Evaluation of the Brake’s Performance Dependence Upon Technical Condition of Car Tires as a Factor of Road Safety Management

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tire Size Depending on the Vehicle Weight

2.2. Tire Size Depending on the Date of Manufacture of the Vehicle

2.3. Analysis of the Influence of Tires on the Braking Process During Control Ests on the VIS

- Weight measuring the axle of the vehicle (result calculated per kg);

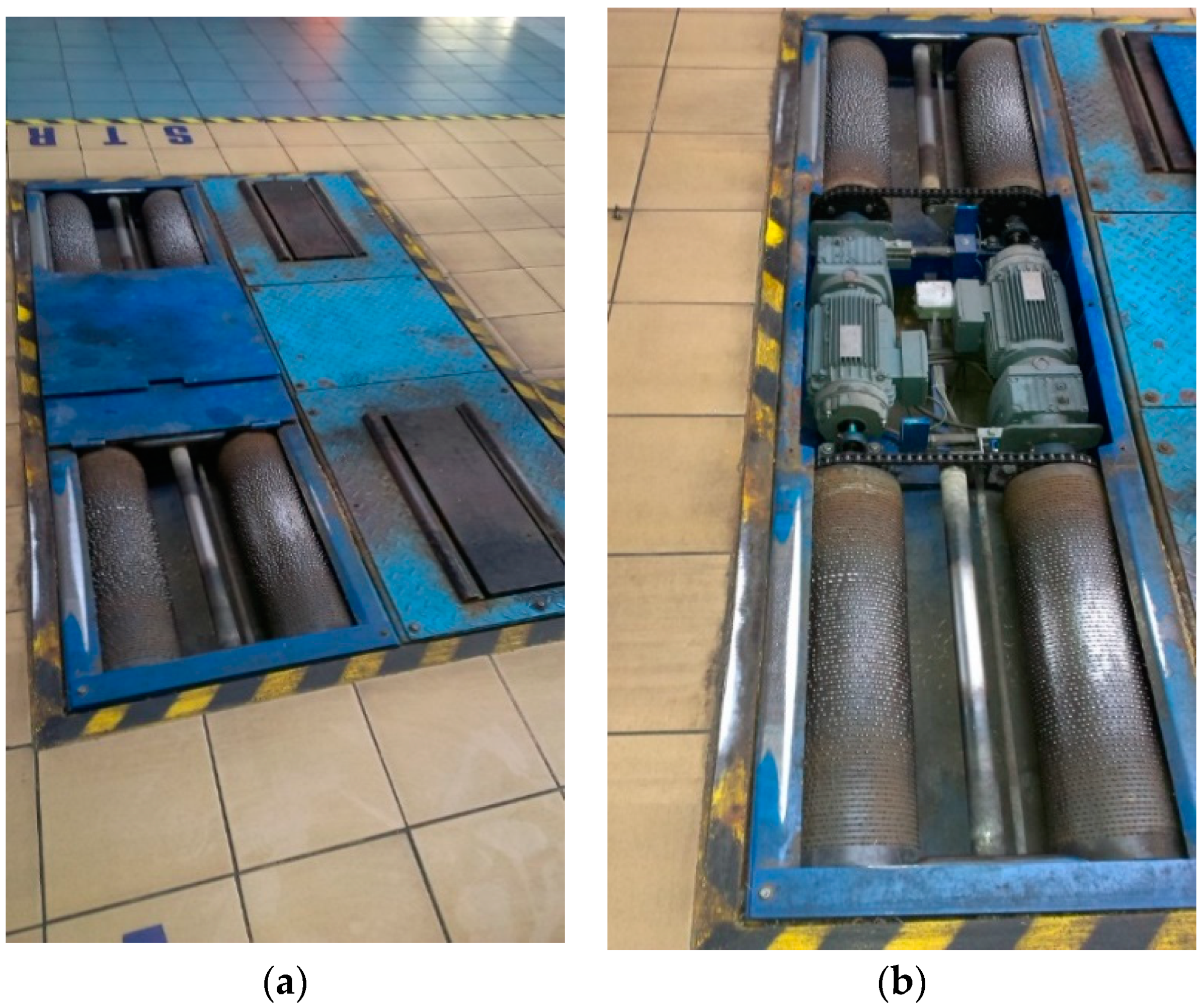

- Two drive units that are made up of: A gear motor and a system of two rollers (welded steel drums) connected by a chain (Figure 5a,b);

- Aa system that measures braking forces using strain gauges.

- Ford Escort-MKVII 1.6 16 V, with a mileage of 200 km,

- Opel Astra-G 1.4 16 V, with a mileage of 165,000 km.

