Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path

Abstract

:1. Introduction

2. Materials and Methods

- Stating desired retrofit targets and collecting input data about the process and its existing Heat Exchanger Network (process streams data extraction from a process scheme, further identification of hot and cold process streams, current hot and cold utility heat load, and existing heat exchanger performance and heat duties). Depicting the current HEN using the Grid Diagram (GD).

- The EMAT (exchanger minimum approach temperature) value determination. It is a minimum allowable temperature approach of process media in the newly designed HEs creating new Utility Paths. The EMAT value evaluation is dependent on the existing HEN parameters and is discussed by Zhu and Asante [29].

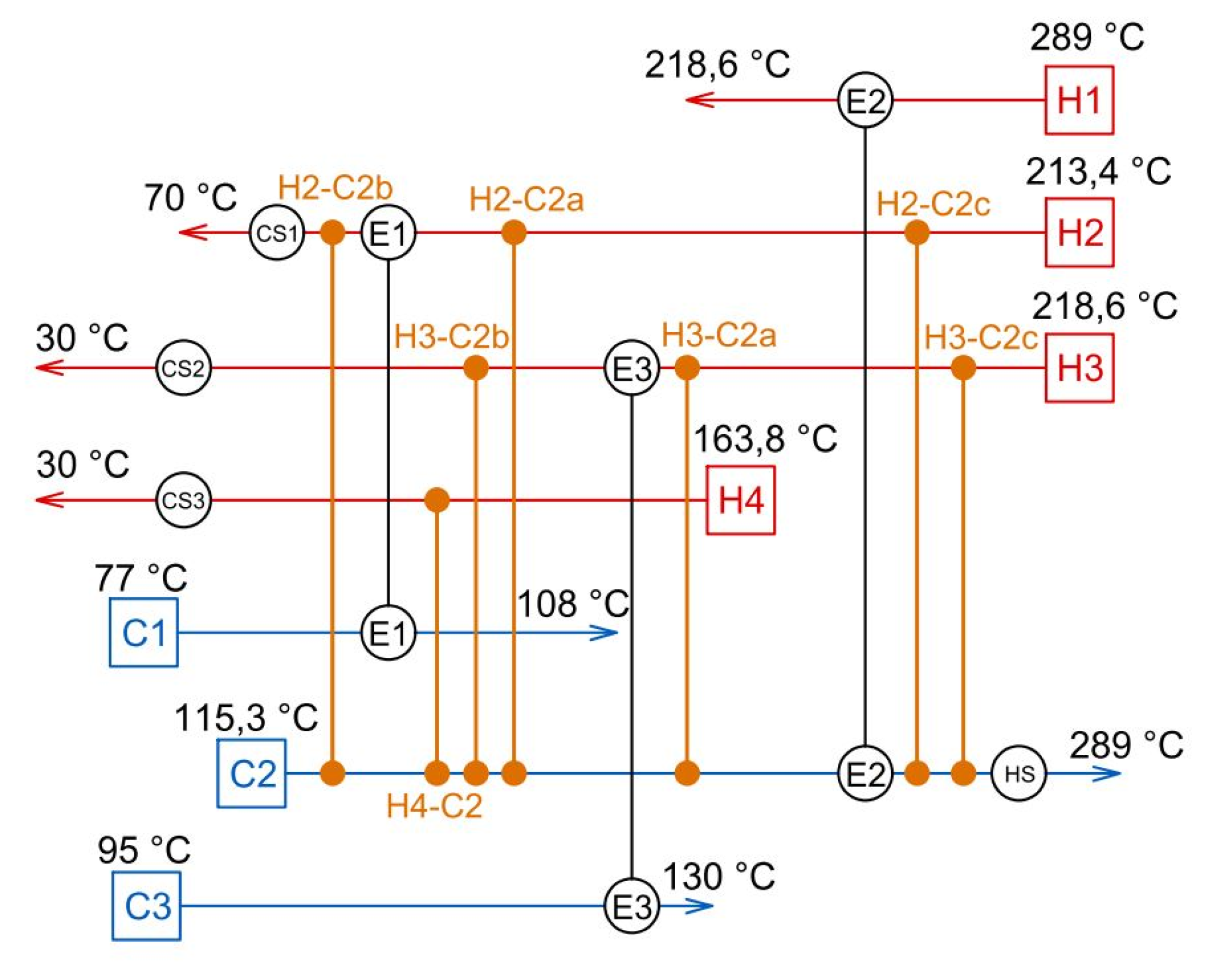

- All thermodynamically feasible Utility Paths, thus the potential locations for the new HE insertion, are drawn to the GD of the current non-standard HEN. The obtained representation of feasible Utility Paths in GD is called the Retrofit Superstructure Grid Diagram (RSGD), which is a platform for the most efficient Utility Path identification. Only feasible matches are included in RSGD, which simplifies its structure and excludes unrealizable HEN modifications.

