Numerical Characterization of an Ultrasonic Mist Generator as an Evaporative Cooler

Abstract

1. Introduction

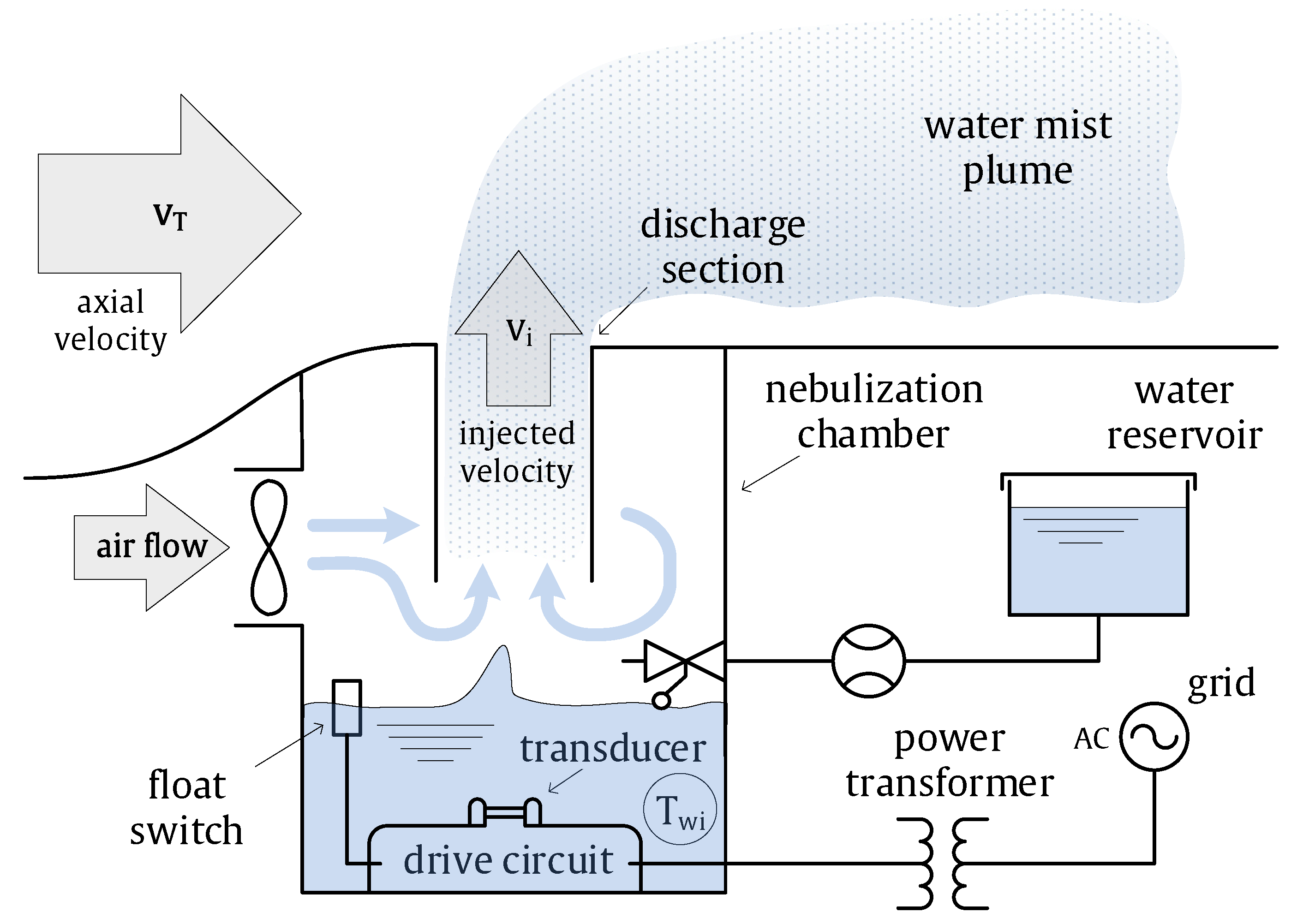

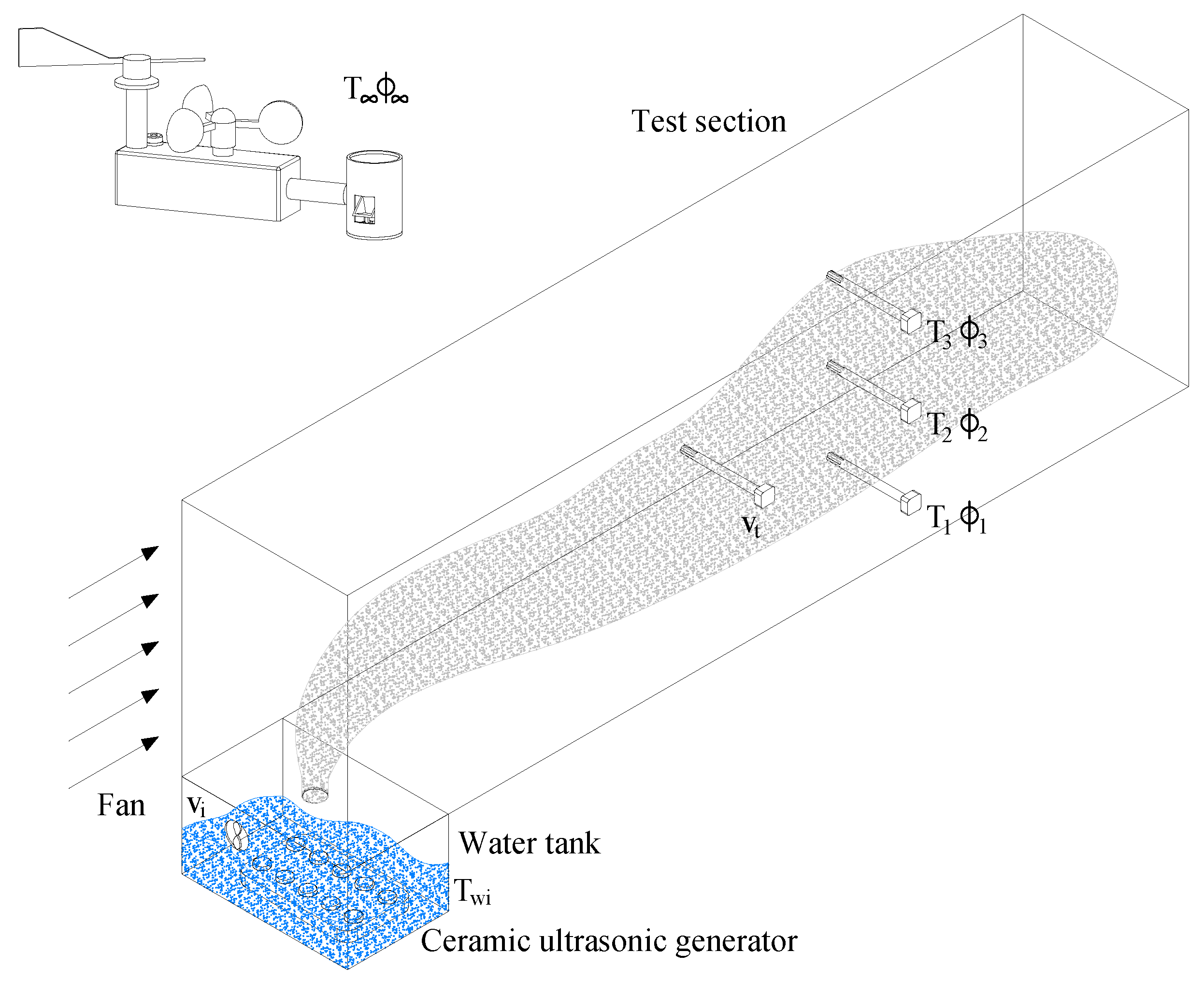

2. Materials and Methods

2.1. Experimental Test Facility

2.2. Wind-Tunnel Experiments

2.3. Physical Model

2.4. Mathematical Method (Governing Equations)