3. Results

3.1. Measurements of the Weight of the Front Axle Wheels–0 Series

3.2. Interval Measurements of Braking Forces—Series I

3.3. Measurements of Braking Forces Depending on the Pressure on the Brake Pedal—Series II

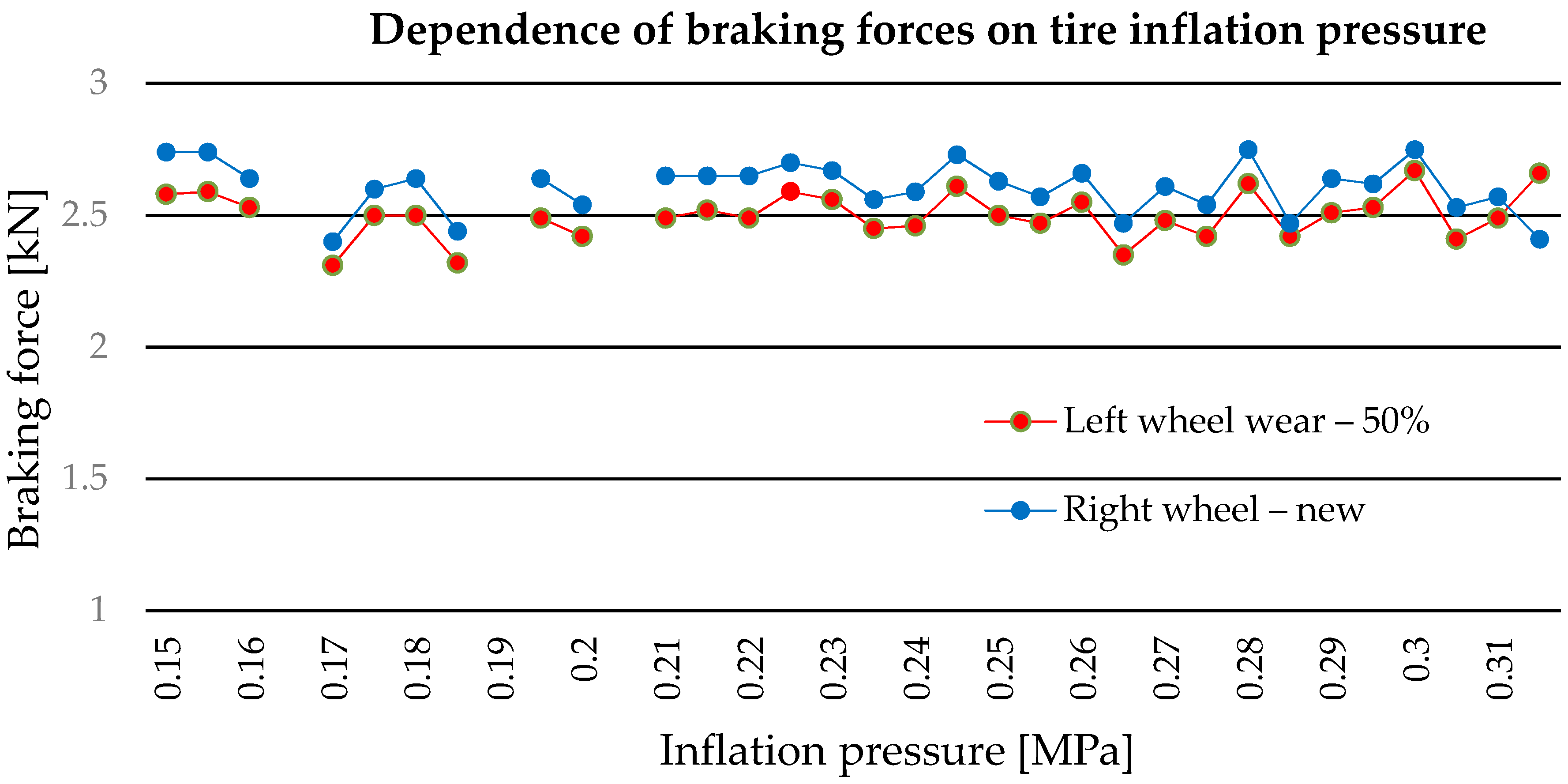

3.4. Measurements of Braking Forces at Varying Tire Inflation Pressures—Series III, IV, V, VI

4. Conclusions

- There is no clear trend of any decrease or increase in braking power depending on the inflation pressure of the tires in the tested pressure range.

- Tire tread wear has a virtually unpredictable effect on the braking force obtained.

- The additional payload of vehicles does not affect the increase or decrease in braking force, depending on the inflation pressure and tread wear level.

Author Contributions

Funding

Conflicts of Interest

References

- Tan, J.; Xiao, J.; Zhou, X. Market equilibrium and welfare effects of a fuel tax in China: The impact of consumers’ response through driving patterns. J. Environ. Econ. Manag. 2019, 93, 20–43. [Google Scholar] [CrossRef]

- Kim, N.; Rousseau, A.; Rask, E. Vehicle-level control analysis of 2010 Toyota Prius based on test data. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 1483–1494. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Swic, A.; Mitoraj-Wojtanek, M. The Development of Electromobility in Poland and EU States as a Tool for Management of CO2 Emissions. Energies 2019, 12, 1–22. [Google Scholar]

- Silva, C.A.M. Grid Electrified Vehicles: Performance. Design and Environmental Impacts, 1st ed.; Nova Science Publishers: New York, NY, USA, 2013; pp. 20–283. [Google Scholar]

- Tucki, K.; Mruk, R.; Orynycz, O.; Wasiak, A.; Botwinska, K.; Gola, A. Simulation of the Operation of a Spark Ignition Engine Fueled with Various Biofuels and Its Contribution to Technology Management. Sustainability 2019, 11, 2799. [Google Scholar] [CrossRef] [Green Version]

- Tucki, K.; Mruk, R.; Orynycz, O.; Wasiak, A.; Swic, A. Thermodynamic Fundamentals for Fuel Production Management. Sustainability 2019, 11, 4449. [Google Scholar] [CrossRef] [Green Version]

- Bokhari, A.; Chuah, L.F.; Yusup, S.; Klemeš, J.J.; Akbar, M.M.; Kamil, R.N.M. Cleaner production of rubber seed oil methyl ester using a hydrodynamic cavitation: Optimization and parametric study. J. Clean. Prod. 2016, 4, 31–41. [Google Scholar] [CrossRef]

- Periasamy, K.; Vijayan, S. Design and development of air-less car tire. Int. J. Adv. Eng. Technol. 2014, 7, 1312–1317. [Google Scholar]

