Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experiment

3. Results

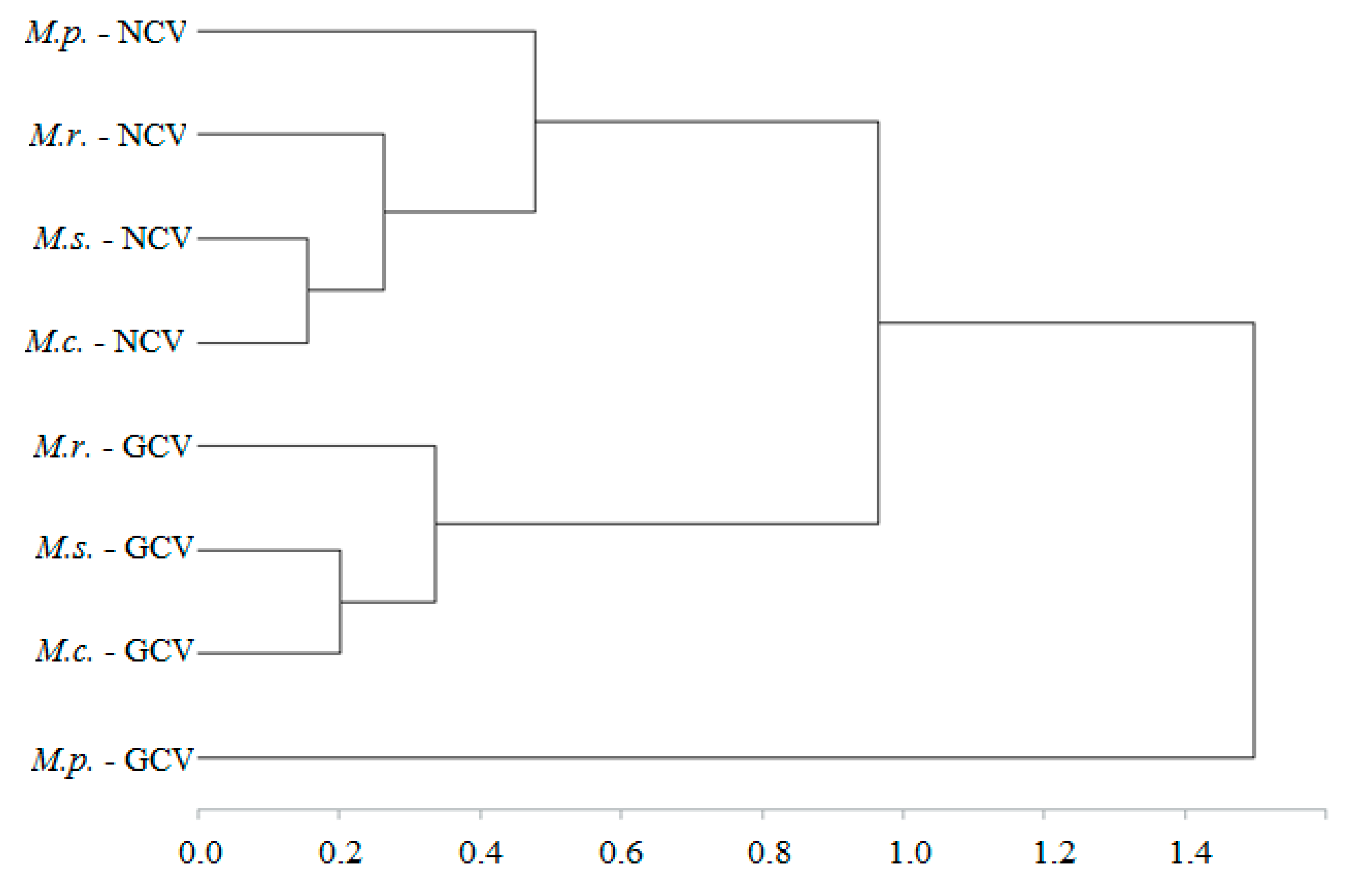

3.1. Results of Proximate and Ultimate Analysis

3.2. Emission Factors

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kraszkiewicz, A.; Stryjecka, M.; Nowosad, N.; Kocira, S. Burden for the environment by the products of pellets from plant biomass incineration in low-power heating devices. Rocz. Ochr. Srodowiska 2018, 20, 1269–1285. [Google Scholar]

