A Reservoir Operation Policy Using Inter-Basin Water Transfer for Maximizing Hydroelectric Benefits in Brazil

Abstract

:1. Introduction

2. Mathematical Modeling

2.1. Mathematical Modeling of Hydrothermal Coordination

- T: number of intervals of the planning horizon;

- N: number of hydroeletric plants;

- : coefficient of present value;

- : total complementary generation (thermal, energy import and deficit) (MW);

- : total hydroelectric generation (MW);

- : demand (eletric energy market) (MW);

- : volume stored in the reservoir i at the end of the interval t (hm);

- : specific productivity of plant i ();

- : average volume stored in the reservoir i at the end of the interval t ();

- : volume evaporated in the reservoir i in the interval t ();

- : net water head of the plant t in the interval t ();

- : incremental water inflow to the reservoir of the plant i in the interval t ();

- : turbinated flow of the plant i in the interval t (/s);

- : flow release of the plant i in the interval t ();

- : spill flow of the plant i during the interval t ();

- : minimum and maximum bounds of stored volume for the reservoir of the plant i at the end of interval t ();

- : minimum and maximum bounds of the flow realese for the plant i in the interval t ();

- : minimum and maximum bounds of turbinated flow for the plant i in the interval t ();

- : minimum and maximum bounds of hydraulic generation for the plant i in the interval t (MW);

- : number of seconds in the interval t in seconds ();

- : group of indexes of the plants immediately upstream of plant i;

2.2. Mathematical Modeling of Water Transfer Applied to Hydrothermal Coordination

2.3. Optimized Operation of Hydroelectric Power Plant Reservoirs for Electric Power Generation

3. Methodology

3.1. Network Flow Applied to Hydrothermal Coordination

3.2. Particle Swarm Optimization (PSO)

3.3. Proposed Approach

3.3.1. Deployed Optimization Model (NF+PSO)

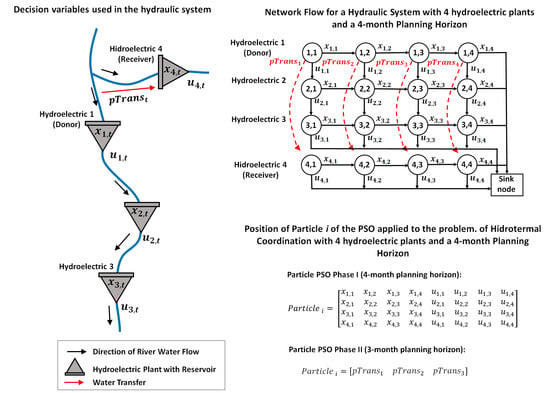

- Step 1—Particles Initialization: In this step the position and velocity of the particles are initialized. The position of a particle is represented by a two-dimensional matrix , where N corresponds to the number of hydroelectric power plants in the system and T corresponds to the number of intervals of the planning horizon. The matrix has columns, because the first T columns of the matrix represent the reservoir volume and the second half of the columns refers to the flow release of the plants. Figure 4 illustrates the modeling used for PSO particles implemented for a hydrothermal system consisting of three hydroelectric and four months. This step corresponds to phase I of the algorithm and it is responsible for generating the feasible initial population.

- Step 2—Particles Evaluation: The hydrothermal coordination optimization aims at minimizing the operational cost of the system. Thus, Equation (1) was used as a function of swarm particle evaluation to minimize the cost of hydrothermal system operation. The particle evaluation in the current iteration is compared to the evaluation in the previous iteration and, if the value of the current evaluation is better than in the previous iteration, the position vector is updated, otherwise it is retained.

- Step 3—FindinggBest: In this phase, the search for the best particle is performed, that is, the one with the best suitability of the whole swarm for subsequent updating of the swarm particle velocity.

- Step 4—Network Flow part 01: The first step of Network Flow is responsible for determining the non-basic arcs named super basic, i.e., through the Arc Partition Strategies (APS), the Network Flow establishes for each particle, according to its position vector, which elements of this vector will be updated. The details of each APS are described below:

- -

- Step 4.1—Arc Partition Strategy based on Hydraulic Production Function (APS-HPF): This arc splitting strategy recommends that, as far as possible, the basic arcs be composed of volumes. Thus, if a volume arc is within its operating limits, this arc will be at the base. Otherwise, the basic arc will be a flow release arc. As a result that the process is iterative, if the volume arc falls within its limits during the next iterations, the volume arc returns to the base.