- Kannan, D.; Diabat, A.; Shankar, K.M. Analyzing the drivers of end-of-life tire management using interpretive structural modeling (ISM). Int. J. Adv. Manuf. Technol. 2014, 9, 1603–1614. [Google Scholar] [CrossRef]

- Nazarko, J.; Czerewacz-Filipowicz, K.; Kuźmicz, A.K. Comparative analysis of the Eastern European countries as participants of the new silk road. J. Bus. Econ. Manag. 2017, 18, 1212–1227. [Google Scholar] [CrossRef] [Green Version]

- Bignozzi, M.C.; Sandrolini, F. Tyre rubber waste recycling in self-compacting concrete. Cem. Concr. Res. 2006, 4, 735–739. [Google Scholar] [CrossRef]

- Koishi, M.; Govindjee, S. Inverse design methodology of a tire. Tire Sci. Technol. 2001, 3, 155–170. [Google Scholar] [CrossRef]

- Olatunbosun, O.A.; Bolarinwa, O. FE simulation of the effect of tire design parameters on lateral forces and moments. Tire Sci. Technol. 2004, 3, 146–163. [Google Scholar] [CrossRef]

- 2018 Road Safety Statistics: What is Behind the Figures? European Commission—Fact Sheet. Available online: https://europa.eu/rapid/press-release_MEMO-19-1990_en.htm (accessed on 26 October 2019).

- Mohan, A.; Dutta, S.; Madav, V. Characterization and upgradation of crude tire pyrolysis oil (CTPO) obtained from a rotating autoclave reactor. Fuel 2019, 250, 339–351. [Google Scholar] [CrossRef]

- Tire Recycling by Continuous Pyrolysis. Available online: https://reoil.pl/oferta/ (accessed on 26 October 2019).

- Amari, T.; Themelis, N.J.; Wernick, I.K. Resource recovery from used rubber tires. Resour. Policy 1999, 3, 179–188. [Google Scholar] [CrossRef]

- Ferrer, G. The economics of tire manufacturing. Conserv. Recycl. 2007, 4, 1–30. [Google Scholar]

- Lee, S.J.; Lee, H.A.; Yi, S.I.; Kim, D.S.; Yang, H.W.; Park, G.J. Design flow for the crash box in a vehicle to maximize energy absorption. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 179–200. [Google Scholar] [CrossRef]

- Barroso, A.; Giarratana, M.S.; Pasquini, M. Product portfolio performance in new foreign markets: The EU trademark dual system. Res. Policy 2019, 48, 11–21. [Google Scholar] [CrossRef]

- The United Nations Economic Commission for Europe (UNECE). Transport. Available online: http://www.unece.org/trans/welcome.html (accessed on 30 November 2019).

- Study on Some Safety-Related Aspects of Tyre Use. Available online: https://op.europa.eu/en/publication-detail/-/publication/f3f32f73-7b42-4dda-b830-b3bd48090cfb (accessed on 30 November 2019).

- Kim, S.; Park, H.; Moon, B.; Sung, K.; Koo, J.M.; Seok, C.S. The prediction methodology for tire’s high speed durability regulation test using a finite element method. Int. J. Fatigue 2019, 118, 77–86. [Google Scholar] [CrossRef]

- Zakład Produkcji Granulatu Gumowego. Available online: http://orzelsa.com/pl/zaklad-produkcji-granulatu-gumowego/ (accessed on 26 October 2019).

- Castillo-Manzano, J.I.; Castro-Nuño, M.; Fageda, X. Exploring the relationship between truck load capacity and traffic accidents in the European Union. Transp. Res. Part E Logist. Transp. Rev. 2016, 88, 94–109. [Google Scholar] [CrossRef] [Green Version]

- Olszewski, P.; Szagała, P.; Wolański, M.; Zielińska, A. Pedestrian fatality risk in accidents at unsignalized zebra crosswalks in Poland. Accid. Anal. Prev. 2015, 84, 83–91. [Google Scholar] [CrossRef]

- Polish National Police. Road Traffic Office. Road Accidents in Poland in 2017. Available online: http://statystyka.policja.pl/st/ruch-drogowy/76562.Wypadki-drogowe-raporty-roczne.html (accessed on 26 October 2019).

- Regulation No 117 of the Economic Commission for Europe of the United Nations (UN/ECE)—Uniform Provisions Concerning the Approval of Tyres with Regard to Rolling Sound Emissions and to Adhesion on Wet Surfaces and/or to Rolling Resistance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1544800715965&uri=CELEX:42011X1123(03) (accessed on 26 October 2019).

- Proposal for a Council Decision on the Accession of the European Community to United Nations Economic Commission for Europe Regulation No 106 Concerning the Approval of Pneumatic Tyres for Agricultural Vehicles and Their Trailers. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52000PC0160 (accessed on 26 October 2019).

- Tyre Regulations. Available online: https://tpmszone.co.uk/tpms-information/regulations/ (accessed on 26 October 2019).

- Uniform Provisions Concerning the Approval of: Wheels for Passenger Cars and Their Trailers. Available online: https://www.interregs.com/catalogue/details/ece-124/regulation-no-124-00/wheels-passenger-cars/ (accessed on 26 October 2019).

- SAE J267 Wheels/Rims—Truck and Bus—Performance Requirements and Test Procedures for Radial and Cornering Fatigue. Available online: https://www.sae.org/standards/content/j267_201411/ (accessed on 26 October 2019).

