Micro-Degradation Characteristics and Mechanism of ZnO Varistors under Multi-Pulse Lightning Strike

Abstract

:1. Introduction

2. Experiment

2.1. Impulse Test and Waveform

2.2. Experimental Procedure

- (1)

- Sample selection: three ZnO varistor samples of A, B and C specifications were selected in the experiment. All the samples had a nominal discharge current 20 kA, a maximum discharge current 40 kA and a maximum continuous operating voltage of 385 V. Measured for its static parameter varistor voltage value and leakage current value, the sample with the closest static parameter electrical characteristics was selected as the test product and the varistor voltage was about 680 V. Nine samples of the same batch were selected for each specification.

- (2)

- Impulse test: use multi-pulse current to perform an impulse test on the ZnO varistor. The impulse test process is shown in Figure 3. Every five pulse currents were recorded as a group and a test was performed. Each adjacent two impact groups had time intervals of 30 min, as this time interval was enough to allow the ZnO varistor to cool to room temperature and then perform the next test until the ZnO varistor static parameter varistor voltage change exceeded the original ±10%, or the leakage current exceeded 20 μA or the mechanical damage occurred directly. When the ZnO varistor failed, the impulse test was stopped and the relevant data was recorded.

- (3)

- After each test measure the temperature, varistor voltage and leakage current of the surface of the ZnO varistor and checked whether the ZnO varistor was broken or perforated and took a picture of the damaged ZnO varistor.

- (4)

- Scanning electron microscope (SEM) was used to scan the ZnO varistor samples before and after the impact and the X-ray diffractometer (XRD) was used to diffract and to observe the microstructure characteristics and phase structure changes of the ZnO varistor.

