Study on Characteristic and Energy of Argillaceous Weakly Cemented Rock under Dynamic Loading by Hopkinson Bar Experiment

Abstract

1. Introduction

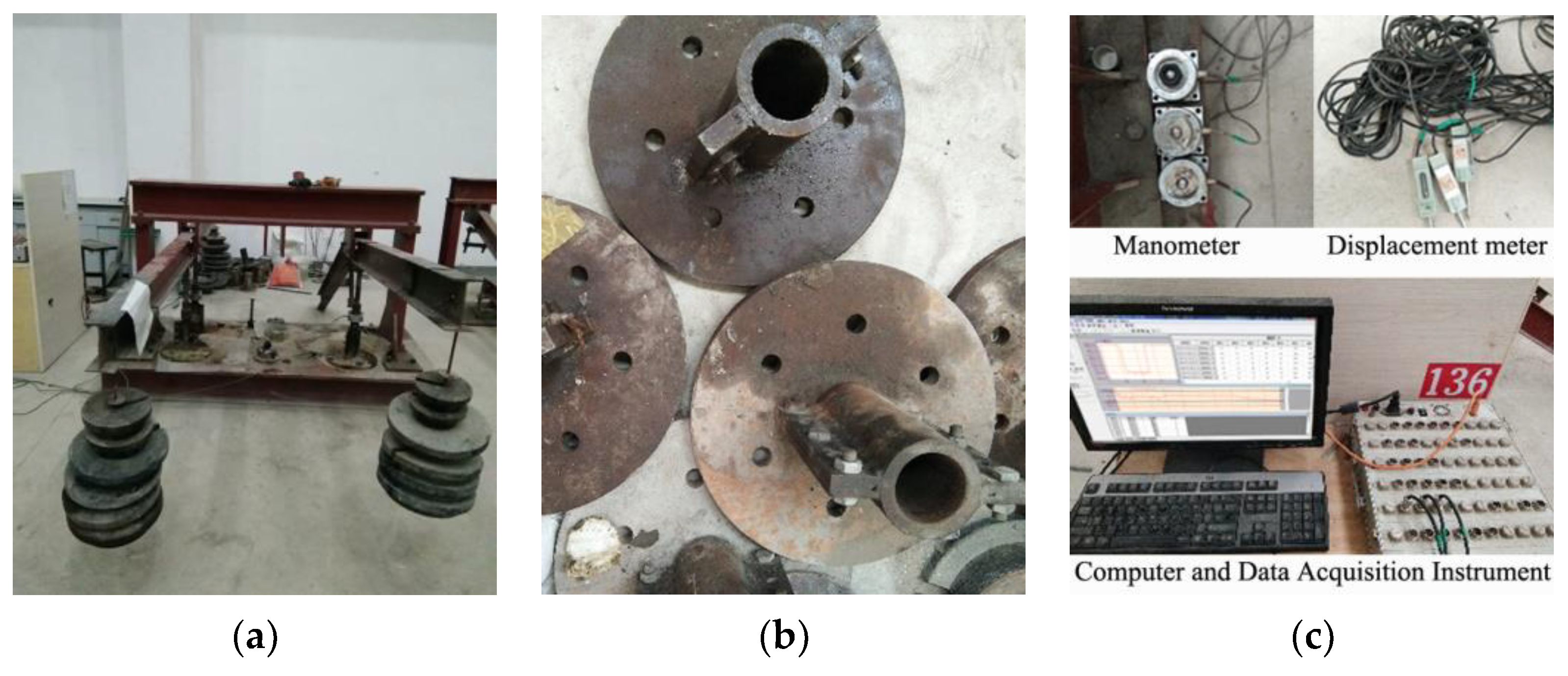

2. Materials and Methods