- Janiszewski, J. Diagnostic utility vehicles in the Vehicle Inspection Station. Electr. Eng. 2015, 81, 205–211. [Google Scholar]

- Al-Saleh, K.S. Productivity improvement of a motor vehicle inspection station using motion and time study techniques. J. King Saud Univ. Eng. Sci. 2011, 23, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Żurowski, W.; Różycka, A. Analysis of technical safety requirements during diagnostic and maintenance car vehicles with all limit means for 3.5 t. Autobusy 2017, 6, 485–490. [Google Scholar]

- Burdzik, R.; Warczek, J. The influence of tyre pressure and vehicle load on evaluation of brake system effectiveness by vehicles services stations items. Sci. J. Sil. Univ. Technol. Ser. Transp. 2010, 66, 15–24. [Google Scholar]

- Tarkowski, S.; Mikus, D. Vehicle’s deceleration in selected terms of motion. Autobusy 2017, 17, 438–441. [Google Scholar]

- Caban, J.; Droździel, P.; Barta, D.; Liščák, S. Vehicle tire pressure monitoring systems. Diagnostyka 2014, 15, 11–14. [Google Scholar]

- Tarkowski, S.; Mikus, D.; Lotko, W. Age and technical condition of car tires and its impact to deceleration during braking maneuver. Autobusy 2017, 6, 440–444. [Google Scholar]

- Kałuża, R. Influence of the type and degree of wear of a car tire on the result of the static puncture test. Logistyka 2015, 4, 1397–1404. [Google Scholar]

- Kamiński, T.; Pelc, J. Pneumatic tires failures and communication accidents. Logistyka 2015, 5, 969–974. [Google Scholar]

- Bęczkowska, S.; Korzeb, J.; Koziak, S.; Opala, M.; Weyssenhoff, A. Non-uniformities and defects in materials of passenger car tyres-selected issues. Wars. Univ. Technol. Transp. 2018, 121, 9–20. [Google Scholar]

- Kotyk, M.; Piotrowski, M. Influence of gas temperature and pressure on radial stiffness vehicle tyres. Logistyka 2015, 4, 4176–4184. [Google Scholar]

- Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Dierkes, W.K.; Blume, A. Measuring rubber friction using a Laboratory Abrasion Tester (LAT100) to predict car tire dry ABS braking. Tribol. Int. 2015, 131, 191–199. [Google Scholar] [CrossRef]

- Chen, Z.; Xie, Z.; Zhang, J. Measurement of Vehicle-Bridge-Interaction force using dynamic tire pressure monitoring. Mech. Syst. Signal Process. 2018, 104, 370–383. [Google Scholar] [CrossRef]

- Antona-Makoshi, J.; Mikami, K.; Lindkvist, M.; Davidsson, J.; Schick, S. Accident analysis to support the development of strategies for the prevention of brain injuries in car crashes. Accid. Anal. Prev. 2018, 117, 98–105. [Google Scholar] [CrossRef]

- Prochowski, L. The analysis of a car motion path after collision with a concrete barrier. Maint. Reliab. 2011, 13, 71–80. [Google Scholar]

- Huang, M.; Guibert, M.; Thévenet, J.; Fayolle, C.; Chaussée, T.; Guy, L.; Vanel, L.; Loubet, J.L.; Sotta, P. A new test method to simulate low-severity wear conditions experienced by rubber tire materials. Wear 2018, 410, 72–82. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Zheng, D.; Schmerwitz, F.; Wriggers, P. An advanced abrasion model for tire wear. Wear 2018, 396–397, 75–85. [Google Scholar] [CrossRef]

- Gent, A.N.; Walter, J.D. The Pneumatic Tire; US. DOT HS 810561; National Highway Traffic Safety Administration: Washington, DC, USA, 2006; pp. 1–707. Available online: https://www.nhtsa.gov/search?keywords=DOT+HS+810561 (accessed on 17 December 2019).

- Prochowski, L. Pojazdy Samochodowe. Mechanika Ruchu, 1st ed.; Wydawnictwa Komunikacji i Łączności: Warszawa, Polska, 2016; pp. 255–289. [Google Scholar]

- Prochowski, L.; Unarski, J.; Wach, W.; Wicher, J. Podstawy Rekonstrukcji Wypadków Drogowych, 1st ed.; Wydawnictwa Komunikacji i Łączności: Warszawa, Polska, 2014; pp. 133–216. [Google Scholar]

- Wicher, J. Bezpieczeństwo Samochodów I Ruchu Drogowego, 1st ed.; Wydawnictwa Komunikacji i Łączności: Warszawa, Polska, 2012; pp. 137–170. [Google Scholar]

- General Director for National Roads and Motorways. Report on the Technical Condition of the Surface of the National Road Network Administered by the General Directorate for National Roads and Motorways. Wrocław Branch at the End of 2017. Available online: https://www.gddkia.gov.pl/pl/a/30240/ROK-2017 (accessed on 26 October 2019).

- Heinrich, G.; Klüppel, M. Rubber friction, tread deformation and tire traction. Wear 2008, 265, 1052–1060. [Google Scholar] [CrossRef]

- Tiwari, A.; Miyashita, N.; Espallargas, N.; Persson, B.N.J. Rubber friction: The contribution from the area of real contact. J. Chem. Phys. 2018, 148, 224701. [Google Scholar] [CrossRef] [Green Version]

- Krmela, J.; Krmelová, V. Dynamic Experiment of Parts of Car Tyres. Procedia Eng. 2017, 187, 763–768. [Google Scholar] [CrossRef]

- Prajwowski, K.; Gołębiewski, W. Effect of tire type on braking distance at different outdoor temperatures. Autobusy 2017, 7, 109–112. [Google Scholar]