3. Results and Discussion

3.1. Relationship between Microstructure Characteristics and Impact Life of ZnO Varistor

3.2. The Transformation of ZnO Varistor Grain Structure during Impulse

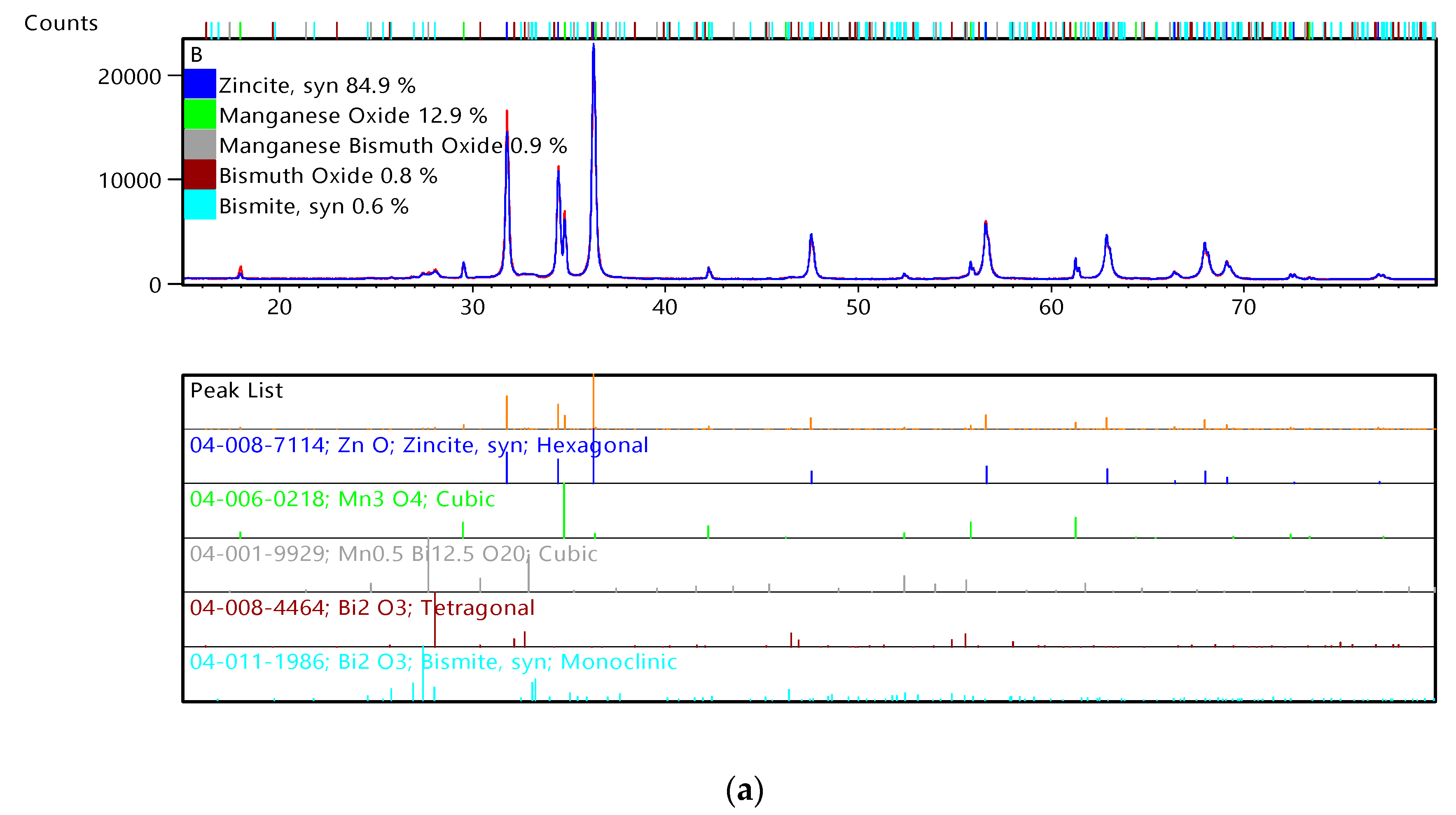

3.3. Variation of Crystalline Materials of ZnO Varistor

3.4. Micro-Damage Mechanism Based on Linear Chain Theory

4. Conclusions

- (1)

- The composition of the trace elements added in the grain boundary layer of the ZnO varistor and the average grain size were different, resulting in different impact resistance performances. Under multiple pulses, the addition of the trace elements did not improve the impact capability of the ZnO varistor. The number of the impact resistance of the ZnO varistor was inversely proportional to the grain size: the smaller the grain size, the greater the number of the impact resistance;

