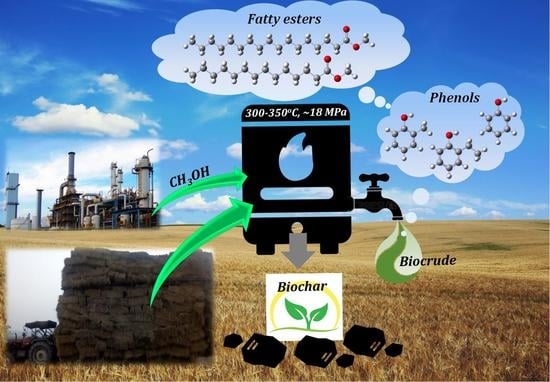

Hydrothermal Liquefaction of Rice Straw Using Methanol as Co-Solvent

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Feedstock Characterization

2.2. HTL Reactor

2.3. Experimental Procedure

2.4. Product Characterization

3. Results and Discussion

3.1. Effect of Temperature and Reaction Time

3.2. Effect of Rice-Straw-to-Water Ratio

3.3. Influence of Methanol as a Co-Solvent

3.4. Role of Alkali Catalysts

3.5. Bio-Crude Composition

3.6. Process Energy Balance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- McLaughlin, O.; Mawhood, B.; Jamieson, C.; Slade, R. Rice straw for bioenergy: The effectiveness of policymaking and implementation in Asia. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1540–1554. [Google Scholar] [CrossRef]

- Sarma, S.D. Paddy Residue Burning: Drivers, Challenges and Potential Solutions. Available online: http://www.teriin.org/article/paddy-residue-burning-drivers-challenges-and-potential-solutions (accessed on 20 March 2020).

- Nanda, S.; Mohammad, J.; Reddy, S.N.; Kozinski, J.A.; Dalai, A.K. Pathways of lignocellulosic biomass conversion to renewable fuels. Biomass. Conv. Bioref. 2014, 4, 157–191. [Google Scholar] [CrossRef]

- Zhou, X.; Broadbelt, L.J.; Vinu, R. Mechanistic understanding of thermochemical conversion of polymers and lignocellulosic biomass. In Advances in Chemical Engineering: Thermochemical Process Engineering; Van Geem, K., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 49, pp. 95–198. [Google Scholar]

- Tekin, K.; Karagöz, S.; Bektaş, S. A review of hydrothermal biomass processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Peterson, A.A.; Vogel, F.; Lachance, R.P.; Froling, M.; Antal, J.M.J.; Tester, J.W. Thermochemical biofuel production in hydrothermal media: A review of sub and supercritical water technologies. Energy Environ. Sci. 2008, 1, 32–65. [Google Scholar] [CrossRef]

- Toor, S.S.; Rosendahl, L.; Rudolf, A. Hydrothermal liquefaction of biomass: A review of subcritical water technologies. Energy 2011, 36, 2328–2342. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, F.S. Effects of various solvents on the liquefaction of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 2008, 49, 3498–3504. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Lin, H.; Zheng, Y.; Zhao, J.; Pelletier, A.; Li, K. Effects of solvents and catalysts in liquefaction of pinewood sawdust for the production of bio-crudes. Biomass Bioenergy 2013, 59, 158–167. [Google Scholar] [CrossRef]

- Zhu, W.W.; Zong, Z.M.; Yan, H.L.; Zhao, Y.P.; Lu, Y.; Wei, X.Y.; Zhang, D. Cornstalk liquefaction in methanol/water mixed solvent. Fuel Process. Technol. 2014, 117, 1–7. [Google Scholar] [CrossRef]

- Piǹkowska, H.; Wolak, P.; Zƚociǹska, A. Hydrothermal decomposition of alkali lignin in sub- and supercritical water. Chem. Eng. J. 2012, 187, 410–414. [Google Scholar] [CrossRef]

- Yuan, Z.; Cheng, S.; Leitch, M.; Xu, C. Hydrolytic degradation of alkaline lignin in hot-compressed water and ethanol. Bioresour. Technol. 2010, 101, 9308–9313. [Google Scholar] [CrossRef]