- Merwe, N.A.; Els, P.S.; Žuraulis, V. ABS braking on rough terrain. J. Terramechanics 2018, 80, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.H.; Joo, B.S.; Lee, S.M.; Jang, H. Size effect of tire rubber particles on tribological properties of brake friction materials. Wear 2018, 394, 80–86. [Google Scholar] [CrossRef]

- Zöller, C.; Wagner, P.; Winner, H. Tires and vertical dynamics of wheeled mobile driving simulators. Transp. Res. Part F Traffic Psychol. Behav. 2017, 61, 69–83. [Google Scholar]

- Kardas-Cinal, E.; Lozia, Z.; Więckowski, D. Comparison of the level of simulated vibrations acting on a child transported in a road car or a railway vehicle. Pr. Nauk. Politech. Warszawskiej Transp. 2016, 112, 153–163. [Google Scholar]

- Angelo, C.M.; Machado, F.A.C.; Schön, C.G. Influence of tire sizes over automobile body spectrum loads and fatigue damage accumulation. Mater. Des. 2015, 67, 385–389. [Google Scholar] [CrossRef]

- Kovalyov, V.; Morozov, D. Accident Mechanism Modeling for Failure of Tires in Motion. Transp. Res. Procedia 2017, 20, 355–360. [Google Scholar] [CrossRef]

- Nyaaba, W.; Frimpong, S.; Anani, A. Fatigue damage investigation of ultra-large tire components. Int. J. Fatigue 2019, 119, 247–260. [Google Scholar] [CrossRef]

- European Division of Cars into Classes by Size. Available online: https://autobooking.com/pl-pl/news/europejski-podzial-samochodow-na-klasy-wedlug-wielkosci (accessed on 30 November 2019).

- LibTech. Car Class—Division into Market Segments. Available online: http://libtech.com.pl/klasa-samochodow-podzial-segmenty-rynkowe/ (accessed on 30 November 2019).

- Audi. Wheels and Tires. Available online: https://www.audiwarszawa.pl/download/katalog-opon-i-kol-audi.pdf (accessed on 30 November 2019).

- Citroën Tyres. Available online: https://www.citroen.co.uk/owner-services/maintenance/tyres (accessed on 30 November 2019).

- Skoda Brochures. Available online: https://www.skoda.co.uk/discover/download-a-brochure (accessed on 30 November 2019).

- Toyota Brochures. Available online: https://www.toyota.com/brochures/cars-minivan (accessed on 30 November 2019).

- Fiat Brochures. Available online: https://www.fiatprofessional.com/brochure (accessed on 30 November 2019).

- Peugeot Range. Available online: https://www.peugeot.co.uk/peugeot-model-range/ (accessed on 30 November 2019).

- Original Equipment. Available online: https://www.continental-tyres.ie/car/why-continental/original-equipment (accessed on 30 November 2019).

- Inter Cars. Tire Catalog. Available online: https://intercars.com.pl/pl/kategoria/359/ (accessed on 30 November 2019).

- Car Specifications. Available online: https://www.autocentrum.pl/dane-techniczne/ (accessed on 30 November 2019).

- Automobile Catalog. Available online: https://www.automobile-catalog.com/ (accessed on 30 November 2019).

- Tire Selection Configurator. Available online: https://www.opony.com/opona-do/skoda (accessed on 30 November 2019).

- Car Makes. Available online: https://www.wheel-size.com/size/ (accessed on 30 November 2019).

- Tire Replacements. Available online: https://www.opony.com.pl/narzedzia/zamienniki-opon/ (accessed on 30 November 2019).

- Devices for Diagnosing Pneumatic Braking Systems. Available online: https://trans.info/pl/urzadzenia-do-diagnozowania-pneumatycznych-ukladow-hamulcowych-56e170f9bfbba055760f387c-3168# (accessed on 30 November 2019).

- Ryme. Tire Tracks Gauge 3d Scanner. Available online: http://www.ryme.com/producto/escaner-de-huellas-de-neumaticos/ (accessed on 30 November 2019).

| Scale | Left Wheel | Right Wheel |

|---|---|---|

| Left scale | 422 | 352 |

| Right scale | 429 | 373 |

| Braking Force [kN] | ||||||

|---|---|---|---|---|---|---|

| Left Wheel | Right Wheel | |||||

| Measurement Number | Interval 2 min. | Interval 4 min. | Interval 6 min. | Interval 2 min. | Interval 4 min. | Interval 6 min. |

| 1 | 2.16 | 2.11 | 2.29 | 2.04 | 2.03 | 2.15 |

| 2 | 2.05 | 2.21 | 2.17 | 1.88 | 2.12 | 2.07 |

| 3 | 2.24 | 2.24 | 2.25 | 2.11 | 2.18 | 2.18 |

| 4 | 2.11 | 2.27 | 2.00 | 1.98 | 2.13 | 2.02 |

| 5 | 2.07 | 2.23 | 2.21 | 1.95 | 2.17 | 2.12 |

| Average value | 2.13 | 2.21 | 2.18 | 1.99 | 2.13 | 2.11 |

| Standard deviation | 0.08 | 0.06 | 0.11 | 0.09 | 0.06 | 0.06 |

| Left Wheel | Right Wheel | |||||

|---|---|---|---|---|---|---|

| Pedal Force [N] | ||||||

| Measurement Number | 100 | 110 | 120 | 100 | 110 | 120 |

| 1 | 1.04 | 1.39 | 1.65 | 1.06 | 1.41 | 1.67 |

| 2 | 1.14 | 1.34 | 1.57 | 1.16 | 1.33 | 1.60 |

| 3 | 1.14 | 1.48 | 1.65 | 1.16 | 1.48 | 1.71 |

| 4 | 1.10 | 1.36 | 1.74 | 1.10 | 1.45 | 1.76 |

| 5 | 1.16 | 1.34 | 1.68 | 1.16 | 1.40 | 1.73 |

| Average force on the wheels [kN] | 1.12 | 1.38 | 1.66 | 1.13 | 1.41 | 1.69 |

| Measurement Number | Pumping Pressure | Force on the Brake Pedal | Braking Force Left Wheel | Braking Force Left Wheel Converted to the Pressure 145 N on the Pedal | Braking Force Right Wheel | Braking Force Right Wheel Converted to the Pressure 145 N on the Pedal |

