The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation

Abstract

:1. Introduction

2. Materials and Methods

- Storage material: In this case, the pure PCM storage material.

- Storage component: All auxiliary equipment such as containment, insulation and heat exchangers required to unlock the storage capacity of the material.

- Storage system concept: All components required for the building supply and for the provision of heat and/or cold. Storage materials, storage components and conventional building service systems for energy provision are included. The main function of the storage system concept is to supply a defined building (building type, energetic standard and climate location) over a defined heating or cooling period. Examples of the possible benefits of PCM systems are the increased use of environmental heat and cold or the reduction of heating or cooling load peaks, which enables lower installed heating or cooling capacities.

2.1. LCA Specifications

2.2. Analysis at the Material Level

2.3. Analysis at the Component Level

2.4. Analysis at the System Level

2.5. Storage LCA Tool

3. Results

3.1. Material Level

3.2. Component and System Levels

3.2.1. Helsinki—North European Insulation Standard

3.2.2. Athens—North European Insulation Standard

3.2.3. Centralized Heating System with PCM Storage: Office Block in Helsinki

4. Discussion

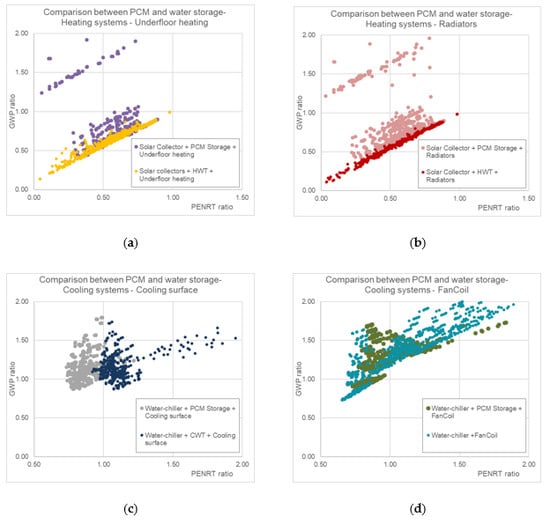

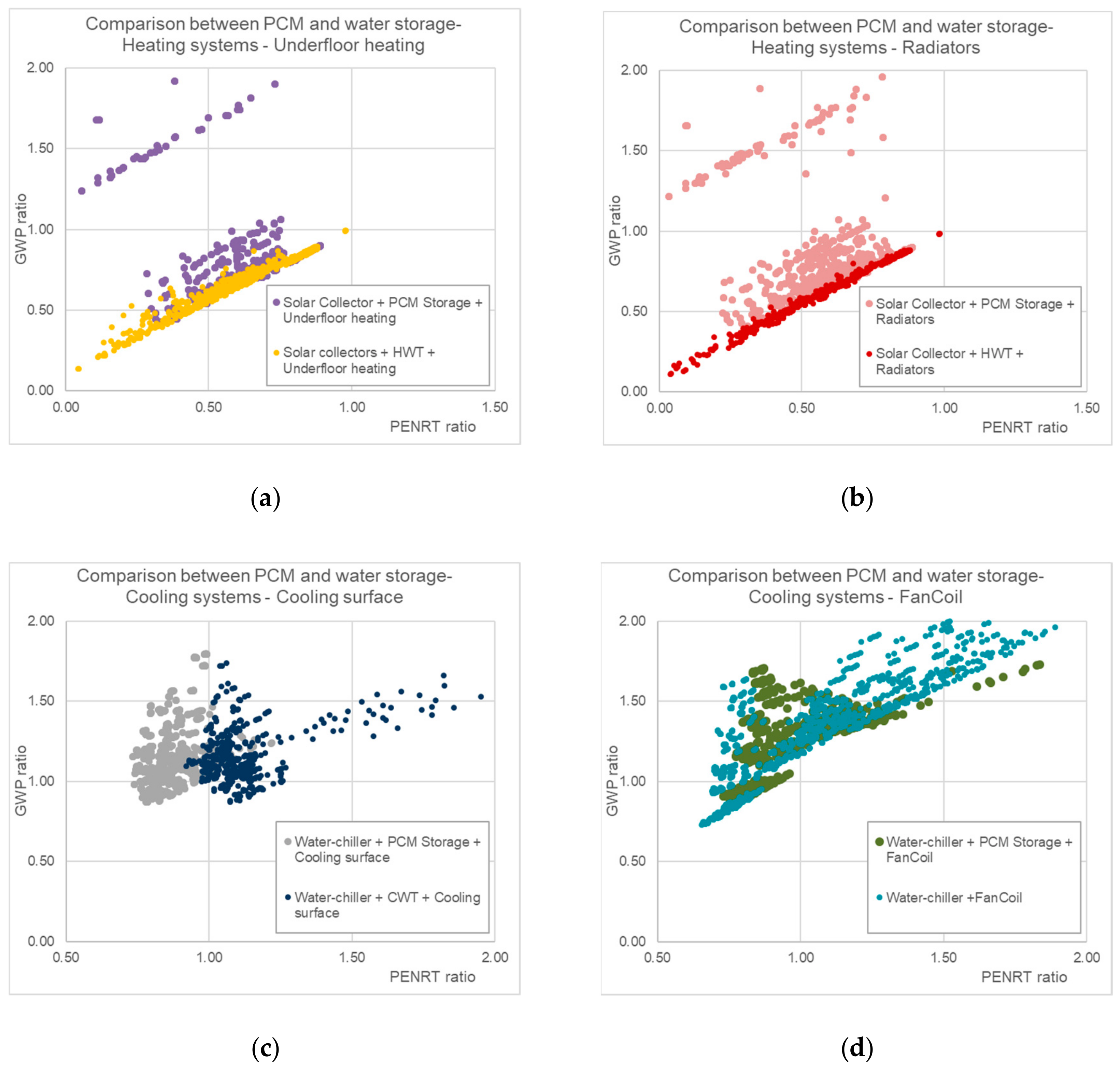

4.1. Centralized Heating Systems

- 6 collector sizes (1.03 to 228.8 m2);