- Malins, K.; Kampars, V.; Brinks, J.; Neibolte, I.; Murnieks, R.; Kampare, R. Bio-crude from thermo-chemical hydro-liquefaction of wet sewage sludge. Bioresour. Technol. 2015, 187, 23–29. [Google Scholar] [CrossRef]

- Zhang, B.; Keitz, M.; Valentas, K. Thermal effects on hydrothermal biomass liquefaction. Appl. Biochem. Biotechnol. 2008, 147, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Wei, N.; Via, B.K.; Wang, Y.; McDonald, T.; Auad, M.L. Liquefaction and substitution of swichgrass (Panicum virgatum) based bio-crude into epoxy resins. Ind. Crop. Prod. 2014, 57, 116–123. [Google Scholar] [CrossRef]

- Valdez, P.J.; Savage, P.E. A reaction network for the hydrothermal liquefaction of Nannochloropsis sp. Algal. Res. 2013, 2, 416–425. [Google Scholar] [CrossRef]

- Valdez, P.J.; Tocco, V.J.; Savage, P.E. A general kinetic model for the hydrothermal liquefaction of microalgae. Bioresour. Technol. 2014, 163, 123–127. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Li, H.; Zeng, G.M.; Tong, J.Y.; Xie, W. Sub- and supercritical liquefaction of rice straw in the presence of ethanol-water and 2-propanol-water mixture. Energy 2007, 32, 2081–2088. [Google Scholar] [CrossRef]

- Li, H.; Yuan, X.; Zeng, G.; Tong, J.; Yan, Y.; Cao, H.; Wang, L.; Cheng, M.; Zhang, J.; Yang, D. Liquefaction of rice straw in sub- and supercritical 1,4-dioxane-water mixture. Fuel Process. Technol. 2009, 90, 657–663. [Google Scholar] [CrossRef]

- Singh, R.; Chaudhary, K.; Biswas, B.; Balagurumurthy, B.; Bhaskar, T. Hydrothermal liquefaction of rice straw: Effect of reaction environment. J. Supercrit. Fluids 2015, 104, 70–75. [Google Scholar] [CrossRef]

- Zhou, C.; Zhu, X.; Qian, F.; Shen, W.; Xu, H.; Zhang, S.; Chen, J. Catalytic hydrothermal liquefaction of rice straw in water/ethanol mixtures for high yields of monomeric phenols using reductive CuZnAl catalyst. Fuel Process. Technol. 2016, 154, 1–6. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, C.; Hao, S.; Luo, G.; Zhang, S.; Chen, J. Effect of glycerol as co-solvent on yields of bio-crude from rice straw through hydrothermal liquefaction. Bioresour. Technol. 2016, 220, 471–478. [Google Scholar] [CrossRef]

- Castello, D.; Pedersen, T.H.; Rosendahl, L.A. Continuous hydrothermal liquefaction of biomass: A critical review. Energies 2018, 11, 3165. [Google Scholar] [CrossRef] [Green Version]

- Brand, S.; Kim, J. Liquefaction of major lignocellulosic biomass constituents in supercritical ethanol. Energy 2015, 80, 64–74. [Google Scholar] [CrossRef]

- Saraswat, V.K.; Bansal, R. India’s Leapfrog to Methanol Economy. Available online: http://niti.gov.in/writereaddata/files/document_publication/Article%20on%20Methanol%20Economy_Website.pdf (accessed on 20 March 2020).

- ASTM E1131-08. Standard Test Method for Compositional Analysis by Thermogravimetry. Available online: http://www.astm.org/Standards/E1131.htm (accessed on 20 March 2020).

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Chopra, J.; Mahesh, D.; Yerrayya, A.; Vinu, R.; Rajnish, K.; Sen, R. Performance enhancement of hydrothermal liquefaction for strategic and sustainable valorization of de-oiled yeast biomass into green bio-crude. J. Clean. Prod. 2019, 227, 292–301. [Google Scholar] [CrossRef]

- Run-dong, L.; Bing-shuo, L.; Tian-hua, Y.; Ying-hui, X. Liquefaction of rice stalk in sub- and supercritical ethanol. J. Fuel Chem. Technol. 2013, 41, 1459–1465. [Google Scholar]

- Francis, H.E.; Lloyd, W.G. Predicting heating value from elemental composition. J. Coal Qual. 1983, 2, 2. [Google Scholar]