- Every realizable Utility Path contained in RSGD is verified from the Maximum Heat Recovery Potential (Rmax) point of view using a linear programming (LP) model to the Network Pinch diagnosis. Specifically, there is an applied so-called Basic LP Model P1 for Identification of the Network Pinch published by Zhu and Asante [29]. This linear model allows finding Rmax (i.e., a suitable location for the new HE insertion) considering a specified EMAT value. Use of the linear model ensures finding the so-called global optimum solution, i.e., the optimal location for a new HE insertion is obtained, which is the main objective of this part of the developed method. Linear model implementation is also less difficult due to its simplicity in comparison with using the non-linear model. For the LP Model P1 application, any software enabling numerical programming can be used. In this work, the educational version of software Maple 2018 (Maplesoft, Waterloo, ON, Canada) [30] from the company Maplesoft is used, where the optimization package Simplex provides an appropriate numerical tool. The linear model consists of the process and thermal characteristics of the streams (as a flowrate and specific heat capacity), the heat balance of existing heat exchangers, and the EMAT value. The objective function is the maximization of the Rmax value described above.

- When all the potential Utility Paths from the RSGD are assessed by the LP model, the obtained results are sorted to the so-called Retrofit Identification Table (RIT) from the most beneficial to the least beneficial Utility Path in terms of achievable Rmax. The main advantage of using RIT is the simultaneous profitability evaluation of each potential Utility Path, the location for a new HE insertion, and its heat duty.

- The most beneficial Utility Path found in RIT (therefore with highest Rmax) is suitable for the new HE insertion. These results obtained in the RI stage are input data for the following (detail design) stage of the developed retrofit method.

- In case that the results of RI do not satisfy the required reduction of utility loads to the desired level, the RI stage is applied repeatedly, taking the most beneficial Utility Path from the previous search as a basis of the HEN topology for the next search, for finding the next most beneficial Utility Path (see Figure 3).

- The new HEs are of the same type, design, and size as adjacent exchangers operating with the same fluids. This ensures the purchase and maintenance cost minimization and the interchangeability of the exchangers and their parts.