2.4.1. Continuous Phase (Moist Air)

2.4.2. Discrete Phase

2.5. Numerical Method

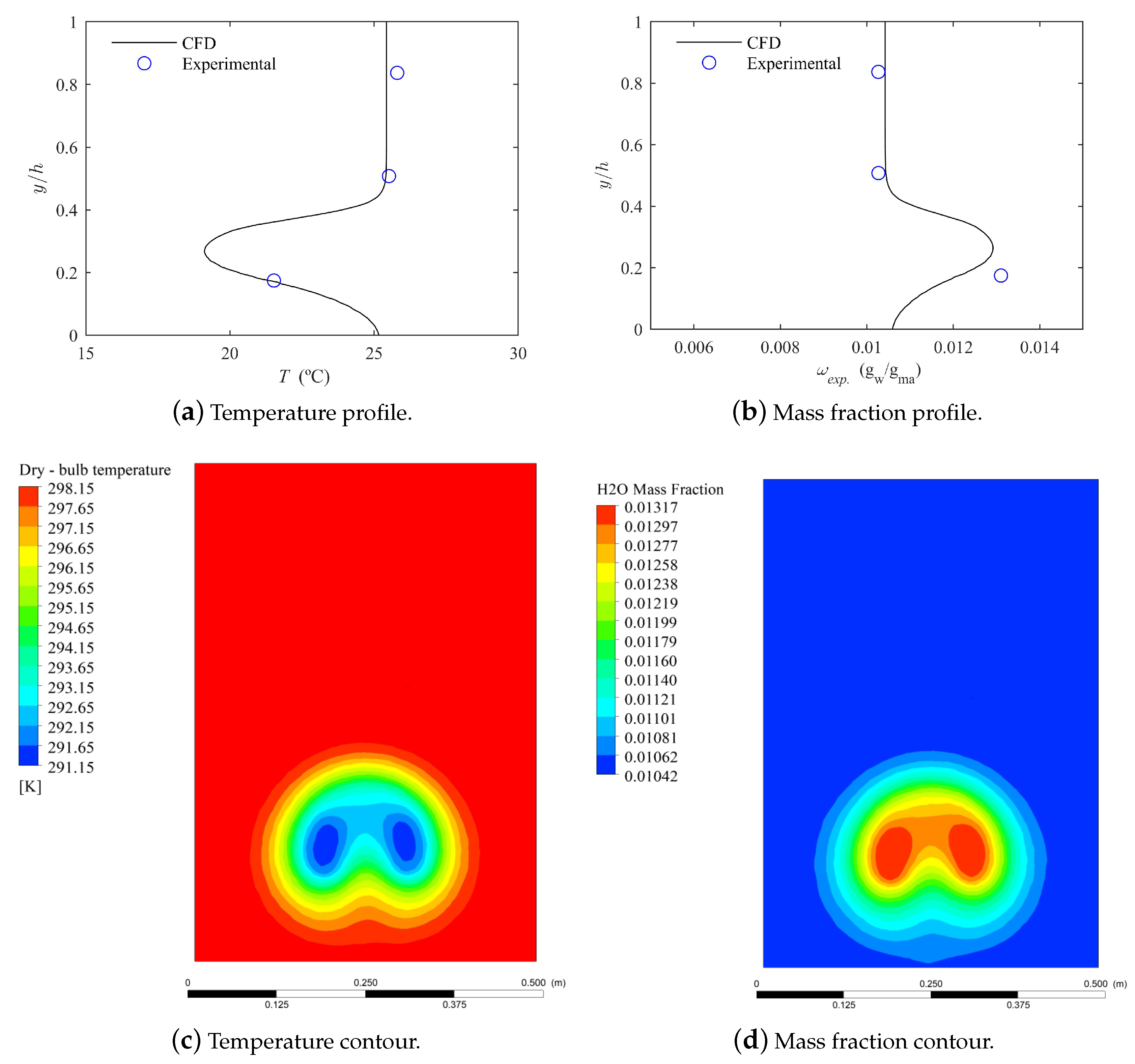

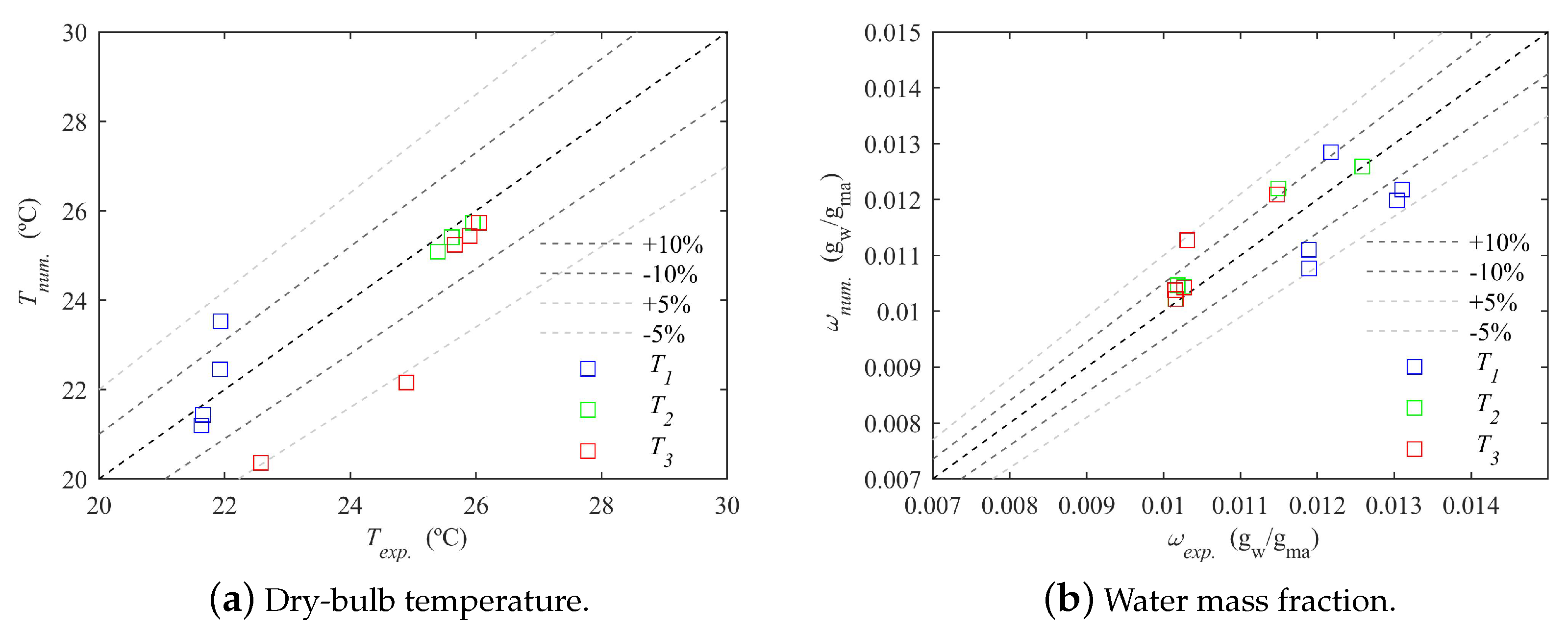

3. Results and Discussion

3.1. Problem Validation

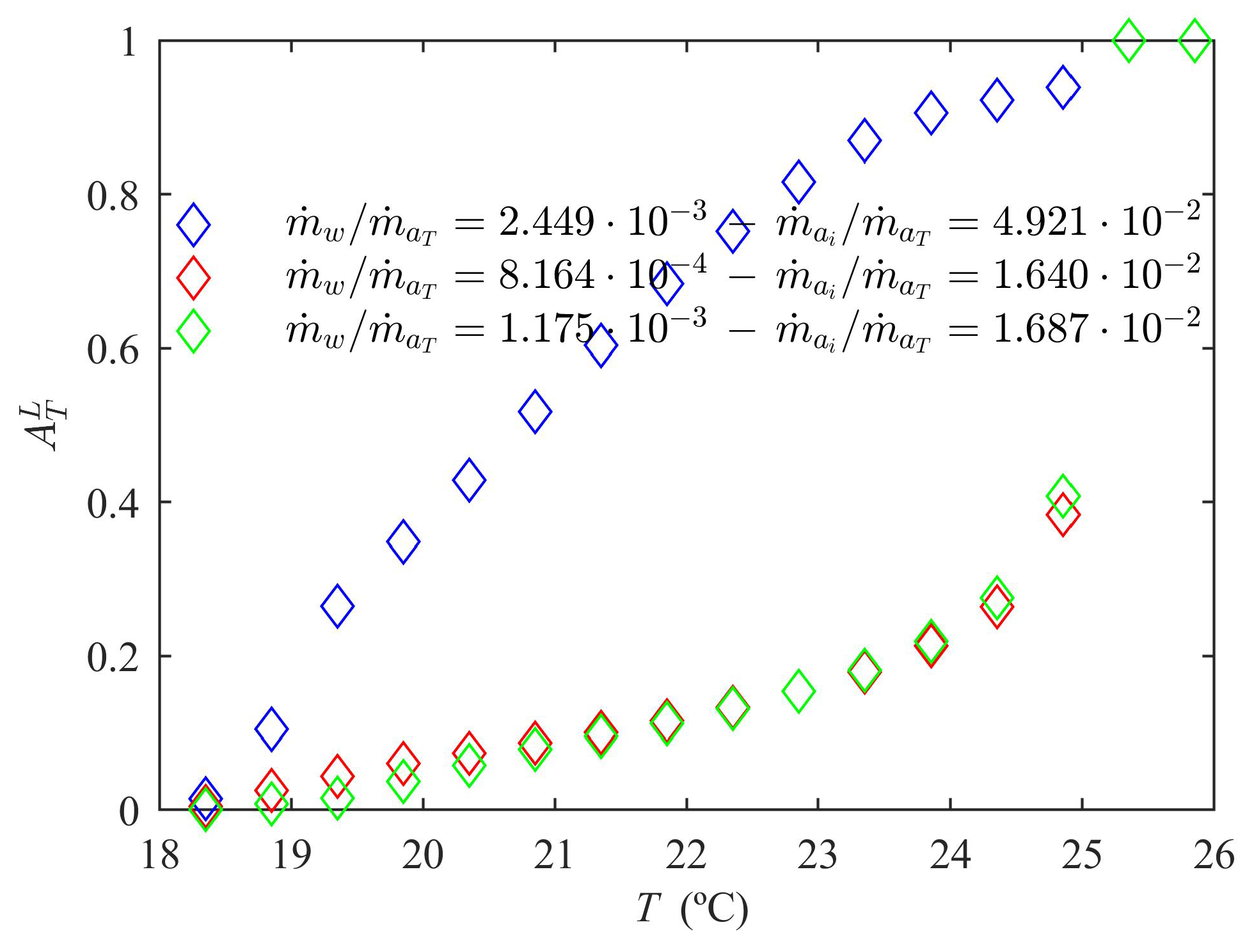

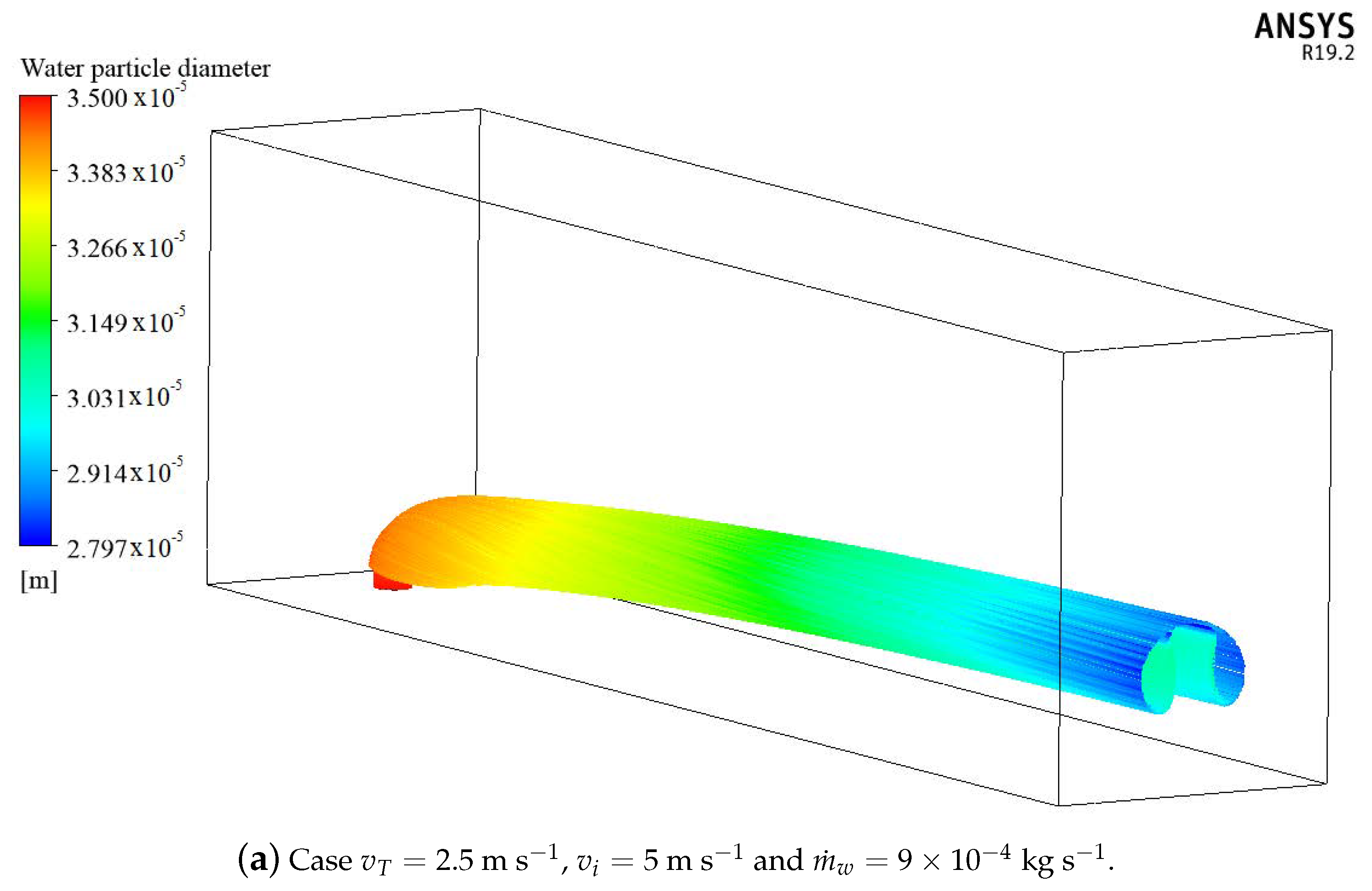