- Nam, H.; Capareda, S.C.; Ashwath, N.; Kongkasawan, J. Experimental investigation of pyrolysis of rice straw using bench-scale auger, batch and fluidized bed reactors. Energy 2015, 93, 2384–2394. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lee, M.K.; Chang, Y.M. Fast pyrolysis of rice straw, sugarcane bagasse and coconut shell in an induction-heating reactor. J. Anal. Appl. Pyrol. 2006, 76, 230–237. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Pedersen, T.H.; Jasiūnas, L.; Casamassima, L.; Singh, S.; Jensen, T.; Rosendahl, L.A. Synergetic hydrothermal co-liquefaction of crude glycerol and aspen wood. Energy Convers. Manag. 2015, 106, 886–889. [Google Scholar] [CrossRef] [Green Version]

- Feng, S.; Wei, R.; Leitch, M.; Xu, C.C. Comparative study on lignocellulose liquefaction in water, ethanol, and water/ethanol mixture: Roles of ethanol and water. Energy 2018, 155, 234–241. [Google Scholar] [CrossRef]

- Panagiotopoulou, P.; Vlachos, D.G. Liquid phase catalytic transfer hydrogenation of furfural over a Ru/C catalyst. Appl. Catal. A Gen. 2014, 480, 17–24. [Google Scholar] [CrossRef]

- Li, H.; Yuan, X.; Zeng, G.; Huang, D.; Huang, H.; Tong, J.; You, Q.; Zhang, J.; Zhou, M. The formation of bio-oil from sludge by deoxy-liquefaction in supercritical ethanol. Bioresour. Technol. 2010, 101, 2860–2866. [Google Scholar] [CrossRef] [PubMed]

- Sing, S.K.; Ekhe, J.D. Towards effective lignin conversion: HZSM-5 catalysed one-pot solvolytic depolymerisation/ hydrodeoxygenation of lignin into value added compounds. RSC Adv. 2014, 4, 27971–27978. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S. Non-catalytic and catalytic hydrothermal liquefaction of biomass. Res. Chem. Intermed. 2013, 39, 485–498. [Google Scholar] [CrossRef]

- Minowa, T.; Kondo, T.; Sudirjo, S.T. Thermochemical liquefaction of Indonesian biomass residues. Biomass Bioenergy 1998, 14, 517–524. [Google Scholar] [CrossRef]

- Zhu, Z.; Toor, S.S.; Rosendahl, L.; Yu, D.; Chen, G. Influence of alkali catalyst on product yield and properties via hydrothermal liquefaction of barley straw. Energy 2015, 80, 284–292. [Google Scholar] [CrossRef]

- Singh, R.; Prakash, A.; Dhiman, S.K.; Balagurumurthy, B.; Arora, A.K.; Puri, S.K.; Bhaskar, T. Hydrothermal conversion of lignin to substituted phenols and aromatic ethers. Bioresour. Technol. 2014, 165, 319–322. [Google Scholar] [CrossRef]

- Pelzer, A.W.; Sturgeon, M.R.; Yanez, A.J.; Chupka, G.; O’Brien, M.H.; Katahira, R.; Cortright, R.D.; Woods, L.; Beckham, G.T.; Broadbelt, L.J. Acidolysis of α-O-4 aryl-ether bonds in lignin model compounds: A modeling and experimental study. ACS Sustain. Chem. Eng. 2015, 3, 1339–1347. [Google Scholar] [CrossRef]

- Liu, A.; Park, Y.; Huang, Z.L.; Wang, B.W.; Ankumah, R.O.; Biswas, P.K. Product identification and distribution from hydrothermal conversion of walnut shells. Energy Fuels 2006, 20, 446–454. [Google Scholar] [CrossRef]

- Cheng, S.; D’cruz, I.; Wang, M.C.; Leitch, M.; Xu, C.B. Highly efficient liquefaction of woody biomass in hot-compressed alcohol-water co-solvents. Energy Fuels 2010, 24, 4659–4667. [Google Scholar] [CrossRef]

- Yokoyama, S.; Suzuki, A.; Murakami, M.; Ogi, T.; Koguchi, K.; Nakamura, E. Liquid fuel production from sewage sludge by catalytic conversion using sodium carbonate. Fuel 1987, 66, 1150–1155. [Google Scholar] [CrossRef]