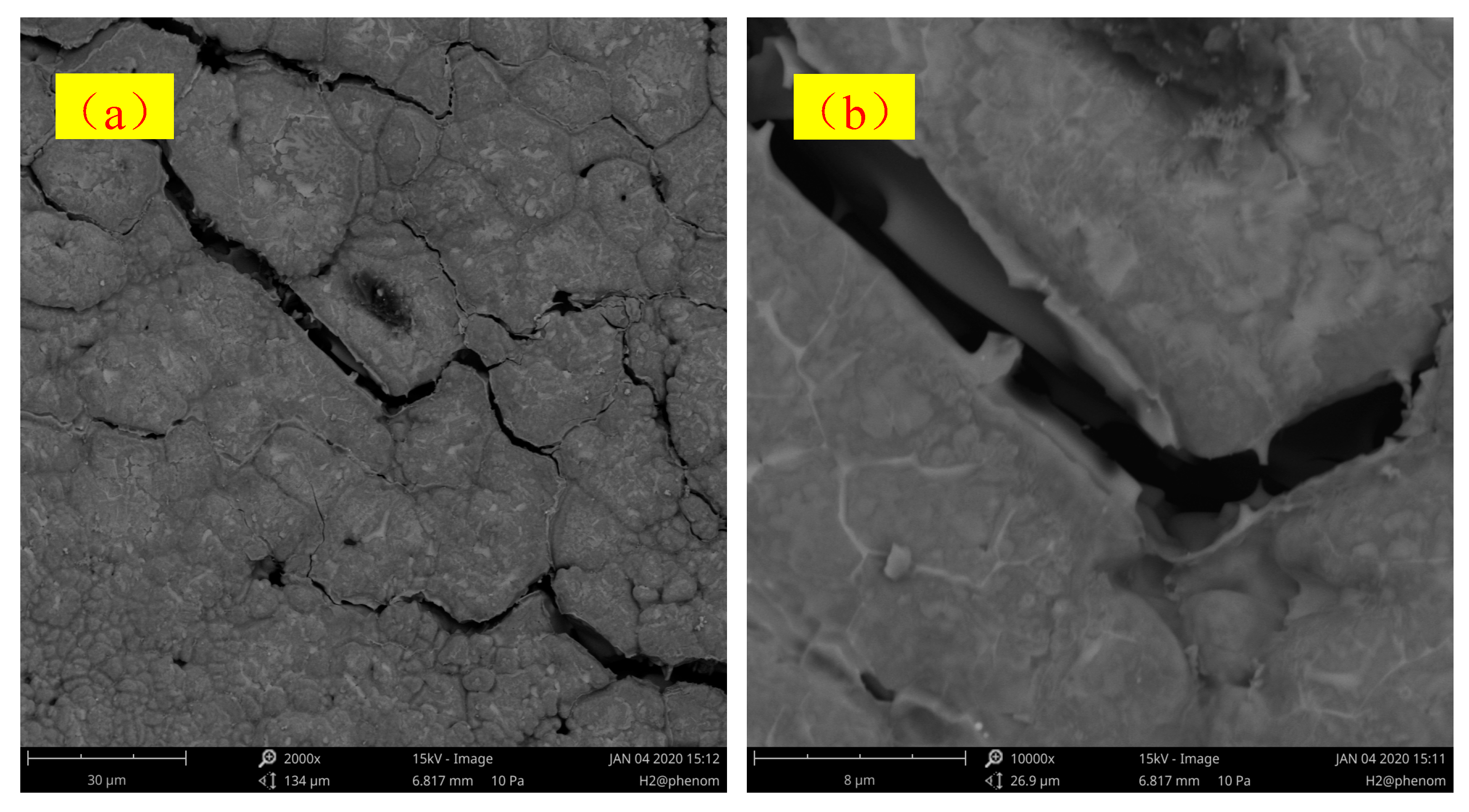

- (2)

- The multi-pulse lightning current caused the grain size of the ZnO varistor to become smaller and the grain boundary to grow and there was obvious crack channels. The gap width of the crack channel increased with the increase in the number of impacts. Metamorphosis occurred, which eventually led to the severe destruction or even crushing of the grains. The proportion of Bi in several crystal phases was changed. The high temperature of the injected current caused the internal crystal phase structure of the ZnO varistor to change;

- (3)

- The destruction of the multi-pulse current was mainly due to the unevenness of the various parts of the varistor and the accumulation of heat, which caused the unit cell variable grain boundary to melt through, resulting in a reduction in the overall resistance of the ZnO varistor.

Author Contributions

Funding

Conflicts of Interest

References

- Su, Y.; Sun, L.; Yang, Z. Research progress of low voltage varistor. Electron. Compon. Mater. 2010, 29, 74–78. [Google Scholar]

- Yang, Z.; Chen, L. Analysis and application of capacitance change during the deterioration of zinc oxide varistor. High Volt. Technol. 2010, 36, 2167–2172. [Google Scholar]

- Li, X.; Zhang, J.; Chen, L. Research on the design method of combined surge protector. Electr. Porcelain Arrester 2017, 4, 16–22. [Google Scholar]

- Yang, D.; Zhang, X.; Xu, Y. The failure mode and failure reason of SPD in low-voltage power supply system. Electr. Porcelain Arrester 2007, 4, 43–46. [Google Scholar]

- Protection Against Lightning—Part 1: General Principles; IEC 62305-1; International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Heidler, F.; Flisowski, Z.; Zischank, W.; Bouquegneau, C.; Mazzetti, C. Parameters of lightning current given in IEC 62305-background, experiments and outlook. In Proceedings of the 2008 ICLP, Uppsala, Sweden, 23–26 June 2008. [Google Scholar]

- Yang, S.; Chen, S.; Zhang, Y. Characteristics analysis of the induced overcurrent generated by close triggered lightning on the overhead transmission power line. J. Trop. Meteorol. 2010, 16, 59–65. [Google Scholar]