2.1. Materials

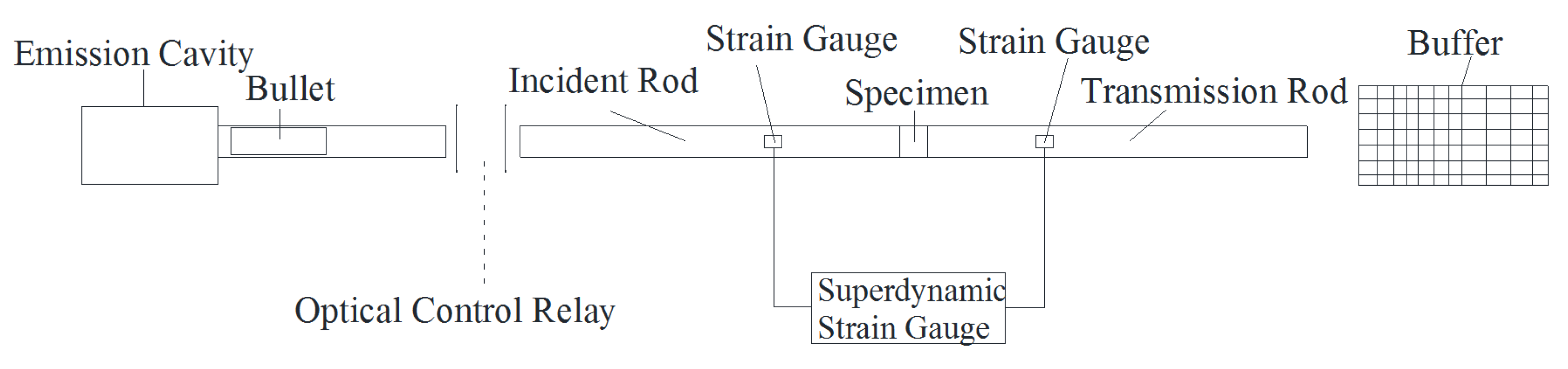

2.2. Methods

3. Results

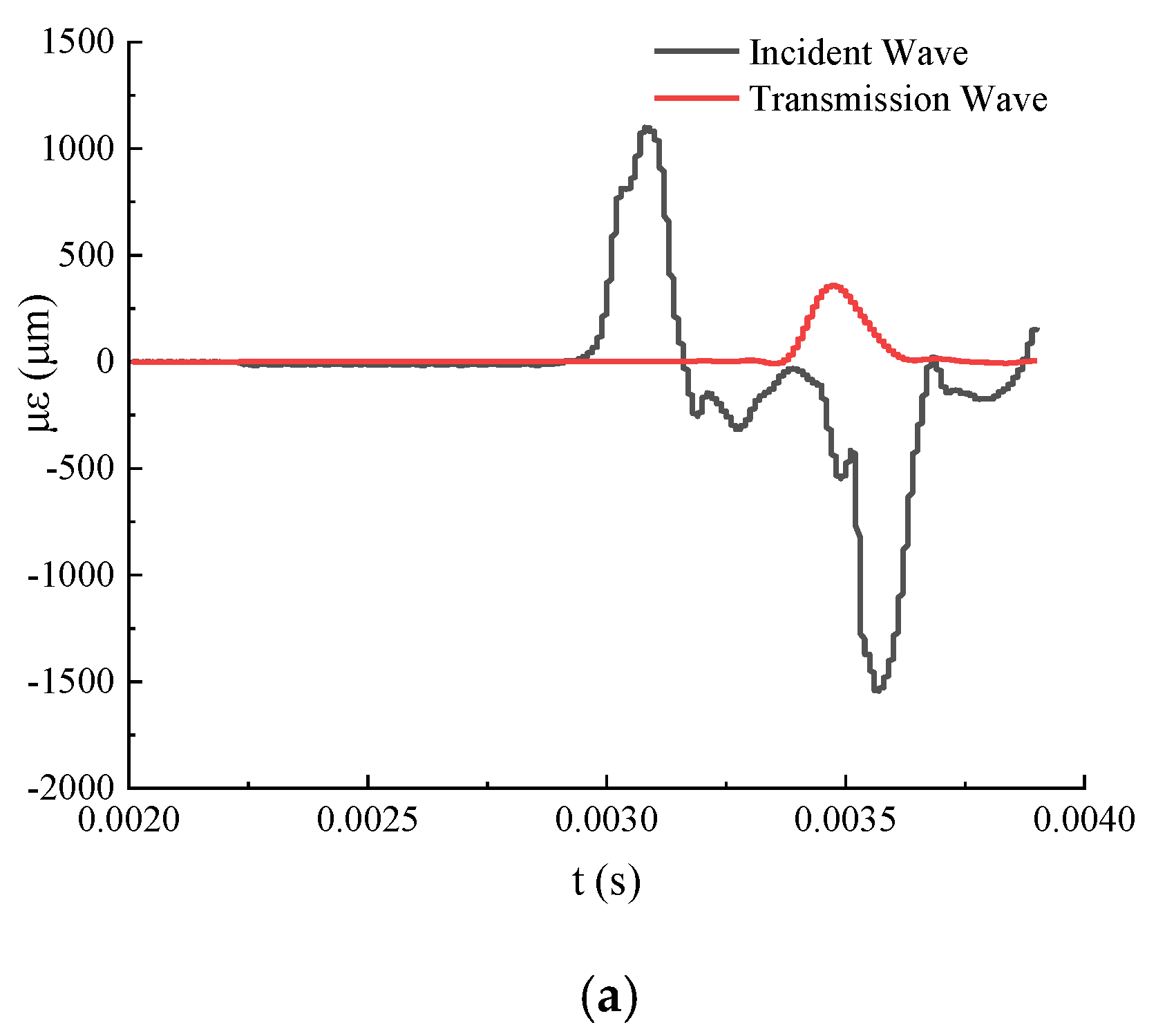

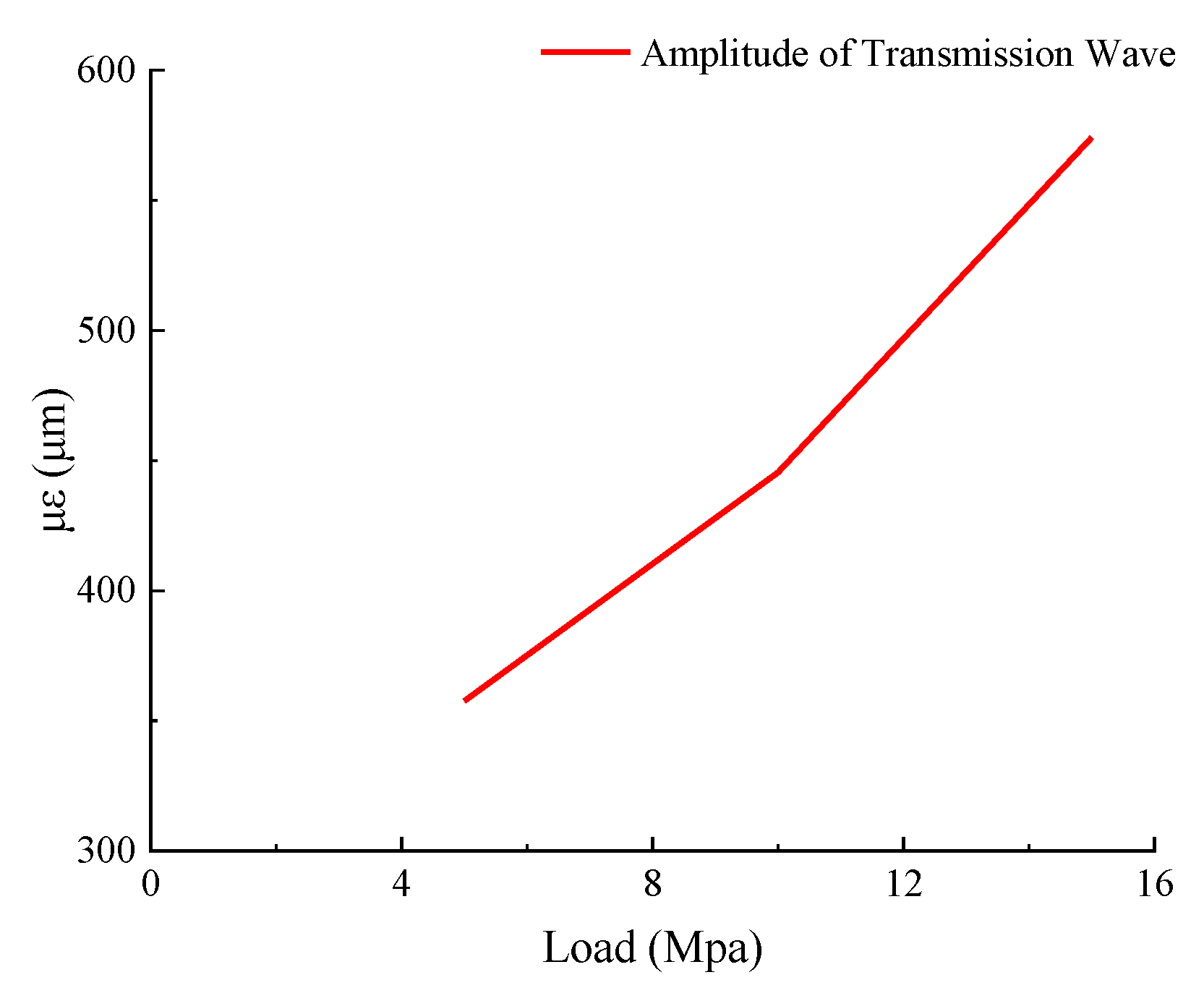

3.1. Waveform Analysis under Different Reorganization Loads

