Modelling of Passive Heat Removal Systems: A Review with Reference to the Framatome KERENA BWR Reactor: Part I

Abstract

1. Introduction

- Pre-pressurized core flooding tanks

- Elevated tank natural circulation loops

- Elevated gravity drain tanks

- Passively cooled steam generators or natural circulation

- Passive residual heat removal heat exchangers

- Passively cooled core isolation condensers

- Sump natural circulation

- Containment pressure suppression pools

- Containment passive heat removal/pressure suppression systems

- Passive containment spraying

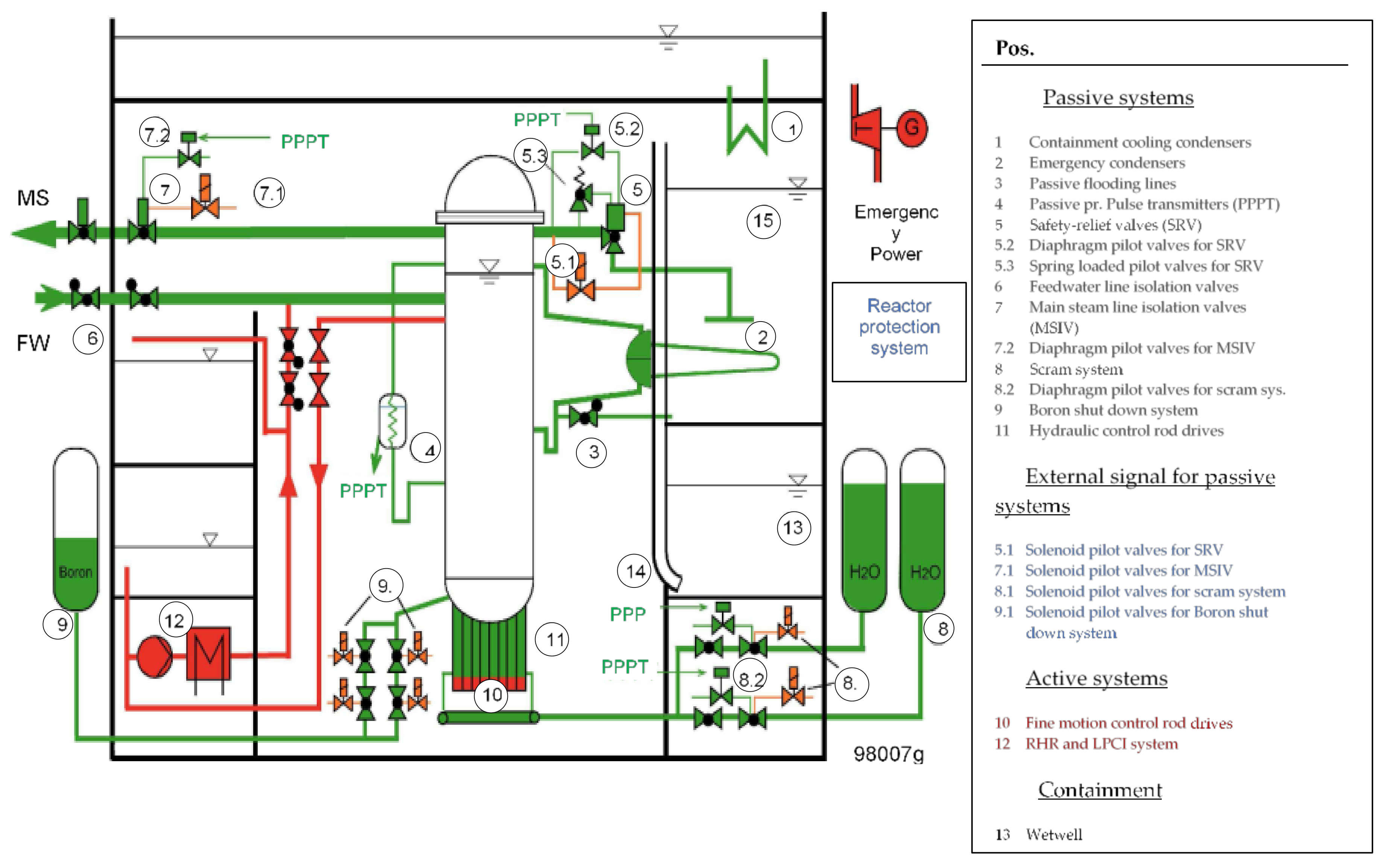

KERENA (SWR 1000) Reactor

2. Condensation Inside Inclined Tubes

2.1. Flow Characteristics

2.2. Heat Transfer Correlations

| Authors (Year) Reference | Correlations |

|---|---|

| Chato (1962) [35] | |

| Boyko, L.D. (1967) [37] | |

| Chen (1987) [39] | |

| Dobson and Chato (1998) [40] | , , For , For |

| Sarma (2002) [42] | |

| Cavallini (2002) [43] | |

| Cavallini (2006) [44] | For hydrocarbons, CT = 1.6; other refrigerants, CT = 2.6 a) for , ΔT independent flow regime b) for , ΔT dependent flow regime |

| Shah (2008) [45] | In regime I: In regime II: For horizontal tubes, the equation is recommended only if In regime II: |