- -

- Step 4.2—Arc Partition Strategy based on Cascade Energy Transfer 1 (APS-CET1): This strategy attempts to transfer energy among all periods of the planning horizon, that is, it attempts to transfer energy across the entire cascade (power plants system) and among all planning intervals, allowing the transfer of large blocks of energy between intervals. Energy transfer is done by creating a cycle between two intervals, in which changes made by the PSO are made only on the variables in that cycle.

- -

- Step 4.3—Arc Partition Strategy based on Cascade Energy Transfer 2 (APS-CET2): This APS represents a variant of APS-CET1, in which the main difference is the transfer of energy only between the planning horizon periods defined between the intervals of highest and lowest marginal cost of system operation.

- Step 5—Particles Velocity Update: Since PSO works together with network flow, the update of the velocity performed by Equation (17) will only be applied at the velocity vector positions at which Network Flow defined as super basic arcs, calculated by step 4. Therefore, there is only the updating of the velocity vector positions related to the super basic arcs. This fact decreases the computational cost, since the entire velocity vector is not updated. In this step the PSO velocity updating is used to seek the walking direction of the super basic arcs.

- Step 6—Network Flow part 02: In the second phase of the network flow, the following steps are performed:

- -

- Step 6.1—Cycles Identification: A cycle occurs when a super basic arc is inserted into the tree structure of the net, in which the orientation of the net basic arcs may agree or disagree with the formed cycle, which is determined by the orientation of the inserted super basic arc. Modifying the arcs values of a cycle allows the calculation of the effect of this change on the objective function. Thus, after the identification of the super basic arcs in step 4 and the walking direction in step 5, in this step there is the identification of the cycles formed by the addition of the super basic arc in the tree structure. Figure 5 shows the cycle formed by the addition of the super basic arc in the tree structure defined by the basic arcs , forming the cycle , which are within the dashed area in red.

- -

- Step 6.2—Walk Projection of Super Basic Arcs: This step is intended to prevent the canalization violation of the super basic arcs. In order to prevent this, the walk direction of the super basic arch should be annulled when it is within one of its limits, and its walk direction would imply in a violation of your canalization. For instance: If the super basic arc is at its lower limit (minimum flow release) and the walk direction of this arc implies a decrease in its value, its walk direction should be zero so as to avoid a violation of its minimum canalization limit.

- -

- Step 6.3—Basic Arcs Walk Direction: The walk direction of basic arcs is calculated based on the cycles formed by the super basic arcs in which the basic arcs participate. For each cycle, the walk direction of the basic arcs refers to the values given by combining (sum) the directions of the super basic arcs, in which the base arcs that agree with the direction of the formed cycle will be positive, otherwise they will be negative. In the example in Figure 5, the base arcs agree with the super basic arc and the basic arcs disagree with .

- -

- Step 6.4—Maximum Step Calculation: The maximum step size is calculated so that none of the arcs violate their canalization limits. After calculating the walk direction of the super basic and basic arcs, the walk direction signal of the decision variable must be analyzed. Depending on the signal, negative or positive, the arc may vary to its lower or upper limit respectively. Therefore, for each decision variable, its maximum step is calculated, aiming at not violating its limits. The maximum step value for all decision variables is given by the smallest value found between the maximum steps of the variables that correspond to a basic arc or super basic arc present in at least one cycle.

- -

- Step 6.5 - Optimum Step Calculation: The optimal step value is determined by one-dimensional searching using the golden ratio method [44].

- Step 7—Particles Position Update: Since the velocity values of each position relating to the decision variables, defined by the network flow, are calculated, the position of the particle in the next iteration is updated by Equation (16). Thus, only the arcs of the cycle formed by the super basic arc are their values modified. Throughout the iterations of the algorithm, new cycles are formed updating the particles in search of the best operating policy for the hydrothermal system. Steps 2 through 7 correspond to optimization algorithm phase II and, therefore, they aim to find the optimal values for the final volumes and flow releases of each hydroelectric plant of the system.

- Step 8—Transfer Performance: This last step corresponds to phase III of the algorithm and it is responsible for calculating the optimal value to be transferred from the donating power plant to the receiving power plant based on the volume and flow release values of the current iteration. Thus, after each phase II iteration and based on the results found in this iteration, the corresponding phase III iteration begins. Details of this modeling will be described in the following subsection.

