1. Introduction

According to the Canadian Biomass Magazine, the global demand of pellets is in continuous increase by more than 2 million metric tons per year, projected to reach 35 million metric tons by 2025 [

1]. Statistics Canada [

2] reported that, in 2019, Canada exported more than 2.5 million metric tons for an approximate amount of 500 million CAD. The three most important countries that received Canadian pellets were the UK for an amount of about 300 million CAD, Japan with 100 million CAD and the US for 59 million CAD. Compared to 2018, all these countries have increased their demand of the Canadian pellets, which show the importance of this market for the Canadian economy. It is, then, valuable to keep developing this sector with the production of competitive high-value pellets. It is anticipated that woody biomass would not be able to satisfy the increasing demand of the pellets and there is high attention to explore alternative feedstock for the pellet production. In addition to the use of woody biomass, by-products or crop residues coming from the agricultural sector can be explored as a potential feedstock to produce solid biofuel. Other than its availability and low cost, agricultural biomass presents reasonable physical and chemical properties with calorific values approaching the woody biomass [

3,

4].

Solid fuel production can be expanded by introducing high quality and energy efficient pellets made from non-conventional renewable resources. The quality of pellets highly depends on the physico-chemical characteristics of the feedstock, pellet processing conditions, and behavior during storage.

The compressive force, the particle size and the moisture content of the raw material, which are different for each type of agricultural biomass, played an important role on mechanical properties; in particular, the compression process during pellet production. These findings were presented by Mani et al. [

5]. Henriksson et al. [

6] confirmed the influence of the moisture content of the raw material on the production of the pellets. This observation was applied for 12 different biomasses going from woody to agricultural biomass. Theerarattananoon et al. [

7] found that increasing the moisture content of the pellets decreased the bulk and true densities of the pellets and their durability. In a similar way, Hartley and Wood [

8] showed that the variation in swelling and adsorption properties is influenced by the moisture content of the pellets. Mostafa et el. [

9] performed a comprehensive review dealing with the most important factors that influence the fabrication of the pellets and its link to having high-quality pellets. Fasina et al. [

10] determined the relationship between the thermodynamic properties of the pellets made with alfalfa and the moisture content of the tested pellets. The authors in [

8] studied and presented the specific heat, latent heat of sorption, and entropy as parameters varying with the moisture content of the pellets. All of these previous studies showed that the moisture content has a direct effect on the physical and chemical properties of the pellets. Sultana and Kumar [

11] showed several criteria that the pellets should complete so the developed pellets can be integrated into the market. The authors in [

11] establish these parameters and presented 11 parameters and three main factors. These factors are the economic factor studying the cost of the production of the pellets. The physical, chemical and mechanical properties and storage time of the pellets are the technical parameters included in the second factor. It was stated by the authors in [

11] that this factor could be directly affected by the moisture content of the pellets. The last presented factor is the environmental factor which includes the gaseous emissions, such as nitrogen, sulfur and methane, that the pellets may contain or can be released during storage. In a similar approach, Dyjakon et al. [

12], Greinert et al. [

13] and Pontaleo et al. [

14] pointed out that the issue of the storage conditions and its effect on delivering high-quality pellets with a high heating value that follows the international standards, including gaseous emissions and the respect to the environment. The effect of the composition of a raw material (i.e., starch, protein, fiber, fat, lignin, moisture content and particle size) on the strength and durability of the product presented in different shapes (i.e., pellets, briquettes and cubes) was presented by Kaliyan and Morey [

15]. In their experiment, the authors in [

15] observed that storing the products under high relative humidity leads to the increase of the moisture content. This practice plays a role in the decrease of the durability and strength of the tested materials. Järvinen and Agar [

16] presented in their study the effect of storage conditions and handling of wood pellets. The wood was subject of the torrefaction process. The authors in [

16] showed that the properties of the pellets, including its density and calorific value, energy, density and durability, are affected by the properties of the raw material and the storage conditions. Correspondingly, a comparison of density, heating value, durability, strength and emissions of wood and agricultural biomass-based pellets was developed by Nủñez et al. [

17] and Lee et al. [

18]. The authors stated that with a heating value reaching 18 MJ/kg, wood pellets and oil palm shell pellets have better properties than coconut shell pellets.