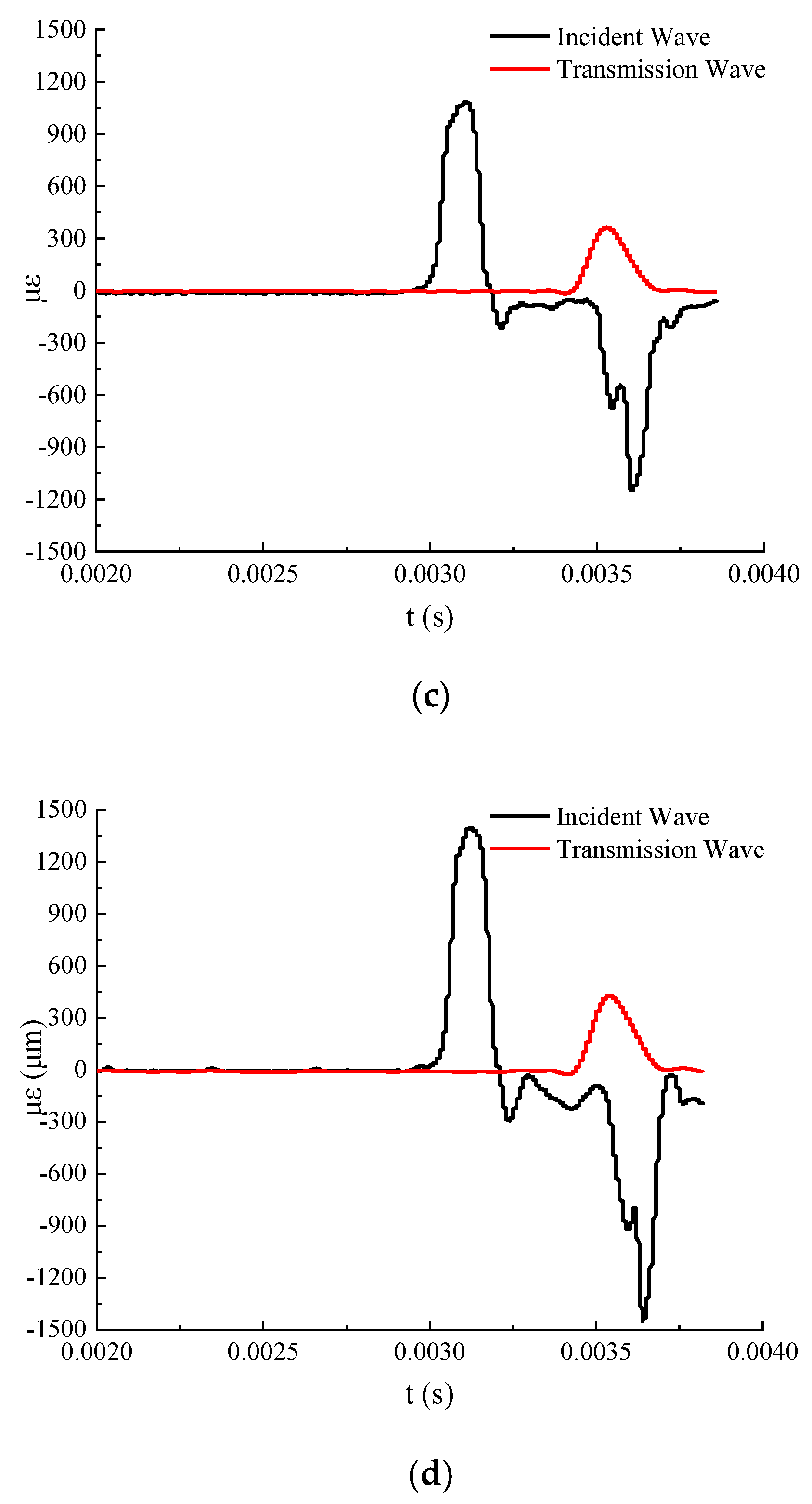

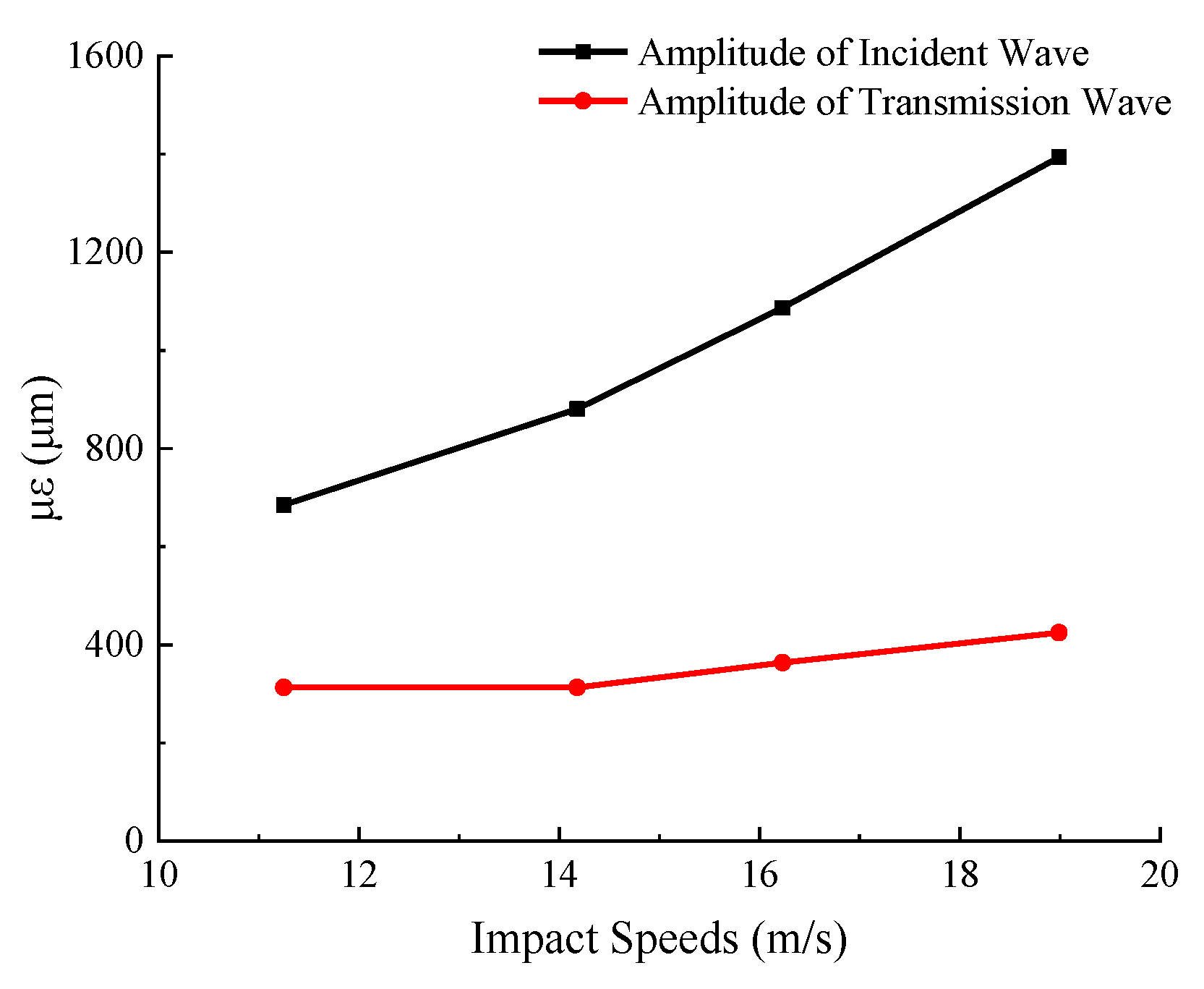

3.2. Waveform of Specimen under Different Impact Velocities

3.3. Analysis of Constitutive Curve under Dynamic Loading