3.3.2. Optimization Model on Inter-basin Water Transfer

- Step 1—Particles Inicialization: In this step the position and velocity of the particles are initialized. The position of a particle is represented by a one-dimensional matrix T, where T corresponds to the number of intervals of the planning horizon. The matrix has T columns because, for each interval t, one must find the optimum value to be transferred from DP to RP. The Equation (18) presents the modeling of the particles used in Phase III of the algorithm, using a planning horizon with 6 intervals.

- Step 2—Particles Evaluation: The phase III aims to minimize the operational cost of hydrothermal system with the use of inter-basin water transfer. Therefore, Equation (1) was also used as evaluation function of swarm particle in order to minimize the cost of hydrothermal system operation. Differences from phase II to phase III are described in Section 2.2.

- Step 3—FindinggBest: In this phase, the search for the best particle of phase III is performed .

- Step 4—Network Flow part 01: This step is responsible for determining the non-basic arcs called phase III superbasic using the transfer arc partition strategy (APS-Transfer). This APS recommends that, as far as possible, the basic arc set be composed by volumes. Thus, if a volume arc is within its operating limits, this arc will be at the base. Otherwise, the basic arc will be a flow release arc. The super basic arcs will be the arcs that link the DP to the RP for all periods of the planning horizon. The APS-Transfer for a system consisting of 03 plants (the last one is a run-of-the-river power plant), and for a 4-intervals planning horizon is illustrated in Figure 6.

- Step 5—Particles Velocity Update: This step aims to update the elements of the velocity vector at which the Network Flow has defined as super basic arcs (transfer arcs).

- Step 6—Network Flow part 02: As in phase II, in this one the following steps are performed:

- -

- Step 6.1—Cycles Identification: it identifies the cycle originated by the transfer arc. As in phase II, the orientation of the network basic arcs may or may not agree with the formed cycle. Figure 7 shows the cycle formed by the addition of the super basic arc in the tree structure defined by the basic arcs , forming the cycle .

- -

- Step 6.2—Walk Projection of Super Basic Arcs: This phase is responsible for preventing violation of the canalization of the boundaries of the arcs involved in water transfer from both the donating plant and the receiving plant. Two such situations may occur: The first case is when the walk direction of the super basic arc implies a violation of the minimum volume of the donating plant, in which case more water is to be removed from the DP than it can provide. The second case occurs when the RP is already at its maximum flow release and cannot receive more water from the DP. Thus, if any of these situations should occur, the walk direction of the transfer arc super basic should be canceled, assigning the zero value to the super basic arc walking direction.

- -

- Steps 6.3, 6.4 and 6.5: These steps are performed in a similar way as they occur in phase II.

- Step 7—Particle Position Update: This step is responsible for updating the pTrans vector, which stores the positions related to the amount of water to be transferred from the donating plant to the receiving plant.

4. Results and Discussions

- Case Study 01: Test system using, as natural flows, 100% of the Long-Term Average (LTA) with and without transfer for a planning period of two years;

- Case Study 02: Test system using 100% of LTA the flow observed from May 2013 to April 2018 with and without water transfer.

4.1. Case Study 01

4.2. Case Study 02

4.3. Financial and Environmental Impact Analysis

- Scenario 01: 60% of the energy produced at Henry Borden is spent on pumping water. Therefore, 515.60 average MW of pumping power and 3,895,379.28 MWh of electricity per year are required. Thus, there are 2,596,919,52 MWh of electricity and 29,645 average MW of power for commercialization.

- Scenario 02: 40% of the energy produced at Henry Borden is spent on pumping water. It corresponds to the inverse of scenario 01 for pumping and marketing.

- : is the Average Availability Factor;

- : is the Forced Downtime Rate;

- : is the Scheduled Downtime Rate;

- : is Maximum Load Factor;

- : is a Available Average Power

- : is the Installed Power.

4.4. Emission by Thermoelectric Plants

- : is the emission of given by the fuel combustion measured in tonnes/year (/year);

- : is the amount of fuel burning in tons (t);

- : is the net calorific value used to convert the amount of fuel for the different types to a “physical” unit of energy unit (generally Joules);

- : is the carbon content per unit of energy per fuel type (t/TJ);

- : is the oxidation factor of carbon.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahmed, M.M.; Shimada, K. The Effect of Renewable Energy Consumption on Sustainable Economic Development: Evidence from Emerging and Developing Economies. Energies 2019, 12, 2954. [Google Scholar] [CrossRef] [Green Version]