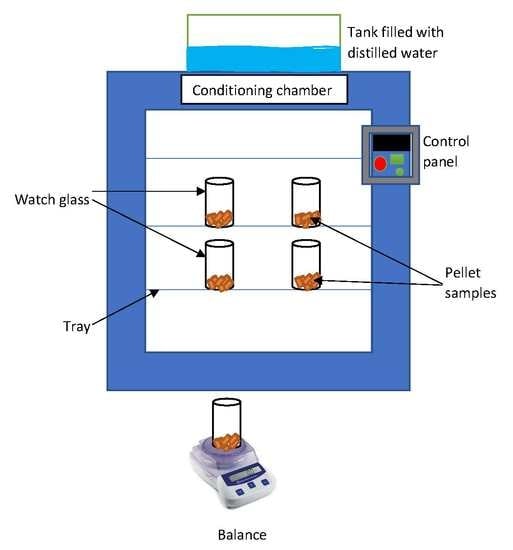

Storage is one of the important processes practiced during pellet production as well as before using as fuel in bioenergy industries. Usually, application of non-adequate storage conditions, leads to increase in the moisture content of the pellets and eventually deteriorating the physico-chemical properties of the pellets. It is important to know the moisture adsorption behavior of the pellets during storage at different conditions. This can help to determine the best storage conditions depending on the moisture sorption behavior. Keeping this in view, the present study is divided into two parts: an experimental and modeling study. Accordingly, the moisture sorption behavior of the mixed biomass pellets was determined experimentally using an economy line humidity chamber. The mathematical modeling part determined the most suitable models for prediction of the moisture sorption of the pellets with the variation of the storage conditions. Usually, the selected model is the one that presents a high coefficient of correlation, and a low standard and chi-square errors. In this study, it is shown that using a residual plot can be beneficial for the determination of the best fitting mathematical model. Finally, the thermodynamic properties of the tested materials, which include determination of the net isosteric heat and the entropy changes of sorption, were also presented in this study.

3. Results and Discussion

The comparison of the results presented in

Table 1 shows that mixing pellets with agricultural biomass, in particular switchgrass, will decrease the higher heat value of the pellets by around 7% if mixed with pine and around 4% with spruce wood. Harun et al. [

3] presented the mineral composition and comparison between spruce, pine and mixed spruce–switchgrass and pine–switchgrass pellets. Switchgrass presented high values of calcium, magnesium, phosphorus and potassium compared to spruce and pine. Accordingly, presence of calcium in the mixed pellets was higher compared to the woody pellets (i.e., pine or spruce). The same authors in [

3] showed the existence of a negligible amount of silicon, sulfur and chloride for both woody and mixed biomass pellets.

Figure 1a,b show the general behavior of the equilibrium moisture content (EMC) of spruce–switchgrass and pine–switchgrass pellets versus the relative humidity for different temperatures. According to the van der Waals sorption isotherms classification in [

28], the moisture sorption of pellets followed the type II sigmoid shape, commonly applied for the food products. Karunanithy et al. [

20] and Krupińska et al. [

21] confirmed the type II sigmoid shape of the moisture sorption for woody pellets and ones made with agricultural biomass. The values shown in

Figure 1a are similar to those obtained by Hartley and Wood [

8] for wood pellets and Fasina and Sokhansanj [

29] for alfalfa pellets and Bennamoun et al. [

30] for mixed agro–woody pellets, with a maximum value of the equilibrium moisture content (EMC) around 18% (wet basis). Krupińska et al. [

21] stated that, in order to have safe storage along with prevention from microbiological degradation, it is important to keep the equilibrium moisture content under 23%, which represents 0.3 kg/kg in dry basis.

Typically, the physico-chemical composition of the material gets influenced by varying the temperature; and increasing the temperature leads to the decrease of the EMC [

21]. However, in this study, the temperature did not have a significant effect on the EMC for both the pellets as shown in

Figure 1a,b. Desmorieux et al. [

31] and Belahmidi et al. [

32] found similar trend with temperatures in the range 25–40 °C for alga and 25–60 °C for food material.

As the EMC values were almost the same for different initial moisture content of the pellets, it was more appropriate to use the dimensionless mean value of the EMC, as represented in

Figure 2. The results presented in the figure were compared to the ones obtained by Bennamoun et al. [

30], where the produced pellets were made with 1:1 spruce or pine and hay or reed canary grass (RCG) using some protocol defined in this study. Indeed,

Figure 2 shows that, at low to medium relative humidity lower than 60%, there is almost no difference in the EMC between all the products. Pellets made with pine–hay and Pine–RCG have shown a moisture content slightly lower than the other pellets. At high relative humidity, the difference in the moisture content between the different pellets was more observable. In fact, mixing wood biomass with agricultural biomass has lowered the equilibrium moisture content. However, this difference depends on the used material. Accordingly, spruce–switchgrass pellets have shown higher EMC than pine–switchgrass pellets. Moreover, EMC of pine–switchgrass pellets was higher than EMC of pine–hay and lower than Pine–RCG pellets.

Figure 2 shows that at higher relative humidity (RH) about 90%, the spruce–switchgrass pellets absorb more moisture than the pine–switchgrass pellets. This could be related to the characteristics of the materials and the existence of tracheid in spruce more than the pine, particularity the softwood.

