1. Introduction

As the fan is widely applied in national defense construction and industrial production, it plays a significant role in the national economy and daily life [

1]. However, the efficiency of the fan is relatively low, resulting in a huge waste of energy. Therefore, the investigation into fan optimization is of great significance for energy conservation, emission reduction and the improvement of energy allocation.

Due to the complicated geometry of the fan, the gas flow characteristics and internal mechanism is complex. There are multiplex phenomena such as flow separation and vortex loss [

2,

3], which relates to the performance and efficiency of the fluid machinery. In order to promote the efficiency, it is necessary to study the flow characteristics and structure optimization. As multiple structural parameters need to be considered for the fan design and each parameter has a certain value range, which has different influence degrees on the aerodynamic performance of the fan.

In terms of experimental research, advance technology is used to observe the internal flow pattern of the fan. Comparing the flow field distribution under different design parameters, optimization for the aerodynamic performance is realized. The jet phenomenon in the impeller flow channel is experimentally observed [

4], and the results reveal that the Reynolds number and the rotational speed have an important effect on the instability and uniformity of flow field. Later, hot-wire anemometer is adopted to measure the internal flow field of the fan [

5], and the smoke visualization technology is chosen to observe the gas flow trajectory under different inlet conditions [

6], so as to elaborate on the gas flow pattern. The five-hole probe technology can also be used to investigate the flow field at the impeller inlet and outlet under different operating conditions [

7]. The study finds that the backflow phenomenon still exists in the flow channel even under design conditions, which affects the aerodynamic performance. Meanwhile, empirical formula [

8] is put forward to reveal the relationship between fan noise and impeller design parameters through experimental measurements, and studies the effects of blade number, chord length and blade inclination on the wake width. On this basis, the relevance between fan frequency and the blade number is summarized [

9]. The research results indicate that the design parameters of the impeller have an important influence on the aerodynamic performance of the fan. Zhou et al. [

10] proposes a relationship between the blade trailing edge thickness and the energy characteristics of the fan through experiments. The research results demonstrate that the high-pressure region is enlarged with blade thickness. However, the diffusion of the trailing edge is poor at the same time, which intensifies the energy dissipation.

For numerical simulation, it is usually used as the optimal approach to evaluate the energy performance and internal flow field. Numerical simulation results can illustrate the eccentric vortex motion of airfoil blades [

11] and present that the inclination angle plays an important part in the change of vortex size and aerodynamic performance. The change in the impeller wrap angle has been numerically found to promote the efficiency of the fan [

12]. Lin et al. [

13] selected the NACA4412 airfoil as the basis for blade design, and the fan performance has been improved by adjusting the blade inlet and outlet angle. The influence of the blade inlet angle at 25–36 degrees on the flow field of the fan has been explored [

14], and the results demonstrate that the performance of the fan is promoted by 6% when the blade inlet angle is 27 degrees. In addition, the optimal fan has leakage reduction of 2.79% and 3.6% at the tip clearance of 2 and 2.5 mm, respectively. Studies about the influence of blade thickness on the flow characteristics of the fan have been analyzed [

15]; the research results reveal that the efficiency is decreased with thicker blades, but the efficient working range becomes wider. On this basis, the mutual effects of the blade number, the outlet angle, and the diameter ratio of the impeller on the fan performance are comprehensively considered through numerical calculations [

16]. The results indicate that the fan exhibits significant differences among different structure combinations under lower operating pressures.

For design optimization, plenty of optimization models and methods have been employed to conduct optimization research about the aerodynamic performance of the fan based on the influence of structural parameters. The hybrid multiobjective optimization method is adopted to perform numerical calculations combined with response surface model [

17]. The proposed optimal structure effectively promotes the efficiency of the fan. The fan design with particle swarm algorithm realizes the improvement of the total pressure and efficiency [

18]. The methods of inverse problem design [

19], genetic algorithm [

20] and Oseen vortex method [

21] have also been used to realize the structure optimization. Choosing blade number and the outlet angle as optimization parameters and the fan efficiency as the optimization target [

22], the final scheme is to increase the blade number by two and reduce the outlet angle by 0.5 degrees. The interpolation simulated annealing algorithm is applied to the fan optimization [

23], and the results indicate that the pressure rise has also been promoted while satisfying the assumed efficiency. Hybrid multiobjective evolutionary algorithm was developed [

24] with six variables related to the blade inclination angle and blade profile, and the efficiency of the fan can be improved and the torque is reduced through the multiobjective optimization process. Chen et al. [