3.3.1. Stress–Strain Curve Analysis under Different Reorganization Loads

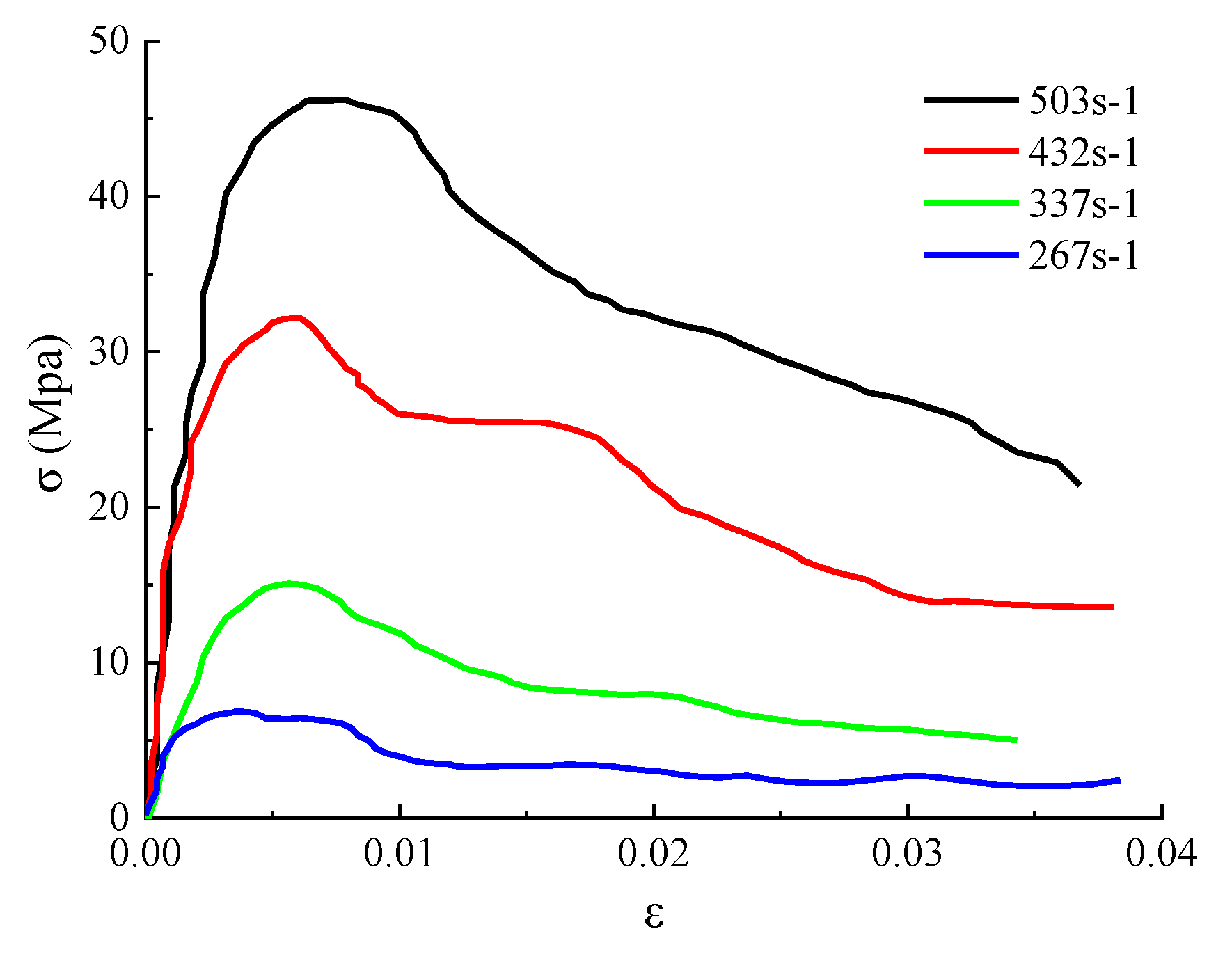

3.3.2. Stress–Strain Curve Analysis under Different Impact Velocities