- Mateos, E.; Ormaetxea, L. Sustainable Renewable Energy by Means of Using Residual Forest Biomass. Energies 2019, 12, 13. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk-Juśko, A. The influence of the ash from the biomass on the power boiler pollution. J. Ecol. Eng. 2017, 18, 200–204. [Google Scholar] [CrossRef]

- Nádudvari, Á.; Fabiańska, M.J.; Marynowski, L.; Kozielska, B.; Konieczyński, J.; Smółka-Danielowska, D.; Ćmiel, S. Distribution of coal and coal combustion related organic pollutants in the environment of the Upper Silesian Industrial Region. Sci. Total Environ. 2018, 628, 1462–1488. [Google Scholar] [CrossRef]

- Ozgen, S.; Caserini, S.; Galante, S.; Giugliano, M.; Angelino, E.; Marongiu, A.; Hugony, F.; Migliavacca, G.; Morreale, C. Emission factors from small scale appliances burning wood and pellets. Atmos. Environ. 2014, 94, 144–153. [Google Scholar] [CrossRef]

- Villeneuve, J.; Palacios, J.H.; Savoie, P.; Godbout, S. A critical review of emission standards and regulations regarding biomass combustion in small scale units (<3 MW). Bioresour. Technol. 2012, 111, 1–11. [Google Scholar]

- Zhang, R.; Lei, K.; Bu, Q.Y.; Cao, J.; Liu, D. Effects of alkali and alkaline earth metal species on the combustion characteristics of single particles from pine sawdust and bituminous coal. Bioresour. Technol. 2018, 268, 278–285. [Google Scholar] [CrossRef]

- Liang, F.; Wang, R.; Jiang, C.; Yang, X.; Zhang, T.; Hu, W.; Mi, B.; Liu, Z. Investigating co-combustion characteristics of bamboo and wood. Bioresour. Technol. 2017, 243, 556–565. [Google Scholar] [CrossRef]

- Ullah, H.; Liu, G.; Yousaf, B.; Ali, M.U.; Abbas, Q.; Zhou, C. Combustion characteristics and retention-emission of selenium during co-firing of torrefied biomass and its blends with high ash coal. Bioresour. Technol. 2017, 245, 73–80. [Google Scholar] [CrossRef]

- Maj, G. Analysis of Energy Properties and Emissions Factors of Selected Plant Biomass and Peat. In Proceedings of the IX International Scientific Symposium Farm Machinery and Processes Management in Sustainable Agriculture: Symposium Proceedings, Lublin, Poland, 22–24 November 2017; pp. 222–227. [Google Scholar]

- Konieczyński, J.; Komosiński, B.; Cieślik, E.; Konieczny, T.; Mathews, B.; Rachwa, T.; Rzońca, G. Research into properties of dust from domestic central heating boiler fired with coal and solid biofuels. Arch. Environ. Prot. 2017, 43, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Czop, M.; Kajda-Szcześniak, M. Environmental impact of straw based fuel combustion. Arch. Environ. Prot. 2013, 39, 71–80. [Google Scholar] [CrossRef] [Green Version]

- Gürkan, G.A.K.; Demirel, B.; Selvi, K.Ç.; Kabas, Ö.; Vladut, V. Evaluation of waste biomass from oat cultivation for energy. Acta Tech. Corviniensis-Bull. Eng. 2016, 9, 163. [Google Scholar]

- Szyszlak-Barglowicz, J.; Zajac, G.; Slowik, T. Research on Emissions from Combustion of Pellets in Agro Biomass Low Power Boiler. Rocz. Ochr. Srodowiska 2017, 19, 715–730. [Google Scholar]

- Fernandes, E.R.K.; Marangoni, C.; Souza, O.; Sellin, N. Thermochemical characterization of banana leaves as a potential energy source. Energy Convers. Manag. 2013, 75, 603–608. [Google Scholar] [CrossRef]