- Silva, I.R.S.; de AL Rabêlo, R.; Rodrigues, J.J.P.C.; Solic, P.; Carvalho, A. A preference-based demand response mechanism for energy management in a microgrid. J. Clean. Prod. 2020, 255, 120034. [Google Scholar] [CrossRef]

- Lin, B.; Ankrah, I.; Manu, S.A. Brazilian Energy Efficiency and Energy Substitution: A road to Cleaner National Energy System. J. Clean. Prod. 2017, 162, 1275–1284. [Google Scholar] [CrossRef]

- Gils, H.C.; Simon, S.; Soria, R. 100% Renawable Energy Supply for Brazil - The Role of Sector Coupling and Regional Development. Energies 2017, 10, 1859. [Google Scholar] [CrossRef] [Green Version]

- Energy Research Company. National Energy Balance 2018. (In Portuguese). Available online: Http://http://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-2019 (accessed on 8 June 2019).

- Mahmoudi, R.; Emrouznejad, A.; Khosroshahi, H.; Khashei, M. Performance evaluation of termal power plants considering CO2 emission: A multistage PCA, clustering, game theory and data envelopment analysis. J. Clean. Prod. 2019, 233, 641–650. [Google Scholar] [CrossRef] [Green Version]

- Hanif, I. Impact of Fóssil Fuels Energy Consumption, Energy Policies, and Urban Sprawl on Carbono Emissions in East Asia and Pacific: A Panel Investigation. Energy Strategy Rev. 2018, 21, 16–24. [Google Scholar] [CrossRef]

- Berga, L. The Role of Hydropower in Climate Change Mitigation and Adaptation: A Review. Engineering 2016, 2, 313–318. [Google Scholar] [CrossRef] [Green Version]

- Leite, P.T.; Carneiro, A.A.F.M.; Carvalho, A.C.P.L.F. Energetic Operation Planning Using Genetic Algorithms. IEEE Trans. Power Syst. 2002, 17, 173–179. [Google Scholar] [CrossRef]

- Soares, S.; Lyra, C.; Tavares, H. Optimal Generation Scheduling of Hydrothermal Power Systems. IEEE Trans. PAS 1980, 03, 1107–1118. [Google Scholar] [CrossRef]

- Anuradha; Sinha, S.K. Genetic Algorithm Based Hydrothermal Generation Scheduling. In Proceedings of the 2015 International Conference on Recent Developments in Control, Automation and Power Engineering, Noida, India, 12–13 March 2015; pp. 332–337. [Google Scholar]

- Zhang, H.; Yeu, D.; Xie, H.; Hu, S.; Weng, S. Pareto-dominance based adaptive multi-objective optimization for hydrothermal coordinated scheduling with environmental emission. Appl. Soft Comput. 2018, 69, 270–287. [Google Scholar] [CrossRef]

- Das, S.; Bhattacharya, A.; Chakraborty, A.K. Fixed head short-term hydrothermal scheduling in presence of solar and wind power. Energy Strategy Rev. 2018, 22, 47–60. [Google Scholar] [CrossRef]

- Feng, Z.; Niu, W.; Cheng, C. Optimizing electrical power production of hydropower system by uniform progressive optimality algorithm based on two-stage search mechanism and uniform design. J. Clean. Prod. 2018, 190, 432–442. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, Y.; Zhang, S.; Geng, S.; Wang, H.; Sang, G. An adaptive particle swarm optimization algorithm for reservoir operation optimization. Appl. Soft Comput. 2014, 18, 167–177. [Google Scholar] [CrossRef]

- Alencar, T.R.; Gramulia, J.; Otobe, R.F.; Asano, P.T. Decision support system based on Genetic Algorithms for optimizing the Operation Planning of Hydrothermal Power Systems. In Proceedings of the IEEE 5th International Youth Conference on Energy, Pisa, Italy, 27–30 May 2015. [Google Scholar]

- Molina, X.B.D.L.C.; Soares, S. Accuracy assessment of the long-term hydro simulation model used in Brazil based on post-operation data. In Proceedings of the 6th International Conference on Clean Electrical Power, Santa Margherita Ligure, Italy, 27–29 June 2017. [Google Scholar]

- Scarcelli, R.O.; Zambelli, M.S.; Filho, S.S.; Carneiro, A.A. Aggregated inflows on stochastic dynamic programming for long term hydropower scheduling. In Proceedings of the North American Power Symposium, Pullman, WA, USA, 7–9 September 2014. [Google Scholar]

