1. Introduction

In Korean regulations, automatic sprinkler systems are required in buildings and factories to control a fire. Applications of sprinkler systems in the building are to suppress the fire and prevent the fire spread from one compartment to another. As a result, it can restrict the untenable conditions caused by smoke hazards and extend the available safe egress time when a fire occurs in the building. Extensive research has been conducted to improve the design and efficiency of sprinkler systems for many years, especially using computational fluid dynamics (CFD) modelling, which can simulate the interaction of water with fire environments and has been widely used and become a powerful tool with many advantages.

Computational fluid dynamics can provide details on an analysis of the interaction between the fire environment and water sprays. The numerical analysis can be completed with a less expensive cost and consumed time and can be used in combination with experimental work to improve technical design for water spray systems. Various numerical studies on the interaction between water spray and fire plume have been reported. The primary concerns are related to extinguishing times and the minimum water flow rate to extinguish the fire. Novozhilow et al. [

1] developed a CFD model of burning rate and extinction in fires by water sprinklers. The extinguishing rates were modeled by calculating the heat transfer and temperature at the solid surface when the sprinklers were in operation. The extinction time was compared to experimental data and found to be in satisfactory agreement. They also developed a CFD model to predict extinguishment times of an array of wood slats by sprinkler water. The wood pyrolysis rate modeled by Arrhenius’s reaction was fully coupled with the gas phase model, and the spray was treated in Lagrangian fashion. The extinguishment times were reasonably close to those measured from experiments [

2]. Nam [

3] investigated the trajectory capacity of water spray from fast response sprinklers into heptane fire via numerical simulations. The simulation was a combination of the water spray model and the free burn fire model. The fire was modeled to avoid complicated chemical combustion by defining prescribed fire source. The results from the simulations compared reasonably well with experimental measurements in terms of actual delivered densities. Hua et al. [

4] introduced a numerical approach to investigate the effect of water spray characteristics on a fire plume. The chemical combustion used the Arrhenius reaction to present fire extinction by water. In the results, a solid cone pattern and a finer water droplet size of the water spray was more effective in extinguishing fires. The flow rate of the water spray had a certain critical value for suppressing a specific fire.

Other studies on the effects of water spray on fire environments without considering fire suppression have also been conducted. O’grady and Novozhilov [

5] used the Fire Dynamic Simulator (FDS) version 4 software to present the effect of the water spray of a sprinkler on the ceiling jet. The numerical results of two different flow rates were validated to free burn fire tests including a 1.5 MW steady-state fire. The relative errors were 7–8% for velocity and 10–15% for the temperature [

5]. Cunfeng Zhang and Wanki Chow [

6] used the FDS code to investigate the interaction of the sprinkler spray and the smoke layer. The cooling effect of the spray and drag force of water particles was analyzed. As a result, the temperature of the smoke layer decrease was almost linear to the working pressure of the sprinkler systems. Chen et al. [

7] discussed the cooling effect of water spray systems in experimental and numerical analyses. Although the flame continued after activating sprinkler due to the lack of the suppression model, the cooling effects by the water spray in a room test within 120 s were obvious. Zhi Tang et al. [

8] presented the effect of water spray on the fire smoke layer inside a hood by FDS simulation. The influence of the water spray characteristics on the downward smoke displacement due to the fact of drag and cooling was analyzed in detail. Other applications of sprinkler modeling were also used in the suppression of rack storage [

9] and conveyor belt fires [

10].

When the water droplets encounter to a fire source, the water is not only cooling the burning surface and surrounding air, but it also impacts the chemical reaction rate of solid fuel. Simultaneously, water droplets also significantly affect the smoke movement by its trajectory. Meanwhile, the complex Arrhenius reaction model is usually used to present chemical combustion. Therefore, when adding fire extinction by a water spray, the numerical simulation is more complicated. Hence, it is necessary for a study that includes the phenomena above to better understand fire characteristics under water spray with a simple fire suppression model. In this present study, fire characteristics after sprinkler activation in a compartment were investigated by numerical analysis in FDS 6.7.0. The mathematical equation of the fire suppression model was introduced in FDS. Experimental work was conducted to collect data related to the heat release rate and ceiling temperature. Based on the experimental data, the numerical simulations proceeded to calibrate the fire suppression model by comparison to the ceiling temperature. Then, the calibrated model was used to investigate the characteristics of the smoke movement during fire suppression. In addition, the smoke spread was analyzed in terms of temperature, velocity, mass flow, and was compared to a case of free burn.