- Kimming, M.; Sundberg, C.; Nordberg, A.A.; Baky, A.; Bernesson, S.; Hansson, P.-A. Replacing fossil energy for organic milk production–potential biomass sources and greenhouse gas emission reductions. J. Clean. Prod. 2015, 106, 400–407. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Mandl, C.; Kerschbaum, M.; Svetlik, T. Strategies and technologies towards zero emission biomass combustion by primary measures. Energy Procedia 2017, 120, 681–688. [Google Scholar] [CrossRef]

- Jambor, J. Uprawa ziół i przetwórstwo zielarskie w Polsce-stan obecny i perspektywy rozwoju. In Proceedings of the 12th International Congress of Polish Herbal Committee, Poznań, Poland, 24–25 May 2007; Volume 53, pp. 25–26. [Google Scholar]

- Najda, A. Ontogenetic Variability of Mint (Mentha Species) a Factor Conditioning the Content of Bioactive Components in the Raw Material; University of Life Sciences in Lublin: Lublin, Poland, 2017. [Google Scholar]

- Olewnicki, D.; Jablonska, L.; Orlinski, P.; Gontar, L. Changes in Polish domestic production of herbal plants and in selected types of enterprises that process herbal plants in the context of the global increase in demand for these products. Sci. J. SGGW. Probl. World Agric. 2015, 15, 68–76. [Google Scholar]

- Najda, A. Chemical composition and antioxidant activity of extracts from Mentha × piperita L. Prog. Phytother. 2017, 18, 251–258. [Google Scholar]

- Obidziński, S. Pelletization process of postproduction plant waste. Int. Agrophys. 2012, 26, 279–284. [Google Scholar] [CrossRef]

- Żabiński, A.; Sadowska, U.; Wcisło, G. Options of use of waste biomass from herbal produc-tion for energy purposes. Agric. Eng. 2015, 19, 139–145. [Google Scholar]

- Stankiewicz, D. Possibilities of using agricultural raw materials for energy production in Poland. Stud. BAS 2010, 21, 237–266. [Google Scholar]

- Obidzinski, S. Profile of water activity and geometric parameters of lemon balm wastes in the aspect of their utilisation as an addition to fodders. Acta Agrophys. 2013, 20, 113–124. [Google Scholar]

- Chan, E.W.C.; Lim, Y.Y.; Wong, S.K.; Lim, K.K.; Tan, S.P.; Lianto, F.S.; Yong, M.Y. Effects of different drying methods on the antioxidant properties of leaves and tea of ginger species. Food Chem. 2009, 113, 166–172. [Google Scholar] [CrossRef]

- Karwowska, K.; Przybył, J. Drying and Processing of Herbs; SGGW Publishing: Warszawa, Poland, 2005; ISBN 83-7244-621-0. [Google Scholar]

- Gruszczyk, M.; Kołodziej, B.; Król, B.; Kucharski, W.A.; Mordalski, R.; Najda, A.; Nurzyńska-Wierdak, R.; Seidler-Łożykowska, K.; Sugier, D.; Wiśniewski, J.; et al. Herb Cultivation Guide for Growers, 2nd ed.; Powszechne Wydawnictwo Rolnicze i Leśne: Warszawa, Poland, 2018; ISBN 978-83-09-01110-1. [Google Scholar]

- Costa, A.G.; Bertolucci, S.K.V.; Chagas, J.H.; Ferraz, E.O.; Pinto, J.E.B.P. Biomass production, yield and chemical composition of peppermint essential oil using different organic fertilizer sources. Ciência e Agrotecnologia 2013, 37, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Santos, V.M.C.S.; Pinto, M.A.S.; Bizzo, H.R.; Deschamps, C. Seasonal variation of vegetative growth, essential oil yield and composition of menthol mint genotypes at southern Brazil. Embrapa Agroindústria de Alimentos-Artigo em periódico indexado (ALICE) 2012, 28, 790–798. [Google Scholar]

- Németh, É.; Szabó, K.; Raihárt, P.; Popp, U. Die wirkung der caliumversorgung auf die production und drogenqualitát von Minzen. Z Arznei–Gevurzpfla 2012, 17, 158–164. [Google Scholar]

- Mahmoodabad, H.A.; Parchin, R.A.; Hokmalipoor, S.; Shaban, M. Changes in yield and growth of green Mint (Mentha spicata L.) Under foliar application of urea and soil application of vermicompost. Int. J. Adv. Biol. Biomed. Res. 2014, 2, 2072–2076. [Google Scholar]