- Queiroz, A.R. Stochastic hydro-thermal scheduling optimization: An overview. Renew. Sustain. Energy Rev. 2016, 62, 382–395. [Google Scholar] [CrossRef]

- Feng, Z.; Niu, W.; Cheng, C.; Wu, X. Optimization of large-scale hydropower system peak operation with hybrid dynamic programming and domain knowledge. J. Clean. Prod. 2017, 171, 390–402. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, P.; Cheng, L.; Wang, H.; Ming, B.; Gong, W. Deriving operating rules for a large-scale hydro-photovoltaic power system using implicit stochastic optimization. J. Clean. Prod. 2018, 195, 562–572. [Google Scholar] [CrossRef]

- De Jong, P.; Kiperstok, A.; Sanchez, A.S.; Dargaville, R.; Torres, E.A. Integrating large scale wind power into the electricity grid in the Northeast of Brazi. Energy 2015, 100, 401–415. [Google Scholar] [CrossRef]

- Raimundo, D.R.; dos Santos, I.F.S.; Filho, G.L.T.; Barros, R.M. Evaluation of greenhouse gas emissions avoided by wind generation in the Brazilian energetic matrix: A retroactive analysis and future potential. Resour. Conserv. Recycl. 2018, 137, 270–280. [Google Scholar] [CrossRef]

- Hoffmann, A.S.; de Carvalho, G.H.; Cardoso, R.A.F., Jr. Environmental licensing challenges for the implementation of photovoltaic solar energy projects in Brazil. Energy Policy 2018, 132, 1143–1154. [Google Scholar] [CrossRef]

- Carstens, D.D.S.; da Cunha, S.K. Challenges and opportunities for the growth of solar photovoltaic energy in Brazil. Energy Policy 2018, 125, 396–404. [Google Scholar] [CrossRef]

- Gul, E.; Kang, J. Multi-Objective Short-Term Integration of Hydrothermal Operation with Wind and Solar Power using Nonlinear Programming. Energy Procedia 2019, 158, 6274–6281. [Google Scholar] [CrossRef]

- Carvalho, M.; Soares, S. An efficient hydrothermal scheduling algorithm. IEEE Trans. Power Syst. 1987, 3, 537–542. [Google Scholar] [CrossRef]

- Rabêlo, R.A.L.; Carneiro, A.A.F.M.; Braga, R.T.V. Component-based development applied to energetic operation planning of hydrothermal power systems. In Proceedings of the IEEE Bucharest Power Tech Conference, Bucharest, Romania, 28 June–2 July 2009. [Google Scholar]

- De Aragão, A.P.; Asano, P.T.L.; Ferreira, F.G.; Rabêlo, R.A.L.; Coimbra, W.T. Development of a computational model based on particle swarm optimization and network flow applied to the problem of hydrothermal coordination. In Proceedings of the IEEE International Conference on Systems, Man, and Cybernetics, Banff, Canada, 5–8 October 2017. [Google Scholar]

- Alguacil, N.; Conejo, A.J. Multiperiod optimal power flow using Benders decomposition. IEEE Trans. Power Syst. 2000, 15, 196–201. [Google Scholar] [CrossRef]

- Almeida, K.C.; Conejo, A.J. Medium-term power dispatch in predominantly hydro systems: An equilibrium approach. IEEE Trans. Power Syst. 2013, 28, 2384–2394. [Google Scholar] [CrossRef]

- Bellman, R. Dynamic Programming; Princeton University: Princeton, NJ, USA, 1957. [Google Scholar]

- Pereira, M.V.F.; Pinto, L.M.V.G. Stochastic optimization of a multireservoir hydroelectric system: A decomposition approach. Water Resour. Res. 1985, 21, 779–792. [Google Scholar] [CrossRef]

- Leite, P.T.; Carneiro, A.; de Carvalho, A. Genetic operators setting for the operation planning of hydrothermal systems. In Proceedings of the VII Brazilian Symposium on Neural Networks, Pernambuco, Brazil, 11–14 November 2002; pp. 124–129. [Google Scholar]

- Chen, P.-H. Hydro plant dispatch using artificial neural network and genetic algorithm. IEEE Trans. Energy Convers. 2007, 4493, 1120–1129. [Google Scholar]

- Huang, S.-J. Enhancement of hydroelectric generation scheduling using ant colony system based optimization approaches. Int. Symp. Neural Networks 2007, 16, 296–301. [Google Scholar] [CrossRef]

