Greenhouse Gas Reduction Effect of Solar Energy Systems Applicable to High-rise Apartment Housing Structures in South Korea

Abstract

:1. Introduction

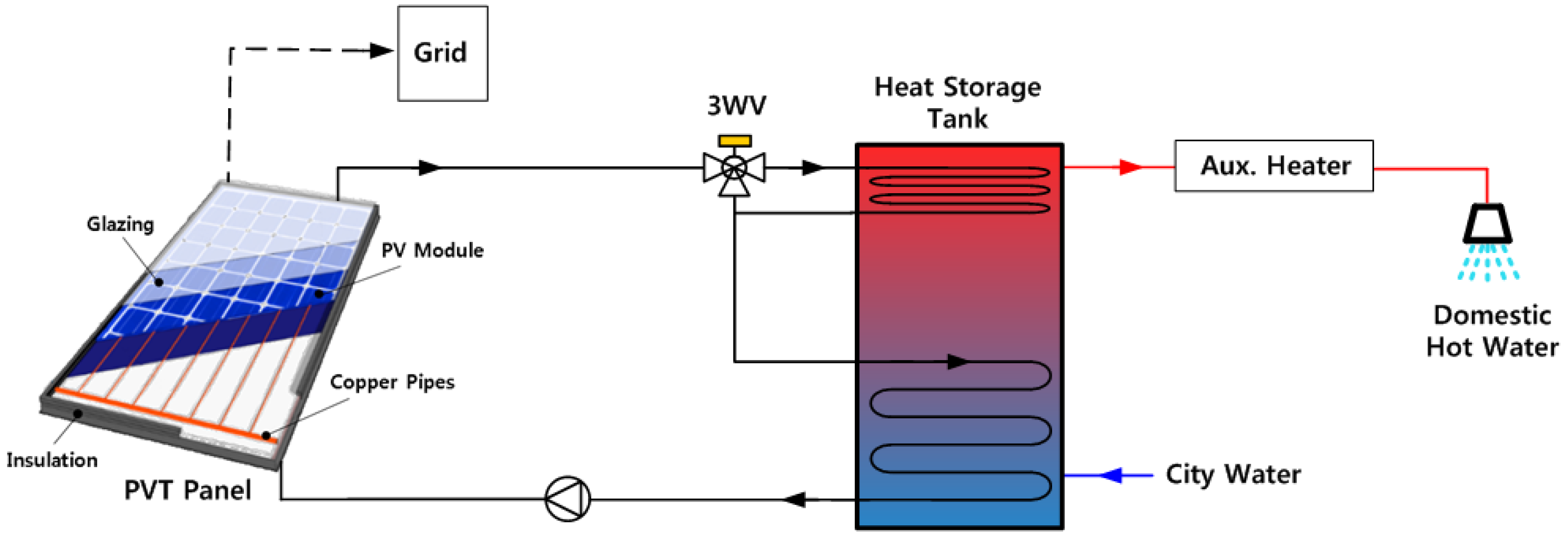

2. Simulation Method and System Modeling

3. Experimental Results and Discussion

3.1. CO2 Calculation Method

- Ton of oil equivalent (toe) = LNG Conversion (Nm3) × LNG Lower Heating Value (toe/Nm3)

- C emission (ton_C) = Ton of oil equivalent (toe) × LNG Carbon emission factor (ton_C/toe)

- CO2 emission (ton_CO2) = (CO2 (Molar mass 44)/C (Molar mass 12)) × C emission (ton_C)

- Example) 200 MJ energy production in Jan. when slope is 45°. Boiler efficiency 90%, City gas (LNG) LHV Conversion value is 5.64 Nm3

- Ton of oil equivalent(toe): 5.64 Nm3 × 0.942 × 10−3 toe/Nm3 = 5.31 × 10−3 toe

- C emission: 5.31 × 10−3 toe × 0.637 ton_C/toe = 3.38 × 10−3 ton_C

- CO2 emission: (44/12) × 3.38×10−3 ton_C = 12.39 × 10−3 ton_CO2

- Carbon (C) emission (kg_C) = Electrical energy production (kWh) × Carbon emission factor of electrical energy (kg_C/kWh)

- Carbon dioxide (CO2) emission (kg_CO2) = (CO2 (Molar mass 44)/C (Molar mass 12)) × Carbon emission (kg_C)

- Example) 10 kWh energy production in Jan. when slope is 45°.