|---|---|---|---|---|---|---|

| [MPa] | [N] | [kN] | [kN] | [kN] | [kN] | |

| 1 | 0.14 | 148 | 2.02 | 1.98 | 2.10 | 2.06 |

| 2 | 0.14 | 149 | 1.86 | 1.81 | 1.95 | 1.90 |

| 3 | 0.15 | 147 | 2.11 | 2.08 | 2.21 | 2.18 |

| 4 | 0.15 | 146 | 2.06 | 2.05 | 1.98 | 1.97 |

| 5 | 0.16 | 152 | 2.23 | 2.13 | 2.28 | 2.18 |

| 6 | 0.16 | 154 | 2.33 | 2.19 | 2.19 | 2.06 |

| 7 | 0.17 | 148 | 2.17 | 2.13 | 2.05 | 2.01 |

| 8 | 0.17 | 154 | 2.39 | 2.25 | 2.20 | 2.07 |

| 9 | 0.18 | 151 | 2.21 | 2.12 | 2.17 | 2.08 |

| 10 | 0.18 | 146 | 2.12 | 2.11 | 2.06 | 2.05 |

| 11 | 0.19 | 126 | 2.01 | 2.31 | 2.06 | 2.37 |

| 12 | 0.19 | 131 | 2.06 | 2.28 | 2.07 | 2.29 |

| 13 | 0.20 | 129 | 2.01 | 2.26 | 2.05 | 2.30 |

| 14 | 0.20 | 133 | 2.12 | 2.31 | 2.13 | 2.32 |

| 15 | 0.21 | 135 | 2.07 | 2.22 | 2.09 | 2.24 |

| 16 | 0.21 | 146 | 2.14 | 2.13 | 2.16 | 2.15 |

| 17 | 0.22 | 143 | 2.12 | 2.15 | 2.12 | 2.15 |

| 18 | 0.22 | 151 | 2.12 | 2.04 | 2.16 | 2.07 |

| 19 | 0.23 | 146 | 2.14 | 2.13 | 2.15 | 2.14 |

| 20 | 0.23 | 151 | 2.23 | 2.14 | 2.19 | 2.10 |

| 21 | 0.24 | 148 | 2.12 | 2.08 | 2.14 | 2.10 |

| 22 | 0.24 | 149 | 2.10 | 2.04 | 2.13 | 2.07 |

| 23 | 0.25 | 140 | 2.02 | 2.09 | 2.04 | 2.11 |

| 24 | 0.25 | 146 | 2.14 | 2.13 | 2.14 | 2.13 |

| 25 | 0.26 | 143 | 2.11 | 2.14 | 2.12 | 2.15 |

| 26 | 0.26 | 148 | 2.14 | 2.10 | 2.15 | 2.11 |

| 27 | 0.27 | 146 | 2.10 | 2.09 | 2.12 | 2.11 |

| 28 | 0.27 | 151 | 2.23 | 2.14 | 2.21 | 2.12 |

| 29 | 0.28 | 148 | 2.14 | 2.10 | 2.17 | 2.13 |

| 30 | 0.28 | 140 | 2.11 | 2.19 | 2.10 | 2.18 |

| 31 | 0.29 | 140 | 2.09 | 2.16 | 2.11 | 2.19 |

| 32 | 0.29 | 141 | 2.11 | 2.17 | 2.13 | 2.19 |

| 33 | 0.30 | 143 | 2.16 | 2.19 | 2.12 | 2.15 |

| 34 | 0.30 | 151 | 2.21 | 2.12 | 2.21 | 2.12 |

| Average | 145 | 2.13 | 2.13 |

| Measurement Number | Pumping Pressure | Force on the Brake Pedal | Braking Force Left Wheel | Braking Force Left Wheel Converted to the Pressure 162 N on the Pedal | Braking Force Right Wheel | Braking Force Right Wheel Converted to the Pressure 162 N on the Pedal |