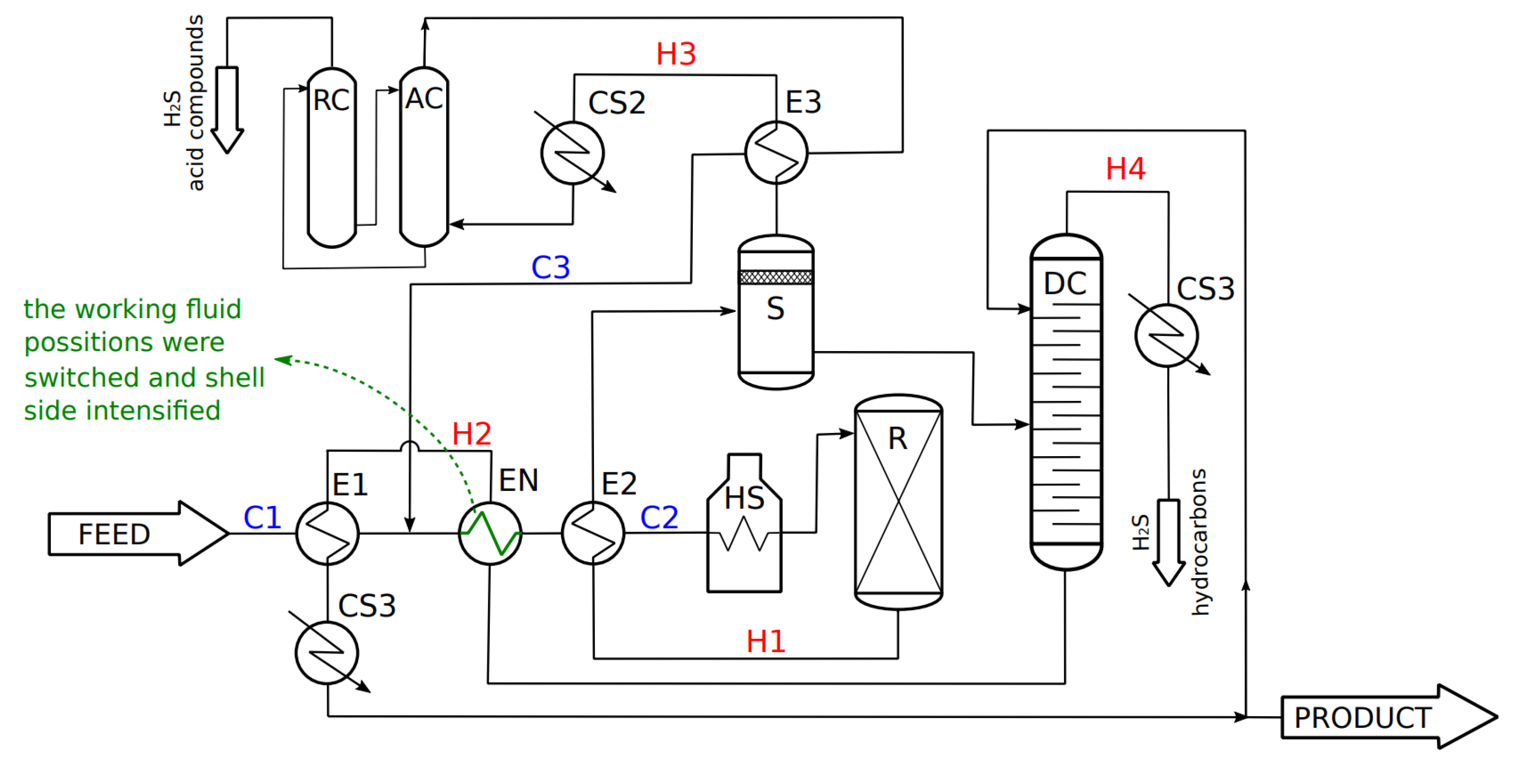

- In case that the new HE does not reach the desired heat duty, try to switch the position of the working fluids in the exchanger, if possible.

- If the desired heat duty is still not reached, the common and cheap technology for heat transfer enhancement may be implemented with respect to the set constraints (allowed pressure drop, etc.). Thus, the required HE performance can be accomplished with minimal investment cost.

- Verify the final retrofit design and consult it with the client, respectively the process operator.