- 12 storage sizes (daily to seasonal storage: 0.05 to 1181 m3);

- 3 building types (single-family house, multifamily house, office building);

- 4 building insulation standards (none, little, moderate, efficient);

- 3 locations (Athens, Strasburg, Helsinki);

- 2 PCMs (RT62HC, SP58).

4.2. Centralized Cooling Systems

- Three water chillers (2 to 31 kW capacity);

- Nine storage sizes (daily to seasonal storage: 0.25 to 19 m3);

- Three building types (single-family house, multifamily house, office building);

- Four building insulation standards (none, little, moderate, efficient);

- Three locations (Athens, Strasburg, Helsinki);

- Three different PCMs (RT10HC, RT11HC, SP15).

4.3. Decenteralized Systems

- Three water chiller powers (18 to 36 kW);

- Three water chiller temperatures (6, 10 or 14 °C);

- Three PCM mass distribution for chilled PCM ceilings (11, 16 or 22 kg/m2);

- Three storage volumes for PCM ventilation systems (1, 2 or 3 m3);

- Three volume flow rates for PCM ventilation systems (500, 1000 or 2000 m3/s);

- One building type (office building);

- Four building insulation standards for chilled PCM ceiling simulations (none, little, moderate, efficient);

- One building insulation standard for PCM ventilation systems (efficient);

- Three locations (Athens, Strasburg, Helsinki);

- Four different PCMs (RT18HC, SP21EK, RT24, SP24).

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Name | Melting Enthalpy (Wh/kg) | Melting Range (°C) | Heat Capacity (kJ/kg K) | Melting Point (°C) | Density (kg/m3) |