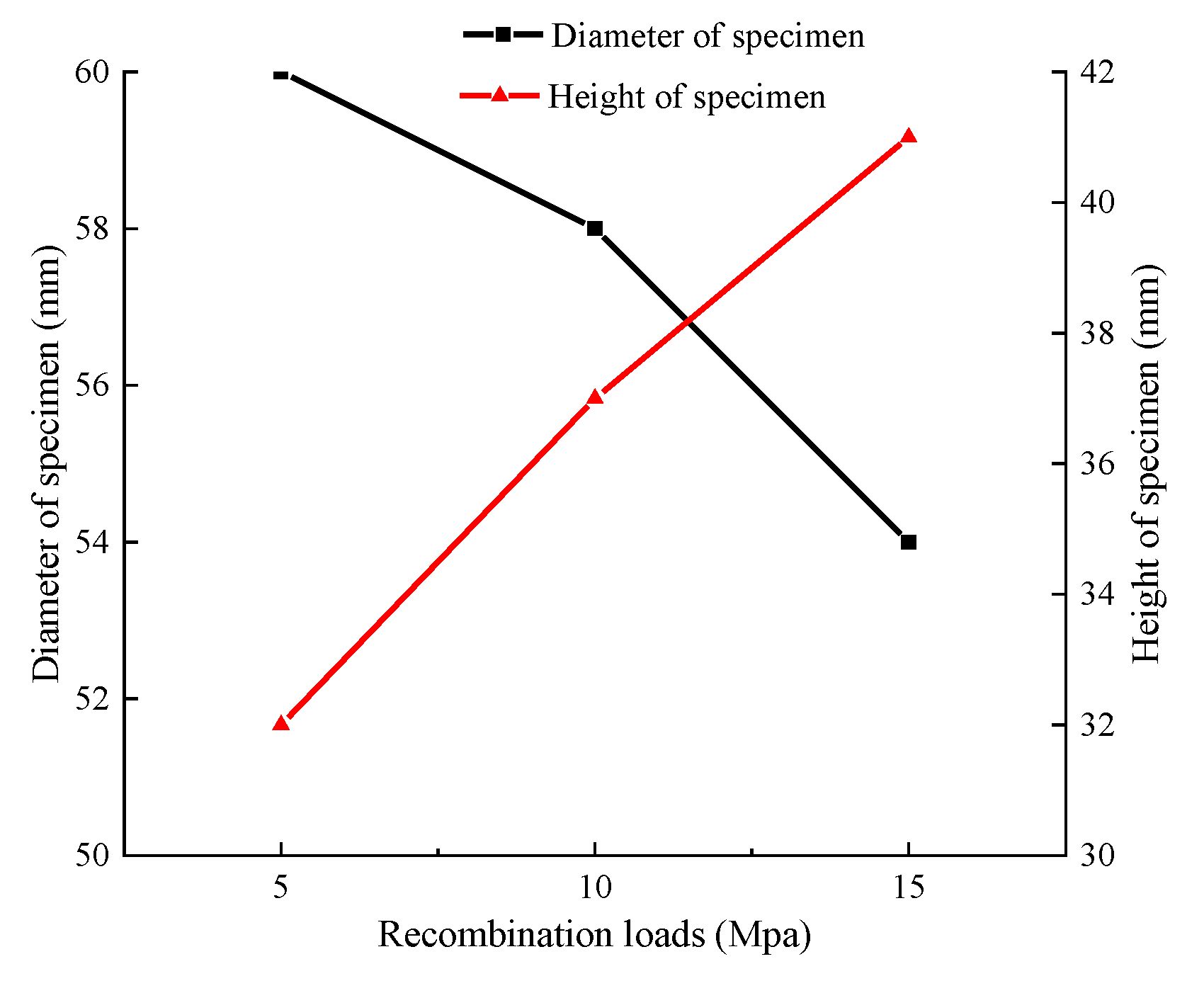

3.4. Analysis of Morphological Characteristics

3.4.1. Characteristic Analysis of Impact Morphology of Argillaceous Weak Cemented Rock Mass under Different Reorganization Loads

