1. Introduction

In recent years, increasingly stringent fuel consumption and pollution emission regulations have brought unprecedented challenges to the automotive industry. Therefore, many companies have adopted advanced technical methods to improve engine efficiency [

1]. Studies show that the application of increasingly flexible and variable valve systems can improve the Miller cycle, reduce the pumping loss of the part-load on the gasoline engine, and improve the thermal efficiency and fuel economy [

2,

3]. Wang et al. found that the gasoline-fueled Miller cycle exhibited higher engine efficiency by up to 6.9% at an indicated mean effective pressure (IMEP) of 7.5 bar [

4]. Li’s research found that when the Miller cycle was used, the indicated specific fuel consumption (ISFC) was reduced by 11% relative to the ISFC of the original engine [

5].

The variable valve actuation (VVA) is mainly divided into three categories, including the mechanical, electromagnetic, and electro-hydraulic types [

6,

7,

8]. The mechanical type has high reliability and control accuracy. However, the adjustment degree of freedom in this scheme is low so that the flexibility is limited [

9,

10]. On the other hand, the electromagnetic type has functional shortcomings such as problems associated with motion control. Meanwhile, the response frequency of the solenoid valve limits the maximum speed of the engine [

11,

12]. Moreover, the electro-hydraulic type has superior characteristics, including flexible mechanism configuration, high system rigidity and fast response [

13,

14,

15]. It is worth noting that the 1.4 L MultiAir engine developed by the Fiat company is driven by an electro-hydraulic valve mechanism, where the rated speed of the engine is 5500 rpm. Studies show that the fuel consumption of this engine reduces by 7.6%, when compared to conventional engines [

16,

17]. Wei et al. produced a prototype that can realize the throttle control of gasoline engines without throttling [

18]. Hu et al. reduced the

emissions of diesel engines through the continuously variable valve lift (VL) mechanism [

19]. These achievements indicate that the electro-hydraulic variable valve has reasonable application prospects.

The electro-hydraulic VVA involves multiple hydraulic components. When the hydraulic system is working, the multi-factor coupling effect imposes pressure fluctuations on the system [

20,

21]. These pressure fluctuations can cause vibration, noise, and fatigue failure of hydraulic components in hydraulic systems, thereby reducing the service life of the workpiece and the overall performance of the engine [

22]. Han et al. analyzed the transient pressure of the hydraulic oil circuit of the electro-hydraulic VVA and studied the influence of the opening slope of the return solenoid valve on the system pressure [

23]. Xie et al. reduced the hydraulic fluctuations effectively in the VVA by improving the quality of moving parts and designing the valve cam profile [

24]. Furthermore, Zhong et al. analyzed the effects of different engine speeds and throttle openings on the pressure fluctuations [

25].