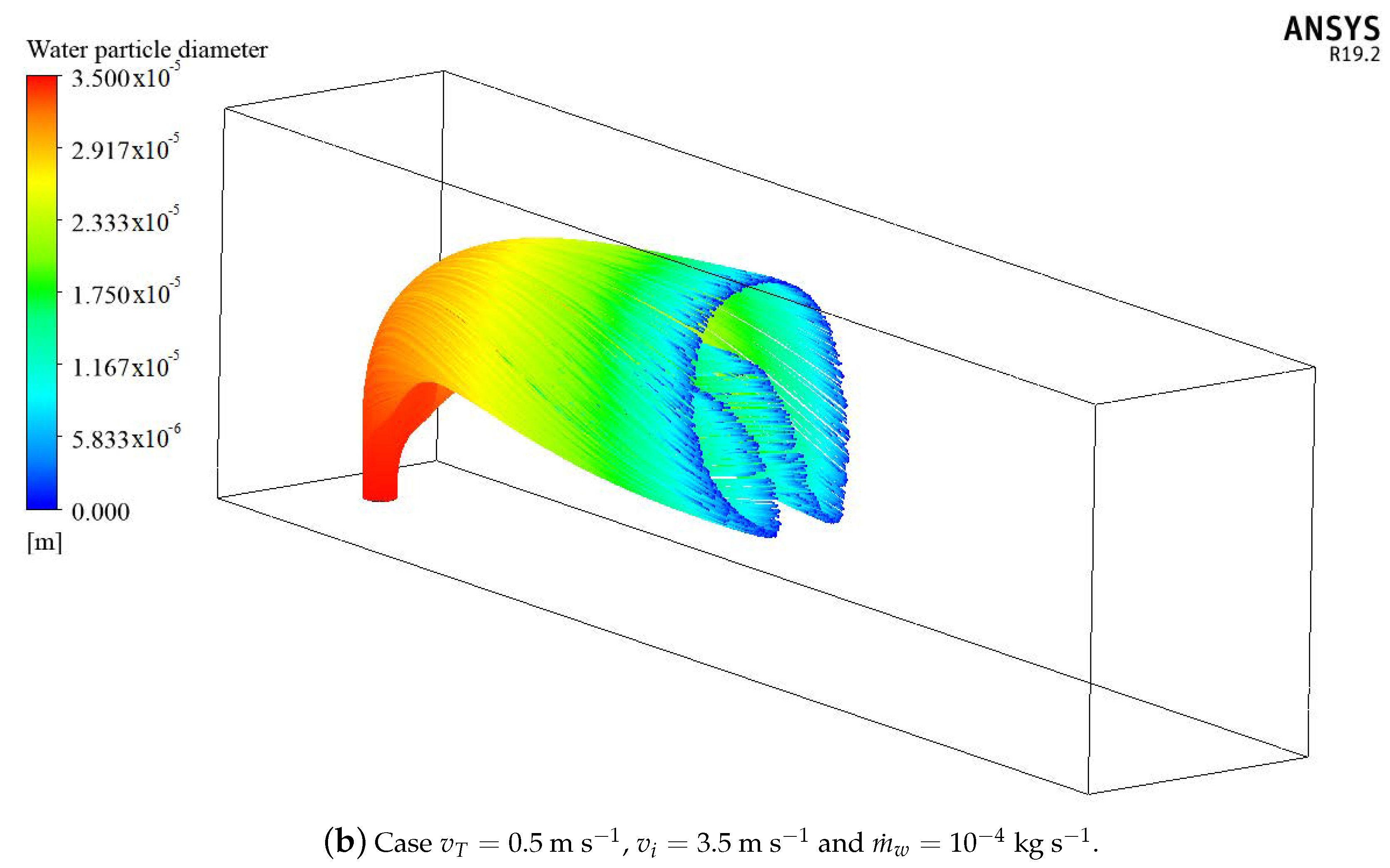

3.2. Parametric Analysis

3.3. Optimization Analysis

4. Conclusions

- The average evaporative cooling efficiency evaluated at the outlet section of the domain, , increases when the water-to-air mass flow and air-to-air mass flow ratios ( and ) increase. A maximum value of is found for and .

- A dimensionless correlation for the average evaporative cooling efficiency evaluated at the outlet section of the domain, , as a function of the relevant parameters has been developed. It shows an excellent agreement with the predicted results.

- The observations regarding the wet length have allowed identifying the operation ranges that produce a more homogeneous distribution of water mist and, therefore, promote the evaporation. These ranges are and .

- The optimization analysis based on the coefficient of performance has proven that the operational ranges leading to the best overall performance are and . Under these conditions, there is a better distribution of the water mist throughout the control section and a more homogeneous and effective evaporative cooling process. This will not only improve the performance of the air-cooled condenser heat pump, but also lower the overall ancillary power consumption.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Symbols | |