3. Case Study

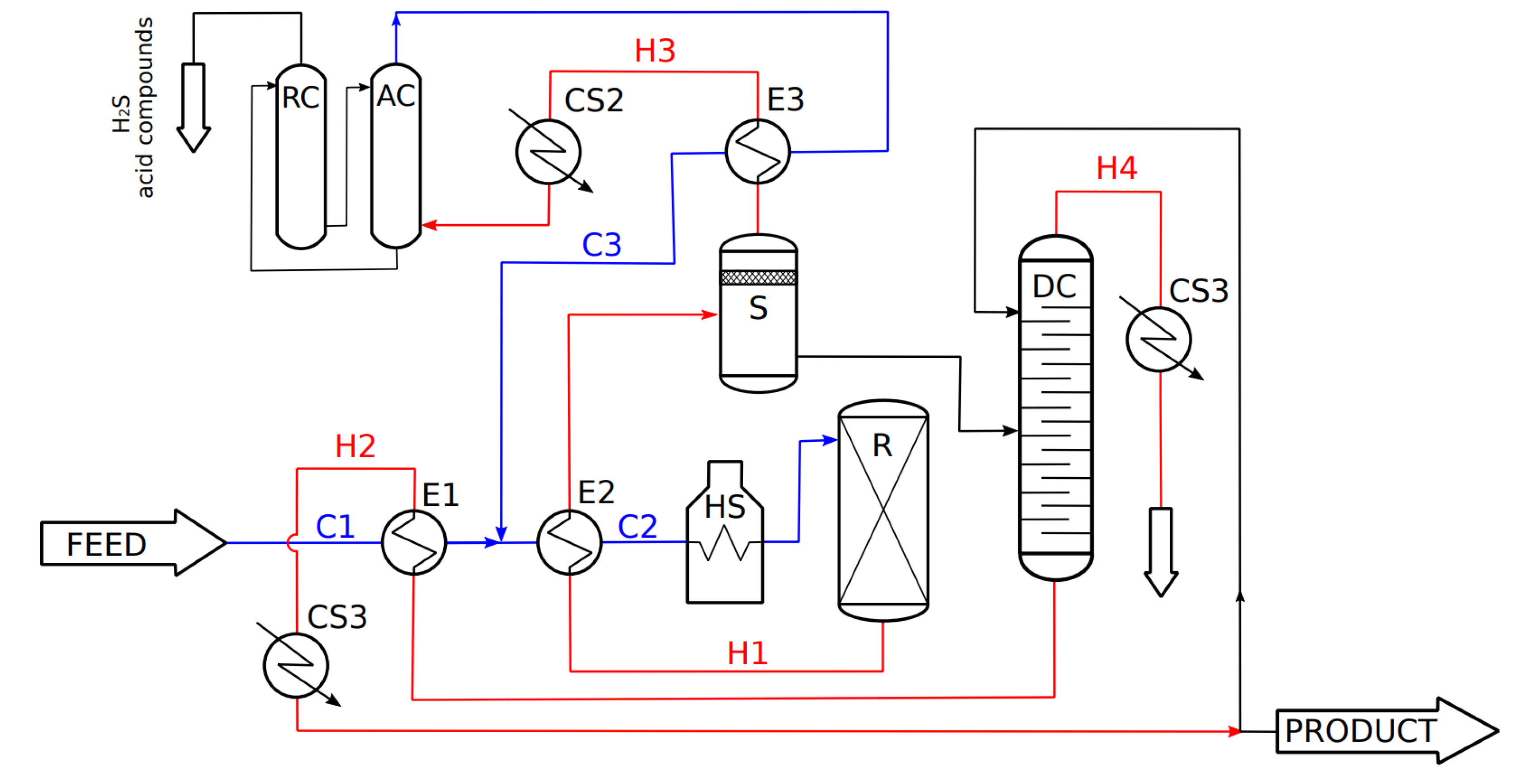

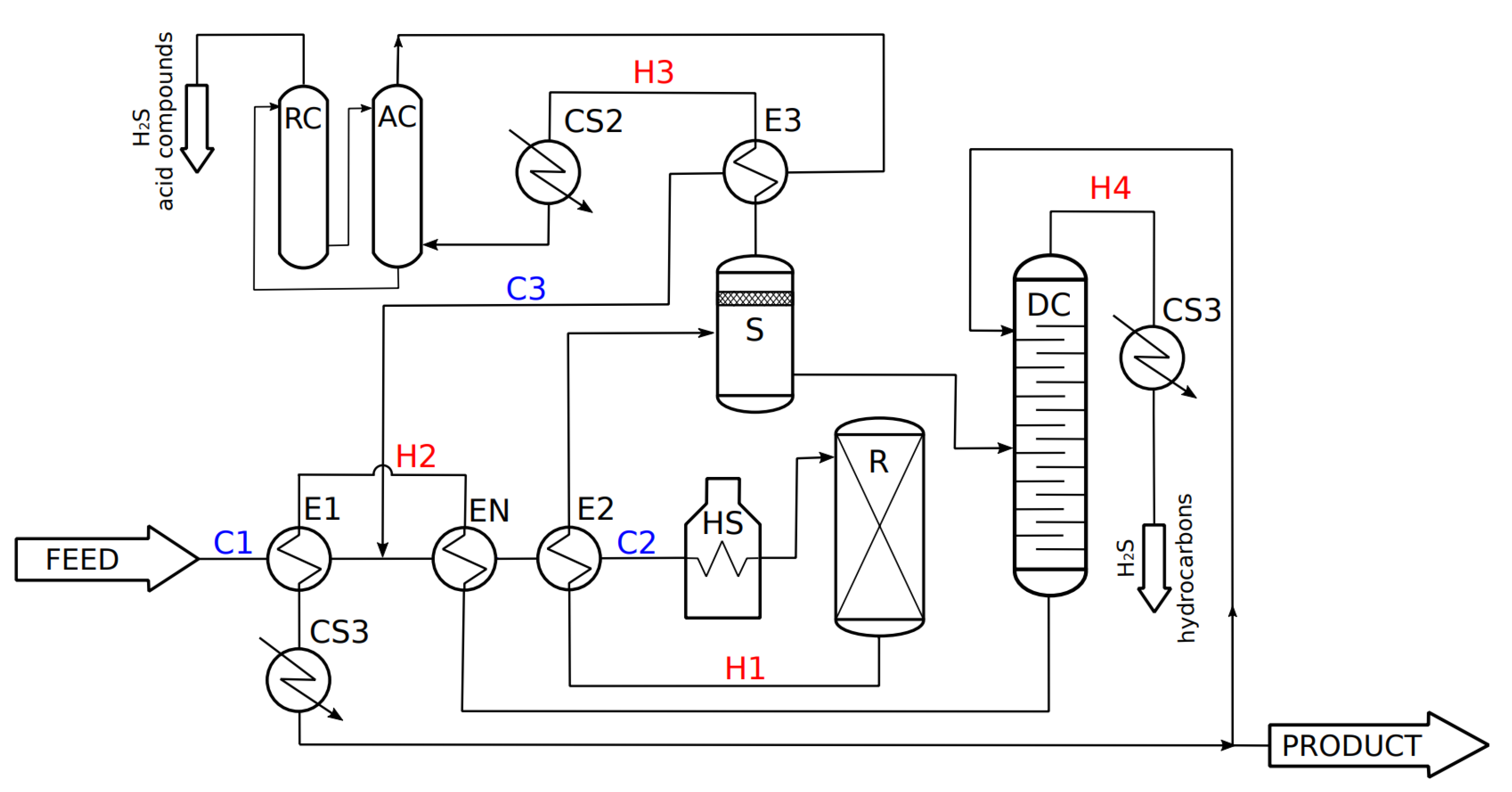

Description of the Studied Process

4. Results and Discussion

4.1. Preparation Procedure to the HEN Retrofit Design

- (i)

- The requirements received by the plant owner imply that the retrofit of the hydrogenation process could be defined as the energy retrofit, which aims to reduce the hot utility demand (i.e., the process furnace fuel consumption) by at least 30% with minimal investment costs, while the process media pressure drop can exceed maximum 30 kPa for each.