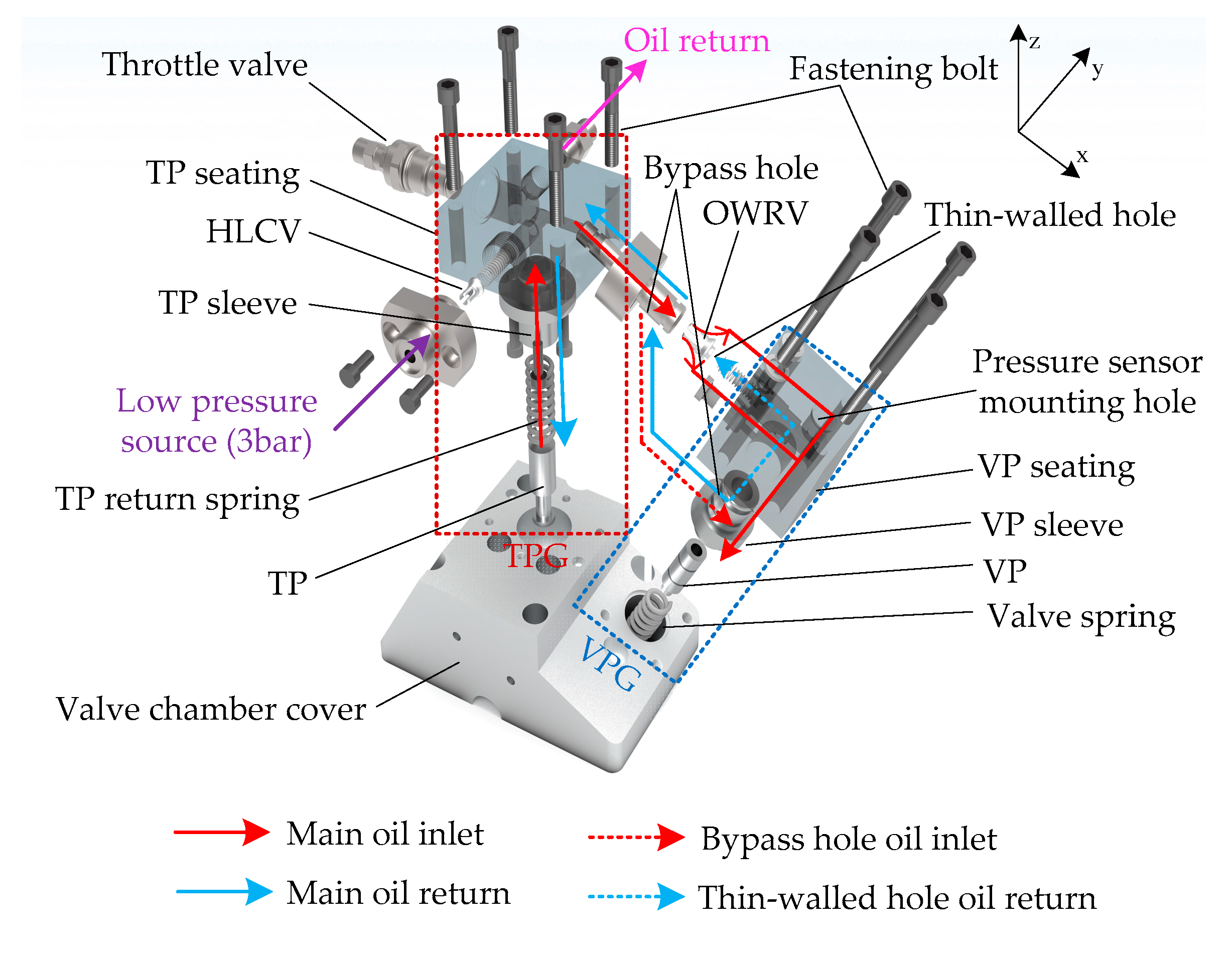

It is worth noting that the electro-hydraulic VVA is limited by space and compact structure. However, structural parameters such as the tappet piston, valve piston, and pipe diameter play a key role in the valve performance. Moreover, the valve spring preload and rigidity, the valve piston quality, and the diameter size of the thin-walled hole of valve-seating buffer mechanism (VSBM) components also have a remarkable impact on the vibration and pressure fluctuation of the hydraulic system. In the present study, these parameters were analyzed through numerical simulations and experimental study. Moreover, solutions to reduce the pressure fluctuation were obtained successfully.

The Taguchi method is utilized widely in the design and analysis of the experimental method to optimize the performance characteristics through the setting of process parameters. Based on orthogonal arrays, the number of experiments, which may lead to an increase in time and cost, can be reduced by using the Taguchi method. It employs a specific design of orthogonal arrays to learn the full set of parameters by performing the least number of experiments only. Interaction problems are often encountered in the orthogonal experiment [

26,

27,

28]. Feng et al. performed the multi-objective optimization of the forging process parameters on the helical gear precision by using the Taguchi method. They determined the optimal combination of process parameters through the modified Taguchi method [

29]. Shin and Lee studied the accelerated condition of the brush wear on a small brush-type DC motor by using the Taguchi method and analyzed the impact of various factors to assess the influencing potential of important factors accurately, objectively, and quantitatively on data [

30]. Accordingly, they demonstrated that the orthogonal experiment could be used to analyze the effect of multi-factor coupling on the VVA, thereby seeking the optimal combination of key parameters through the Taguchi method.

In the present study, a cam-driven hydraulic variable valve actuation (CDH-VVA) was designed. By controlling the opening of the throttle valve, the VL acted as a continuous variable. Moreover, the mathematical model of the CDH-VVA was established and the transfer function of the throttle opening to the VL was derived. The influence of the dynamic characteristics and main performance parameters of the hydraulic power components in the system on the VL was analyzed. Moreover, the AMESim simulation model was established. Then the correctness of the simulation model was verified through the test. An orthogonal experiment with interaction was designed in this regard. Furthermore, the effect of multi-factor coupling on VL and pressure fluctuations was investigated through the Taguchi method to obtain the optimal combination of horizontal factors. For better space layout, the valve-seating velocity (VSV) and the pressure fluctuation were reduced. The effect of the key parameter coupling on the hydraulic VVA was studied through further simulation analysis. Measurements for reducing the pressure fluctuation were finally proposed.