|---|---|---|---|---|---|---|

| [MPa] | [N] | [kN] | [kN] | [kN] | [kN] | |

| 1 | 0.15 | 166 | 2.55 | 2.49 | 2.50 | 2.44 |

| 2 | 0.15 | 166 | 2.75 | 2.68 | 2.60 | 2.54 |

| 3 | 0.16 | 163 | 2.58 | 2.56 | 2.42 | 2.41 |

| 4 | 0.16 | 168 | 2.81 | 2.71 | 2.72 | 2.62 |

| 5 | 0.17 | 157 | 2.55 | 2.63 | 2.60 | 2.68 |

| 6 | 0.17 | 174 | 2.84 | 2.64 | 2.77 | 2.58 |

| 7 | 0.18 | 158 | 2.52 | 2.58 | 2.61 | 2.68 |

| 8 | 0.18 | 165 | 2.74 | 2.69 | 2.59 | 2.54 |

| 9 | 0.19 | 154 | 2.37 | 2.49 | 2.47 | 2.60 |

| 10 | 0.19 | 154 | 2.48 | 2.61 | 2.51 | 2.64 |

| 11 | 0.20 | 160 | 2.58 | 2.61 | 2.63 | 2.66 |

| 12 | 0.20 | 166 | 2.63 | 2.57 | 2.76 | 2.69 |

| 13 | 0.21 | 151 | 2.40 | 2.57 | 2.48 | 2.66 |

| 14 | 0.21 | 154 | 2.48 | 2.61 | 2.55 | 2.68 |

| 15 | 0.22 | 154 | 2.28 | 2.40 | 2.39 | 2.51 |

| 16 | 0.22 | 154 | 2.33 | 2.45 | 2.44 | 2.57 |

| 17 | 0.23 | 171 | 2.59 | 2.45 | 2.60 | 2.46 |

| 18 | 0.23 | 163 | 2.43 | 2.42 | 2.40 | 2.39 |

| 19 | 0.24 | 169 | 2.67 | 2.56 | 2.57 | 2.46 |

| 20 | 0.24 | 165 | 2.54 | 2.49 | 2.48 | 2.43 |

| 21 | 0.25 | 171 | 2.62 | 2.48 | 2.48 | 2.35 |

| 22 | 0.25 | 160 | 2.53 | 2.56 | 2.62 | 2.65 |

| 23 | 0.26 | 166 | 2.60 | 2.54 | 2.52 | 2.46 |

| 24 | 0.26 | 160 | 2.43 | 2.46 | 2.49 | 2.52 |

| 25 | 0.27 | 169 | 2.53 | 2.43 | 2.47 | 2.37 |

| 26 | 0.27 | 161 | 2.58 | 2.60 | 2.63 | 2.65 |

| 27 | 0.28 | 168 | 2.57 | 2.48 | 2.66 | 2.57 |

| 28 | 0.28 | 158 | 2.46 | 2.52 | 2.56 | 2.62 |

| 29 | 0.29 | 157 | 2.37 | 2.45 | 2.51 | 2.59 |

| 30 | 0.29 | 160 | 2.51 | 2.54 | 2.56 | 2.59 |

| 31 | 0.30 | 160 | 2.49 | 2.52 | 2.61 | 2.64 |

| 32 | 0.30 | 166 | 2.58 | 2.52 | 2.63 | 2.57 |

| 33 | 0.31 | 158 | 2.49 | 2.55 | 2.29 | 2.35 |

| 34 | 0.31 | 165 | 2.66 | 2.61 | 2.65 | 2.60 |

| Average | 162 | 2.54 | 2.55 |

| Measurement Number | Pumping Pressure | Force on the Brake Pedal | Braking Force Left Wheel | Braking Force Left Wheel Converted to the Pressure 140 N on the Pedal | Braking Force Right Wheel | Braking Force Right Wheel Converted to the Pressure 140 N on the Pedal |