- (ii)

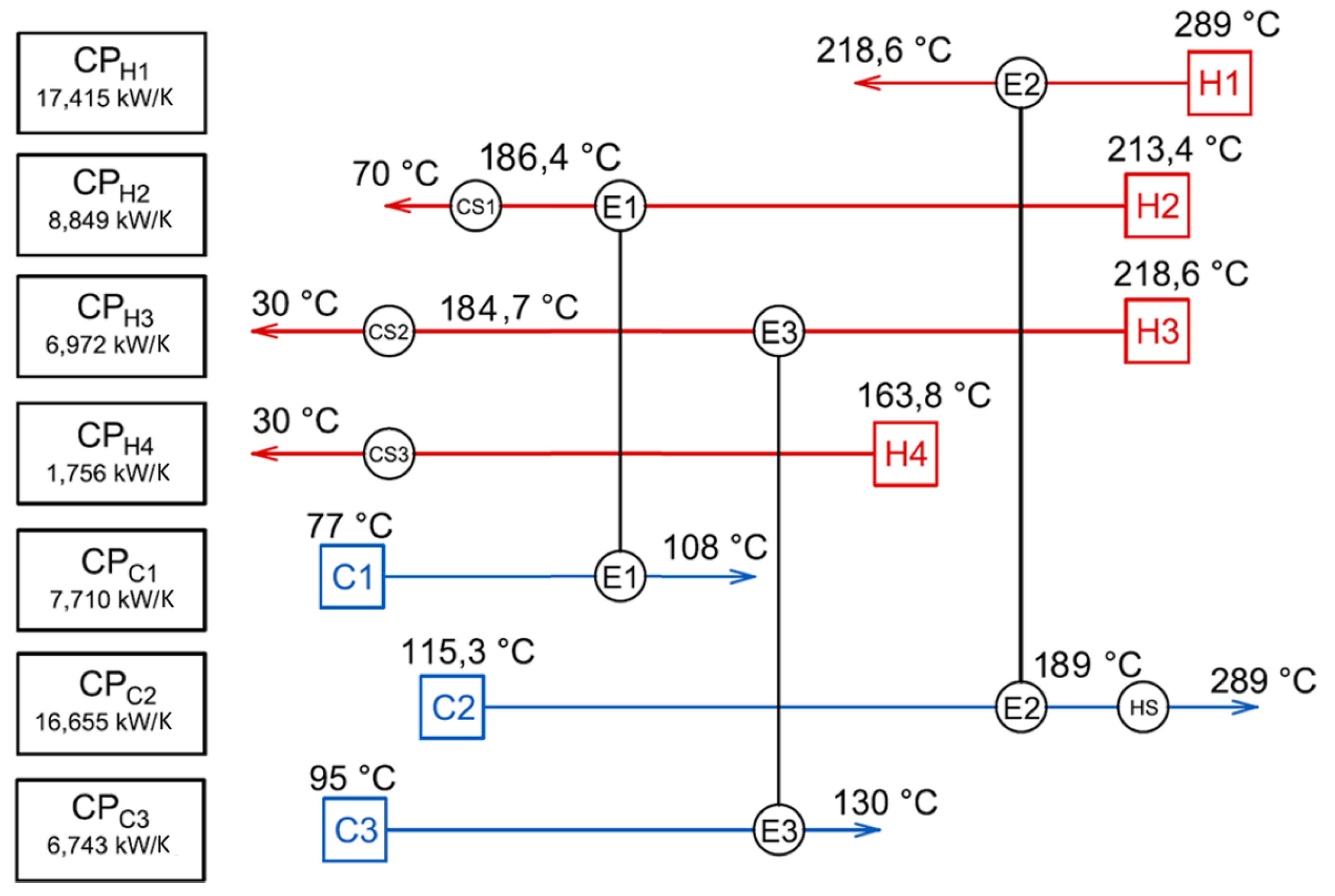

- Within the process input data collection, the hot and cold streams, taking part in the process heat exchange, were identified, via Section 3. All key equipment was analyzed, including the heat exchangers forming the current HEN, whose main characteristics are summarized in Table 1. According to the collected data, the Grid Diagram was further generated and is illustrated in Figure 5. As it is observed in GD, the current HEN does not contain any Utility Path; therefore, it is defined as the non-standard HEN, and thus the developed retrofit method can be applied.

- (iii)

- The EMAT value determination adequate for the existing HEs retrofit as well as for the potential newly designed HEs was carried out according to the instruction provided in [29]. Individual EMAT values of the existing heat exchangers in the studied process range between approximately 88 and 109 °C. Taking into account a very high oversizing of the existing exchangers (see Table 1), the EMAT = 40 °C has been assessed as a practical and operationally easy to achieve value for the existing heat exchangers and also for any new units placed to the HEN of studied process. Additionally, the feasibility of meeting the required hot utility saving was verified by performing the standard targeting procedure (Klemeš et al. [31]). The maximum feasible hot utility saving for the obtained EMAT value is 52.3%, which is high above the client’s hot utility saving demand, which is 30%. However, reaching this significant savings would presumably lead to significant modifications of current HEN and thus high investment cost. As the investment cost minimization is required, a utility saving lower than 52.3% is assumed.