5. Analysis of the Main Factors Affecting the System

The orthogonal test demonstrated that the piston area, spring preload force of the VSBM, the VSP, and the valve piston mass exhibited a significant impact on the system. Moreover, significant interactional effects between the spring preload force of the VSBM and other factors were also observed. The orthogonal test result points out the direction for further exploration of valve motion characteristics and pressure fluctuations, and lays the foundation for subsequent experimental research.

5.1. Effect of Spring Preload on the System

Figure 8 shows the VL and VPC pressure curves when the valve spring preload is set to 195 N, 205 N, and 215 N. As the preload of the valve spring increases, under the same spring stiffness and push-open valve force, the spring displacement and the VL decrease. Moreover, the maximum difference is 8.27 − 8 = 0.27 mm, and the CT is basically the same. It is observed that there is no obvious change in the fluctuation range of the VPC pressure curve, and the general trend is the same. The maximum pressure increases as the spring preload increases, and the maximum difference is 30.3 − 28.6 = 1.7 bar. Therefore, the VSP has little effect on the VPC pressure, which affects the VL.

Figure 9 shows the VL curve, VPC pressure, and thin-walled hole flow curve when the spring preload of the VSBM was set to 30 N, 40 N, and 50 N. As the spring preload of the VSBM increases, under the same spring stiffness and push-open valve force, the spring displacement decreases and the VL decreases. Moreover, it is found that the maximum difference is 8.18 − 8 = 0.18 mm. The VL reaches the maximum peak lag, and the CT is basically the same. The pressure of the VPC increases as the preload force increases. Furthermore, the amplitude of the pressure fluctuation increases, and the maximum amplitude difference is 14.6 − 7.3 = 7.3 bar. According to the description provided in

Section 4.3, the horizontal factors

and

analyzed from the orthogonal test were considered to select the

factor with a smaller preload. Therefore, it was observed that the pressure fluctuation trend was affected by the thin-walled hole of the VSBM. Each time the peaks and troughs of the pressure fluctuations corresponded to the changes in the flow of the thin-walled hole, the effect of the diameter size of the thin-walled hole on the pressure fluctuations was further analyzed.

5.2. Effect of the Diameter Size of the Thin-Walled Hole of VSBM on the Pressure Fluctuation

The throttling phenomenon caused by the flow of the hydraulic oil not only causes flow loss, but also aggravates the pressure fluctuation within the hydraulic system, reduces the throttling effect in the hydraulic system, and can reduce the pressure fluctuation caused by throttling in the system. The correlation of the flow

between the TPC and the VPC and the pressure difference

is described as follows:

where,

and

denote the effective flow area and flow coefficient, respectively. Moreover,

and

are the geometric flow area and density of the liquid, respectively.

When the VP returns to the valve seating at the remaining 2 mm, then the hydraulic oil in the VPC returns to the TPC through the thin-walled hole. The smaller size of the thin-walled hole can reduce the effective flow area, thereby reducing the flow between the VPC and the TPC. Therefore, the valve can be seated smoothly. Moreover, the abovementioned equation shows that when the flow rate remains basically unchanged, the small effective flow area produces a significant pressure difference , which is beneficial to reduce the seating VSV. However, during the valve movement, the pressure fluctuation inside the hydraulic system gets aggravated between the VPC and the TPC. According to the evaluation index of FEV Group GmbH on VSV, when the VSV is less than 0.5 , the valve obtains stable seating. Therefore, considering the stable seating, it is necessary to increase the diameter size of the thin-walled hole appropriately.

Figure 10 shows the VPC pressure curves and valve movement velocity curves when the diameter of the thin-walled hole of the VSBM was set to 1.4 mm, 1.5 mm and 1.6 mm. During the phase of the valve opening and rising, the high-pressure oil mainly flows from the check valve of the VSBM (main inlet channel) and the bypass hole (auxiliary oil channel) to the VPC and pushes the valve upward. Therefore, in the rising stage of the valve, changing the diameter size of the thin-walled hole does not lead to a significant change in the pressure fluctuation of the hydraulic system. When the VP returns to the valve seating at the remaining 2 mm, the high-pressure oil only passes through the thin-walled hole. The flow area suddenly decreases, causing pressure fluctuations. With the decrease in the diameter size of the thin-walled holes, the pressure fluctuations become more obvious. The diameter size of the thin-walled hole simultaneously affects the VSV and CT. On the premise of affecting the VSV and CT without selecting a larger diameter, pressure fluctuations in the hydraulic system can be reduced.