The calculated constants of GAB, Peleg, Oswin and Henderson models, along with the coefficient of determination (

R2), the standard error (

S) and the chi-square error (

χ2) are shown in

Table 3. As clearly shown, Peleg model had the lowest coefficient of determination and the highest calculated errors for all pellets. GAB, Oswin and Henderson models showed coefficient of determination equal to or higher than 0.990 and lower errors comparing to Peleg model.

Based on the examination of the errors, the Oswin model is proposed to be the most suitable model for sorption isotherms of the spruce–switchgrass pellets since it gave lowest standard error and chi-square error of 0.049 and 0.007, respectively. Similarly, these three models also showed good fitting for pine–switchgrass pellets. GAB model presented the lowest chi-square error with a value of 0.008, against 0.009 for Henderson model and 0.010 for Oswin model. In order to select the most suitable model, Chen [

33] added the residual plot as one of the qualitative criteria. Appropriately, the adequate model is the one showing the most uniform distribution of the residual plot. Several studies [

20,

29] adopted the same approach and used this criterion in order to model the moisture sorption isotherms.

Figure 3a,b show the residual plot for Oswin, GAB and Henderson models. The observation of the distribution of the residuals confirms the selection of Oswin model as the most adequate model for spruce–switchgrass pellets, with more uniform distribution of the residuals within the interval [−0.058, 0.062], compared to the other two models—[−0.062, 0.083] for the GAB model and [−0.133, 0.061] for the Henderson model. Similarly, examination of the residual results for the pine–switchgrass pellets shows that GAB model is the most accurate model for the prediction of their sorption isotherms. These results are in agreement with the previous study [

20]. They demonstrated that the Oswin model better described the moisture sorption isotherms of their several tested materials coming from agriculture wastes. However, for different kinds of wood species, the EMC was represented better by the GAB and Peleg models [

21]. In a different study [

29] study, it was found that the Hasley model described better the equilibrium moisture of pellets made with alfalfa.

Similar results and tendency of the sorption curves were obtained by Bennamoun et al. [

30] with a work that studied the sorption moisture of a mixture of four combinations of woody and agricultural biomass: spruce-hay, spruce–RCG, pine–hay and Pine–RCG. RCG is the red canary grass. All the combinations were 1:1, as described in this study. However, the adequate model presented by Bennamoun et al. [

30] that predicted the sorption moisture well was the Oswin model for all the biomass combinations and for all the tested temperatures.

The net isosteric heat and the entropy of sorption are determined by representing schematically, −

ln(RH) versus the inverse of the temperature

1/T (1/K). The results for the two sorts of pellets are shown in the following

Figure 4.

As

Figure 4 is showing, the value of the slop is decreasing with the equilibrium moisture content. Using Equation 4, this means that the net isosteric heat of sorption is decreasing with the increase of the equilibrium moisture content. This observation is in agreement with the results obtained by Meze’e et al. [

25] and Ouertani et al. [

24], obtained for different kinds of wood, and Haque et al. [

22] for several sorts of rice. Indeed, the net isosteric heat of sorption varied from 13.26 kJ/mole for an EMC

M = 4% to 0.29 kJ/mole at

M = 12% for the spruce–switchgrass pellets. These values were 16.02 and 0.29 kJ/mole, respectively, for the pine–switchgrass pellets. As reported by Meze’e et al. [

25] and Ouertani et al. [

24], this decrease of the

Qiso with the EMC increase is confirming the solid water-surface interactions. On the other side, as reported by Haque et al. [

22], no changes in the

Qiso at high EMC is due to the existence of the free water.

Ouertani et al. [

24], Simo-Tagne et al. [

27] and Haque et al. [

22] fitted their obtained results to certain curves. Indeed, Ourtani et al. [

24] and Simo-Tagne et al. [

27] wrote the

Qiso as an exponential function of the EMC. Similarly, Haque et al. [

22] proposed polynomial variation. Following this approach, it is proposed in

Table 4 the variation of the net isosteric heat of sorption as function on the equilibrium moisture content. This approach is applied for the both tested materials (i.e., spruce–switchgrass and pine–switchgrass pellets). In order to compare the results,

Table 4 includes also calculation of some of the results obtained from the experimental study performed by Bennamoun et al. [

30], dealing with spruce–RCG, Pine–RCG, spruce-hay and pine–hay pellets. The parameters of the all fitting curves are obtained using Excel software.

Table 4 shows that the net isosteric heat of sorption can be deduced using a polynomial function of the second degree of the equilibrium moisture content calculated in percentage in wet basis. Moreover, the results of the table show the low value of the

Qiso obtained for spruce and the mixed spruce–switchgrass and pine–switchgrass, compared to the other pellets mixed with hay and RCG, at low EMC (the highest value is registered for pine–hay pellets). As confirmation of the previous observation, this difference disappears at high EMC.