4.2. Retrofit Identification (RI Stage) of HEN–the Most Beneficial Utility Path Localization

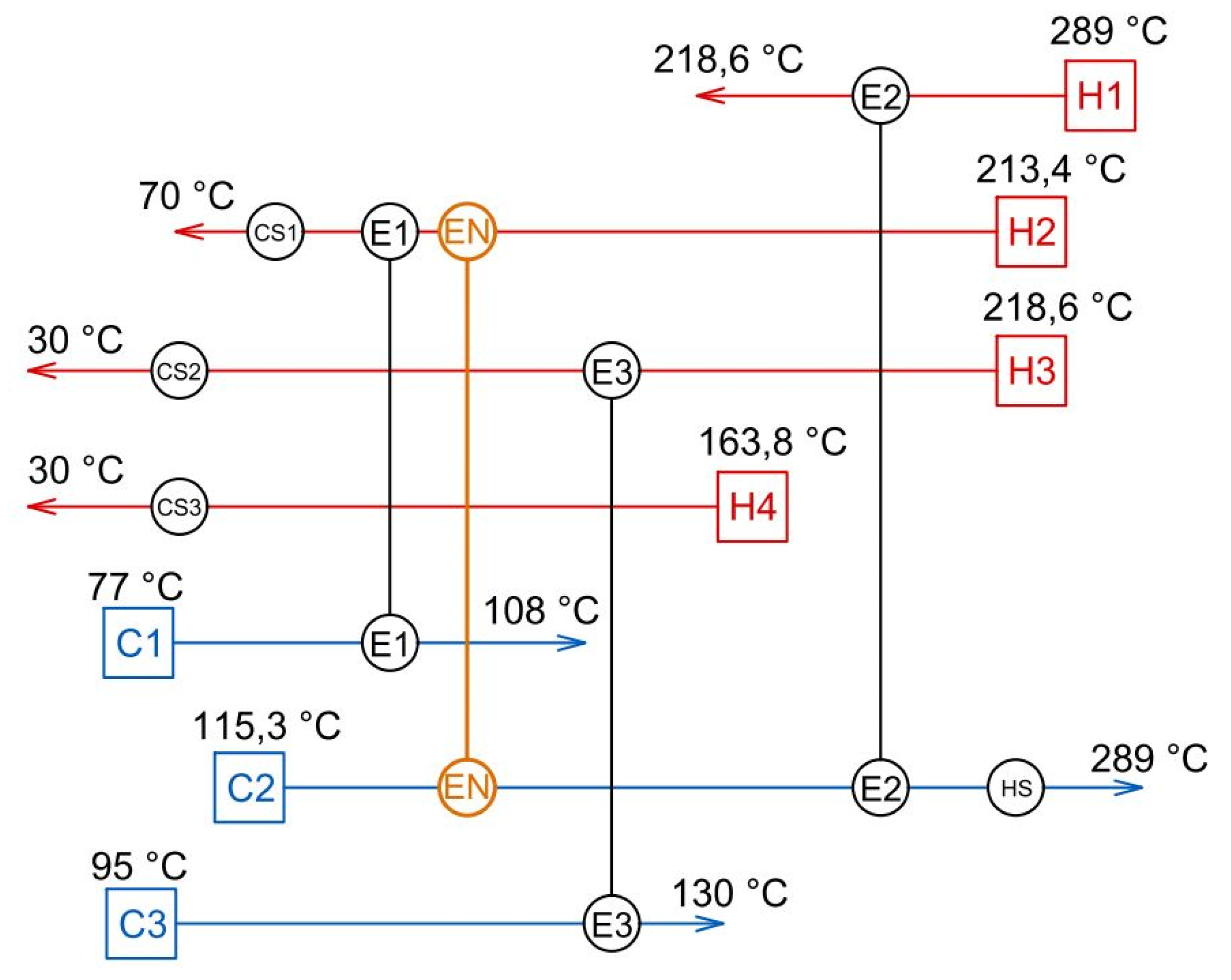

4.3. Detail Design (DD) Stage of the New Heat Exchanger (EN) Creating Most Beneficial Utility Path

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sreepathi, B.K.; Rangaiah, G.P. Review of heat exchanger network retrofitting methodologies and their applications. Ind. Eng Chem Res. 2014, 53, 11205–11220. [Google Scholar] [CrossRef]

- Hohman, E.C. Optimum Networks of Heat Exchange. Ph.D. Thesis, University of Southern California, Los Angeles, CA, USA, June 1971. [Google Scholar]

- Huang, F.; Elshout, R.V. Optimizing the heat recovery of crude units. Chem. Eng. Prog. 1976, 72, 68–72. [Google Scholar]

- Umeda, T.; Itoh, J.; Shiroko, K. Heat exchange system synthesis. Chem. Eng. Prog. 1978, 74, 70–76. [Google Scholar]

- Linnhoff, B.; Mason, D.R.; Wardle, I. Understanding heat exchanger networks. Comp. Chem. Eng. 1979, 3, 295–302. [Google Scholar] [CrossRef]

- Linnhoff, B.; Townsend, D.W.; Boland, D.; Hewitt, G.F.; Thomas, B.E.A.; Guy, A.R.; Marsland, R.H. A User Guide on Process Integration for the Efficient Use of Energy, 1st ed.; IChemE: London, UK, 1982. [Google Scholar]