- Vardon, D.R.; Sharma, B.K.; Grant, V.B.; Rajagopalan, K. Thermochemical conversion of raw and defatted algal biomass via hydrothermal liquefaction and slow pyrolysis. Bioresour. Technol. 2012, 109, 178–187. [Google Scholar] [CrossRef] [PubMed]

| Proximate Analysis (wt.%) * | Elemental Analysis (wt.%) ** | HHV | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volatile Matter | Fixed Carbon | Moisture | Ash | C | H | N | S | O | (MJ kg−1) | |

| Rice Straw | 66.1 | 15.4 | 5.7 | 12.8 | 37.1 | 5.2 | 0.5 | 0.1 | 44.3 | 12.1 |

| Expt. Code | Temperature (°C) | Reaction Time (min) | Conversion (%) | Bio-Crude Yield (wt.%) | Bio-Char Yield (wt.%) | Gas + Aqueous Yield (wt.%) |

|---|---|---|---|---|---|---|

| R1 | 300 | 30 | 75.5 | 10.8 ± 0.4 | 24.6 ± 0.5 | 64.6 |

| R2 | 325 | 30 | 74.4 | 15.1 ± 0.6 | 25.6 ± 1.3 | 59.3 |

| R3 | 350 | 30 | 78.6 | 12.9 ± 0.7 | 21.4 ± 0.8 | 65.7 |

| R4 | 300 | 60 | 75.2 | 12.3 ± 1.5 | 24.8 ± 1.8 | 62.9 |

| R5 | 325 | 60 | 77.1 | 9.2 ± 0.5 | 22.9 ± 0.7 | 67.9 |

| R6 | 350 | 60 | 80.0 | 3.1 ± 1.2 | 20.0 ± 0.3 | 76.9 |

| Expt. Code | Temp. (°C) | Time (min) | Elemental Composition of Bio-Crude (wt.% db) | HHV of Bio-Crude (MJ kg−1) | Elemental Composition of Bio-Char (wt.% db) | HHV of Bio-Char (MJ kg−1) | ERBC (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O * | C | H | N | O # | ||||||

| R1 | 300 | 30 | 72.9 | 7.9 | 0.3 | 18.9 | 32.7 | 51.6 | 4.5 | 0.4 | 30.7 | 20.1 | 29.4 |

| R2 | 325 | 30 | 73.5 | 7.0 | 0.5 | 19.0 | 31.9 | 46.6 | 3.4 | 0.3 | 36.9 | 16.5 | 39.8 |

| R3 | 350 | 30 | 69.2 | 6.9 | 0.6 | 23.2 | 29.8 | 53.4 | 3.8 | 0.4 | 29.6 | 20.0 | 31.7 |

| R4 | 300 | 60 | 77.1 | 8.4 | 0.4 | 14.1 | 35.3 | 51.3 | 4.3 | 0.2 | 31.4 | 19.8 | 35.9 |

| R5 | 325 | 60 | 73.3 | 7.0 | 0.4 | 19.3 | 31.7 | 39.5 | 3.2 | 0.3 | 44.2 | 13.1 | 24.1 |

| R6 | 350 | 60 | 65.7 | 6.4 | 0.5 | 27.4 | 27.6 | 49.7 | 3.4 | 0.4 | 33.7 | 17.8 | 7.1 |

| Expt. Code | Water: Methanol (Vol.%/Vol.%) | Elemental Composition of Bio-Crude (wt.% db) | HHV of Bio-Crude (MJ kg−1) | Elemental Composition of Bio-Char (wt.% db) | HHV of Bio-Char (MJ kg−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O * | C | H | N | O # | ||||