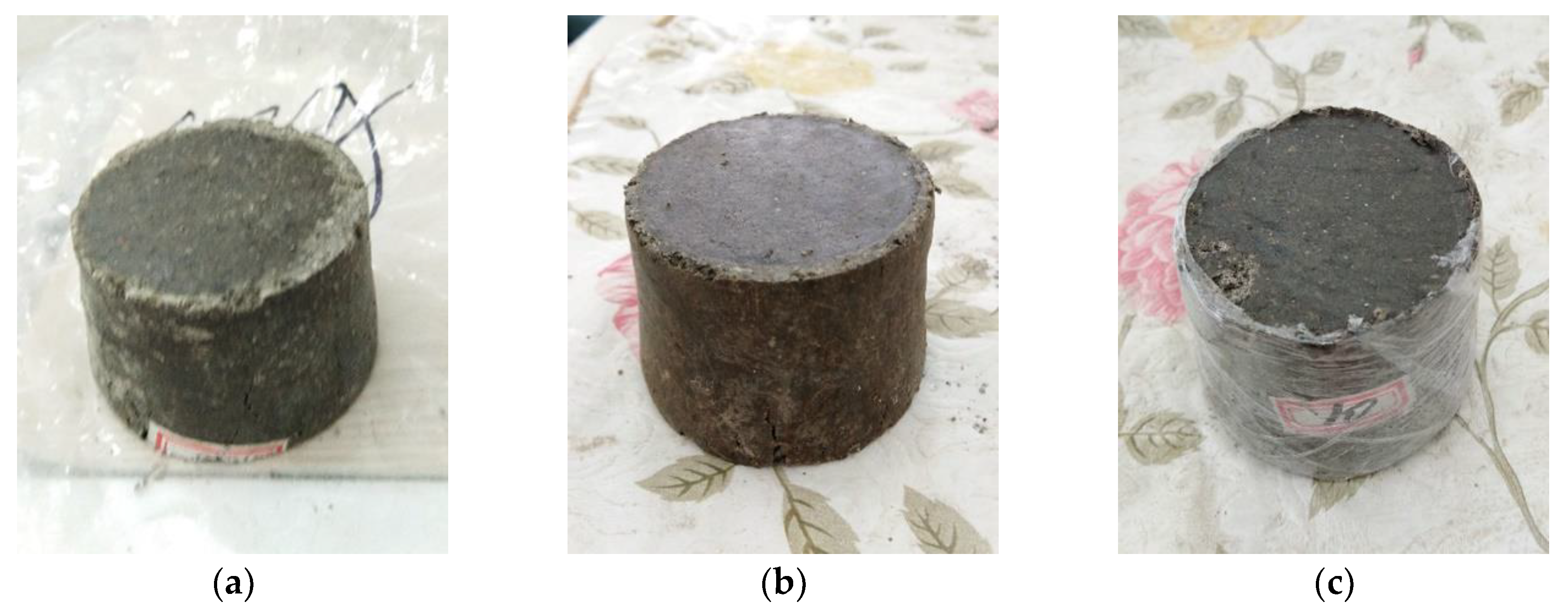

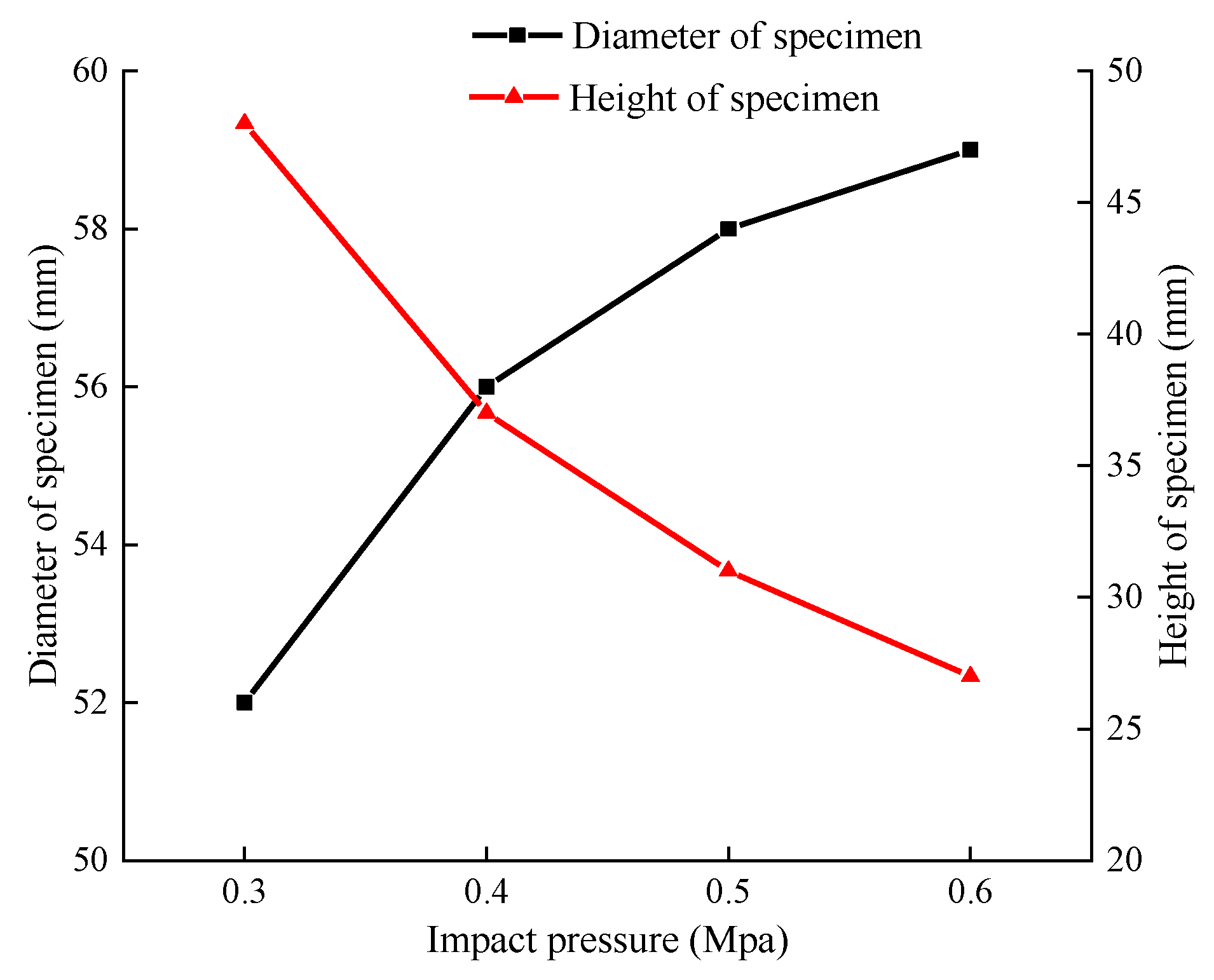

3.4.2. Characteristic Analysis of Impact Morphology under Different Impact Velocities

4. Discussion

- Compaction stage. At this stage, the stress–strain curves show the characteristics of concave change. There are two reasons for this feature: the first is compression bar gradually compacted with the specimen. In the test, the specimen is clamped between the incident rod and the projection rod. Because the surface of the specimen is coated with lubricant, the contact between the compression rod and the specimen is not completely dense. Therefore, there will be a compaction transition period between the compression rod and the specimen in the initial stage of the test; the second is the closure of micro-cracks in the argillaceous weakly cemented rock mass. The material composition of the sample of argillaceous weak cemented rock mass is complex. There are a lot of joints and micro-cracks in the original state. Under the action of axial stress, the internal micro-cracks will close gradually, and the defects such as micro-pore will shrink gradually. Because of the above two reasons, the macro-deformation resistance of the specimens is increasing.

- Approximate linear elastic stage. At this stage, the stress–strain curve basically shows a straight-line upward variation. The stress wave is reflected repeatedly in the sample to achieve uniform stress and strain. In this stage, the external loads are not enough to make the crack grow and evolve or produce new cracks in the sample, only to make the deformation of the original crack stable, or to produce small amplitude changes. The elastic energy accumulates continuously, and the elastic deformation state of the sample does not change qualitatively. At this stage, the slope of the curve basically remains unchanged.

- Microcrack propagation stage. At this stage, the stress increases slowly with the increase in strain, and the curve is convex. Due to the continuous increase in stress acting on the specimen, the old crack of the specimen expands and a new crack occurs; the argillaceous weakly cemented rock has higher plastic deformation under the condition of higher water content, at this time plastic deformation gradually becomes the dominant deformation of the specimen. At the end of this stage, the stress of the specimen reaches its maximum value, and the slope of the curve tends to zero. At this time, the stress value is the peak stress, and the corresponding strain value is the peak strain.