|---|---|---|---|---|---|

| RT10HC | 0.055 | 10–12 | 2.0 | 10 | 770 |

| RT10HC (Enc 1) | 0.041 | 10–12 | 1.7 | 10 | 1270 |

| RT11HC | 0.055 | 10–12 | 2.0 | 11 | 770 |

| RT11HC (Enc 1) | 0.041 | 10–12 | 1.7 | 11 | 1270 |

| RT18HC | 0.072 | 16–20 | 2.0 | 18 | 825 |

| RT18HC (Enc 1) | 0.053 | 16–20 | 1.7 | 18 | 1311 |

| RT21 | 0.043 | 18–23 | 2.0 | 21 | 825 |

| RT21 (Enc 1) | 0.032 | 18–23 | 1.7 | 21 | 1311 |

| RT24 | 0.043 | 21–24 | 2.0 | 24 | 825 |

| RT24 (Enc 1) | 0.032 | 21–24 | 1.7 | 21 | 1311 |

| RT62HC | 0.043 | 60–63 | 2.0 | 62 | 825 |

| SP15 | 0.050 | 15–17 | 2.0 | 15 | 1350 |

| SP15 (Enc 1) | 0.037 | 15–17 | 1.7 | 15 | 1700 |

| SP21EK | 0.047 | 21–23 | 2.0 | 21 | 1350 |

| SP21EK (Enc 1) | 0.035 | 21–23 | 1.7 | 21 | 1551 |

| SP58 | 0.069 | 56–59 | 2.0 | 58 | 1350 |

| SP58 (Enc 1) | 0.051 | 56–59 | 1.7 | 58 | 1551 |

| Water | 2.000 | 0 | 4.2 | 0 | 1000 |

| Name | GWP (kg CO2 eq./kWh 1) | PENRT (MJ/kWh 1) | Payback Cycles GWP | Payback Cycles PENRT |

|---|---|---|---|---|

| RT10HC | 18.3 | 880.9 | 82.8 | 226.0 |

| RT10HC (Enc) | 91.9 | 1877.9 | 372.8 | 476.4 |

| RT11HC | 18.1 | 877.01 | 81.9 | 225.0 |

| RT11HC (Enc) | 91.6 | 1873.8 | 371.9 | 475.3 |

| RT18HC | 316.4 | 15,348.6 | 1309.5 | 3981.9 |

| RT18HC (Enc) | 1398.9 | 28,602.2 | 5751.4 | 7414.2 |

| RT21 | 314.6 | 15,325.5 | 1302.1 | 3975.9 |

| RT21 (Enc) | 1397.3 | 28,582.2 | 5745.0 | 7409.0 |

| RT24 | 314.2 | 15,318.6 | 1300.4 | 3974.1 |

| RT24 (Enc) | 1396.9 | 28,576.1 | 5743.5 | 7407.4 |

| RT62HC | 314.2 | 15,318.6 | 1300.4 | 3974.1 |

| SP15 | 12.0 | 180.95 | 49.6 | 47.0 |

| SP15 (Enc) | 88.9 | 1266.1 | 360.9 | 324.6 |

| SP21EK | 127.1 | 1794.2 | 523.0 | 465.8 |

| SP21EK (Enc) | 777.7 | 10,673.4 | 3195.7 | 2766.8 |

| SP58 | 527.1 | 7795.0 | 2169.2 | 2023.7 |

| SP58 (Enc) | 1173.5 | 16,616.6 | 4824.2 | 4309.6 |

| Water | 0.0 | 0.01 | 0.009 | 0.0 |

Appendix B

| Location | Helsinki | Strasbourg | Athens |

|---|---|---|---|

| θMean, year (°C) | 6.05 | 11.22 | 16.54 |

| θMonthly_min (°C) | −4.97 | 2.09 | 6.63 |

| θMonthly_max (°C) | 18.36 | 20.07 | 25.87 |

| Amplitude (°C) | 11.67 | 8.99 | 9.62 |

| Office Building | ||||

|---|---|---|---|---|

| Insulation Level | None | Little | Moderate | Efficient |

| (Mediterranean) | (Central Europe) | (North Europe) | ||

| U exterior wall W/(m2K) | 2.10 | 0.93 | 0.38 | 0.35 |

| U roof W/(m2K) | 2.77 | 0.56 | 0.20 | 0.15 |

| U floor W/(m2K) | 2.83 | 0.95 | 0.30 | 0.20 |

| U window W/(m2K) | 2. 83 | 2.83 | 1.40 | 0.70 |

| Building Type | Insulation Level | Location | Heating Demand kWh/m2/y | Cooling Demand kWh/m2/y |

|---|---|---|---|---|

| Office Building | None | Athens | 196.79 | 53.79 |

| Little | Athens | 75.53 | 47.84 | |

| Moderate | Athens | 29.56 | 48.01 | |

| Efficient | Athens | 17.93 | 42.74 | |

| Little | Strasbourg | 160.20 | 8.02 | |

| Moderate | Strasbourg | 72.76 | 13.88 | |

| Efficient | Strasbourg | 48.53 | 13.87 | |

| Moderate | Helsinki | 137.39 | 4.08 | |

| Efficient | Helsinki | 93.32 | 4.95 |

Appendix C

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. A/RES/70/1. Available online: https://sustainabledevelopment.un.org/ (accessed on 31 March 2020).