2.3. In-Pipe Condensation Modelling with One-Dimensional Codes

2.3.1. ATHLET

2.3.2. RELAP5/ Mod 3.3

2.3.3. TRACE

2.3.4. Application and Assessment of 1D Codes for Passive Safety Systems Analyses

2.4. CFD Modelling

3. Condensation on the Outside of Inclined Tubes

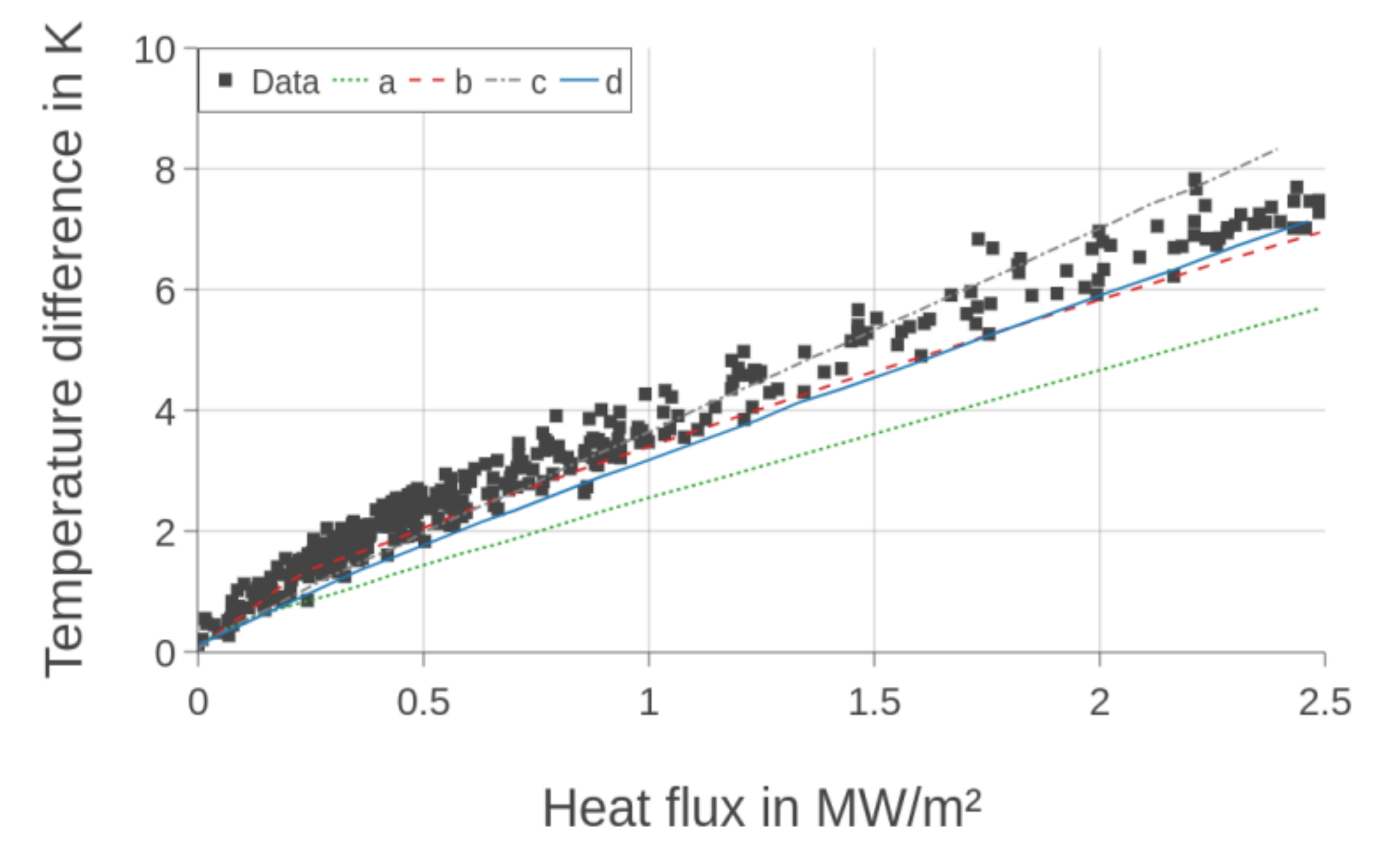