- C emission: 10 kWh × 0.1319 kg_C/kWh = 1.319 kg_C → 1.4 × 10−3 ton_C

- CO2 emission: (44/12) × 1.319 kg_C = 4.84 kg_CO2 → 4.84 × 10−3 ton_CO2

3.2. Energy Production and CO2 Reduction by Slope

3.3. Influence of Azimuth

4. Conclusions

- All three systems showed maximum CO2 reduction values at 35° facing south, and PV, ST, and PVT showed reductions of 67.4, 114.6, and 144.7 kg_CO2/m2·year, respectively.

- If installed on a vertical wall, the CO2 reduction will decrease by about 35–40% compared to the maximum value, and the reduction will be about 20% less than maximum when installed at a slope of 75°. If it maintains harmony with the building, slightly inclined installation is better than vertical installation.

- Regardless of the slope and azimuthal angle, ST has 1.6 times and PVT has 2.1 times greater CO2 reduction than the PV which is most widely used in buildings.

- It should be noted that ST (almost the same) and PVT (1.4 times) installed on vertical walls have a greater greenhouse gas reduction effect than PV installed at the optimal slope of 35°.

- Since the decreased rate of CO2 reduction when installed facing SW and SE is within 10% of the south facing reduction, ST and PVT are recommended for installation on walls or balconies with an azimuthal angle of S ± 45°.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Thermal energy production rate of PVT (W) | |

| Electrical energy production rate of PV (kWh/m2) | |

| Thermal energy production of PVT (MJ/m2) | |

| Area of PVT solar collector (m2) | |

| Collector heat removal factor | |

| Solar radiation absorbed by a collector (W/m2) | |

| Collector overall heat loss coefficient (W/m2∙K) | |

| PVT inlet temperature (°C) | |

| PVT ambient temperature (°C) | |

| Electric energy production rate of PVT (W) | |

| Transmittance-absorptance product of solar collector | |

| The incident angle modifier | |

| The total radiation incident upon the collector surface (kW/m2) | |

| PV cell efficiency of PVT (%) | |

| PV cell efficiency of PVT at reference condition (%) | |

| Efficiency modifier (temperature), STC (1/K) | |

| Efficiency modifier (incident radiation), STC (h∙m2/kJ) | |

| Annual thermal efficiency of PV/PVT (%) | |

| Annual electrical efficiency of ST/PVT (%) | |

| Annual solar fraction | |

| Rate of thermal energy required for hot water (W) | |

| Rate of thermal energy used as auxiliary heater (W) |

References

- MOTIE. To Respond to the New Climate System ⌈2030 New Industry of Energy Expansion Strategy⌋; Ministry of Trade, Industry and Energy: Seoul, Korea, 2015. [Google Scholar]

- Noh, J.Y.; Hwang, D.K. Solar Hot Water System and Photovoltaic System Performance Analysis in an Apartment. In Proceedings of the SAREK Summer Annual Conference, Yongpyong, Korea, 26–28 June 2013; pp. 339–342. [Google Scholar]

- Kim, J.S.; Lee, E.J.; Hwang, J.H. A Study on Electric Capacity and CO2 by the Roof Top PV System of the Industrial Building in Korea. J. Korean Sol. Energy Soc. 2010, 30, 131–136. [Google Scholar]

- KEA. Renewable Energy Trend Data; Korea Energy Agency: Yongin, Korea, 2014. [Google Scholar]