- Strain softening stage. At this stage, the stress–strain curve decreases at a certain slope, and after the peak stress, the bearing capacity of the specimen decreases. Because of the plastic deformation of the specimen, the specimen maintains a certain integrity and enters the plastic deformation stage.

5. Conclusions

- Separate Hopkinson pressure bar test system is the most widely used system in rock dynamic mechanics test. Two-channel DH3816 super-dynamic signal acquisition instrument is selected as the data acquisition system for this test. Its signal acquisition frequency can reach 10 M, which meets the test requirements.

- Dynamic impact uniaxial tests of reconstituted argillaceous weakly cemented rock mass specimens were carried out by using split Hopkinson pressure bar device. The strain waveform curves corresponding to different reorganization loads and different impact velocities were obtained. From the strain curve, it can be seen that the amplitude of transmission wave increases with the increase in recombination load, which indicates that the less energy absorbed by the specimen for extrusion deformation, the smaller the deformation and the lower the plasticity of the specimen with the increase in recombination load.

- The stages of dynamic stress–strain curves of argillaceous weakly cemented rock mass can be divided into compaction stage, approximate linear elastic stage, microcrack growth stage and strain softening stage, which are similar to those of the quasi-static compression test.

- From the stress–strain curves, it can be seen that the greater the restructuring load of the specimen of argillaceous weakly cemented rock mass is, the less obvious the compression stage of the stress–strain curve is, and the greater the elastic modulus is. The peak strength and modulus of elasticity of argillaceous weakly cemented rock samples are correlated with strain rate. The peak strength and modulus of elasticity increase with the increase in strain rate. When the strain rate is greater than 500 s−1, the strain softening stage has a significant downward trend, which indicates that the impact velocity causes certain damage to the internal cementation structure of the specimen.