- United Nations. Analysis of the Voluntary National Reviews Relating to Sustainable Development Goal 7: Ensuring Access to Affordable, Reliable, Sustainable and Modern Energy for All. Available online: https://sustainabledevelopment.un.org/sdg7 (accessed on 31 March 2020).

- Energy European Commission. Heating and Cooling. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/heating-and-cooling_en (accessed on 11 May 2020).

- Dulac, J.; Abergel, T.; Delmastro, C. Buildings: Tracking Clean Energy Progress. Available online: https://www.iea.org/tcep/buildings/ (accessed on 18 March 2020).

- Arce, P.; Medrano, M.; Gil, A.; Oró, E.; Cabeza, L.F. Overview of thermal energy storage (TES) potential energy savings and climate change mitigation in Spain and Europe. Appl. Energy 2011, 88, 2764–2774. [Google Scholar] [CrossRef]

- Horn, R.; Burr, M.; Fröhlich, D.; Gschwander, S.; Held, M.; Lindner, J.P.; Munz, G.; Nienborg, B.; Schossig, P. Life Cycle Assessment of Innovative Materials for Thermal Energy Storage in Buildings. Procedia CIRP 2018, 69, 206–211. [Google Scholar] [CrossRef]

- Rindt, C.; Lan, S.; Gaeini, M.; Zhang, H.; Nedea, S.; Smeulders, D.M.J. Phase Change Materials and Thermochemical Materials for Large-Scale Energy Storage. In Continuous Media with Microstructure, 2nd ed.; Albers, B., Kuczma, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 187–197. ISBN 978-3-319-28241-1. [Google Scholar]

- Shigeishi, R.A.; Langford, C.H.; Hollebone, B.R. Solar energy storage using chemical potential changes associated with drying of zeolites. Sol. Energy 1979, 23, 489–495. [Google Scholar] [CrossRef]

- Aprea, P.; de Gennaro, B.; Gargiulo, N.; Peluso, A.; Liguori, B.; Iucolano, F.; Caputo, D. Sr-, Zn- and Cd-exchanged zeolitic materials as water vapor adsorbents for thermal energy storage applications. Appl. Therm. Eng. 2016, 106, 1217–1224. [Google Scholar] [CrossRef]

- Frazzica, A.; Freni, A. Adsorbent working pairs for solar thermal energy storage in buildings. Renew. Energy 2017, 110, 87–94. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Zhang, Y. Review of thermal energy storage technologies based on PCM application in buildings. Energy Build. 2013, 67, 56–69. [Google Scholar] [CrossRef]

- Rubitherm. PCM RT-Serie. Available online: https://www.rubitherm.eu/index.php/produktkategorie/organische-pcm-rt (accessed on 18 March 2020).

- Rubitherm. PCM SP-Serie. Available online: https://www.rubitherm.eu/index.php/produktkategorie/anorganische-pcm-sp (accessed on 18 March 2020).

- Nienborg, B.; Gschwander, S.; Munz, G.; Fröhlich, D.; Helling, T.; Horn, R.; Weinläder, H.; Klinker, F.; Schossig, P. Life Cycle Assessment of thermal energy storage materials and components. Energy Procedia 2018, 155, 111–120. [Google Scholar] [CrossRef]

- Ostermann, E.; Butala, V.; Stritih, U. PCM thermal storage system for ‘free’ heating and cooling of buildings. Energy Build. 2015, 106, 125–133. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Life Cycle Initiative. Paris Agreement, Sustainable Development Goals and Life Cycle Thinking. Available online: https://www.lifecycleinitiative.org/paris-agreement-sustainable-development-goals-life-cycle-thinking/ (accessed on 8 May 2020).