| area of the droplet (m) | |

| percentage area for temperature T, at section x (-) | |

| b | domain width (m) |

| drag coefficient (-) | |

| specific heat at constant pressure (J kg K) | |

| D | mist inlet area diameter (m) |

| mass diffusivity (m s) | |

| droplet diameter (m) | |

| arithmetic mean diameter (m) | |

| Sauter mean diameter (m) | |

| Rosin–Rammler mean drop diameter (m) | |

| pressure loss (Pa) | |

| safety factor numerical value in the GCI analysis () (-) | |

| g | gravitational constant (m s) |

| h | domain height (m) |

| heat transfer coefficient (W m K) | |

| mass transfer coefficient (m s) | |

| enthalpy of vaporization (J kg) | |

| L | domain length (m) |

| wet length (m) | |

| l | distance between inlet sections (m) |

| M | cumulative mass fraction (-) |

| m | mass (kg) |

| air mass flow rate at the mist discharge section (kg s) | |

| air mass flow rate at the inlet section of the domain (kg s) | |

| mass flow rate of water mist (kg s) | |

| Nu | Nusselt number (-) |

| N | number of droplets (-) |

| n | Rosin–Rammler spread factor (-) |

| p | pressure (Pa) |

| Pr | Prandtl number (-) |

| Q | volumetric flow rate of air (m s) |

| cooling capacity (W) | |

| Re | Reynolds number (-) |

| r | grid refinement ratio in the GCI analysis (-) |

| Sc | Schmidt number (-) |

| Sh | Sherwood number (-) |

| s | order of convergence in the GCI analysis () (-) |

| T | dry temperature (C) |

| wet bulb temperature (C) | |

| temperature of the water in the tank (C) | |

| mean temperature calculated at section x (C) | |

| t | time (s) |

| average air flow velocity in the mist discharge section (m s) | |

| average air flow velocity in the wind tunnel (m s) | |

| power absorbed by the primary fan (W) | |

| power absorbed by the secondary fan (W) | |

| power absorbed ultrasonic generator device (W) | |

| y | molar concentration (mol m) |

| Greek symbols | |

| relative error of the solutions in the GCI analysis (-) | |

| fan efficiency (-) | |

| evaporative cooling efficiency calculated at section x (-) | |

| dynamic viscosity (kg m s) | |

| mass fraction of moist air (kg kg) | |

| relative humidity (-) | |

| density (kg m) | |

| stress tensor (kg m) | |

| Re | Reynolds number (-) |

| Subscripts | |

| a | air |

| d | droplet |

| ∞ | ambient conditions |

| moist air | |

| w | water |

| Abbreviations | |

| CFD | computational fluid dynamics |

| COP | coefficient of performance |

| GCI | grid convergence index |

| HVAC | heating, ventilation and air-conditioning |

| SMD | Sauter mean diameter |

References

- IEA. The Future of Cooling: Opportunities for Energy-Efficient Air Conditioning; Annual report; IEA: Paris, France, 2018. [Google Scholar]

- Martínez, P.; Ruiz, J.; Cutillas, C.; Martínez, P.; Kaiser, A.; Lucas, M. Experimental study on energy performance of a split air-conditioner by using variable thickness evaporative cooling pads coupled to the condenser. Appl. Therm. Eng. 2016, 105, 1041–1050. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Al-Farayedhi, A.A.; Gandhidasan, P. Experimental investigation of a vapor compression system with condenser air pre-cooling by condensate. Appl. Therm. Eng. 2017, 110, 1255–1263. [Google Scholar] [CrossRef]

- Yu, F.; Ho, W.; Chan, K.; Sit, R. Theoretical and experimental analyses of mist precooling for an air-cooled chiller. Appl. Therm. Eng. 2018, 130, 112–119. [Google Scholar] [CrossRef]

- Hooman, K.; Guan, Z.; Gurgenci, H. 9-Advances in dry cooling for concentrating solar thermal (CST) power plants. In Advances in Concentrating Solar Thermal Research and Technology; Blanco, M.J., Santigosa, L.R., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2017; pp. 179–212. [Google Scholar] [CrossRef]

- Yao, Y. Research and applications of ultrasound in HVAC field: A review. Renew. Sustain. Energy Rev. 2016, 58, 52–68. [Google Scholar] [CrossRef]

- Yao, Y.; Pan, Y.; Liu, S. Power ultrasound and its applications: A state-of-the-art review. Ultrason. Sonochemistry 2020, 62, 104722. [Google Scholar] [CrossRef] [PubMed]

- Tissot, J.; Boulet, P.; Trinquet, F.; Fournaison, L.; Macchi-Tejeda, H. Air cooling by evaporating droplets in the upward flow of a condenser. Int. J. Therm. Sci. 2011, 50, 2122–2131. [Google Scholar] [CrossRef]

- Hou, Y.; Tao, Y.; Huai, X.; Guo, Z. Numerical characterization of multi-nozzle spray cooling. Appl. Therm. Eng. 2012, 39, 163–170. [Google Scholar] [CrossRef]

- Alkhedhair, A.; Gurgenci, H.; Jahn, I.; Guan, Z.; He, S. Numerical simulation of water spray for pre-cooling of inlet air in natural draft dry cooling towers. Appl. Therm. Eng. 2013, 61, 416–424. [Google Scholar] [CrossRef]

- Xia, L.; Gurgenci, H.; Liu, D.; Guan, Z.; Zhou, L.; Wang, P. CFD analysis of pre-cooling water spray system in natural draft dry cooling towers. Appl. Therm. Eng. 2016, 105, 1051–1060. [Google Scholar] [CrossRef]

- Sadafi, M.; Ruiz, J.; Lucas, M.; Jahn, I.; Hooman, K. Numerical and experimental study on a single cone saline water spray in a wind tunnel. Int. J. Therm. Sci. 2017, 120, 190–202. [Google Scholar] [CrossRef]

- Kim, K.D.; Jin, D.H.; Choi, Y.C. Numerical simulation on the generation of ultrasound and formation of water fog in the ultrasonic gas atomizer. Ultrasonics 2020, 102, 105851. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, J. Experimental Characterization and Modelling of the Binomial Distribution System-Drift Eliminator in Cooling Towers. Ph.D. Thesis, Technical University of Cartagena, Cartagena, Spain, 2014. [Google Scholar]

- Martínez, P.; Ruiz, J.; Martínez, P.; Kaiser, A.; Lucas, M. Experimental study of the energy and exergy performance of a plastic mesh evaporative pad used in air conditioning applications. Appl. Therm. Eng. 2018, 138, 675–685. [Google Scholar] [CrossRef]

- Ruiz, J.; Cutillas, C.; Kaiser, A.; Zamora, B.; Sadafi, H.; Lucas, M. Experimental study on pressure loss and collection efficiency of drift eliminators. Appl. Therm. Eng. 2019, 149, 94–104. [Google Scholar] [CrossRef]