3.1. Correlations Obtained from Experiments

3.2. Outside Condensation Modelling with One-Dimensional Codes

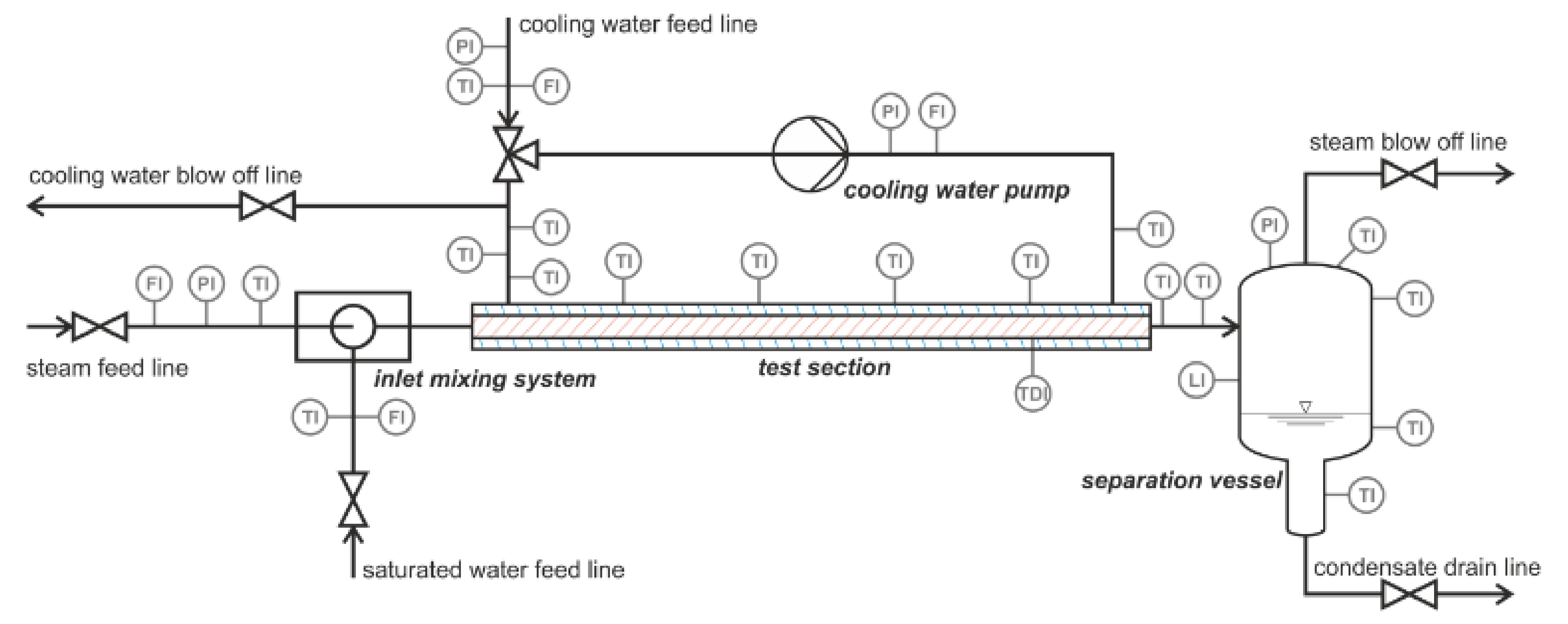

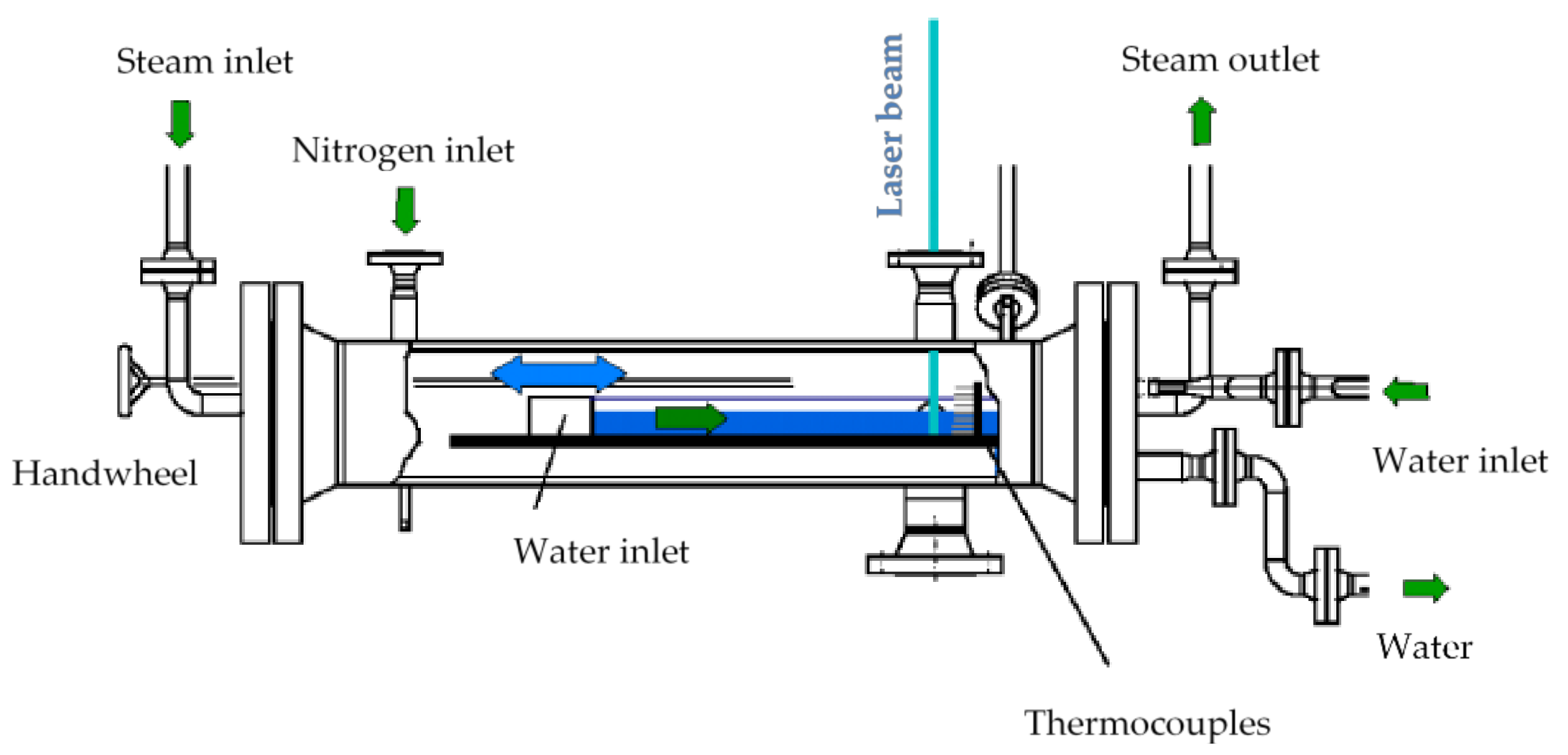

4. Experimental Test Facilities

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| Area (m2), Distribution | |

