80, 286–300. [Google Scholar]

- Zhu, J.; Zhang, Y.; Chen, H.B. A frequency and duration analysis method for probabilistic optimal power flow with wind farms. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 680–693. [Google Scholar] [CrossRef]

- Hoppmann, J.; Volland, J.; Schmidt, T.S. The economic viability of battery storage for residential solar PV systems—A review and a simulation model. Renew. Sustain. Energy Rev. 2014, 39, 1101–1118. [Google Scholar] [CrossRef]

- Beltran, H.; Perez, E.; Aparicio, N. Daily Solar Energy Estimation for Minimizing Energy Storage Requirements in PV Power Plants. IEEE Trans. Sustain. Energy 2013, 4, 474–481. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Jian, L.; Liao, X. Multi-objective hydro-thermal-wind coordination scheduling integrated with large-scale electric vehicles using IMOPSO. Renew. Energy 2018, 128, 91–107. [Google Scholar] [CrossRef]

- De, R.K.; Ganguly, A. Energy, Exergy and Economic Analysis of a Solar Hybrid Power System Integrated Double-Effect Vapor Absorption System-Based Cold Storage. Int. J. Air-Cond. Refrig. 2019, 27, 115–124. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z. China Needs Prompt Construction of a Strong National Power Grid (Excerption). Electricity 2005, 16, 5–8. [Google Scholar]

| Discharge Depth | 0.1 | 0.25 | 0.5 | 0.75 | 1 |

| Cycles | 10000 | 4000 | 1000 | 800 | 400 |

| Typical Days | Sunny Day | Cloudy Day | Rainy Day |

| Daily Abandoned Electricity Rate/% | 16.57 | 37.83 | 29.83 |

| Operation Time | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1st year | 1 | 22.66 | 5 | 13.24 | 10 | 7.81 | 15 | 5.67 |

| 2nd year | 0.50 | 25.79 | 1.30 | 21.41 | 2.67 | 17.31 | 6.05 | 11.69 |

| 3rd year | —— | —— | 0.59 | 25.13 | 0.83 | 23.61 | 1.51 | 20.83 |

| 4th year | —— | —— | —— | —— | 0.37 | 26.62 | 0.68 | 24.30 |

| 5th year | —— | —— | —— | —— | —— | —— | 0.29 | 26.70 |

| Operation Time | /MWh | /% | /MWh | /% | /MWh | /% | ||

| 1st year | 20 | 4.46 | 25 | 3.86 | 30 | 3.42 | ||

| 2nd year | 10.14 | 7.70 | 14.19 | 5.94 | 18.96 | 4.65 | ||

| 3rd year | 2.69 | 17.28 | 5.71 | 12.01 | 9.29 | 8.23 | ||

| 4th year | 0.84 | 23.48 | 1.38 | 21.12 | 2.20 | 18.72 | ||

| 5th year | 0.43 | 26.59 | 0.60 | 25.13 | 0.83 | 23.61 | ||

| 6th year | —— | —— | —— | —— | 0.43 | 26.59 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Lian, C.; Ma, C.; Zhang, Y. Research on Energy Storage Optimization for Large-Scale PV Power Stations under Given Long-Distance Delivery Mode. Energies 2020, 13, 27. https://doi.org/10.3390/en13010027

Yang Y, Lian C, Ma C, Zhang Y. Research on Energy Storage Optimization for Large-Scale PV Power Stations under Given Long-Distance Delivery Mode. Energies. 2020; 13(1):27. https://doi.org/10.3390/en13010027

Chicago/Turabian StyleYang, Yang, Chong Lian, Chao Ma, and Yusheng Zhang. 2020. "Research on Energy Storage Optimization for Large-Scale PV Power Stations under Given Long-Distance Delivery Mode" Energies 13, no. 1: 27. https://doi.org/10.3390/en13010027