- Gramulia Junior, J. An Approach Based on Genetic Algorithms for Management and Control of Interbasin Water Transfer in Contribution to Operation Planning of the Hydrothermal Systems (In Portuguese); Federal University of ABC (UFABC): Santo André - SP, Brazil, 2014. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995. [Google Scholar]

- Naderipour, A.; Abdul-Malek, Z.; Nowdeh, S.A.; Gandoman, F.H.; Moghaddam, M.J.H. A Multi-Objective Optimization Problem for Optimal Site Selection of Wind Turbines for Reduce Losses and Improve Voltage Profile of Distribution Grids. Energies 2019, 12, 2621. [Google Scholar] [CrossRef] [Green Version]

- Tolba, M.A.; Rezk, H.; Tulsky, V.; Diab, A.A.Z.; Abdelaziz, A.Y.; Vanin, A. Impact of Optimum Allocation of Renewable Distributed Generations on Distribution Networks Based on Different Optimization Algorithms. Energies 2018, 11, 245. [Google Scholar] [CrossRef] [Green Version]

- Matos, V.L.; Finardi, E.C.; da Silva, E.L. Comparison between the Energy Equivalent Reservoir per Subsystem and per Cascade in the Long-Term Operational Planning in Brazil. In Proceedings of the International Conference on Engineering Optimization, Rio de Janeiro, Brazil, 1–5 June 2008. [Google Scholar]

- Pham, M.H.; Vu, T.A.T.; Nguyen, D.Q.; Dang, V.H.; Ngueyn, N.T.; Ngueyn, T.V. Study on Selecting the Optimal Algorithm and the Effective Methodology to ANN-Based Short-Term Load Forecasting Model for the Southern Power Company in Vietnam. Energies 2019, 12, 2283. [Google Scholar] [CrossRef] [Green Version]

- Franco, P.E.C.; Carvalho, M.F.; Soares, S. A network flow model for short-term hydro-dominated hydrothermal scheduling problems. IEEE Trans. Power Syst. 1994, 9, 1016–1022. [Google Scholar] [CrossRef]

- Sherali, H.D.; Shetty, C.M.; Bazaraa, M.S. Nonlinear Programming: Theory and Algorithms; Wiley-Interscience: New Jersey, NJ, USA, 2018. [Google Scholar]

- EMAE—Henry Borden Hydroelectric Power Plant. (In Portuguese). Available online: Http://www.emae.com.br/conteudo.asp?id=Usina-Hidroeletrica-Henry-Borden (accessed on 13 June 2019).

- EMAE—Metropolitan Water and Energy Company S.A. Financial Statements. (In Portuguese). Available online: Http://www.emae.com.br/ri/arquivos.asp?id=9 (accessed on 1 June 2019).

- CBB—Central Bank of Brazil. Price Indices. (In Portuguese). Available online: Https://www.bcb.gov.br/controleinflacao/indicepreco (accessed on 13 June 2019).

- CBB—Central Bank of Brazil. Citizen Calculator. (In Portuguese). Available online: Https://www3.bcb.gov.br/CALCIDADAO/publico/exibirFormCorrecaoValores.do?method=exibirFormCorrecaoValores (accessed on 13 June 2019).

- ONS—National System Operator. Monthly Operation Program Report. (In Portuguese). Available online: Http://www.ons.org.br/AcervoDigitalDocumentosEPublicacoes/Informe%20do%20PMO%20-%20MAI%20RV4.pdf (accessed on 15 June 2019).

- CCEE—Electricity Trading Chamber. Newave - 25_L - 06/2019. (In Portuguese). Available online: Https://www.ccee.org.br/ccee/documentos/NW201906 (accessed on 15 June 2019).

- IEA—International Energy Agency. CO2 Emissions from Fuel Combustion: Highlights. Available online: Https://webstore.iea.org/co2-emissions-from-fuel-combustion-2018-highlights (accessed on 17 June 2019).

- CDM—Clean Development Mechanism. Tool to Calculate Project or Leakage CO2 Emissions from Fossil Fuel Combustion. Available online: Https://cdm.unfccc.int/methodologies/PAmethodologies/tools/am-tool-03-v2.pdf (accessed on 17 June 2019).