| (Constant) | |

| Specific heat at constant pressure (J/(kg K)) | |

| Diameter (m) | |

| Hydraulic diameter (m) | |

| Condensation coefficient | |

| Fr | Froude number |

| Fanning friction factor | |

| Fraction of the surface covered by a liquid film | |

| Mass flux (kg/(m2s)) | |

| Galilei number | |

| Grashof number | |

| Shear velocity (m/s) | |

| Gravitational acceleration (9.81 m/s2) | |

| Enthalpy (J/kg) | |

| Heat transfer coefficient (W/(m2K)) | |

| Δilv | Latent heat (J/kg) |

| Superficial heat transfer coefficient (W/(m2K)) | |

| Jakob number | |

| Dimensionless gas velocity | |

| Turbulent kinetic energy (J/kg) | |

| Transfer velocity (m/s) | |

| Length (m) | |

| Nu | Nusselt number |

| Number of tubes | |

| Exponent | |

| Normal vector | |

| Relative molar mass | |

| Mass (kg) | |

| Mass flow (kg/s) | |

| Pressure drop (Pa/m) | |

| Prandtl number | |

| Pressure | |

| q′ | Rate of heat flow (kW) |

| q″ | Heat flux (kW/m2) |

| Effective maximum drop radius (m) | |

| Radius of a departing droplet (m) | |

| Effective length (between conduction and interface resistance) (m) | |

| r | Minimal droplet radius (m) |

| Temperature (K) | |

| Gas constant | |

| Turbulent velocity scale (m/s) | |

| Velocity (m/s) | |

| x | Quality |

| Martinelli number | |

| Factor | |

| Re | Reynolds number |

| Radius (m), Relaxation time (1/s) | |

| Rayleigh number | |

| Greek | |

| Void fraction | |

| Γ | Interphase volumetric mass exchange (kg/(m³s)) |

| Film thickness (m) | |

| = | |

| Modified void factor | |

| Kinematic viscosity (m2/s) | |

| Inclination angle (°) | |

| Contact angle (°) | |

| Heat capacity ratio | |

| Thermal conductivity (W/(mK)) | |

| Dynamic viscosity (kg/(ms)) | |

| Density (kg/m³) | |

| Surface tension (N/m), Heat surface length (m) | |

| Shear stress (N/ m2) | |

| Lockhart-Martinelli two-phase parameter | |

| Turbulent dissipation rate (J/kgs) | |

| Subscript | |

| crit | Critical |

| DC | Dobson and Chato |

| Equal | |

| evap | Evaporation |

| F | Fluid |

| film | Film condensation |

| Gas | |

| Interface | |

| Laminar | |

| Liquid | |

| Minimum value | |

| Natural convection | |

| Outside | |

| Stratified | |

| at | Saturation condition |

| Two-phase | |

| tot | Total |

| Turbulent | |

| Vapor | |

| Wall | |

| Abbreviations | |

| ATHLET | Analysis of thermal-hydraulics of leaks and transients |

| BWR | Boiling water reactor |

| CCC | Containment cooling condenser |

| CFD | Computational fluid dynamics |

| CMT | Core makeup tank |

| DCC | Direct contact condensation |

| DNS | Direct numerical simulation |

| DW | Drywell |

| ESBWR | Economic simplified boiling water reactor |

| EC | Emergency condenser |

| GDCS | Gravity driven cooling system |

| GRS | Gesellschaft für Anlagen- und Reaktorsicherheit |

| HZDR | Helmholtz-Zentrum Dresden-Rossendorf |

| HWR | Heavy water reactor |

| INKA | Integral Test Stand Karlstein |

| INVEP | Invert Edward pipe |

| LWR | Light water reactor |

| PCCS | Passive containment cooling system |

| PWR | Pressurized water reactor |

| PPPT | Passive pressure pulse transmitter |

| PSI | Paul Scherrer Institute |

| PTS | Pressurized thermal shock |

| RELAP | Reactor excursion and leak analysis program |

| RPV | Reactor pressure vessel |

| SC | Suppression chamber |

| SCWR | Supercritical water reactor |

| SD | Surface divergence |

| SETCOM | Separate effect test for condensation modelling |

| SRT | Surface renewal theory |

| TRACE | TRAC/RELAP advanced computational engine |

| TransAt | Transport phenomena analysis tool |

| USNRC | U.S. Nuclear Regulatory Commission |

| VOF | Volume of fluid |

References

- International Nuclear Safety Advisory Group. The Safety of Nuclear Power; IAEA: Vienna, Austria, 1992. [Google Scholar]

- Goldberg, A.; Rosner, R. Nuclear Reactors: Generation to generation; American Academy of Arts and Science: Boston, MA, USA, 2011; ISBN 978-0-9842760-0-4. [Google Scholar]

- Passive Safety Systems and Natural Circulation in Water Cooled Nuclear Power Plants; IAEA: Vienna, Austria, 2009; Volume 1624.

- Passive Safety Systems in Advanced Water Cooled Reactors (AWCRs); IAEA: Vienna, Austria, 2013; Volume 1705.

- Brettschuh, W. SWR 1000: AREVA’s advanced, medium-sized boilling water reactor with passive safety features. In Proceeding of the Conference New Nuclear Power Plants Technologies 2007, Budapest, Hungary, 14–20 October 1974. [Google Scholar]

- Heinrich, M.; Walter, M.; Oldenburg, J. Bewertung neuer Reaktorkonzepte und der Übertragbarkeit sicherheitstechnischer Lösungen auf in Betrieb befindliche Anlagen. In GRS-Gesellschaft für Anlagen- und Reaktorsicherheit mbH, GRS Abschlussberich 2012; GRS: Berlin, Germany, 2012. [Google Scholar]

- Schaffrath, A. Experimentelle und analytische Untersuchungen zur Wirksamkeit des Notkondensators des SWR600, 100. In Jülich Forschungszentrum Zentralbibliothek 1997; JuSER: Jülich, Germany, 1997. [Google Scholar]

- Ringel, H.; Schuster, C.; Knorr, J. Thermohydraulic behaviour of a passive pressure pulse transmitter. ATW 1995, 43, 770–775. [Google Scholar]

- Ringel, H. Experimentelle Untersuchungen zum Verhalten und zur Beschreibung der thermohydraulischen Eigenschaften des Passiven Impulsgebers. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2001. [Google Scholar]

- Leyer, S.; Wich, S. The Integral Test Facility Karlstein—INKA. Sci. Technol. Nucl. Install. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Wright, R.F.; Gagnon, A.; Skinner, J.; Groome, J. Evaluation of the Scaling of the APEX-1000 Test Facility to AP1000 for Design Basis Events. In Proceedings of the 2004 International Congress on Advances in Nuclear Power Plants-ICAPP’04, Pittsburgh, PA, USA, 13–17 June 2004. [Google Scholar]

- Huggenberger, M.; Aubert, C.; Bandurski, T.; Dreier, J.; Fischer, O.; Strassberger, H.; Yadigaroglu, H. ESBWR related passive decay heat removal tests in PANDA. ICONE-7. In Proceedings of the 7th International Conference on Nuclear Engineering, Tokyo, Japan, 19–23 April 1999. [Google Scholar]

- Kuran, S.; Xu, Y.; Sun, X.; Cheng, L.; Yoon, H.J.; Revankar, S.T.; Ishii, M.; Wang, W. Startup transient simulation for natural circulation boiling water reactors in PUMA facility. Nucl. Eng. Des. 2006, 236, 2365–2375. [Google Scholar] [CrossRef]

- Furuya, M. Experimental and Analytical Modeling of Natural Circulation and Forced Circulation BWRs; Delft University Press: Amsterdam, The Netherland, 2006. [Google Scholar]

- Manera, A. Experimental and Analytical Investigations on Flashing-Induced Instabilities in Natural Circulation Two-Phase Systems. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 2003. [Google Scholar]

- Schuster, C. Betriebsverhalten eines Kreislaufs mit Naturumlaufströmung. Kernenergie 1991, 34. [Google Scholar]

- Cloppenborg, T. Passive Wärmeabfuhr. Ph.D. Thesis, TU Dresden, Dresden, Germany, 2015. [Google Scholar]

- Juhn, P.; Kupitz, J.; Cleveland, J.; Cho, B.; Lyon, R. IAEA activities on passive safety systems and overview of international development. Nucl. Eng. Des. 2000, 201, 41–59. [Google Scholar] [CrossRef]

- Szijarto, R. Condensation of Steam in Horizontal Pipes: Model Development and Validation. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2015. [Google Scholar]

- Schaffrath, A.; Walter, D.; Delmastro, D.; Gimenez, M.; Zanocco, P. Berechnung des Notkondensators des Integralreaktors CAREM. atw International Zeitschrift für Kernenergie 2003, 48, 111–115. [Google Scholar]

- Fukano, T. THERMOPEDIA, Thermodynamics, Heat and Mass Transfer, and Fluids Engineering. 2011. Available online: http://thermopedia.com/; (accessed on 18 December 2019).