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Vernier/Geneva, Switzerland, 2009; DIN EN ISO 14040:2006; Available online: https://www.iso.org/standard/37456.html (accessed on 18 March 2020).

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Vernier/Geneva, Switzerland, 2009; DIN EN ISO 14044:2006; Available online: https://www.iso.org/standard/38498.html (accessed on 18 March 2020).

- Kylili, A.; Fokaides, P.A. Life Cycle Assessment (LCA) of Phase Change Materials (PCMs) for building applications: A review. J. Build. Eng. 2016, 6, 133–143. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Menoufi, K.; Castell, A.; Farid, M.M.; Boer, D.; Cabeza, L.F. Life Cycle Assessment of experimental cubicles including PCM manufactured from natural resources (esters): A theoretical study. Renew. Energy 2013, 51, 398–403. [Google Scholar] [CrossRef] [Green Version]

- Nienborg, B.; Henninger, S.; Gschwander, S.; Horn, R.; Di Bari, R.; Klinker, F.; Weinläder, H. Ökologische Bewertung Ausgewählter Konzepte und Materialien zur Wärme-und Kältespeicherung (Speicher-LCA); Fraunhofer ISE: Freiburg, Germany, 2019. [Google Scholar]

- TIK Universität Stuttgart. Speicher-LCA Tool: Ökologische Bewertung Ausgewählter Konzepte und Materialien zur Wärme-und Kältespeicherung. Available online: https://www.iabp.uni-stuttgart.de/new_downloadgallery/GaBi_Downloads/SpeicherLCA.zip (accessed on 11 June 2020).

- GaBi ts; thinkstep: A sphera company: Leinfelden-Echterdingen, Germany. 2019. Available online: http://www.gabi-software.com/international/support/gabi-version-history/gabi-ts-version-history/zip (accessed on 11 June 2020).

- European Commitee for Standardization. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; CEN: Brussel, Belgium, 2018; EN 15804:2018; Available online: https://standards.cen.eu/dyn/www/f?p=204:110:0::::FSP_PROJECT,FSP_ORG_ID:40703,481830&cs=1B0F862919A7304F13AE6688330BBA2FF (accessed on 18 March 2020).

- European Commitee for Standardization. Sustainability of Construction Works—Assessment of Buildings. Part. 2: Framework for the Assessment of Environmental Performance; CEN: Brussel, Belgium, 2010; EN 15643-2; Available online: https://standards.cen.eu/dyn/www/f?p=CENWEB:110:0::::FSP_PROJECT:31551&cs=3C10098881B7F32BADFB51EC51B33CFB9 (accessed on 18 March 2020).

- European Commitee for Standardization. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; CEN: Brussel, Belgium, 2012; EN 15978:2012; Available online: https://standards.cen.eu/dyn/www/f?p=CENWEB:110:0::::FSP_PROJECT:31325&cs=31465126A6847927D74F7803C93FBA4E7 (accessed on 18 March 2020).

- Gantner, J.; Wittstock, B.e.a. EeBGuide Part B: BUILDINGS: Operational Guidance for Life Cycle Assessment Studies of the Energy-Efficient Buildings Initiative. Available online: https://www.eebguide.eu/eebblog/ (accessed on 4 December 2019).

- Joint Research Centre. ILCD Handbook—General Guide on LCA—Detailed Guidance. Available online: https://eplca.jrc.ec.europa.eu/ilcdHandbook.html (accessed on 4 March 2020).

- Thermal Energy System Specialists, LLC. TRNSYS; Thermal Energy System Specialists, LLC: Madison, WI, USA, 2018. [Google Scholar]

- IEA—International Energy Agency. Solar Heating & Cooling Programm Task 58/ECES Annex 33: Material and Component Development for Thermal Energy Storage. Available online: https://task58.iea-shc.org/ (accessed on 8 May 2020).

- Bundesinstitut für Bau-, Stadt- und Raumforschung. ÖKOBAUDAT. Available online: https://oekobaudat.de/ (accessed on 3 April 2020).