- Yaacob, M.M.; Ghani, R.A. Voltage-current characteristics of metal oxide varistors for low voltage telephone lightning protector under the application of multiple lightning impulse. In Proceedings of the Conference Record of the 1998 IEEE International Symposium on Electrical Insulation, Arlington, VA, USA, 7–10 June 1998. [Google Scholar]

- Vahidi, B.; Cornick, K.; Greaves, D. Effects of multiple stroke on ZnO surge arresters. In Proceedings of the 24th International Conference on Lightning Protection, Birmingham, UK, 14–18 September 1998; pp. 960–963. [Google Scholar]

- Heinrich, C.; Wagner, S.; Richter, B.; Kalkner, W. Multipulse tests on surge arresters for medium and low voltage systems. In Proceedings of the 24th International Conference on Lightning Protection, Birmingham, UK, 14–18 September 1998; pp. 790–794. [Google Scholar]

- Haryono, T.; Sirait, K.T.; Tumiran, K. The damage of ZnO arrester block due to multiple impulse currents. Telkomnika 2011, 9, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Haryono, T.; Sirait, K.T.; Tumiran, K. Effect of multiple lightning strikes on the performance of ZnO lightning arrester block. High Volt. Eng. 2011, 37, 2763–2771. [Google Scholar]

- Lou, J. Research on the Destruction Mechanism of MOV Based on Microstructure under Different Impact Conditions. Master’s Thesis, Nanjing University of Information Science and Technology, Nanjing, China, 2016. [Google Scholar]

- Tsuboi, T.; Takami, J.; Okabe, S. Energy absorption capacity of a 500 kV surge arrester for direct and multiple lightning strokes. IEEE Trans. Dielectr. Electr. Insul. 2014, 22, 916–924. [Google Scholar] [CrossRef]

- Zhang, Y.; Lv, W.; Chen, S. Ten-year progress of Guangdong field lightning comprehensive observation experiment. J. Meteorol. 2016, 74, 655–671. [Google Scholar]

- Zhang, Y.; Lv, W.; Zhang, Y. Observation and characteristic analysis of the process of ground flashover in Guangzhou area. High Volt. Technol. 2013, 39, 383–392. [Google Scholar]

- Xu, L.; Yang, Z.; You, Z. Research on dynamic characteristics of zinc oxide varistor before and after deterioration. Electr. Porcelain Arrester 2014, 4, 132–138. [Google Scholar]

- Lee, B.H.; Kang, S.M. Properties of ZnO varistor blocks under multiple lightning impulse voltages. Curr. Appl. Phys. 1997, 12, 1168–1175. [Google Scholar] [CrossRef]