In addition, based on the description given in

Section 2.4.2. and Equation (8), the changes in the entropy for the sorption isotherms can be easily determined. Indeed, the curves of

Figure 4 show that the change in the entropy decrease with the equilibrium moisture content for all tested materials (i.e., spruce–switchgrass, pine–switchgrass and spruce pellets). Similar results were obtained by Meze’e et al. [

25], Ouertani et al. [

24] and Simo-Tagne et al. [

27], studies applied for different kinds of wood. Furthermore, the changes in entropy, for spruce–switchgrass pellets, varied from 0.037 kJ/mole.K for an EMC of 4% to around zero at an equilibrium moisture content of 12%. Similarly, the variation of the entropy for pine–switchgrass pellets varied from 0.045 kJ/mole.K at

M = 4% to around zero for an EMC of 12%. These results are within the same range presented by Meze’e et al. [

25] (with a range from 0.026 to 0.105 kJ/mole.K, for tropical wood), Ouertani et al. [

24] (these values varied from 0.009 to 0.1 kJ/mole.K obtained for jack pine and palm wood). Using the experimental study of Bennamoun et al. [

30] for pellet mixtures of spruce, pine, hay and RCG, closer results and similar tendency were obtained. In fact, pine–hay pellets have registered the highest change in entropy at the low EMC of 4% with the value of 0.077 kJ/mole.K, followed by spruce–RCG pellets with 0.055 kJ/mole.K for the same EMC. As reported by Meze’e et al. [

25], determination of the change in entropy is linked to the arrangement of the molecules of water and represents the order of its sorption. A similar approach as the net isosteric heat of sorption is applied and the change of entropy is presented as function of the equilibrium moisture content leading to

Table 5.

Table 5 shows that polynomial function of the third degree for spruce–switchgrass and pine–switchgrass pellets are applicable to determine the variation of the entropy as function of the EMC (in % wet basis). Those results were obtained using Excel software. Using the experimental results obtained by Bennamoun et al. [

30], it was possible also to determine the variation of the entropy for other mixed pellets (i.e., Pine–RCG, spruce–RCG and pine–hay). The results show that mixing the wood biomass with the agricultural biomass increased the difference in entropy for low EMC; this is probably due to the increase in the porosity of the pellets after mixing with the Agricultural biomass. This difference decreased with the increase of the EMC to reach around zero at an equilibrium moisture content equal to 12%.

Figure 5 shows the how the isosteric heat of sorption varying with the change of entropy for several types of pellets.

Figure 5a represents the pellets of this study and

Figure 5b is the part obtained from the published study of Bennamoun et al. [

30].

The results shown in

Figure 5 are similar to and within the range of those obtained by Meze’e et al. [

25], Ouertani et al. [

24] for different kinds of wood samples.

Figure 5a, is showing the results of spruce–switchgrass and pine–switchgrass pellets, with a maximum value of the isosteric heat of sorption of 16 kJ/mole for pine–switchgrass pellets. This maximum value was obtained at a difference in entropy of 0.045 kJ/mole·K. With the objective to compare the obtained calculations with others, results of the pellets tested by Bennamoun et al. [

30] were introduced in

Figure 5b. This last shows higher maximum values of net isosteric heat of sorption of around 30 kJ/mole for pine–hay pellets for a change in entropy of 0.077 kJ/mole·K.

The results shown in

Figure 5 clearly demonstrate the straight line between the net isosteric heat of sorption and the change in entropy, which validate the enthalpy–entropy compensation theory. This approach assumes that there is a linear relationship between the enthalpy and the entropy. This theory was studied for several physical and chemical processes [

24]. This approach allows the following equation to be written:

where

Tβ is the isokinetic temperature (K). As explained by Ouertani et al. [

24], this temperature is the temperature where all reactions proceed at the same rate.

ΔGβ is the free energy of Gibb calculated at the isokinetic temperature. Ouertani et al. [

24] indicate that water sorption is considered as spontaneous is the free energy is negative and considered as non-spontaneous if the free energy is positive.

Using Excel software, it is simple to determine the isokinetic temperature and the free energy of Gibbs for all the samples. The results of this estimation are represented in the

Table 6.

Table 6 shows that mixed pellets with switchgrass have isokinetic temperatures between 347 and 349 K. This temperature was lower for pellets mixed with RCG and higher for pine–hay pellets. Similarly, the free energy of Gibb was around 0.57 and 0.62 kJ/mole for mixed pellets with switchgrass. This energy was higher for pellets mixed with RCG and lower for pine–hay pellets.