- Baker, O.; Petroleum, M. Desgin of pipelines for the simultaneous flow of oil and gas. In Proceedings of the Fall Meeting of the Petroleum Branch of AIME. Society of Petroleum Engineers, Dallas, TX, USA, 19–21 October 1953. [Google Scholar]

- White, P.D.; Huntington, R.L. Horizontal co-current two-phase flow of fluids in pipe lines. Pet. Eng. 1955, 9, 40. [Google Scholar]

- Govier, G.W.; Omer, M.M. The Horizontal Pipeline Flow of Air-Water Mixtures. Can. J. Chem. Eng. 1962, 40, 93. [Google Scholar] [CrossRef]

- Traviss, D.P.; Baron, A.B.; Rohsenow, W.M. Forced-Convetcion Condensation inside Tubes; Mechanical Engineering Department MIT: Cambridge, MA, USA, 1971. [Google Scholar]

- Soliman, H.M.; Azer, N.Z. Flow Patterns during condensation inside a horizontal tube. ASHRAE J. 1971, 77, 211. [Google Scholar]

- Soliman, H.M.; Azer, N.Z. Visual studies of flow patterns during condensation inside horizontal tubes. In Proceedings of the Fifth International Heal Transfer Conference, Tokyo, Japan, 3–7 September 1974. [Google Scholar]

- Taitel, Y.; Dukler, A.E. A model for predicting flow regime transitions in horizontal and near horizontal gas-liquid flow. Adv. Chem. Eng. 1976, 1, 47–55. [Google Scholar] [CrossRef]

- Breber, G.; Palen, J.; Taborek, J. Prediction of horizontal tube-side condensation of pure components using flow regime criteria. Int. J. Heat Mass Transf. 1980, 102, 471–476. [Google Scholar]

- Soliman, H. Analytical and Experimental Studies of Flow Patterns during Condensation inside Horizontal Tubes. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 1974. [Google Scholar]

- El Hajal, J.; Thome, J.; Cavallini, A. Condensation in horizontal tubes, part 1: Two-phase flow pattern map. Int. J. Heat Mass Transf. 2003, 46, 3349–3363. [Google Scholar] [CrossRef]

- Kattan, N.; Thome, J.; Favrat, D. Flow boiling in horizontal tubes: Part 1-Development of adiabatic two phase flow pattern map. J. Heat Transf. 1998, 120, 140–147. [Google Scholar] [CrossRef]

- Tandon, T.; Varma, H.; Gupta, C. A new flow regime map for condensation inside horizontal tubes. J. Heat Transf. 1982, 104, 763–768. [Google Scholar] [CrossRef]

- Zhuang, X.; Gong, M.; Chen, G.; Zou, X.; Shen, J. Two-phase flow pattern map for R170 in a horizontal smooth tube. Int. J. Heat Mass Transf. 2016, 102, 1141–1149. [Google Scholar] [CrossRef]

- Chato, J.C. Laminar Condensation inside Horizontal and Inclined Tubes. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1960. [Google Scholar]

- Nusselt, W. Die Oberflachenkondensation des Wasserdampfes. VDI-Zs 1916, 60. [Google Scholar]

- Boyko, L.D.; Kruzhilin, G.N. Heat transfer and hydraulic resistance during condensation of steam in a horizontal tube and in a bundle of tubes. Int. J. Heat Mass Transf. 1967, 10, 361–373. [Google Scholar] [CrossRef]

- Kosky, P.G.; Staub, F.W. Local condensing heat transfer coefficients in the annular flow regime. J. Heat Transf. 1971, 17, 1037–1043. [Google Scholar] [CrossRef]

- Chen, S.; Gerner, F.; Tien, C. General film condensaion correlations. Exp. Heat Transf. 1987, 1, 93–107. [Google Scholar] [CrossRef]

- Dobson, M.K.; Chato, J.C. Condensation in smooth horizontal tubes. J. Heat Transf. 1998, 120, 193–213. [Google Scholar] [CrossRef]

- Moser, K.W.; Webb, R.L.; Na, B. A new equivalent reynolds number model for condensation in smooth tubes. J. Heat Transf. 1998, 120, 410–417. [Google Scholar] [CrossRef]

- Sarma, P.K.; Sastry, C.V.; Rao, C.V.; Kakac, S.; Liu, H. Convective condensation heat transfer in a horizontal condenser tube. Int. J. Therm. Sci. 2002, 41, 295–301. [Google Scholar] [CrossRef]

- Cavallini, A.; Censi, G.; Del Col, D.; Doretti, L.; Longo, G.A.; Rossetto, L. Condensation of halogenated refrigerants inside smooth tubes. HVAC R Res. 2002, 8, 429–451. [Google Scholar] [CrossRef]

- Cavallini, A. Condensation in horizontal smooth tubes: A new heat transfer model for heat exchanger design. Heat Transf. Eng. 2006, 27, 31–38. [Google Scholar] [CrossRef]

- Shah, M. An improved and extended general correlation for heat transfer during condensation in plain tubes. HVAC R Res. 2009, 15, 889–913. [Google Scholar] [CrossRef]

- Geißler, T.; Beyer, M.; Hampel, U.; Prasser, H.; Leyer, S.; Walther, M. Experimental and numerical investigation of flow structure and heat transfer during high pressure condensation in a declined pipe at COSMEA facility. In Proceedings of the 16th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-16), Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- ATHLET Mod 3.1 A: User’s Manual; GRS: Garching, Germany, 2016.

- Dittus, F.; Boelter, L. Heat Transfer in Automobile Radiators of the Tubular Type; University of California Press: Berkeley, CA, USA, 1930. [Google Scholar]

- McAdams, W. Heat Transmission; McGraw-Hill Book Company: New York, NY, USA, 1954. [Google Scholar]

- Collier, J. Convective Boiling and Condensation; McGraw-Hill International Book: New York, NY, USA, 1981. [Google Scholar]

- Carpenter, F.G.; Colburn, A.P. The effect of vapor velocity on condensation inside tubes. Gen. Discuss. Heat Transf. 1951, 20–26. [Google Scholar]

- RELAP5/mod3.3 Code Manual Volume I.: Code Structure, System Models, and Solution Methods; Idaho National Engineering Laboratory: Idaho Falls, ID, USA, 2001.

- RELAP5/mod3.3 Code Manual Volume IV.: Models and Correlations; Idaho National Engineering Laboratory: Idaho Falls, ID, USA, 2001.

- Sellars, J.R.; Tribus, M.; Klein, J.S. Heat transfer to laminar flows in a round tube or flat conduit. ASME 1956, 78, 441. [Google Scholar]

- TRACE V5.0 Theory Manual; United States Nuclear Regulatory Commission: Washington, DC, USA, 2010.