5.3. Effect of Stiffness on the Pressure Fluctuation

The orthogonal test shows that the spring preload has a significant effect on the system, and the spring preload is correlated to the spring stiffness. Therefore, the effects of the valve spring stiffness and the spring stiffness of the VSBM on the system were further analyzed and discussed in this section.

Figure 11 shows the VPC pressure curves and VL curves when the spring stiffness of VSBM is 1

, 5

and 10

The VPC pressure curves show that when the spring stiffness is 1

, the pressure fluctuation is significant, which affects the valve descent process. However, when the spring stiffness is 5

and 10

, there is no obvious change in the pressure fluctuation. With the increase in the spring stiffness, the amplitude of pressure fluctuations decreases. Therefore, the spring stiffness was appropriately increased to effectively reduce the pressure fluctuation.

Figure 12 shows the VPC pressure curves when the spring stiffness of the valve is 25

, 35

and 45

. As the valve spring stiffness increases, the amplitude of the pressure fluctuation decreases, viz.

. It is observed that

, viz. the amplitude of the pressure fluctuations does not change significantly. When the valve returns to the buffer stage, as the valve spring stiffness decreases, the valve cavity pressure produces a peak and a trough. Therefore, the spring stiffness is appropriately increased to effectively reduce the pressure fluctuation.

The abovementioned analysis shows that increasing the spring stiffness can reduce the pressure fluctuation. Therefore, increasing the natural frequency of the hydraulic variable valve mechanism can also reduce its vibration, which can reduce the pressure fluctuation in the hydraulic system. The natural frequency of the hydraulic variable valve mechanism is

. As a result, increasing the total stiffness

of the mechanism and reducing the total mass

of the moving parts can increase the natural frequency of the CDH-VVA. The mechanical stiffness in the hydraulic variable valve mechanism is higher than the stiffness of the hydraulic oil. Therefore, the total stiffness of the hydraulic variable valve mechanism mainly depends on the stiffness of the hydraulic oil. When the high-pressure oil pushes the valve to open through the VPC, it is equivalent to applying a force

on the hydraulic piston end. Moreover, the pressure of the hydraulic oil increases

accordingly. Due to the compressibility of the hydraulic oil, the valve piston produces a slight displacement

. The rigidity of the hydraulic system is mathematically expressed as follows:

where

and

denote the volume change of hydraulic oil and the area of VP, respectively.

The elastic modulus

of the hydraulic oil is described as follows:

where

is the total volume of the hydraulic oil. Then, the Equations (21) and (22) are combined to obtain the stiffness of the hydraulic oil as follows:

The stiffness of the hydraulic system is proportional to the square of the area of VP and inversely proportional to the total volume of hydraulic oil. Therefore, the area of the VP should be increased, the total volume of the hydraulic oil should be reduced, and the rigidity of the hydraulic system should be increased. Moreover, reducing the mass of the valve moving parts can also increase the system rigidity .

Figure 13 shows the pressure distribution in the VPC when the valve piston mass is set to 50 g, 60 g, and 70 g. With the increase in the valve mass, there is no obvious change in the first pressure fluctuation, while the amplitude of the second and third pressure fluctuations exhibits a remarkable increasing trend. Moreover, the maximum pressure fluctuation amplitude difference is 3.6 bar. It is worth noting that changing the valve piston material and reducing the material processing to reduce the valve piston mass can reduce pressure fluctuations.

Figure 14 shows the pressure distributions in the VPC, when the VP area is set to 123 mm

2, 143 mm

2 and 165 mm

2. Clearly, as the area of the VP increases, the amplitude of pressure fluctuations decreases significantly. Moreover, the maximum peak pressure drops from

to

, and the drop pressure reaches 19.2 bar. The optimal values of the horizontal factor A selected based on the orthogonal experiment are

and

, combined with the simulation analysis results, finally

was selected.

Figure 15 shows the pressure distributions in the VPC when the total volume of the hydraulic oil in the system is in the following order:

. As the total volume of the hydraulic oil in the system decreases, there is no significant change in the first pressure fluctuation, while the amplitude of the second and third pressure fluctuations changes significantly. When the total volume of the hydraulic oil in the system is

, the third pressure fluctuation is almost zero. Therefore, appropriately reducing the total volume of the hydraulic oil in the system can reduce the pressure fluctuation.