- Tjoe, T.N.; Linnhoff, B. Using pinch technology for process retrofit. Chem. Eng. 1986, 93, 47–60. [Google Scholar]

- Carlsson, A.; Franck, P.A.; Berntsson, T. Design better heat exchanger network retrofits. Chem. Eng. Progr. U. S. 1993, 89, 87–96. [Google Scholar]

- Lakshmanan, R.; Bañares-Alcántara, R. A novel visualisation tool for heat exchanger network retrofit. Ind. Eng. Chem. Res. 1996, 35, 4507–4522. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Bañares-Alcántara, R. Retrofit by inspection using thermodynamic process visualization. Comput. Chem. Eng. 1998, 22, 809–812. [Google Scholar] [CrossRef]

- Yong, J.Y.; Varbanov, P.S.; Klemeš, J.J. Heat exchanger network retrofit supported by extended Grid Diagram and heat path development. Appl. Therm. Eng. 2015, 89, 1033–1045. [Google Scholar] [CrossRef]

- Gadalla, M.A. A new graphical method for Pinch Analysis applications: Heat exchanger network retrofit and energy integration. Energy 2015, 81, 159–174. [Google Scholar] [CrossRef]

- Akpomiemie, M.O.; Smith, R. Cost-effective strategy for heat exchanger network retrofit. Energy 2018, 146, 82–97. [Google Scholar] [CrossRef] [Green Version]

- Grossmann, I.E. Mixed-integer nonlinear programming techniques for the synthesis of engineering systems. Res. Eng. Des. 1990, 1, 205–228. [Google Scholar] [CrossRef] [Green Version]

- Ciric, A.R.; Floudas, C.A. A comprehensive optimization model of the heat exchanger network retrofit problem. Heat Recover. Syst. CHP 1990, 10, 407–422. [Google Scholar] [CrossRef]

- Dolan, W.B.; Cummings, P.T.; Le Van, M.D. Algorithmic efficiency of simulated annealing for heat exchanger network design. Comput. Chem. Eng. 1990, 14, 1039–1050. [Google Scholar] [CrossRef]

- Yee, T.F.; Grossmann, I.E. A screening and optimization approach for the retrofit of heat-exchanger networks. Ind. Eng. Chem. Res. 1991, 30, 146–162. [Google Scholar] [CrossRef]

- López-Maldonado, L.A.; Ponce-Ortega, J.M.; Segovia-Hernández, J.G. Multiobjective synthesis of heat exchanger networks minimizing the total annual cost and the environmental impact. Appl. Therm. Eng. 2011, 31, 1099–1113. [Google Scholar] [CrossRef]

- Asante, N.D.; Zhu, X.X. An automated approach for heat exchanger network retrofit featuring minimal topology modifications. Comput. Chem. Eng. 1996, 20, 7–12. [Google Scholar] [CrossRef]

- Smith, R.; Jobson, M.; Chen, L. Recent development in the retrofit of heat exchanger networks. Appl. Therm. Eng. 2010, 30, 2281–2289. [Google Scholar] [CrossRef] [Green Version]

- Bakhtiari, B.; Bedard, S. Retrofitting heat exchanger networks using a modified Network Pinch approach. Appl. Therm. Eng. 2013, 51, 973–979. [Google Scholar] [CrossRef]

- Smith, R. Chemical Process Design and Integration; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Jiang, N.; Han, W.; Guo, F.; Yu, H.; Xu, Y.; Mao, N. A novel heat exchanger network retrofit approach based on performance reassessment. Energy Convers. Manag. 2018, 177, 477–492. [Google Scholar] [CrossRef]

- Rathjens, M.; Fieg, G. Design of Cost-Optimal Heat Exchanger Networks Considering Individual, Match-Dependent Cost Functions. Chem. Eng. Trans. 2018, 70, 601–606. [Google Scholar]

- Lai, Y.Q.; Wan Alwi, S.R.; Manan, Z.A. Heat Exchanger Network Retrofit Considering Physical Distance, Pressure Drop and Available Equipment Space. Chem. Eng. Trans. 2019, 76, 367–372. [Google Scholar]

- Linnhoff, B.; Hindmarsh, E. The pinch design method for heat exchanger networks. Chem. Eng. Sci. 1983, 38, 745–763. [Google Scholar] [CrossRef]

- Varbanov, P.S.; Klemeš, J.J. Rules for path construction for HENs debottlenecking. Appl. Therm. Eng. 2000, 20, 1409–1420. [Google Scholar] [CrossRef]

- HTRI. Available online: https://www.htri.net (accessed on 12 December 2019).

- Zhu, X.X.; Asante, N.D.K. Diagnosis and Optimization Approach for Heat Exchanger Network Retrofit. AIChE J. 1999, 45, 1488–1503. [Google Scholar] [CrossRef]

- Maple. Available online: https://www.maplesoft.com (accessed on 15 May 2020).