- Gnielinski, V. New equations flow regime heat and mass transfer in turbulent pipe and channel flow. Int. J. Chem. Eng. 1976, 16, 359–368. [Google Scholar]

- Bhatti, M.S.; Shah, R.K.; Aung, W. Turbulent and Transition Flow Convective Heat Transfer in Ducts. In Handbook of Single-Phase Convective Heat Transfer; Wiley-Interscience: New York, NY, USA, 1987. [Google Scholar]

- Incropera, F.P.; De Witt, D.P. Introduction to Heat Transfer, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1990. [Google Scholar]

- Holman, J. Heat Transfer; McGraw-Hill Book Co.: New York, NY, USA,, 1981. [Google Scholar]

- Kuhn, S.; Schrock, V.; Peterson, P. Final Report on U. C. Berkeley, Single Tube Condensation Studies; U.C. Berekley: Berekley, CA, USA, 1994; UCB-NE-4201. [Google Scholar]

- Schaffrath, A. Experimentelle und analytische Untersuchungen zur Wirksamkeit des Notkondensators des SWR600/1000. In Berichte des Forschungzentrums Jülich; Forschungzentrum Jülich: Jülich, Germany, 1996. [Google Scholar]

- Schaffrath, A. KONWAR—Eine Erweiterung von ATHLET zur Berechnung der Kondensation in waagerechten Rohren. In Berichte des Forschungszentrums Jülich; Forschungszentrum Jülich: Jülich, Germany, 1997. [Google Scholar]

- Schaffrath, A.; Krüssenberg, A.K.; Fjodorow, A.; Gocht, U.; Lischke, W. Modeling of condensation in horizontal tubes. Nucl. Eng. Des. 2001, 204, 251–265. [Google Scholar] [CrossRef]

- Alt, S.; Lischke, W. Heat transfer in horizontal tubes during two phase natural circulation with presence of noncondensing gas. Heat Mass Transf. 2000, 36, 575–582. [Google Scholar] [CrossRef]

- Choi, K.Y.; Park, H.S.; Kim, S.J.; No, H.C.; Bang, Y.S. Assessment and improvement of condensation models in RELAP5/MOD 3.2. Nucl. Technol. 1998, 124, 103–117. [Google Scholar] [CrossRef]

- Choi, K.Y.; Chung, H.J.; No, H.C. Direct-contact condensation heat transfer model in RELAP5/MOP3.2 with/without noncondensable gases for horizontally stratified flow. Nucl. Eng. Des. 2002, 211, 139–151. [Google Scholar] [CrossRef]

- Kim, H.J. Local Properties of Countercurrent Stratified Steam-Water Flow. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 1983. [Google Scholar]

- Zhou, W.; Wolf, B.; Revankar, S. Assessment of RELAP5/MOD3.3 condensation models for the tube bundle condensation in the PCCS of ESBWR. Nucl. Eng. Des. 2013, 264, 111–118. [Google Scholar] [CrossRef]

- Macedo, L.A.; Torres, W.M. Simulation of steam condensation in the prescence of noncondensable gases in horizontal condenser tubes using RELAP5 for advanced nuclear reactors. In Proceedings of the International Nuclear Atlantic Conference, Rio de Janeiro, Brazil, 27 September–2 October 2009. [Google Scholar]

- Aglar, F. Assessment of the RELAP5/MOD3.3 code for condensation in the presence of air using experimental data and theoretical model. Ann. Nucl. Energy 2013, 60, 329–340. [Google Scholar] [CrossRef]

- Szijártó, R.; Freixa, J.; Prasser, H.-M. Performance of heat transfer models of thermal-hydraulic system codes at the Invert Edwards Pipe Experiment. In Proceedings of the NOTHOS-9, Kaohsiung, Taiwan, 9–13 September 2012. [Google Scholar]

- Prasser, H.-M.; Boettger, A.; Zschau, J.; Gocht, T. Needle shaped conductivity probes with integrated micro-thermocouple and their application in rapid condensation experiments with non-condensable gases. Kerntechnik 2003, 68, 114–120. [Google Scholar]

- Szijártó, R.; Freixa, J.; Prasser, H.-M. Simulation of condensation in a closed, slightly inclined horizontal pipe with a modified RELAP5 code. Nucl. Eng. Des. 2014, 273, 288–297. [Google Scholar] [CrossRef]

- Lee, K.W.; Cheong, A.; Shin, A. Assessment of condensation heat transfer models of MARS-KS and TRACE codes using PASCAL test. In Proceedings of the 25th International Conference Nuclear Energy for New Europe, Portoroz, Slovenia, 5–8 September 2016. [Google Scholar]

- Pollman, A.; Vierow, K.; Marzo, M. Analysis of rapid-condensation transient using TRACE. Nucl. Eng. Des. 2012, 250, 512–519. [Google Scholar] [CrossRef]

- Lee, W.H. A Pressure Iteration Scheme for Two-Phase Flow Modeling. Multiphase Transport: Fundamentals, Reactor Safety, Applications; Hemisphere Publishing: Washington, DC, USA, 1980; pp. 407–432. [Google Scholar]

- Da Riva, E.; Del Col, D. Numerical simulation of laminar liquid film condensation in a horizontal circular minichannel. J. Heat Transf. 2012, 134, 051019. [Google Scholar] [CrossRef]

- Qiu, G.; Cai, W.; Li, S.; Wu, Z.; Jian, Y.; Yao, Y. Numerical simulation on forced convective condensation of steam upward flow in a vertical pipe. Adv. Mech. Eng. 2014, 2014, 11. [Google Scholar] [CrossRef]

- Liu, Z.; Sundan, B.; Yuan, J. VOF modeling and analysis of filmwise condensation between vertical parallel plates. Heat Transf. Res. 2012, 43, 47–68. [Google Scholar] [CrossRef]

- Szijarto, R.; Badillo, A.; Niceno, B.; Prasser, H.-M. Condensation models for the water-steamn interface and volume of fluid method. Int. J. Multiph. Flow 2017, 93, 63–70. [Google Scholar] [CrossRef]

- Goldbrunner, M.; Karl, J.; Hein, D. Experimental investigation of heat transfer phenomena during direct contact condensation in the presence of noncondensable gas by means of linear raman spectroscopy. In Proceedings of the 10th International Symposium on Laser Techniques Applied to FluidMechanics, Lisbon, Portugal, 10–13 July 2000. [Google Scholar]

- Nichols, B.D.; Hirt, C.W.; Hotchkiss, R.S. SOLA-VOF: A solution algorithm for transient fluid flow with multiple free boundaries. In Technical Report No. LA-8355; Los Alamos Scientific Laboratory: Los Alamos, NM, USA, 1980. [Google Scholar]

- Hirt, C.W.; Nichols, B.D. Volume of Fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Welch, S.W.J.; Wilson, J. A volume of fluid based method for fluid flows with phase change. J. Comput. Phys. 2000, 160, 662–682. [Google Scholar] [CrossRef]