- De, R.K.; Ganguly, A. Energy, Exergy and Economic Analysis of a Solar Hybrid Power System Integrated Double-Effect Vapor Absorption System-Based Cold Storage. Int. J. Air Cond. Ref. 2019, 26, 1950018. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.S.; Park, H.S.; Yoon, H.K. A Comparative Analysis on the Generation Efficiencies of the Photovoltaic Systems and Building Integrated Photovoltaic Systems. J. Arch. Inst. Korea Plan. Des. 2013, 29, 37–44. [Google Scholar]

- Hestnes, A.G. Building Integration of Energy Systems. Sol. Energy 1999, 67, 181–187. [Google Scholar] [CrossRef]

- Yang, T.; Athienitis, A.K. Experimental Investigation of a Two-Inlet Air-Based Building Integrated Photovoltaic/Thermal (BIPV/T) System. Appl. Energy 2015, 159, 70–79. [Google Scholar] [CrossRef]

- Motte, F.; Notton, G.; Christian, C.; Canaletti, J.-L. Design and Modelling of a New Patented Thermal Solar Collector with High Building Integration. Appl. Energy 2013, 102, 631–639. [Google Scholar] [CrossRef]

- Yoon, J.H. The Latest Technology of Building Integrated Photovoltaic(BIPV) and Solar Thermal(BIST) Systems. Constr. Technol. Rev. Ssangyong 2011, 59, 4–9. [Google Scholar]

- Leone, G.; Beccali, M. Use of Finite Element Models for Estimating Thermal Performance of Facade-Integrated Solar Thermal Collector. Appl. Energy 2016, 171, 392–404. [Google Scholar] [CrossRef]

- Shi, J.; Su, W.; Zhu, M.; Chen, H.; Pan, Y.; Wan, S.; Wang, Y. Solar Water Heating System Integrated Design in High-Rise Apartment in China. Energy Build. 2013, 58, 19–26. [Google Scholar] [CrossRef]

- Windholz, B.; Zauner, C.; Rennhofer, M.; Schranzhofer, H. Solar Thermal Energy Conversion and Photovoltaics in a Multifunctional Façade. In Proceedings of the CISBAT, Lausanne, Switzerland, 14–16 September 2011. [Google Scholar]

- Luo, X.; Hou, Q.; Wang, Y.; Xin, D.; Gao, H.; Zhao, M.; Gu, Z. Experimental on a Novel Solar Energy Heating System for Residential Buildings in Cold Zone of China. Procedia Eng. 2017, 205, 3061–3066. [Google Scholar] [CrossRef]

- KEEI. 2014 Energy Consumption Saurvey; Korea Energy Economics Institute: Ulsan, Korea, 2015. [Google Scholar]

- KEA. New & Renewable Energy Supply Statistics 2014, 2015 ed.; Korea Energy Agency: Yongin, Korea, 2015. [Google Scholar]

- Yoon, J.H.; Sim, S.R.; Shin, U.C.; Kwak, H.Y. A Study on the Optimum Application Method of Solar Thermal System to reduce Thermal Load and Carbon Emission in Apartment Building. J. Korean Sol. Energy Soc. 2011, 31, 135–142. [Google Scholar] [CrossRef] [Green Version]

- Shrivastava, R.; Kumar, V.; Untawale, S. Modeling and Simulation of Solar Water Heater: A TRNSYS Perspective. Renew. Sustain. Energy Rev. 2017, 67, 126–143. [Google Scholar] [CrossRef]

- Valdiserri, P. Evaluation and control of thermal losses and solar fraction in a hot water solar system. Int. J. Low Carbon Technol. 2018, 13, 260–265. [Google Scholar] [CrossRef]

- Nasruddin, M.I.; Lubis, A.; Satio, K.; Yabase, H.; Aisyah, N. Energy Analysis for the Solar Thermal Cooling System in Universitas Indonesia. Int. J. Air Cond. Ref. 2019, 26, 1950023. [Google Scholar]

- Dubey, S.; Subiantoro, A. Numerical Study of Integrated Solar Photovoltaic Thermal Module with a Refrigeration System for Air-Conditioning and Hot Water Production under the Tropical Climate Conditions of Singapore. Int. J. Air Cond. Ref. 2018, 26, 1850021. [Google Scholar] [CrossRef]