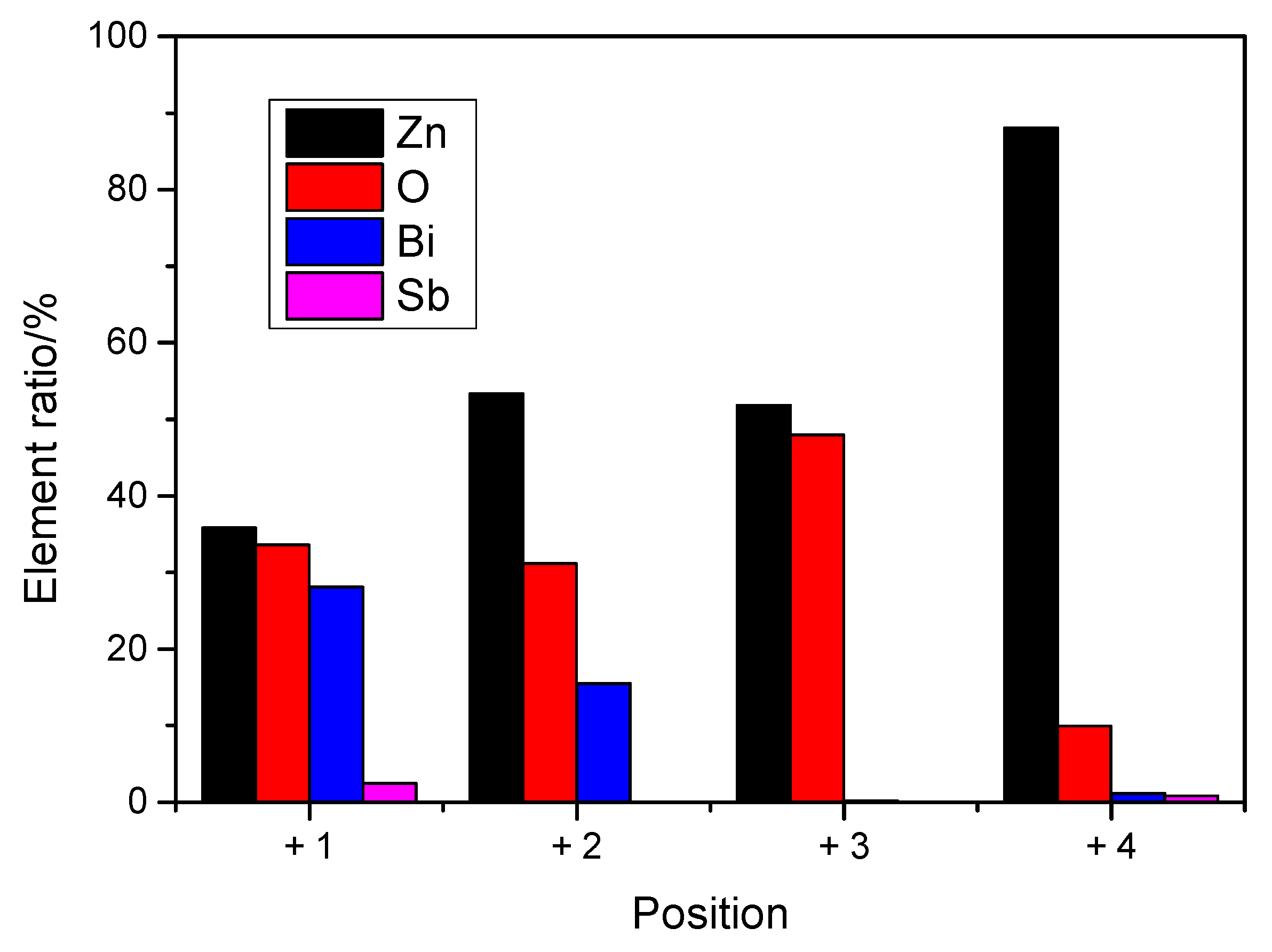

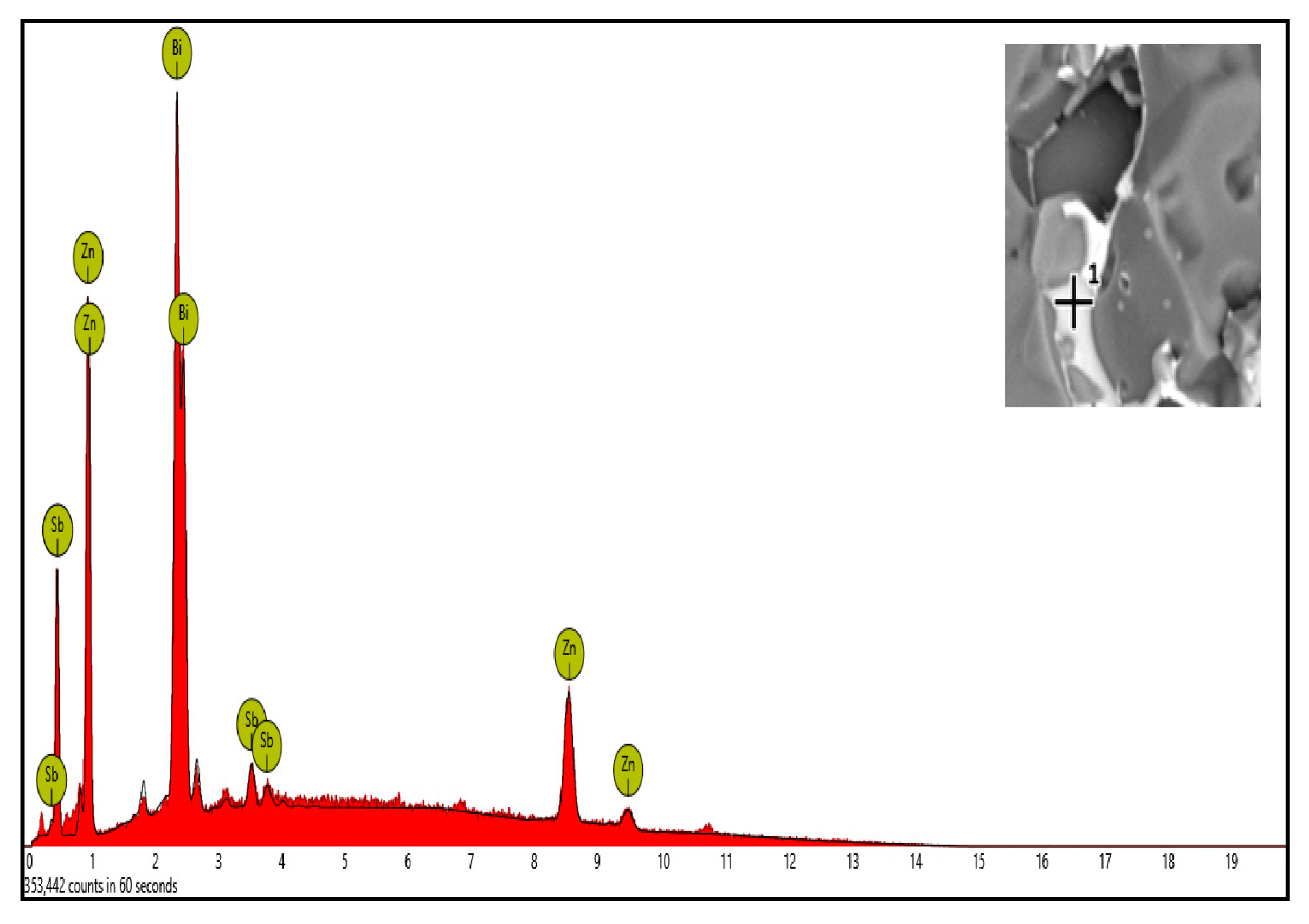

| Position/Element | Zn (%) | O (%) | Bi (%) | Sb (%) |

|---|---|---|---|---|

| +1 | 35.85 | 33.59 | 28.07 | 2.48 |

| +2 | 53.34 | 31.14 | 15.51 | 0 |

| +3 | 51.87 | 47.94 | 0.19 | 0 |

| +4 | 88.03 | 9.98 | 1.13 | 0.86 |

| Sample Serial Number | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 |

|---|---|---|---|---|---|---|---|---|---|

| Impact Life | 15 | 16 | 15 | 16 | 16 | 15 | 16 | 16 | 17 |

| Sample Serial Number | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 |

| Impact Life | 6 | 7 | 6 | 7 | 8 | 7 | 7 | 7 | 8 |

| Sample Serial Number | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

| Impact Life | 3 | 4 | 4 | 3 | 5 | 4 | 5 | 4 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Xing, H.; Li, C.; Cai, R.; Lv, D. Micro-Degradation Characteristics and Mechanism of ZnO Varistors under Multi-Pulse Lightning Strike. Energies 2020, 13, 2620. https://doi.org/10.3390/en13102620

Zhang C, Xing H, Li C, Cai R, Lv D. Micro-Degradation Characteristics and Mechanism of ZnO Varistors under Multi-Pulse Lightning Strike. Energies. 2020; 13(10):2620. https://doi.org/10.3390/en13102620

Chicago/Turabian StyleZhang, Chunlong, Hongyan Xing, Chunying Li, Ran Cai, and Dongbo Lv. 2020. "Micro-Degradation Characteristics and Mechanism of ZnO Varistors under Multi-Pulse Lightning Strike" Energies 13, no. 10: 2620. https://doi.org/10.3390/en13102620