- Zhaohui, Y.; Xiwen, Z.; Xuefang, W. Numerical simulation of condensation induced water- hammer. Tsinghua Sci. Technol. 1997, 2, 599–602. [Google Scholar]

- Štrubelj, L.; Ézsöl, G.; Tiselj, I. Direct contact condensation induced transition from stratified to slug flow. Nucl. Eng. Des. 2010, 240, 266–274. [Google Scholar] [CrossRef]

- Lavieville, J.; Quemerais, E.; Boucker, M.; Maas, L. NEPTUNE CFD V1.0 User Guide; EDF R&D Chatou: Paris, France, 2005. [Google Scholar]

- Hughes, E.D.; Duffey, R.B. Direct contact condensation and momentum transfer in turbulent separated flows. Int. J. Multiph. Flow 1991, 17, 599–619. [Google Scholar] [CrossRef]

- Egorov, Y. Validation of CFD codes with PTS relevant test cases. In Technical report EVOL-ECORA-D07; ANSYS: Frankfurt, Germany, 2004. [Google Scholar]

- Apanasevich, P.; Lucas, D.; Beyer, M.; Szalinski, L. CFD based approach for modeling direct contact condensation heat transfer in two-phase turbulent stratified flows. Int. J. Therm. Sci. 2015, 95, 123–135. [Google Scholar] [CrossRef]

- Shen, L.; Triantafyllou, G.; Yue, D. Turbulent diffusion near a free surface. J. Fluid Mech. 2000, 407, 145–166. [Google Scholar] [CrossRef]

- Ceuca, S.C.; Macián-Juan, R. CFD Simulation of direct contact condensation with ANSYS CFX using locally defined heat transfer coefficient. In Proceedings of the ICONE-20, Anaheim, CA, USA, 30 July–3 August 2012. [Google Scholar]

- Banerjee, S. Turbulence structure and transport mechanisms at interfaces. In Proceedings of the 9th International Heat Transfer Conference, Boulder, CO, USA, 19–24 August 1990. [Google Scholar]

- Hunt, J.; Graham, J. Free stream turbulence near plance boundaries. J. Fluid Mech. 1978, 84, 209–235. [Google Scholar] [CrossRef]

- Banerjee, S.; Lakehal, D.; Fulgosi, M. Surface divergence models for scalar exchange between turbulent streams. Int. J. Multiph. Flow 2004, 30, 963–977. [Google Scholar] [CrossRef]

- Lakehal, D.; Fulgosi, M.; Yadigaroglu, G. Direct numerical simulation of condensing stratified flow. J. Heat Transf. 2008, 130, 021501. [Google Scholar] [CrossRef]

- Zschaeck, G.; Frank, T.; Burns, A. CFD modeling and validation of wall condensation in the presence of non-condensable gases. Nucl. Eng. Des. 2014, 279, 137–146. [Google Scholar] [CrossRef]

- Ambrosini, W.; Bucci, M.; Forgione, N.; Oriolo, F.; Paci, S.; Magnaud, J.; Studer, E.; Reinecke, E.; Kelm, S.; Jahn, W.; et al. Comparison and analysis of the condensation benchmark results. In Proceedings of the 3rd European Review Meeting on Severe Accident Research, Nessebar, Bulgaria, 23–25 September 2008. [Google Scholar]

- Kuhn, S.; Peterson, P.; Schrock, V. Determination of the local heat flux in condensation experiment. Exp. Heat Transf. 1996, 9, 149–163. [Google Scholar] [CrossRef]

- Kuhn, S.; Schrock, V.; Peterson, P. An investigation of condensation from steam-gas mixture flowing downward inside a vertical tube. Nucl. Eng. Des. 1997, 177, 53–69. [Google Scholar] [CrossRef]

- Lehmkuhl, J.; Kelm, S.; Bucci, M.; Allelein, H. Improvement of wall condensation modeling with suction wall function for contaiment application. Nucl. Eng. Des. 2016, 299, 105–111. [Google Scholar] [CrossRef]

- Müller, H.; Lehmkuhl, J.; Kelm, S.; Hundhausen, A.; Belt, A.; Allelein, H.J. Development of a wall condensation model for coarse mesh containment scale applications. In Proceedings of the CFD4NRS-6, Boston, MA, USA, 13–15 September 2016. [Google Scholar]

- Punetha, M.; Khandkar, S. A CFD based modelling approach for predicting steam condensation in the presence of non-condensable gases. Nucl. Eng. Des. 2017, 324, 280–296. [Google Scholar] [CrossRef]

- Le Fevre, E.J.; Rose, J.W. A theory of heat transfer by dropwise condensation. In Proceedings of the 3rd International Heat Transfer Conference, Chicago, IL, USA, 7–12 August 1966. [Google Scholar]

- Rose, J.W. Dropwise condensation theory. Int. J. Heat Mass Transf. 1981, 2, 191–194. [Google Scholar] [CrossRef]

- Bonner, R.W. Correlation for dropwise condensation heat transfer: Water, organic fluids and inclination. Int. J. Heat Mass Transf. 2013, 61, 245–253. [Google Scholar] [CrossRef]

- Browne, M.W.; Bansal, P.K. An overview of condensation heat transfer on horizontal tube bundles. Appl. Therm. Eng. 1999, 19, 565–594. [Google Scholar] [CrossRef]

- The RELAP5-3D© Code Development Team. RELAP5-3D© Code Manual Volume IV: Models and Correlations; Idaho National Engineering Laboratory: Idaho Falls, ID, USA, 2012.

- United States Nuclear Regulatory Commission. TRACE V5.0 Theory Manual—Field Equations, Solution Methods and Physical Models; United States Nuclear Regulatory Commission: Washington, DC, USA, 2012.