| R10 | 75:25 | 71.5 | 7.7 | 1.6 | 19.2 | 32.1 | 44.4 | 3.4 | 1.7 | 37.7 | 15.7 |

| R11 | 50:50 | 72.7 | 7.8 | 1.7 | 17.8 | 32.8 | 36.4 | 3.1 | 1.3 | 46.4 | 11.7 |

| R12 | 25:75 | 69.1 | 7.7 | 2.3 | 20.9 | 31.2 | 30.8 | 2.7 | 1.1 | 52.6 | 8.7 |

| R13 | 50:50 (1) | 71.7 | 7.7 | 2.3 | 18.3 | 32.3 | 27.4 | 2.7 | 1.0 | 56.1 | 7.2 |

| R14 | 50:50 (2) | 73.5 | 7.9 | 2.4 | 16.2 | 33.3 | 23.4 | 2.3 | 0.8 | 60.7 | 4.8 |

| R15 | 50:50 (3) | 73.8 | 7.7 | 2.3 | 16.2 | 33.2 | 23.3 | 2.3 | 0.8 | 60.8 | 4.9 |

| Temp. (°C) | Rice Straw (g) | Solvent (mL) | Solvent: Water (Vol./Vol.) | Solvent | Bio-Crude Yield (wt.%) | HHV (MJ kg−1) | O (wt.%) | C (wt.%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 300 | 20 | 300 | - | Water | 29.1 | 27.2 | 45.3 | 47.4 | Yuan et al. [18] |

| 20 | 300 | - | Ethanol | 13.0 | 33.5 | - | - | ||

| 20 | 300 | 1:1 | Ethanol–water | 38.4 | 29.7 | - | - | ||

| 20 | 300 | - | 2-Propanol | 15.1 | 35.8 | 18.5 | 71.3 | ||

| 20 | 300 | 1:1 | 2-Propanol–water | 39.7 | 30.7 | 27.3 | 63.8 | ||

| 300 | 30 | 300 | - | Water | 12.3 | 35.3 | 14.1 | 77.1 | This study |

| 30 | 300 | 1:1 | Methanol–water | 36.8 | 32.8 | 17.8 | 72.7 | ||

| 30 | 300 | 1:1 | Methanol–water+KOH | 40.0 | 32.3 | 18.3 | 71.7 |

| Water | Water:Methanol 50:50 (Vol.%/Vol.%) | Water:Methanol 50:50 (Vol.%/Vol.%) + KOH | |

|---|---|---|---|

| Energy content of rice straw (EF) (kJ) | 363 | 363 | 363 |

| Heat of rice straw (QRS) (kJ) | 6.93 | 6.93 | 6.93 |

| Heat of water (QH2O) (kJ) | 362.62 | 181.30 | 181.30 |

| Heat of methanol (QMethanol) (kJ) | - | 32.65 | 32.65 |

| Heat required for HTL process (EHTL) (kJ) | 263.96 | 157.80 | 157.80 |

| Total energy of products (EP) (kJ): Energy recovered in bio-crude (kJ) Energy recovered in bio-char (kJ) Energy recovered in gases (kJ) | 322.62 130.26 137.64 54.72 | 424.50 305.00 64.75 54.72 | 478.34 387.83 35.79 54.72 |

| EF + Qsolvent (kJ) | 725.62 | 576.96 | 576.96 |

| Energy recovery (ER) (%) | 44.5 | 73.6 | 82.9 |

| Energy consumption ratio (ECR) | 2.03 | 0.52 | 0.41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yerrayya, A.; Shree Vishnu, A.K.; Shreyas, S.; Chakravarthy, S.R.; Vinu, R. Hydrothermal Liquefaction of Rice Straw Using Methanol as Co-Solvent. Energies 2020, 13, 2618. https://doi.org/10.3390/en13102618

Yerrayya A, Shree Vishnu AK, Shreyas S, Chakravarthy SR, Vinu R. Hydrothermal Liquefaction of Rice Straw Using Methanol as Co-Solvent. Energies. 2020; 13(10):2618. https://doi.org/10.3390/en13102618

Chicago/Turabian StyleYerrayya, Attada, A. K. Shree Vishnu, S. Shreyas, S. R. Chakravarthy, and Ravikrishnan Vinu. 2020. "Hydrothermal Liquefaction of Rice Straw Using Methanol as Co-Solvent" Energies 13, no. 10: 2618. https://doi.org/10.3390/en13102618

APA StyleYerrayya, A., Shree Vishnu, A. K., Shreyas, S., Chakravarthy, S. R., & Vinu, R. (2020). Hydrothermal Liquefaction of Rice Straw Using Methanol as Co-Solvent. Energies, 13(10), 2618. https://doi.org/10.3390/en13102618