- Kołodziej, B. The effect of the term of plantation establishment, rejuvenating ploughing and Asahi SL application in peppermint culture. Ann. UMCS Agric. 2008, 63. [Google Scholar] [CrossRef]

- ISO. EN-ISO 18122:2016-01 Solid Biofuels. Determination of Ash Content 2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. EN-ISO 18123:2016-01 Solid Fuels—Determination of Volatile Content by Gravimetric Method; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. EN-ISO 18134-3:2015 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. EN-ISO 1928:2009 Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- ISO. EN-ISO 16948:2015-07 Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. ISO 16994:2016 Solid Biofuels—Determination of Total Content of Sulphur and Chlorine; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Borycka, B. Commodity Study on Food and Energy Utilization of Rich-Food Waste of the Fruit and Vegetables Industry; Radom University of Technology: Radom, Poland, 2008. [Google Scholar]

- Maj, G. Emission factors and energy properties of Agro and forest biomass in aspect of sustainability of energy sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef] [Green Version]

- Sahu, S.G.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Gustavsson, L.; Johansson, B.; Svenningsson, P. Reducing CO2 emissions by substituting biomass for fossil fuels. Energy 2015, 20, 1097–1113. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M. Thermal characteristics of the combustion process of biomass and sewage sludge. J. Therm. Anal. Calorim. 2013, 114, 519–529. [Google Scholar] [CrossRef] [Green Version]

- Modaresi, Z.K.; Karimi, G.; Mowla, D. Study of co-combustion of dried sewage sludge with coke: Thermogravimetric assessment and gaseous emissions. J. Environ. Chem. Eng. 2019, 7, 102871. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Osman, A.I. Mass spectrometry study of lignocellulosic biomass combustion and pyrolysis with NOx removal. Renew. Energy 2020, 146, 484–496. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.A.; Ghosal, G.K. A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 2005, 84, 487–494. [Google Scholar] [CrossRef]

- Maj, G.; Piekut, J. Comparing Emission Factors and Physicochemical Properties of Waste-Biomass Leaves of Selected Species of Trees. Pol. J. Environ. Stud. 2018, 27, 2155–2162. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Biomass sources for thermal conversion. Techno-economical overview. Fuel 2017, 195, 182–189. [Google Scholar] [CrossRef]

- Krugly, E.; Martuzevicius, D.; Puida, E.; Buinevicius, K.; Stasiulaitiene, I.; Radziuniene, I.; Minikauskas, A.; Kliucininkas, L. Characterization of gaseous-and particle-phase emissions from the combustion of biomass-residue-derived fuels in a small residential boiler. Energy Fuels 2014, 28, 5057–5066. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Lalak, J.; Martyniak, D.; Kasprzycka, A.; Żurek, G.; Moroń, W.; Chmielewska, M.; Wiącek, D.; Tys, J. Comparison of selected parameters of biomass and coal. Int. Agrophys. 2016, 30, 475–482. [Google Scholar] [CrossRef] [Green Version]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Hülsbergen, K.-J.; Feil, B.; Biermann, S.; Rathke, G.-W.; Kalk, W.-D.; Diepenbrock, W. A method of energy balancing in crop production and its application in a long-term fertilizer trial. Agric. Ecosyst. Environ. 2001, 86, 303–321. [Google Scholar] [CrossRef]

- Erdal, G.; Esengün, K.; Erdal, H.; Gündüz, O. Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 2007, 32, 35–41. [Google Scholar] [CrossRef]

- Pinstrup Andersen, P. Towards ecologically sustainable world food production. Ind. Environ. Fr. 1999, 22, 10–13. [Google Scholar]

- Parton, W.J.; Del Grosso, S.J.; Marx, E.; Swan, A.L. Agriculture’s role in cutting greenhouse gas emissions. Issues Sci. Technol. 2011, 27, 29–32. [Google Scholar]