- Her, E.J.; Bae, S.; Kim, J.M.; Nam, Y. Feasibility Analysis based on Energy Simulation of PVT Hot Water System. Korean J. Air Cond. Ref. Eng. 2019, 31, 312–321. [Google Scholar]

- Pressani, M.; Sommerfeldt, N.; Madani, H. Investigation of PV/Thermal Collector Models for Use with Ground Source Heat Pumps in Transient Simulations. In Proceedings of the EuroSun Conference, Palma de Mallorca, Spain, 19 August 2016. [Google Scholar]

- Klein, S.A. TRNSYS18 Base Manual; KES Tech: Kocaeli, Turkey, 2019. [Google Scholar]

- Kim, J.H.; Li, L.; Lee, U.J.; Hong, H. Performance Enhancement of Solar Thermal Storage Tank with Heat Exchange Coils (Part 2: Simulation). Korean J. Air Cond. Ref. Eng. 2016, 28, 361–366. [Google Scholar]

- Son, H.S.; Kwon, J.W.; Lee, S.H.; Kim, C.; Hong, H. The effect of upper-heating system in solar water storage tank. Int. J. Air Cond. Ref. 2014, 22, 1450027. [Google Scholar] [CrossRef]

- Cardinale, N.; Piccininni, F.; Stefanizzi, P. Economic Optimization of Low-Flow Solar Domestic Hot Water Plants. J. Renew. Energy 2003, 28, 1899–1914. [Google Scholar] [CrossRef]

- Korea Meteorological Administration. Available online: https://www.weather.go.kr/weather/main.jsp (accessed on 12 May 2020).

- KEC. Guidelines for Local Government Greenhouse Gas Inventories; Korea Environment Corporation: Sungnam, Korea, 2017. [Google Scholar]

- Ozgoren, M.; Aksoy, M.; Bakir, C.; Dogan, S. Experimental Performance Investigation of Photovoltaic/Thermal (PV–T) System. In Proceedings of the EPJ Web of Conferences, Caen, France, 28–31 May 2013; EDP Sciences: Les Ulis, France, 2013; p. 01106. [Google Scholar]

- Kwon, O.H.; Lee, K.S. Photovoltaic System Energy Performance Analysis Using Meteorological Monitoring Data. J. Korean Sol. Energy Soc. 2018, 38, 11–31. [Google Scholar]

- Bergin, M.H.; Ghoroi, C.; Dixit, D.; Schauer, J.J.; Shindell, D.T. Large Reductions in Solar Energy Production Due to Dust and Particulate Air Pollution. Environ. Sci. Technol. Lett. 2017, 4, 339–344. [Google Scholar] [CrossRef] [Green Version]

| Component | Category | Unit | Value | |

|---|---|---|---|---|

| Collector | Area (Gross) | m2 | 2.09 | |

| Fluid heat capacity | kJ/kg∙K | 3.7 | ||

| Tested flow rate | kg/s∙m2 | 0.01835 | ||

| Intercept efficiency | - | 0.6997 | ||

| Efficiency slope | W/m2∙K | 3.6964 | ||

| Efficiency curvature | W/m2∙K2 | 0.0104 | ||

| Storage tank | Volume | L | 200 | |

| Height | m | 1.1 | ||

| Material of heat exchanger | - | STS 304 | ||

| Upper heat exchanger (smooth tube) | Diameter Length | m | ||

| Height (Inlet, Outlet) | m | 0.962 0.881 | ||

| Lower heat exchanger (smooth tube) | Diameter Length | m | ||

| Height (Inlet, Outlet) | m | 0.175 0.067 | ||

| Pump | Maximum flow rate | kg/s | 0.073 | |

| Maximum power | W | 16.7 | ||

| Category | Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp (°C) | 8.0 | 6.1 | 6.4 | 9.4 | 13.4 | 17.2 | 20.9 | 23.4 | 23.2 | 20.7 | 16.6 | 11.7 |