- Meroney, R.N. CFD prediction of cooling tower drift. J. Wind Eng. Ind. Aerodyn. 2006, 94, 463–490. [Google Scholar] [CrossRef]

- Lucas, M.; Martínez, P.; Ruiz, J.; Kaiser, A.; Viedma, A. On the influence of psychrometric ambient conditions on cooling tower drift deposition. Int. J. Heat Mass Transf. 2010, 53, 594–604. [Google Scholar] [CrossRef]

- Montazeri, H.; Blocken, B.; Hensen, J. Evaporative cooling by water spray systems: CFD simulation, experimental validation and sensitivity analysis. Build. Environ. 2015, 83, 129–141. [Google Scholar] [CrossRef]

- Sadafi, M.; Jahn, I.; Hooman, K. Nozzle arrangement effect on cooling performance of saline water spray cooling. Appl. Therm. Eng. 2016, 105, 1061–1066. [Google Scholar] [CrossRef]

- Alkhedhair, A.; Jahn, I.; Gurgenci, H.; Guan, Z.; He, S.; Lu, Y. Numerical simulation of water spray in natural draft dry cooling towers with a new nozzle representation approach. Appl. Therm. Eng. 2016, 98, 924–935. [Google Scholar] [CrossRef]

- Zhang, Z.; He, S.; Yan, M.; Gao, M.; Shi, Y.; Lu, Y.; Liu, J.; Guo, C.; Huang, X. Numerical study on the performance of a two-nozzle spray cooling system under different conditions. Int. J. Therm. Sci. 2020, 152, 106291. [Google Scholar] [CrossRef]

- Morsi, S.A.; Alexander, A.J. An investigation of particle trajectories in two-phase flow systems. J. Fluid Mech. 1972, 55, 193–208. [Google Scholar] [CrossRef]

- Ranz, W.E.; Marshall, W.R. Evaporation from drops part I. Chem. Eng. Prog. 1952, 48, 141–146. [Google Scholar]

- Ranz, W.E.; Marshall, W.R. Evaporation from drops part II. Chem. Eng. Prog. 1952, 48, 173–180. [Google Scholar]

- Ruiz, J.; Kaiser, A.; Zamora, B.; Cutillas, C.; Lucas, M. CFD analysis of drift eliminators using RANS and LES turbulent models. Appl. Therm. Eng. 2016, 105, 979–987. [Google Scholar] [CrossRef]

- ANSYS FLUENT ©Academic Research, ANSYS FLUENT 19. 2018. Available online: https://www.ansys.com (accessed on 1 February 2019).

- Roache, P.J. Computational Fluid Dynamics; Hermosa Publishers: Albuquerque, NM, USA, 1972; p. 446. [Google Scholar]

| 10 Head Ultrasonic Mist Maker | |

|---|---|

| Number of atomizing cores | 10 |

| Ceramic core diameter | 16 mm |

| Input voltage | DC 48 V |

| Input power | 20 W/core |

| Resonance frequency | 1650 ± 50 kHz |

| Maximum atomization amount | 2.5 L h |

| Working water temperature | 1–55 C |

| Working water level | 60–80 mm |

| (m s) | (m s) | (kg s) | ( C) | (%) | ( C) | (%) | ( C) | (%) | ( C) | (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.615 | 3.315 | 25.43 | 51.78 | 21.63 | 81.97 | 25.62 | 50.61 | 25.90 | 49.75 | |

| 0.512 | 2.994 | 24.23 | 55.28 | 21.93 | 73.09 | 22.40 | 68.67 | 24.89 | 53.05 | |

| 2.183 | 3.450 | 25.73 | 49.78 | 22.51 | 72.25 | 25.95 | 49.08 | 26.05 | 48.81 | |

| 0.508 | 4.152 | 24.43 | 54.28 | 21.93 | 73.09 | 20.67 | 83.48 | 22.58 | 67.82 | |

| 1.095 | 3.023 | 25.23 | 52.08 | 21.65 | 81.41 | 25.39 | 50.88 | 25.67 | 49.88 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz, J.; Martínez, P.; Martín, Í.; Lucas, M. Numerical Characterization of an Ultrasonic Mist Generator as an Evaporative Cooler. Energies 2020, 13, 2971. https://doi.org/10.3390/en13112971

Ruiz J, Martínez P, Martín Í, Lucas M. Numerical Characterization of an Ultrasonic Mist Generator as an Evaporative Cooler. Energies. 2020; 13(11):2971. https://doi.org/10.3390/en13112971

Chicago/Turabian StyleRuiz, Javier, Pedro Martínez, Íñigo Martín, and Manuel Lucas. 2020. "Numerical Characterization of an Ultrasonic Mist Generator as an Evaporative Cooler" Energies 13, no. 11: 2971. https://doi.org/10.3390/en13112971

APA StyleRuiz, J., Martínez, P., Martín, Í., & Lucas, M. (2020). Numerical Characterization of an Ultrasonic Mist Generator as an Evaporative Cooler. Energies, 13(11), 2971. https://doi.org/10.3390/en13112971