- Prasser, H.-M.; Beyer, M.; Carl, H.; Manera, A.; Pietruske, H.; Schütz, P.; Weiß, F.P. The multipurpose thermalhydraulic test facility TOPFLOW: An overview on experimental capabilities, instrumentation and results. Kerntechnik 2006, 71, 163–173. [Google Scholar] [CrossRef]

- Hicken, E.F.; Jaegers, H.; Jilich, F.; Schaffrath, A.; Rossendorf, F. The NOKO/TOPFLOW Facility for Natural Convection Flow; IAEA: Vienna, Austria, 2000. [Google Scholar]

- Paladino, D.; Dreier, J. PANDA: A multipurpose integral test facility for LWR safety investigations. Sci. Technol. Nucl. Install. 2012. [Google Scholar] [CrossRef] [PubMed]

- Allelein, H.-J.; Gupta, S.; Poss, G.; Reinecke, E.-A.; Funke, F. German Experimental Activities for Advanced Modeling and Validation Relating to Contaiment Thermal Hydraulic and Source Term; IAEA-CN-251; IAEA: Vienna, Austria, 2017. [Google Scholar]

- Hundhausen, A.; Müller, H.; Kelm, S.; Reinecke, E.; Allelein, H. Towards CFD-Grade measurments in a condensing boundary layer-first measurments of the new SETCOM facility. In Proceedings of the 8th European Review Meeting on Severe Accident Research, Warsaw, Poland, 16–18 May 2017. [Google Scholar]

| Function | Passive Safety System | Reactor Design | Reactor Type | Power (MW.th) |

|---|---|---|---|---|

| Core decay heat removal | Pre-pressurized core flooding tanks | AP1000 | PWR | 3415 |

| WWER-640/V-407, WWER-1000/V-392 | PWR | 1800, 3000 | ||

| APWR+ | PWR | 5000 | ||

| ESBWR | BWR | 4500 | ||

| AHWR | HWR | 750 | ||

| SMART | PWR | 330 | ||

| Elevated tank natural circulation loops | AP1000 | PWR | 3415 | |

| WWER-1000/V-392 | PWR | 3000 | ||

| ACR1000 | HWR | 3180 | ||

| SCWR-CANDU | SCWR | 2540 | ||

| Elevated gravity drain tanks | SWR1000 | BWR | 2778 | |

| AP1000 | PWR | 3415 | ||

| WWER-640/V-407 | PWR | 1800 | ||

| SBWR, ESBWR | BWR | 2000, 4500 | ||

| LSBWR | BWR | 900 | ||

| AHWR | HWR | 750 | ||

| ACR1000 | HWR | 3180 | ||

| SCWR-CANDU | SCWR | 2540 | ||

| IRIS | PWR | 1000 | ||

| Passively cooled steam generator or natural circulation | WWER-640/V-407, WWER-1000/V-392 | PWR | 1800, 3000 | |

| SMART | PWR | 330 | ||

| PSRD | PWR | 100 | ||

| IMR | PWR | 1000 | ||

| IRIS | PWR | 1000 | ||

| APWR+ | PWR | 5000 | ||

| Passive residual heat removal heat exchanger | AP1000 | PWR | 3415 | |

| SCWR-CANDU | SCWR | 2540 | ||

| SCOR | PWR | 2000 | ||

| Passive cooled core isolation condensers | SWR1000 | BWR | 2778 | |

| SBWR and ESBWR | BWR | 2000, 4500 | ||

| ABWR-II | BWR | 4960 | ||

| RMWR | BWR | 3926 | ||

| AHWR | HWR | 750 | ||

| CAREM | PWR | 100 | ||

| Sump natural circulation | AP1000 | PWR | 3415 | |

| WWER-640/V-407 | PWR | 1800 | ||

| MASLWR | PWR | 150 | ||

| Containment cooling or pressure suppression | Containment pressure suppression pools | AP1000 | PWR | 3415 |

| SBWR and ESBWR | BWR | 2000, 4500 | ||

| LSBWR | BWR | 900 | ||

| CAREM | PWR | 100 | ||

| SCOR | PWR | 2000 | ||

| IRIS | PWR | 1000 | ||

| Containment passive heat removal/pressure suppression systems | SWR1000 | BWR | 2778 | |

| AHWR | HWR | 750 | ||

| WWER-640/V-407 | PWR | 1800 | ||

| PSRD | PWR | 100 | ||

| SBWR and ESBWR | BWR | 2000, 4500 | ||

| ABWR-II | BWR | 4960 | ||

| RMWR | BWR | 3926 | ||

| Passive containment spray systems | AP1000 | PWR | 3415 | |

| LSBWR | BWR | 900 | ||

| ACR1000 | HWR | 3180 | ||

| SCWR-CANDU | SCWR | 2540 |

| Safety Functions | Passive Safety Systems | Active Safety Systems | ||

|---|---|---|---|---|

| Decay heat removal from containment | Four containment cooling condensers | Two residual decay heat removal and core flooding systems | ||

| Core flooding (low pressure) | Four core flooding lines | |||

| Decay heat removal from RPV (low pressure) | Four emergency condensers | |||

| Decay heat removal from RPV (high pressure) | ||||

| Limitation of reactor pressure | Six safety relief valves | Solenoid valve, Spring loaded control valve | ||

| Relief of reactor pressure | Diaphragm valve, Solenoid valve | Emergency condenser | ||

| Penetration isolation of main steam-line | Two intrinsic medium actuated quick-closing valves per line: -diaphragm valve/PPPT (passive C) -solenoid valve (passive D) | Gate valve | ||

| Subcriticality | Scram-system (four accumulators) -diaphragm valve/PPPT (passive C) -solenoid valve (passive D) | 137 electrical devices Boron shut-down system | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moonesi Shabestary, A.; Viereckl, F.; Zhang, Y.; Manthey, R.; Lucas, D.; Schuster, C.; Leyer, S.; Hurtado, A.; Hampel, U. Modelling of Passive Heat Removal Systems: A Review with Reference to the Framatome KERENA BWR Reactor: Part I. Energies 2020, 13, 35. https://doi.org/10.3390/en13010035

Moonesi Shabestary A, Viereckl F, Zhang Y, Manthey R, Lucas D, Schuster C, Leyer S, Hurtado A, Hampel U. Modelling of Passive Heat Removal Systems: A Review with Reference to the Framatome KERENA BWR Reactor: Part I. Energies. 2020; 13(1):35. https://doi.org/10.3390/en13010035

Chicago/Turabian StyleMoonesi Shabestary, Amirhosein, Frances Viereckl, Yu Zhang, Rene Manthey, Dirk Lucas, Christoph Schuster, Stephan Leyer, Antonio Hurtado, and Uwe Hampel. 2020. "Modelling of Passive Heat Removal Systems: A Review with Reference to the Framatome KERENA BWR Reactor: Part I" Energies 13, no. 1: 35. https://doi.org/10.3390/en13010035

APA StyleMoonesi Shabestary, A., Viereckl, F., Zhang, Y., Manthey, R., Lucas, D., Schuster, C., Leyer, S., Hurtado, A., & Hampel, U. (2020). Modelling of Passive Heat Removal Systems: A Review with Reference to the Framatome KERENA BWR Reactor: Part I. Energies, 13(1), 35. https://doi.org/10.3390/en13010035