| Category | Unit | Value |

|---|---|---|

| Module size | m2 | 2.09 |

| Open circuit voltage (Voc) | V | 48.8 |

| Short circuit current (Isc) | A | 8.77 |

| Maximum power (Pmax) | W | 332.6 |

| Voltage at maximum power (Vmpp) | V | 39.6 |

| Current at maximum power (Impp) | A | 8.41 |

| Fill factor | % | 77.7 |

| Module efficiency() | % | 15.9 |

| Number of cells | ea | 72 |

| Cell size | cm2 | 242.7 |

| Collector | Type | Flat Plate Solar Collector | ||||

| Size | ||||||

| Area | Gross Area: 2.09m2, Transmission Area: 1.92m2 | |||||

| Tested flow rate | 0.0385 kg/s | |||||

| Intercept efficiency | 0.5299 | |||||

| Efficiency slope | 4.5752 W/m2∙K | |||||

| Efficiency curvature | 0.0206 W/m2∙K2 | |||||

| Absorber plate | Material: A.L Plate, Titanium coated aluminum absorber | |||||

| Coating | Titanium coating | |||||

| Absorptivity | 95.1% | |||||

| Reflectance | 3.7% | |||||

| Tube | Material: Copper | |||||

| Operating fluid | 15% Propylene glycol | |||||

| Insulator | Material | Thickness (mm) | Density (kg/m3) | Heat-resisting Temperature (°C) | Thermal Conductivity (W/m∙K) | |

| Side | EPDM | 10 | 45 | 409 | 0.033 | |

| Bottom | EPDM | 20 | 45 | 409 | 0.033 | |

| Category | Unit | Upper | Lower | Carbon Emission Factor | |||||

|---|---|---|---|---|---|---|---|---|---|

| MJ | kcal | ×10−3 toe | MJ | kcal | ×10−3 toe | kg_C/GJ | ton_C/toe | ||

| Crude oil | kg | 44.9 | 10,730 | 1.073 | 42.2 | 10,080 | 1.008 | 20.00 | 0.829 |

| Gasoline | L | 32.6 | 7780 | 0.778 | 30.3 | 7230 | 0.723 | 18.90 | 0.783 |

| Kerosene oil | L | 36.8 | 8790 | 0.879 | 34.3 | 8200 | 0.820 | 19.60 | 0.812 |

| Diesel oil | L | 37.7 | 9010 | 0.901 | 35.3 | 8420 | 0.842 | 20.20 | 0.837 |

| Natural gas (LNG) | kg | 54.6 | 13,040 | 1.304 | 49.3 | 11,780 | 1.178 | 17.20 | 0.630 |

| City gas (LNG) | Nm3 | 43.6 | 10,430 | 1.043 | 39.4 | 9420 | 0.942 | 15.30 | 0.637 |

| City gas (LPG) | Nm3 | 62.8 | 15,000 | 1.500 | 57.7 | 13,780 | 1.378 | 17.20 | 0.713 |

| Electricity (generation) | kWh | 8.8 | 2110 | 0.211 | 8.8 | 2110 | 0.211 | 0.1319 kg_C/kWh | |

| Electricity (consumption) | kWh | 9.6 | 2300 | 0.230 | 9.6 | 2300 | 0.230 | - | |

| Category | 20° | 35° | 75° | 90° | |

|---|---|---|---|---|---|

| PV | kWh/m2 | 137.4 | 139.4 | 111.9 | 90.9 |

| kg_CO2/m2 | 66.4 | 67.4 | 54.1 | 44.0 | |

| Decreasing rate (%) | −1.5 | 0.0 | −19.7 | −34.7 | |

| ST | MJ/m2 | 1756.1 | 1846.6 | 1427.8 | 1087.6 |

| kg_CO2/m2 | 109.0 | 114.6 | 88.6 | 67.5 | |

| Decreasing rate (%) | −4.9 | 0.0 | −22.7 | −41.1 | |

| PVT | kWh/m2 | 170.9 | 173.4 | 136.9 | 107.9 |

| MJ/m2 | 949.9 | 980.5 | 751.3 | 563.6 | |

| kg_CO2/m2 | 141.6 | 144.7 | 112.8 | 87.2 | |

| Decreasing rate (%) | −2.1 | 0.0 | −22.0 | −39.8 | |

| Category | Energy (PV: kWh/m2, ST: MJ/m2) | CO2 Reduction (kg_CO2/m2) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20° | 35° | 75° | 90° | 20° | 35° | 75° | 90° | ||||||