2. Fire Dynamics Simulator and Fire Suppression Model by Water

Fire Dynamics Simulator v. 6.7.0 (FDS) [

11,

12] was used to simulate the fire suppression in this study. The FDS is a computational fluid dynamics (CFD) model of fire-driven fluid flow. A form of the Navier–Stokes equation was applied for low-speed, thermally-driven flow such as smoke and heat transport from fires. The partial derivatives of the conservation equations of mass, momentum, and energy were approximated as finite differences, and the solution was updated in time on a three-dimensional, rectilinear grid. The combustion model was based on the mixing-limited, infinitely fast reaction of lumped species, called eddy dissipation concept (EDC) model. Thermal radiation was computed using a finite volume technique on the same grid as the flow solver. Water droplets can absorb and scatter thermal radiation. For calculation of absorption coefficients, a gray band model, RAD-CAL was implemented. Lagrangian particles were used to represent the liquid droplets. The mass, momentum, and energy transfer from the Lagrangian particles to gas flow were treated sufficiently by source term in the conservation equation. The model in FDS was successfully tested and validated for a variety of fire problems, natural convective flows, smoke movement [

13,

14], and water-based fire suppression [

15].

The fire suppression by a water spray involving multiple physical phenomena adds complications to CFD. The fire suppression by water was first introduced by Yu et al. [

16] and applied to the FDS simulation by Hamins and McGrattan [

12] as a fire suppression model. When the water droplets drop into burning surfaces, the water is cooling the surface and the surrounding gas, and it is also changing the pyrolysis rate of the solid fuel. A liquid droplet hits a solid horizontal surface in FDS, it is assigned a random horizontal direction and moves at a fixed velocity until it reaches the edge, at which point it drops straight down at the same fixed velocity. While attached to the burning surface, the water droplet forms a thin film that transfers heat to the solid, and heat and mass to the gas by evaporating. In the FDS model, the cooling of unburned surfaces and the reduction in the Heat Release Rate (HRR) are computed locally. However, the exponential nature of fire suppression by water is observed both locally and globally; thus, the local heat release rate per unit area (kW/m

2) can be expressed in the following equation:

where

is the user-specified heat release rate per unit area of fuel (kW/m

2) when no water droplets are applied, and

is a linear function of the local water mass per unit area,

, in units of kg/m

2, which is expressed as:

where α is the extinguishing coefficient and is obtained experimentally in units of m

2/(kg·s). The extinguishing coefficient is dependent on the material properties of the solid fuel and its geometrical configuration. In order to obtain the optimal α value, simulations were performed for calibration by comparison of the ceiling temperature. The detail will be discussed in the next section.