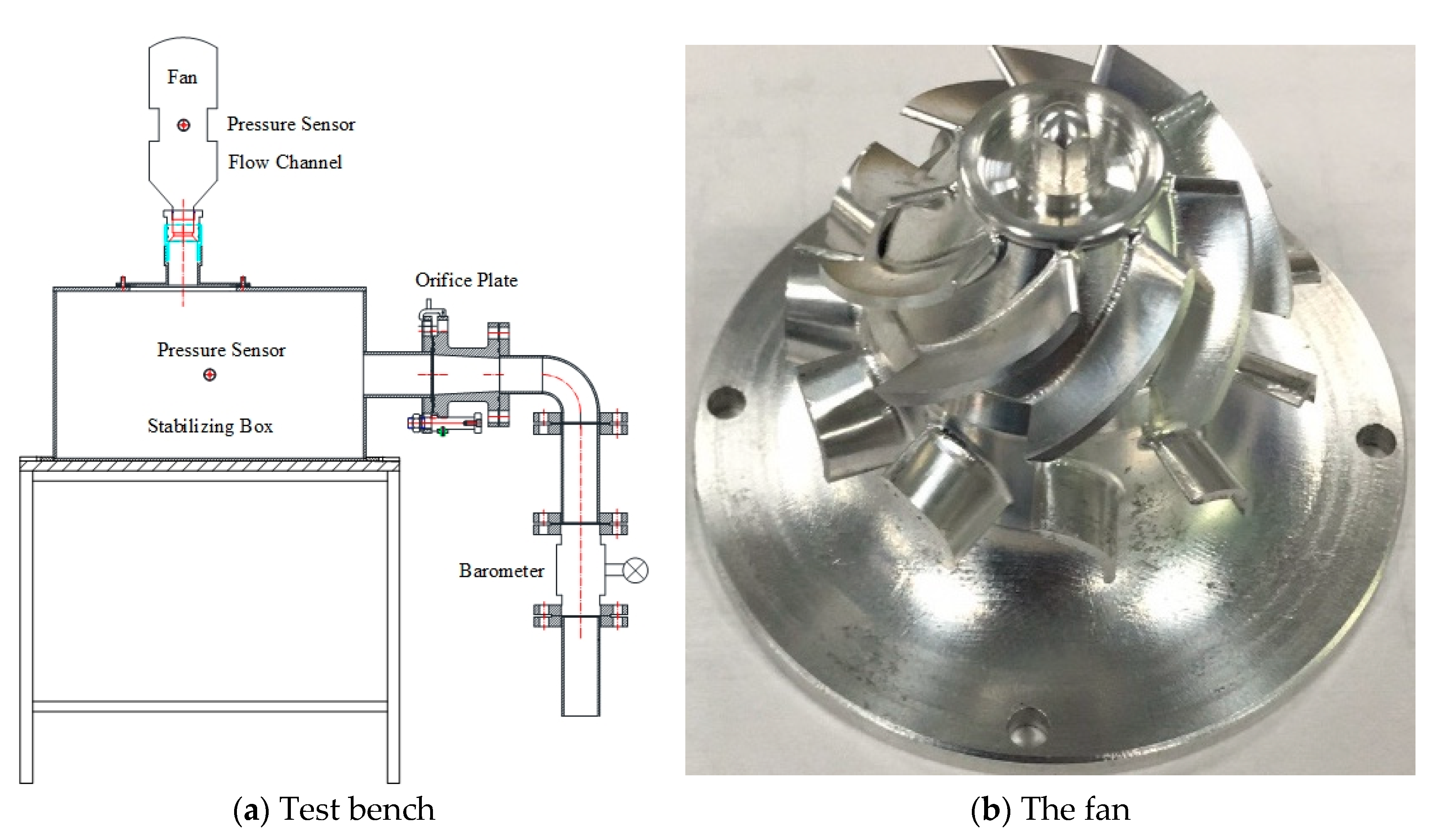

25] realized the optimization research with blade number and blade stagger angle through orthogonal experiments, and found that the blade stagger angle has the greatest effect. After the optimization, the flow of the fan was increased by 0.108 kg/s, and it was experimentally verified. Orthogonal experiment is also employed to study impeller optimization [

26]. The inlet width, outlet width, blade installation angle, and impeller diameter were selected as optimization parameters, and flow rate was selected as the optimization target. Combined with the range and variance analysis, the optimal combination of impellers was obtained, and the aerodynamic performance of the fan was significantly improved.

The aerodynamic performance of the fan with different structural parameters has been studied through experimental research and numerical simulation in the above literature review. On this basis, different optimization algorithms are applied to the fan design, but with various optimization goals. Furthermore, now researches mainly focus on single-target optimization studies, while multiparameter and multiobjective optimization studies on the fan are relatively rare.