| PV | ST | PV | ST | PV | ST | PV | ST | ||||||

| PV | E | 118.6 | 111.9 | 83.3 | 70.3 | 57.3 | 54.1 | 40.3 | 34.0 | ||||

| SE | 131.5 | 131.3 | 102.9 | 85.5 | 63.6 | 63.5 | 49.8 | 41.3 | |||||

| S | 137.4 | 139.4 | 111.9 | 90.9 | 66.4 | 67.4 | 54.1 | 44.0 | |||||

| SW | 132.7 | 133.0 | 105.8 | 88.1 | 64.2 | 64.3 | 51.2 | 42.6 | |||||

| W | 120.2 | 114.3 | 86.4 | 73.0 | 58.1 | 55.3 | 41.8 | 35.3 | |||||

| ST | E | 1430.6 | 1377.2 | 942.6 | 701.9 | 88.8 | 85.4 | 58.5 | 43.5 | ||||

| SE | 1651.6 | 1698.8 | 1297.7 | 984.9 | 102.5 | 105.4 | 80.5 | 61.1 | |||||

| S | 1756.1 | 1846.6 | 1427.8 | 1087.6 | 109.0 | 114.6 | 88.6 | 67.5 | |||||

| SW | 1707.8 | 1793.8 | 1439.5 | 1125.5 | 106.0 | 111.3 | 89.3 | 69.8 | |||||

| W | 1506.7 | 1499.0 | 1108.7 | 863.2 | 93.5 | 93.0 | 68.8 | 53.6 | |||||

| PVT | E | 144.0 | 788.0 | 130.2 | 734.6 | 81.7 | 461.1 | 62.4 | 338.0 | 118.5 | 108.5 | 68.1 | 51.1 |

| SE | 162.3 | 897.2 | 159.4 | 900.9 | 118.2 | 655.0 | 93.1 | 488.6 | 134.2 | 133.0 | 97.8 | 75.3 | |

| S | 170.9 | 949.9 | 173.4 | 980.5 | 136.9 | 751.3 | 107.9 | 563.6 | 141.6 | 144.7 | 112.8 | 87.2 | |

| SW | 163.6 | 927.1 | 161.3 | 949.1 | 121.0 | 740.7 | 95.7 | 584.9 | 136.7 | 136.9 | 104.5 | 82.6 | |

| W | 145.7 | 830.9 | 132.6 | 804.8 | 84.9 | 568.0 | 65.4 | 444.6 | 122.0 | 114.0 | 76.3 | 59.2 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.-H.; Ko, Y.-J.; Kim, J.-H.; Hong, H. Greenhouse Gas Reduction Effect of Solar Energy Systems Applicable to High-rise Apartment Housing Structures in South Korea. Energies 2020, 13, 2568. https://doi.org/10.3390/en13102568

Park C-H, Ko Y-J, Kim J-H, Hong H. Greenhouse Gas Reduction Effect of Solar Energy Systems Applicable to High-rise Apartment Housing Structures in South Korea. Energies. 2020; 13(10):2568. https://doi.org/10.3390/en13102568

Chicago/Turabian StylePark, Chang-Hyun, Yu-Jin Ko, Jong-Hyun Kim, and Hiki Hong. 2020. "Greenhouse Gas Reduction Effect of Solar Energy Systems Applicable to High-rise Apartment Housing Structures in South Korea" Energies 13, no. 10: 2568. https://doi.org/10.3390/en13102568