|---|---|---|---|---|---|---|

| [MPa] | [N] | [kN] | [kN] | [kN] | [kN] | |

| 1 | 0.15 | 133 | 2.06 | 2.17 | 1.95 | 2.05 |

| 2 | 0.15 | 136 | 1.89 | 1.95 | 1.83 | 1.88 |

| 3 | 0.16 | 139 | 1.80 | 1.81 | 1.91 | 1.92 |

| 4 | 0.16 | 140 | 1.94 | 1.94 | 1.94 | 1.94 |

| 5 | 0.17 | 138 | 1.99 | 2.02 | 1.94 | 1.97 |

| 6 | 0.17 | 131 | 1.79 | 1.91 | 1.84 | 1.97 |

| 7 | 0.18 | 122 | 1.85 | 2.12 | 1.93 | 2.21 |

| 8 | 0.18 | 136 | 1.97 | 2.03 | 1.98 | 2.04 |

| 9 | 0.19 | 136 | 1.81 | 1.86 | 1.88 | 1.94 |

| 10 | 0.19 | 137 | 1.89 | 1.93 | 1.83 | 1.87 |

| 11 | 0.20 | 145 | 2.05 | 1.98 | 2.01 | 1.94 |

| 12 | 0.20 | 135 | 1.85 | 1.92 | 1.88 | 1.95 |

| 13 | 0.21 | 139 | 1.95 | 1.96 | 2.00 | 2.01 |

| 14 | 0.21 | 152 | 2.10 | 1.93 | 2.02 | 1.86 |

| 15 | 0.22 | 145 | 2.08 | 2.01 | 2.06 | 1.99 |

| 16 | 0.22 | 137 | 2.04 | 2.08 | 2.03 | 2.07 |

| 17 | 0.23 | 146 | 2.18 | 2.09 | 2.23 | 2.14 |

| 18 | 0.23 | 140 | 2.07 | 2.07 | 2.00 | 2.00 |

| 19 | 0.24 | 145 | 2.00 | 1.93 | 2.03 | 1.96 |

| 20 | 0.24 | 139 | 2.04 | 2.05 | 1.99 | 2.00 |

| 21 | 0.25 | 139 | 2.03 | 2.04 | 2.09 | 2.11 |

| 22 | 0.25 | 137 | 2.19 | 2.24 | 2.10 | 2.15 |

| 23 | 0.26 | 146 | 2.21 | 2.12 | 2.04 | 1.96 |

| 24 | 0.26 | 139 | 2.09 | 2.11 | 2.13 | 2.15 |

| 25 | 0.27 | 140 | 2.09 | 2.09 | 2.17 | 2.17 |

| 26 | 0.27 | 142 | 2.13 | 2.10 | 2.21 | 2.18 |

| 27 | 0.28 | 149 | 2.19 | 2.06 | 2.17 | 2.04 |

| 28 | 0.28 | 143 | 2.10 | 2.06 | 2.16 | 2.11 |

| 29 | 0.29 | 146 | 2.07 | 1.98 | 2.02 | 1.94 |

| 30 | 0.29 | 142 | 2.08 | 2.05 | 2.15 | 2.12 |

| 31 | 0.30 | 143 | 2.14 | 2.10 | 2.13 | 2.09 |

| 32 | 0.30 | 143 | 2.09 | 2.05 | 2.07 | 2.03 |

| 33 | 0.31 | 143 | 2.01 | 1.97 | 2.12 | 2.08 |

| 34 | 0.31 | 145 | 2.05 | 1.98 | 2.12 | 2.05 |

| Average | 140 | 2.02 | 2.03 |

| Measurement Number | Pumping Pressure | Force on the Brake Pedal | Braking Force Left Wheel | Braking Force Left Wheel Converted to the Pressure 172 N on the Pedal | Braking Force Right Wheel | Braking Force Right Wheel Converted to the Pressure 172 N on the Pedal |

|---|---|---|---|---|---|---|

| [MPa] | [N] | [kN] | [kN] | [kN] | [kN] | |

| 1 | 0.15 | 170 | 2.55 | 2.58 | 2.71 | 2.74 |

| 2 | 0.15 | 171 | 2.57 | 2.59 | 2.72 | 2.74 |

| 3 | 0.16 | 175 | 2.57 | 2.53 | 2.69 | 2.64 |

| 4 | 0.16 | |||||

| 5 | 0.17 | 161 | 2.16 | 2.31 | 2.25 | 2.40 |

| 6 | 0.17 | 177 | 2.57 | 2.50 | 2.68 | 2.60 |

| 7 | 0.18 | 166 | 2.41 | 2.50 | 2.55 | 2.64 |

| 8 | 0.18 | 171 | 2.31 | 2.32 | 2.43 | 2.44 |

| 9 | 0.19 | |||||

| 10 | 0.19 | 168 | 2.43 | 2.49 | 2.58 | 2.64 |

| 11 | 0.20 | 171 | 2.41 | 2.42 | 2.53 | 2.54 |

| 12 | 0.20 | |||||

| 13 | 0.21 | 170 | 2.46 | 2.49 | 2.62 | 2.65 |

| 14 | 0.21 | 175 | 2.56 | 2.52 | 2.70 | 2.65 |

| 15 | 0.22 | 173 | 2.50 | 2.49 | 2.67 | 2.65 |

| 16 | 0.22 | 177 | 2.67 | 2.59 | 2.78 | 2.70 |

| 17 | 0.23 | 175 | 2.60 | 2.56 | 2.72 | 2.67 |

| 18 | 0.23 | 174 | 2.48 | 2.45 | 2.59 | 2.56 |

| 19 | 0.24 | 171 | 2.45 | 2.46 | 2.57 | 2.59 |

| 20 | 0.24 | 178 | 2.70 | 2.61 | 2.83 | 2.73 |

| 21 | 0.25 | 178 | 2.59 | 2.50 | 2.72 | 2.63 |

| 22 | 0.25 | 166 | 2.38 | 2.47 | 2.48 | 2.57 |

| 23 | 0.26 | 174 | 2.58 | 2.55 | 2.69 | 2.66 |

| 24 | 0.26 | 177 | 2.42 | 2.35 | 2.54 | 2.47 |

| 25 | 0.27 | 171 | 2.47 | 2.48 | 2.59 | 2.61 |

| 26 | 0.27 | 183 | 2.58 | 2.42 | 2.70 | 2.54 |

| 27 | 0.28 | 175 | 2.67 | 2.62 | 2.80 | 2.75 |

| 28 | 0.28 | 177 | 2.49 | 2.42 | 2.54 | 2.47 |

| 29 | 0.29 | 169 | 2.47 | 2.51 | 2.59 | 2.64 |

| 30 | 0.29 | 175 | 2.57 | 2.53 | 2.67 | 2.62 |

| 31 | 0.30 | 166 | 2.58 | 2.67 | 2.65 | 2.75 |

| 32 | 0.30 | 161 | 2.26 | 2.41 | 2.37 | 2.53 |

| 33 | 0.31 | 168 | 2.43 | 2.49 | 2.51 | 2.57 |

| 34 | 0.31 | 165 | 2.55 | 2.66 | 2.31 | 2.41 |

| Average | 172 | 2.50 | 2.61 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orynycz, O.; Tucki, K.; Wasiak, A.; Sobótka, R.; Gola, A. Evaluation of the Brake’s Performance Dependence Upon Technical Condition of Car Tires as a Factor of Road Safety Management. Energies 2020, 13, 9. https://doi.org/10.3390/en13010009

Orynycz O, Tucki K, Wasiak A, Sobótka R, Gola A. Evaluation of the Brake’s Performance Dependence Upon Technical Condition of Car Tires as a Factor of Road Safety Management. Energies. 2020; 13(1):9. https://doi.org/10.3390/en13010009

Chicago/Turabian StyleOrynycz, Olga, Karol Tucki, Andrzej Wasiak, Robert Sobótka, and Arkadiusz Gola. 2020. "Evaluation of the Brake’s Performance Dependence Upon Technical Condition of Car Tires as a Factor of Road Safety Management" Energies 13, no. 1: 9. https://doi.org/10.3390/en13010009

APA StyleOrynycz, O., Tucki, K., Wasiak, A., Sobótka, R., & Gola, A. (2020). Evaluation of the Brake’s Performance Dependence Upon Technical Condition of Car Tires as a Factor of Road Safety Management. Energies, 13(1), 9. https://doi.org/10.3390/en13010009