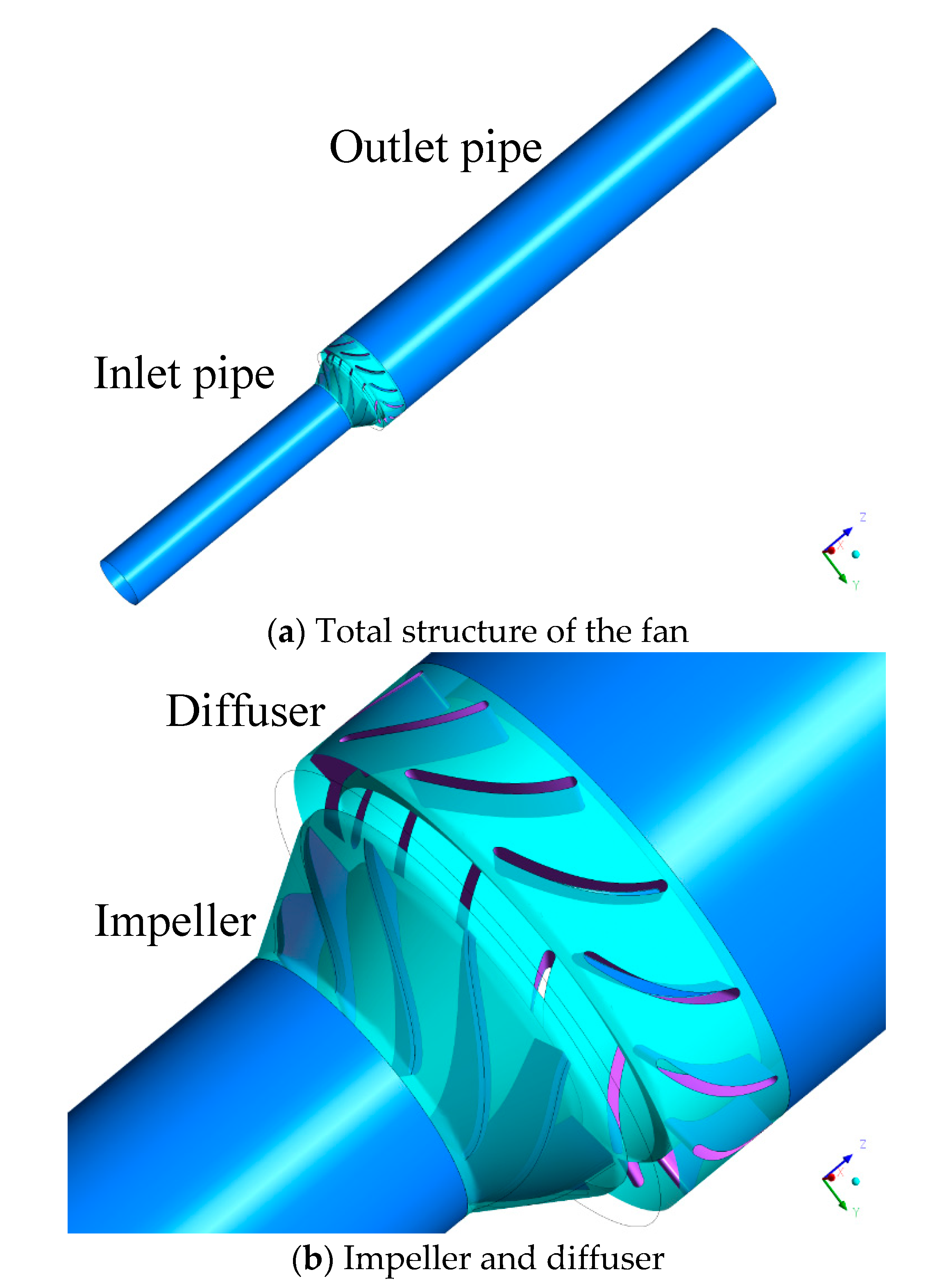

In this paper, investigations on the multiparameter and multiobjective optimization design of the fan are conducted. The hub outlet angle of impeller β1, the impeller outlet angle increment Δβ1, the impeller wrap angle φ, the hub outlet angle of diffuser β2, and the diffuser outlet angle increment Δβ2 are set as optimal parameters, and the pressure rise and efficiency are chosen as optimal objectives. With the conduction of orthogonal optimization design, the optimal fan is obtained. The influence degree of geometric parameters on the aerodynamic performance are studied, the optimal design scheme is obtained, and the internal flow mechanism is explored.