- Krendlinger, E.; Wolfmeier, U.; Schmidt, H.; Heinrichs, F.-L.; Michalczyk, G.; Payer, W.; Dietsche, W.; Boehlke, K.; Hohner, G.; Wildgruber, J. Waxes. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Chichester, UK, 2010; pp. 1–63. ISBN 9783527306732. [Google Scholar]

| Goal and Scope | Analyses of PCMs, Storage Components and Energy Storage Systems |

|---|---|

| System Boundaries | Cradle to grave analyses. Lifecycle modules [22]: Production (A1–A3) Use phase, including operational building energy demand (B6)—storage concept system only End-of-Life (C + D), including waste + credits due to recycling |

| Functional Unit (f.u.) | Defined for each level |

| Lifespan | 20 years |

| Impact Categories | Global warming potential (GWP) (kg CO2 eq./f.u.) Primary energy demand total (PEtot) (MJ/f.u.) Primary energy renewable total (PERT) (MJ/f.u.) Primary energy nonrenewable total (PENRT) (MJ/f.u.) |

| Paraffins | Salt Hydrates |

|---|---|

| RT10HC | SP15 |

| RT11HC | SP21 |

| RT18HC | SP58 |

| RT24 | |

| RT62HC |

| Storage Component | Available Materials |

|---|---|

| Storage material | Water 4 or PCM (Table 2) |

| Storage containment | HDPE 1, steel 4, stainless steel 1,4 |

| Insulation storage | Mineral foam, EPDM 2 foam 4; XPS 3 |

| PCM containment/capsules | Aluminum, steel, HDPE 1 |

| Category | Energy Supply and Storage | Distribution System |

|---|---|---|

| Central heating | (1) Gas boiler 1 (2) Hot water storage + solar collector (3) PCM storage + solar collector | Radiators Underfloor heating |

| Central cooling | (1) Water chiller 1 (2) Split device 1 (3) Water chiller + cold water storage (4) Water chiller + PCM storage | Surface cooling Fan coil |

| Room-integrated | (1) Air cooling 1 (2) PCM surface cooling + Water chiller (3) PCM ventilation system | Natural ventilation 1 Surface cooling Air cooling |

| Name | Melting Enthalpy (Wh/kg) | Melting Range (°C) | Specific Heat Capacity (kJ/kg K) | Melting Point (°C) | Density (kg/m3) |

|---|---|---|---|---|---|

| RT10HC | 57.22 | 10–12 | 1.7 | 10 | 770 |

| SP15 | 52.22 | 15–17 | 2.0 | 15 | 1350 |

| Water | 92.64 | 4.2 | 0 | 1000 |

| Name | GWP (kg CO2 eq./kWh 1) | PENRT (MJ/kWh 1) | Payback Cycles GWP | Payback Cycles PENRT |