- Cereceda-Balic, F.; Toledo, M.; Vidal, V.; Guerrero, F.; Diaz-Robles, L.A.; Petit-Breuilh, X.; Lapuerta, M. Emission factors for PM2.5, CO, CO2, NOx, SO2 and particle size distributions from the combustion of wood species using a new controlled combustion chamber 3CE. Sci. Total Environ. 2017, 584, 901–910. [Google Scholar] [CrossRef]

- Vamvuka, D.; Kakaras, E. Ash properties and environmental impact of various biomass and coal fuels and their blends. Fuel Process. Technol. 2011, 92, 570–581. [Google Scholar] [CrossRef]

| Material | Mentha × piperita L. var. citrata Ehrh.—‘Bergamot’ | Mentha × rotundifolia L. | Mentha spicata L. | Mentha crispa L. | p-Value |

|---|---|---|---|---|---|

| NCV ± Sx (MJ·kg−1) | 15.60D ±0.04 | 15.24C ±0.07 | 14.82A ±0.06 | 15.02B ±0.06 | <0.001 |

| GCV ± Sx (MJ·kg−1) | 16.96D ±0.05 | 16.23C ±0.07 | 15.90A ±0.06 | 16.06B ±0.06 | <0.001 |

| C ± Sx (%) | 47.05D ±0.10 | 45.38C ±0.02 | 44.82A ±0.03 | 44.99B ±0.01 | <0.001 |

| H ± Sx (%) | 5.57A ±0.02 | 5.76C ±0.02 | 5.54A ±0.02 | 5.67B ±0.02 | <0.001 |

| N ± Sx (%) | 0.70C ±0.01 | 0.23A ±0.00 | 0.43B ±0.10 | 0.29A ±0.02 | <0.001 |

| S ± Sx (%) | 0.19D ±0.01 | 0.03A ±0.00 | 0.14C ±0.00 | 0.07B ±0.00 | <0.001 |

| O ± Sx (%) | 29.14 ±0.07 | 36.09 ±0.16 | 32.85 ±0.06 | 35.27 ±0.18 | <0.001 |

| M (%) | 7.52D ±0.17 | 5.28A ±0.07 | 5.94C ±0.03 | 5.58B ±0.02 | <0.001 |

| A ± Sx (%) | 9.83C ±0.06 | 7.23A ±0.09 | 10.29D ±0.06 | 8.13B ±0.18 | <0.001 |

| V ± Sx (%) | 64.99B ±0.19 | 70.36D ±0.30 | 68.10C ±0.75 | 69.23DC ±0.27 | <0.001 |

| FC (%) | 17.66 | 17.13 | 15.67 | 17.06 | <0.001 |

| FR | 0.27 | 0.24 | 0.23 | 0.25 | - |

| Material | CO | CO2 | NOx | SO2 | EDust |

|---|---|---|---|---|---|

| M. × piperita L. var. citrata Ehrh.—‘Bergamot’ | 57.96 | 1419.30 | 2.48 | 0.38 | 12.42 |

| M. × rotundifolia L. | 55.91 | 1369.12 | 0.82 | 0.06 | 9.14 |

| M. spicata L. | 55.21 | 1352.06 | 1.51 | 0.27 | 13.00 |

| M. crispa L. | 55.43 | 1357.32 | 1.00 | 0.15 | 10.27 |

| Material | CO | CO2 | NOx | SO2 | EDust |

|---|---|---|---|---|---|

| M. × piperita L. var. citrata Ehrh.—‘Bergamot’ | 3.71 | 90.96 | 0.16 | 0.02 | 0.80 |

| M. × rotundifolia L. | 3.67 | 89.84 | 0.05 | <0.00 | 0.60 |

| M. spicata L. | 3.73 | 91.24 | 0.10 | 0.02 | 0.88 |

| M. crispa L. | 3.69 | 90.37 | 0.07 | 0.01 | 0.68 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maj, G.; Najda, A.; Klimek, K.; Balant, S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies 2020, 13, 55. https://doi.org/10.3390/en13010055

Maj G, Najda A, Klimek K, Balant S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies. 2020; 13(1):55. https://doi.org/10.3390/en13010055

Chicago/Turabian StyleMaj, Grzegorz, Agnieszka Najda, Kamila Klimek, and Sebastian Balant. 2020. "Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry" Energies 13, no. 1: 55. https://doi.org/10.3390/en13010055