- Rochedo, P.R.R.; Costa, I.V.L.; Imperio, M.; Hoffmann, B.S.; Marschmann, P.R.C.; Oliveira, N.; Szklo, A. Carbon capture and costs Brazil. J. Clean. Prod. 2016, 131, 280–295. [Google Scholar] [CrossRef]

- Solarin, S.A.; Bello, M.O. Interfuel substituition, biomass consumption, economic growth, and sustainable development: Evidence from Brazil. J. Clean. Prod. 2018, 211, 1357–1366. [Google Scholar] [CrossRef]

| Condition | Barra Bonita | Promissão | Três Irmãos | Henry Borden | Total |

|---|---|---|---|---|---|

| without transfer | 82.24 | 154.36 | 330.30 | 20.53 | 588.03 |

| with transfer | 55.05 | 121.57 | 268.56 | 859.21 | 1304.38 |

| difference (2 − 1) | −27.19 | −32.79 | −61.74 | 838.68 | 716.96 |

| Condition | Barra Bonita | Promissão | Três Irmãos | Henry Borden | Total |

|---|---|---|---|---|---|

| without transfer | 74.27 | 149.62 | 310.11 | 23.84 | 557.85 |

| with transfer | 50.37 | 121.40 | 257.19 | 741.13 | 1170.09 |

| difference (2 − 1) | −23.90 | −28.22 | −52.92 | 717.29 | 612.24 |

| Year | Verified Generation (Average MW) | Verified Generation (GWh) | AGR () | |

|---|---|---|---|---|

| 2013 | 107.52 | 941.887 | 94,863,048.06 | 100.71 |

| 2014 | 102.70 | 736.244 | 99,540,879.25 | 135.20 |

| 2015 | 61.30 | 536.990 | 127,583,000.00 | 237.59 |

| 2016 | 102.70 | 901.240 | 153,668,000.00 | 170.50 |

| 2017 | 107.70 | 943.450 | 140,039,000.00 | 148.43 |

| 2018 | 57.54 | 504.050 | 153,668,000.00 | 520.70 |

| Average Verified Generation in Henry Borden | Average Verified Generation in Henry Borden | ||||

|---|---|---|---|---|---|

| Year | Verified Generation (GWh) | AGR () | Verified Generation (GWh) | AGR () | AGR Diference 2 − 1 () |

| 2013 | 941.89 | 94.86 | 2596.92 | 261.55 | 166.69 |

| 2014 | 736.24 | 99.54 | 2596.92 | 351.103 | 251.56 |

| 2015 | 536.99 | 127.58 | 2596.92 | 617.00 | 489.42 |

| 2016 | 901.24 | 153.67 | 2596.92 | 442.77 | 289.11 |

| 2017 | 943.45 | 140.04 | 2596.92 | 385.46 | 245.42 |

| 2018 | 504.05 | 262.46 | 2596.92 | 1352.21 | 1089.75 |

| Total | 4563.86 | 878.15 | 15,581.52 | 3410.10 | 2531.95 |

| Average Verified Generation in Henry Borden1 | Average Verified Generation in Henry Borden2 | ||||

|---|---|---|---|---|---|

| Year | Verified Generation (GWh) | AGR () | Verified Generation (GWh) | AGR () | AGR Diference 2 − 1 () |

| 941.89 | 94.86 | 3895.38 | 392.32 | 297.46 | |

| 2014 | 736.24 | 99.54 | 3895.38 | 526.65 | 427.11 |

| 2015 | 536.99 | 127.58 | 3895.38 | 925.50 | 797.92 |

| 2016 | 901.24 | 153.67 | 3895.38 | 664.16 | 510.49 |

| 2017 | 943.45 | 140.04 | 3895.38 | 578.19 | 438.15 |

| 2018 | 504.05 | 262.46 | 3895.38 | 2028.32 | 1765.86 |

| Total | 4563.86 | 878.15 | 23,372.28 | 5115.16 | 4237.00 |

| Year | Difference in Scenario 01 | Adjusted Value of Scenario 01 | Scenario in Scenario 02 | Adjusted Value of Scenario 02 |

|---|---|---|---|---|

| 2013 | 166,688,179.67 | 227,213,074.43 | 297,463,793.54 | 405,473,640.63 |

| 2014 | 251,562,639.85 | 330,816,720.00 | 427,114,399.41 | 561,675,552.31 |

| 2015 | 489,419,108.76 | 581,466,118.22 | 797,920,163.14 | 947,988,199.90 |

| 2016 | 289,106,778.16 | 320,597,907.44 | 510,494,167.24 | 566,100,050.70 |

| 2017 | 245,421,764.35 | 274,564,199.96 | 438,152,146.53 | 490,180,216.46 |

| 2018 | 1,089,754,994.06 | 1,111,415,945.04 | 1,765,862,991.10 | 1,800,962,873.19 |