3. Experiment Setup

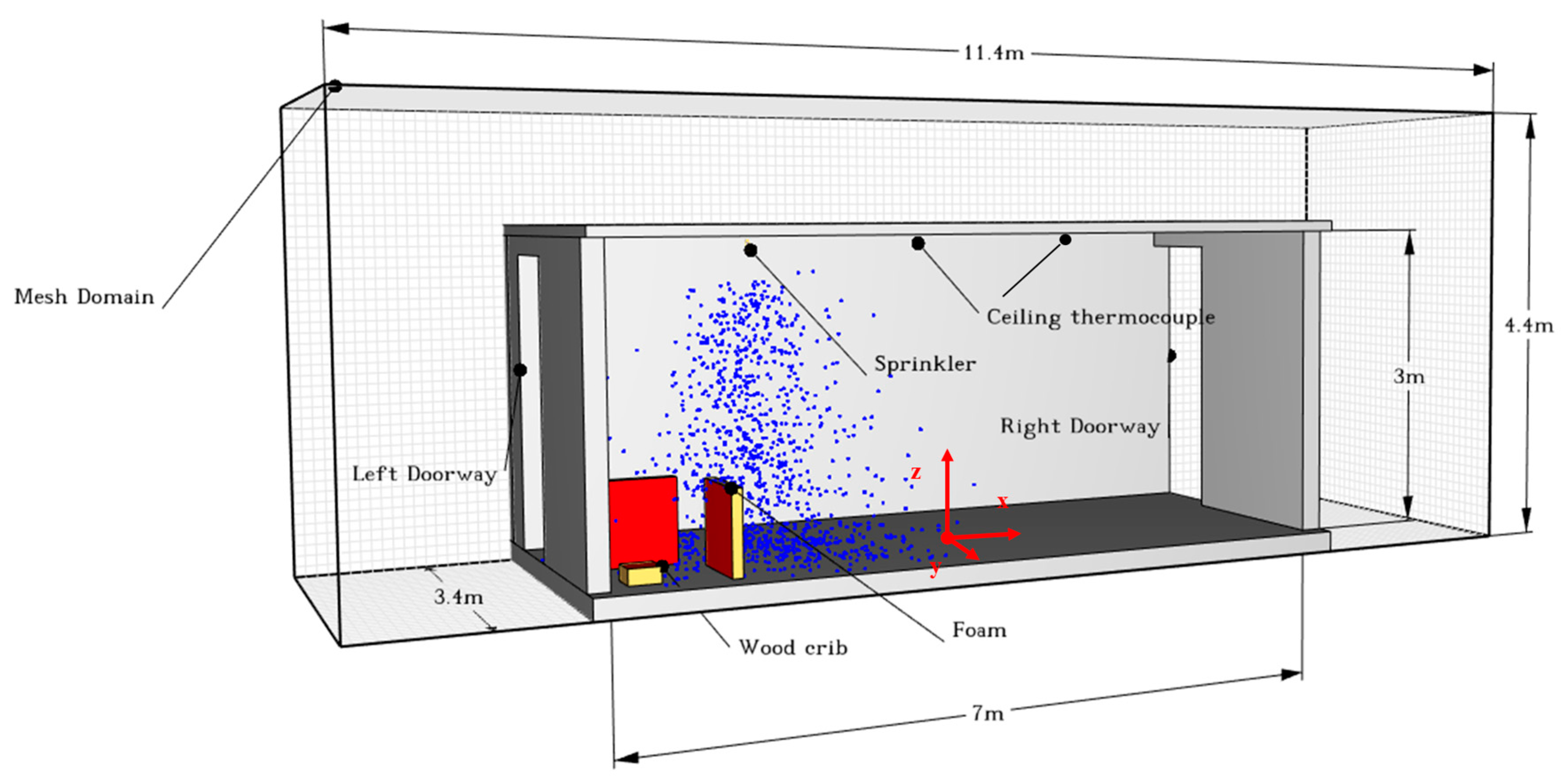

In order to obtain data for calibrating the suppression model, a fire experiment was conducted in a compartment using a water sprinkler. The measurement used to collect ceiling temperature in a compartment. The compartment had dimensions of 3 m (W) × 7 m (L) × 3 m (H) coved by gypsum board in the ceiling, plywood walls, and a concrete floor. Two doorways on opposite walls provided for ventilation. The left doorway was 0.89 m (width) × 2.8 m (height), and the right doorway was 1.04 m (width) × 2.8 m (height) (

Figure 1). A pendant water sprinkler was installed 76 mm below the ceiling. The manufacturer supplied the glass bulb sprinkler with an activation temperature of 68 °C and a K-factor of K = 50 Lpm/bar

0.5. The operation pressure was 1 bar. The spray angle of 10 to 80 degrees was estimated by image analysis. Two K-type thermocouples (range: −200 to +1000 °C, accuracy is ±1 °C) were installed 76 mm from the ceiling to measure the temperature. The ceiling temperature data were recorded by a portable data logger, a midi LOGGER GL240, every second (the measurement accuracy: 0.05% for the K-type thermocouple).

The fire source consisted of a wood crib and polyether foam, described in detail in ISO 6182-10 [

17]. The wood crib, with dimensions of 305 mm × 305 mm × 152 mm, was made with fir lumber of 3 kg and ignited by a pan of heptane. The pure polyether foam of 810 mm × 760 mm × 76 mm was ignited by cotton wicks soaked in heptane. The polyether foam glued to a thick plywood backing and assembled to a steel frame for support. The fire source was placed in the corner of the compartment. The wood crib was positioned 5 mm from each wall (

Figure 1a,d).