- Klemeš, J.J.; Varbanov, P.S.; Wan Alwi, S.R.; Manan, Z.A. Process. Integration and Intensification, Saving Energy, Water and Resources, 2nd ed.; De Gruyter: Berlin, Germany, 2018. [Google Scholar]

- Chemstations. Available online: http://www.chemstations.com (accessed on 12 December 2019).

- Zhu, X.X.; Zanfir, M.; Klemeš, J. Heat transfer enhancement for heat exchanger network retrofit. Heat Transf. Eng. 2000, 21, 7–18. [Google Scholar]

- Mohanty, D.K. Application of firefly algorithm for design optimization of a shell and tube heat exchanger from economic point of view. Int. J. Therm. Sci. 2016, 102, 228–238. [Google Scholar] [CrossRef]

| Heat Exchanger | Unit | E1 | E2 | E3 | HU | CUtot 1 |

|---|---|---|---|---|---|---|

| Geometry | ||||||

| TEMA type | – | AES | AES | AES | ||

| Number of shells in series-parallel | – | 1-1 | 1-2 | 1-1 | ||

| Number of shell-tube passes | – | 1-4 | 1-4 | 1-4 | ||

| Tube length | m | 5.5 | 6 | 6 | ||

| Tube outer diameter/thickness | mm | 25/2.5 | 25/2.5 | 25/2.5 | ||

| Tube layout angle | ° | 30 | 30 | 30 | ||

| Tube pitch | mm | 32 | 32 | 32 | ||

| Number of tubes | – | 80 | 80 | 80 | ||

| Shell outside diameter | mm | 440 | 440 | 440 | ||

| Baffle height | mm | 360 | 420 | 420 | ||

| Baffle spacing | mm | 150 | 240 | 240 | ||

| Number of baffles | – | 30 | 20 | 20 | ||

| Process data | ||||||

| Heat duty | kW | 239 | 1 226 | 236 | 1667 | 2344 1 |

| Heat transfer area | m2 | 34.5 | 75.4 | 37.7 | ||

| Shell side stream | – | C1 | C2 | C3 | ||

| Tube side stream | – | H2 | H1 | H3 | ||

| Shell side heat transfer coeff. | W/m2K | 303.2 | 497.4 | 198.7 | ||

| Tube side heat transfer coeff. | W/m2K | 382.7 | 1709.5 | 2531.1 | ||

| Mean temperature difference | °C | 107 | 89.2 | 86.8 | ||

| Overdesign 2 | % | 119.6 | 67.4 | 76.3 |

| Utility Path | Rmax [kW] | HU [kW] 1 | HU Savings [%] | CU [kW] 1 | CU Savings [%] |

|---|---|---|---|---|---|

| H2-C2a | 2215.2 | 1152.8 | 30.8 | 1829.7 | 21.9 |

| H3-C2a | 2039.9 | 1328.1 | 20.3 | 2004.9 | 14.5 |

| H2-C2b | 1976.1 | 1391.8 | 16.5 | 2068.7 | 11.7 |

| H3-C2b | 1906.4 | 1461.6 | 12.3 | 2138.5 | 8.8 |

| H4-C2 | 1716.0 | 1716.0 | 0.9 | 2328.8 | 0.6 |

| H2-C2c | Required value of EMAT is not achievable in this Utility Path | ||||

| H3-C2c | Required value of EMAT is not achievable in this Utility Path | ||||

| E1 [kW] | E2 [kW] | E3 [kW] | EN [kW] | Rmax [kW] | HU Savings [%] | CU Savings [%] |

|---|---|---|---|---|---|---|

| 239 | 1226 | 236 | 514.1 | 2215.2 | 30.8 | 21.9 |

| Retrofit Stage (Model) | Duty of EN [kW] | HU [kW] | HU Savings [%] |

|---|---|---|---|

| RI stage (LP model) | 514.1 | 1152.8 | 30.8 |

| DD stage (nonlinear simulation) | 561.5 | 1105.4 | 33.7 |

| Unit | EN Parameters Similar to E2 | Working Fluid Switch | Working Fluid Switch + Intensification | ||

|---|---|---|---|---|---|

| Heat duty | [kW] | 561.5 | 561.5 | 561.5 | |

| Heat transfer area | [m2] | 75.4 | 75.4 | 75.4 | |

| Shell side heat trans. coeff. | [W/m2K] | 241.28 | 119.33 | 292.9 | |

| Tube side heat trans. coeff. | [W/m2K] | 88.11 | 1395.5 | 1395.5 | |

| Overdesign | [%] | −69.69 | −43.79 | +9.86 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jegla, Z.; Freisleben, V. Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path. Energies 2020, 13, 2711. https://doi.org/10.3390/en13112711

Jegla Z, Freisleben V. Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path. Energies. 2020; 13(11):2711. https://doi.org/10.3390/en13112711

Chicago/Turabian StyleJegla, Zdeněk, and Vít Freisleben. 2020. "Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path" Energies 13, no. 11: 2711. https://doi.org/10.3390/en13112711

APA StyleJegla, Z., & Freisleben, V. (2020). Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path. Energies, 13(11), 2711. https://doi.org/10.3390/en13112711