| total | 2,531,953,464.86 | 2,846,073,965.09 | 4,237,007,660.94 | 4,772,380,533.19 |

| Power Plant | (MW) | VUC (R$/MWh) | Fuel | IP (%) | TEIF (%) | FCmax (%) | (MW) |

|---|---|---|---|---|---|---|---|

| Angra 2 | 1350 | 20.12 | Nuclear | 7.38 | 1.91 | 100 | 1226.49 |

| Angra 1 | 640 | 31.17 | Nuclear | 16.07 | 4.7 | 100 | 511.91 |

| M. Lago | 929 | 589.83 | Natural Gas | 1.7 | 9.79 | 100 | 823.80 |

| Uruguaiana | 640 | 486.20 | Natural Gas | 4.88 | 4.61 | 100 | 580.71 |

| P. Pecém 1 | 720 | 135.19 | Steam Coal | 5.1 | 14.09 | 100 | 587.01 |

| Mauá 3 | 591 | 68.46 | Natural Gas | 7.37 | 4.27 | 97 | 508.35 |

| Power Plant | (MW) | VUC (R$MWh) | Power per Year (MWh) | Total Cost per Year (R$) |

|---|---|---|---|---|

| Angra 2 | 1226.49 | 20.12 | 10,744,034.29 | 216,169,969.98 |

| Angra 1 | 511.91 | 31.17 | 4,484,295.30 | 139,775,484.46 |

| M. Lago | 823.80 | 589.83 | 7,216,523.34 | 4,256,521,963.98 |

| Uruguaiana | 580.71 | 486.20 | 5,086,965.25 | 2,473,282,502.58 |

| P. Pecém 1 | 587.01 | 135.19 | 5,142,171.23 | 695,170,128.38 |

| Mauá 3 | 508.35 | 68.46 | 4,453,106.12 | 304,859,644.66 |

| Fuel | Conversion Factor (MWh/TJ) | Carbon Content by Fuel Type (tC/TJ) | Carbon Oxidation Factor (%) |

|---|---|---|---|

| Sugarcane Bagasse | 0.0036 | 29.90 | 100 |

| Steam Coal | 0.0036 | 25.80 | 100 |

| Natural Gas | 0.0036 | 15.30 | 100 |

| Fuel Oil | 0.0036 | 21.10 | 100 |

| Diesel Oil | 0.0036 | 20.20 | 100 |

| Fuel | Power (MW) | Energy per Year (MWh) | Energy per Year (TJ) | Quantity of CO2 per Year (tC) |

|---|---|---|---|---|

| Sugarcane Bagasse | 859.34 | 7,424,697.60 | 26,728.91 | 799,194.45 |

| Steam Coal | 859.34 | 7,424,697.60 | 26,728.91 | 689,605.91 |

| Natural Gas | 859.34 | 7,424,697.60 | 26,728.91 | 408,952.34 |

| Fuel Oil | 859.34 | 7,424,697.60 | 26,728.91 | 563,980.03 |

| Diesel Oil | 859.34 | 7,424,697.60 | 26,728.91 | 539,924.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Passos de Aragão, A.; Teixeira Leite Asano, P.; de Andrade Lira Rabêlo, R. A Reservoir Operation Policy Using Inter-Basin Water Transfer for Maximizing Hydroelectric Benefits in Brazil. Energies 2020, 13, 2564. https://doi.org/10.3390/en13102564

Passos de Aragão A, Teixeira Leite Asano P, de Andrade Lira Rabêlo R. A Reservoir Operation Policy Using Inter-Basin Water Transfer for Maximizing Hydroelectric Benefits in Brazil. Energies. 2020; 13(10):2564. https://doi.org/10.3390/en13102564

Chicago/Turabian StylePassos de Aragão, Anderson, Patrícia Teixeira Leite Asano, and Ricardo de Andrade Lira Rabêlo. 2020. "A Reservoir Operation Policy Using Inter-Basin Water Transfer for Maximizing Hydroelectric Benefits in Brazil" Energies 13, no. 10: 2564. https://doi.org/10.3390/en13102564

APA StylePassos de Aragão, A., Teixeira Leite Asano, P., & de Andrade Lira Rabêlo, R. (2020). A Reservoir Operation Policy Using Inter-Basin Water Transfer for Maximizing Hydroelectric Benefits in Brazil. Energies, 13(10), 2564. https://doi.org/10.3390/en13102564