The heat release rate of the fire source could not be determined directly during the compartment fire experiment. Therefore, the HRR measurement was conducted separately without the effect of sprinkler spray.

Figure 2 shows the wood crib and polyether foam were burnt individually under a large-scale calorimeter (LSC), applicable up to 3 MW (ISO 13784-1), to determine the unsteady heat release rate. The principle of LSC is that it is based on the amount of heat released from a burning sample and is proportional to the amount of oxygen consumed during the combustion. The dimensions and weight of the wood crib and polyether foam were the same in the compartment test.

The experimental results of HRR in the free burn and ceiling temperature in the compartment fire equipped with a sprinkler are shown in

Figure 3.

4. Numerical Detail

Figure 4 shows the computational domain coved the compartment test with dimensions of 3.4 m (W) × 11.4 m (L) × 4.4 m (H). The compartment geometry was made based on experiments. The wood crib and polyether foam modeled simple obstructions of the same dimension in the experiment. The fire source presented as burner with a specified heat release rate per unit area (HRRPUA) in units of kW/m

2. The HRR assigned to the top surface of the wood crib and interior surface of polyether foam (red surface,

Figure 2). Sprinkler and ceiling thermocouples were installed in the same location in the experiment. The boundary conditions assigned “OPEN” for the computational domain, and “ADIABATIC” to the wall and floor. The ambient temperature was 29 °C, in agreement with the experiments. A Cartesian coordinate system indicated at the center of the compartment for convenience in the analysis.

In order to model a fire suppression correctly, numerical sprinkler spray parameters need to be specified in detail. Those parameters include the water flow rate, droplet diameter, initial droplet velocity, spray angle, and offset distance. Because of the limit of apparatus, there was a lack of data on sprinkler spray in the experimental report. Therefore, the necessary estimations have been made based on the experimental work and various studies reported in the literature [

18,

19].

The water flow rate of any sprinkler can be calculated based on the K-factor and pipe pressure by the equation:

where

is the water flow rate in L/min, K is the K-factor for the sprinkler L/(min.bar

0.5) which can be obtained from the manufacturer and

is the pressure of the pipe in Bar.

Water spray usually includes various sizes of spherical droplets. The cumulative volume fraction (CVF) is specifies the size distribution of water droplets. This function indicates the fraction of the total mass carried by droplets less than the given diameter. The CVF for a sprinkler spray is represented by a combination of log-normal and Rosin–Rammer distributions [

12]:

where

Dv,0.5 is the median volumetric droplet diameter, µm (i.e., half the mass is carried by droplets with diameters of

Dv,0.5 or less),

γ and σ are empirical constants equal to approximately 2.4 and 0.48, respectively [

12]. The median droplet diameter,

Dv,0.5, is estimated using the formula reported by Yu [

19]:

where

D is the orifice diameter of the sprinkler.

is the density of water in kg/m

3,

is the initial droplet velocity in m/s, and

is the water surface tension in N/m. Analysis of Sheppard’s [

18] data provided an average value of

approximately 1.53 for sprinklers test.

Sheppard [

18] used particle image velocimetry (PIV) and phase Doppler interferometry (PDI) to measure the initial droplet sizes and velocities for the various type of sprinklers. The initial droplet velocity had an average measurement at 0.6 of

. The PIV measurements were taken from the spray atomization length of 0.2 m from the sprinkler orifice, the distance at which no more droplet breaks up downstream from this point.

The angles of the spray were estimated from experimental work providing a 10–80° spray angle. The activation temperature was 68 °C. All sprinkler parameters are summarized in

Table 1.

Grid size is important to verify in numerical simulation, because it directly influences results. In theory, a very small grid can give the accuracy of the calculation, but the time may be wasted unnecessarily. When the deviation between the neighboring results is small enough, the grid can be considered as an independent grid. Before applying the sprinkler simulation, the independent grid tests for the free burn (without sprinkler) were conducted.

Figure 5 shows the temperature at point 1 in the compartment with four different grids (15 cm, 10 cm, 7.5 cm, 5 cm). The result of 15 cm had larger deviations than the results of 10 cm, 7.5 cm, and 5 cm. Therefore, the grid size of 10 cm was chosen in this paper. The grid selection was the same in the simulation of sprinkler interaction with a fire ceiling jet by O’Grady and Novozhilov [

5].