|---|---|---|---|---|

| RT10HC | 18.30 | 880.85 | 82.7 | 226 |

| SP15 | 12.02 | 180.95 | 49.5 | 47 |

| Water | 0.0 | 0.02 | 0.0 | 0.012 |

| Storage component | Material | Amount | Unit | |

| Storage material | SP15 | 1755 | kg | 20% recycling rate |

| Containment | HDPE | 85 | kg | |

| Insulation (storage) | XPS | 11.3 | kg | |

| Heat exchanger | PP capillary tube | 35 | kg | |

| System component | Material | Amount | Unit | |

| Pipework | Steel | 1755 | kg | |

| Pipework insulation | XPS | 2.97 | kg | |

| Heat exchanger | PP capillary tube | 45.5 | kg | |

| Valves | Stainless steel | 32 | kg | |

| Circulation pump | Standard | 250–1000 | W | |

| Heat transfer fluid | Propylene glycol/water | 30.85 | kg | |

| Water chiller | 11 | kW | ||

| Cooling surface | Copper (200 mm distance) | 516 | m2 | |

| Use Phase | Process | Amount | Unit | |

| Electricity | Electricity mix DE | 616.0 | kWh/a |

| Storage Component | A1–A3 | C+D | ||||

|---|---|---|---|---|---|---|

| GWP | PENRT | PERT | GWP | PENRT | PERT | |

| Storage material | 1125.5 | 169,937 | 1042.7 | 26.9 | 358.6 | 27.0 |

| Containment | 165.9 | 6224 | 286.6 | 96.5 | −1902.8 | −289.7 |

| Insulation (storage) | 959.7 | 29,376.7 | 538.4 | 18.5 | −278.5 | −54.8 |

| Heat exchanger | 98 | 2845 | 304.2 | 44.8 | −160.4 | −160.4 |

| System component | GWP | PENRT | PERT | GWP | PENRT | PERT |

| Pipework | 97 | 893.1 | 58.1 | −54.6 | −490.0 | 32.6 |

| Pipework insulation | 251.3 | 7683 | 141.0 | 4.8 | −72.9 | −14.4 |

| Heat exchanger | 127.4 | 3699.2 | 395.4 | 58.3 | −1056.8 | −208.5 |

| Valves | 33 | 394 | 61.6 | −14.4 | −129.8 | 8.2 |

| Circulation pump | 117.8 | 1588 | 254.4 | −17.8 | −254.9 | −26.0 |

| Water chiller | 421.3 | 5731 | 987.8 | −213.2 | −2991.6 | −336.5 |

| Cooling surface | 5627 | 98,806 | 12,733.5 | −567.4 | −26,682 | −4409.2 |

| Use Phase | B6 yearly | B6 Total (20 years) | ||||

| GWP | PENRT | PERT | GWP | PENRT | PERT | |

| Electricity mix | 376.42 | 4935.8 | 2062.1 | 7528.30 | 95,695.05 | 41,241.86 |

| Storage Component | A1–A3 | C + D | ||||

|---|---|---|---|---|---|---|

| GWP | PENRT | PERT | GWP | PENRT | PERT | |

| Storage material | 39,112.6 | 578,430 | 26,345.5 | 340.9 | 4548.3 | 342.5 |

| Containment | 121.0 | 4540 | 209.1 | 70.4 | −1387.9 | −211.3 |

| Insulation (storage) | 6011.1 | 183,994 | 3372.2 | 115.8 | −1744.4 | −343.2 |

| Heat exchanger | 98 | 394 | 304.2 | 44.8 | −160.4 | −160.4 |

| System component | GWP | PENRT | PERT | GWP | PENRT | PERT |

| Pipework | 543.3 | 4918.8 | 320.0 | −300.8 | −2698.9 | 179.3 |

| Pipework insulation | 35.1 | 1073.4 | 19.7 | 0.7 | −10.2 | −2.0 |

| Heat exchanger | 1616 | 46,922.3 | 5015.4 | 739.2 | −13,404.8 | −2644.4 |

| Valves | 33 | 1588.2 | 254.4 | −17.8 | −254.9 | −26.0 |

| Circulation pump | 117.8 | 172,718.2 | 54,986.6 | −8014.0 | −111,185.4 | −32,834.6 |

| Gas boiler | 526.6 | 6364.3 | 983.4 | −137.0 | −1622.8 | −79.6 |

| Underfloor heating | 5627 | 98,805.6 | 12,733.5 | −567.4 | −26,681.8 | −4409.2 |

| Use Phase | B6 yearly | B6 Total (20y) | ||||

| GWP | PENRT | PERT | GWP | PENRT | PERT | |

| Electricity mix | 538.8 | 6848.9 | 2951.7 | 10,776 | 136,979 | 59,034 |

| Gas low temperature boiler | 14,944 | 240,366 | 4576.5 | 298,881 | 4,807,327 | 91,530 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Bari, R.; Horn, R.; Nienborg, B.; Klinker, F.; Kieseritzky, E.; Pawelz, F. The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation. Energies 2020, 13, 3045. https://doi.org/10.3390/en13123045

Di Bari R, Horn R, Nienborg B, Klinker F, Kieseritzky E, Pawelz F. The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation. Energies. 2020; 13(12):3045. https://doi.org/10.3390/en13123045

Chicago/Turabian StyleDi Bari, Roberta, Rafael Horn, Björn Nienborg, Felix Klinker, Esther Kieseritzky, and Felix Pawelz. 2020. "The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation" Energies 13, no. 12: 3045. https://doi.org/10.3390/en13123045

APA StyleDi Bari, R., Horn, R., Nienborg, B., Klinker, F., Kieseritzky, E., & Pawelz, F. (2020). The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation. Energies, 13(12), 3045. https://doi.org/10.3390/en13123045