- The analysis of specimens after impact shows that the deformation of argillaceous weakly cemented rock mass decreases with the increase in restructuring load, and its impact resistance increases; the deformation of specimens increases with the increase in impact speed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cao, D.Y.; Lin, Z.Y.; Zheng, Z.H.; Tan, J.Q. Coalfield Structures and Potential Evaluation of Coal Resources in China. Adv. Mater. Res. 2011, 356, 2937–2940. [Google Scholar] [CrossRef]

- He, M.-C.; Fang, Z.-J.; Zhang, P. Theoretical Studies on the Extrinsic Defects of Montmorillonite in Soft Rock. Mod. Phys. Lett. B 2011, 23, 2933–2941. [Google Scholar] [CrossRef]

- Corkum, A.G.; Martin, C.D. The mechanical behaviour of weak mudstone (Opalinus Clay) at low stresses. Int. J. Rock Mech. Min. Sci. 2007, 44, 196–209. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Zhou, J.-W.; Xu, F.-G.; Xing, H.-G. An Experimental Study on the Water-Induced Strength Reduction in Zigong Argillaceous Siltstone with Different Degree of Weathering. Adv. Mater. Sci. Eng. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Benzaazoua, M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cem. Concr. Comp. 2011, 33, 702–715. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Y.; Xue, S.; Shen, B.; Wang, C.; Lv, J.; Yang, T. Assessment of excavation damaged zone around roadways under dynamic pressure induced by an active mining process. Int. J. Rock Mech. Min. Sci. 2015, 77, 265–277. [Google Scholar] [CrossRef]

- Deng, H.F.; Zhou, M.L.; Li, J.L.; Sun, X.S.; Huang, Y.L. Creep degradation mechanism by water-rock interaction in the red-layer soft rock. Arab. J. Geosci. 2016, 9, 601. [Google Scholar] [CrossRef]

- Martin, C.D.; Lanyon, G.W. Measurement of in-situ stress in weak rocks at Mont Terri Rock Laboratory, Switzerland. Int. J. Rock Mech. Min. Sci. 2003, 40, 1077–1088. [Google Scholar] [CrossRef]

- Koralegedara, N.H.; Maynard, J.B. Chemical, mineralogical and textural properties of the Kope Formation mudstones: How they affect its durability. Eng. Geol. 2017, 228, 312–322. [Google Scholar] [CrossRef]

- Bizjak, K.F.; Petkovšek, B. Displacement analysis of tunnel support in soft rock around a shallow highway tunnel at Golovec. Eng. Geol. 2004, 75, 89–106. [Google Scholar] [CrossRef]

- Li, H.X.; Wang, Y.W.; Tang, B.X. Soft Rock Roadway Mesh Shell Lining Experimental Study of the Mechanical Properties. Adv. Mater. Res. 2013, 671, 774–777. [Google Scholar] [CrossRef]

- Sasaoka, T.; Shimada, H.; Lin, N.Z.; Takamoto, H.; Matsui, K.; Kramadibrata, S.; Sulistianto, B. Geotechnical issues in the application of rock bolting technology for the development of underground coal mines in Indonesia. Int. J. Min. Reclam. Environ. 2013, 28, 150–172. [Google Scholar] [CrossRef]

- Janas, P. Dimensioning of roadway supports in conditions of the Ostrava-Karvina coal field. Int. J. Rock Mech. Min. Sci. Geomech. Abs. 1991, 28, 374. [Google Scholar] [CrossRef]

- Su, X.; Li, Y.; Yang, Y. A Research into Extra-thick compound mudstone roof roadway failure mechanism and security control. Proc. Eng. 2011, 26, 516–523. [Google Scholar]

- Jiang, P.F. Simulation Analysis of the Soft Rock Inclined Shaft Surrounding Rock Control with Different Bolt Support Patterns. Adv. Mater. Res. 2014, 988, 377–382. [Google Scholar] [CrossRef]

- Yadav, S.; Saldana, C.; Murthy, T.G. Experimental investigations on deformation of soft rock during cutting. Int. J. Rock Mech. Min. Sci. 2018, 105, 123–132. [Google Scholar] [CrossRef]

- Arnould, M. Discontinuity networks in mudstones: A geological approach. Bull. Eng. Geol. Environ. 2006, 65, 413–422. [Google Scholar] [CrossRef]

- Fan, G.; Chen, M.; Zhang, D.; Wang, Z.; Zhang, S.; Zhang, C.; Li, Q.; Cao, B. Experimental Study on the Permeability of Weakly Cemented Rock under Different Stress States in Triaxial Compression Tests. Geofluids 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Taylor, L.M.; Chen, E.-P.; Kuszmaul, J.S. Microcrack-induced damage accumulation in brittle rock under dynamic loading. Comp. Methods Appl. Mech. Eng. 1986, 55, 301–320. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. The Effect of Machine Behaviour and Mechanical Properties of Intact Sandstone Under Static and Dynamic Uniaxial Cyclic Loading. Rock Mech. Rock Eng. 2004, 38, 59–67. [Google Scholar] [CrossRef]

- Li, H.B.; Feng, H.P.; Liu, B.; Li, J.R. Experimental Studies on Mechanical Properties of Rock Joints under Dynamic Loading. Key Eng. Mater. 2006, 326, 1709–1712. [Google Scholar] [CrossRef]

- Liu, E.; He, S. Effects of cyclic dynamic loading on the mechanical properties of intact rock samples under confining pressure conditions. Eng. Geol. 2012, 125, 81–91. [Google Scholar] [CrossRef]

- Gong, F.; Ye, H.; Luo, Y. The Effect of High Loading Rate on the Behaviour and Mechanical Properties of Coal-Rock Combined Body. Shock Vibr. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Murrell, S.A.F.; Ismail, I.A.H. The effect of decomposition of hydrous minerals on the mechanical properties of rocks at high pressures and temperatures. Tectonophysics 1976, 31, 207–258. [Google Scholar] [CrossRef]

- Van Itterbeeck, J.; Horne, D.J.; Bultynck, P.; Vandenberghe, N. Stratigraphy and palaeoenvironment of the dinosaur-bearing Upper Cretaceous Iren Dabasu Formation, Inner Mongolia, People’s Republic of China. Cretac. Res. 2005, 26, 699–725. [Google Scholar] [CrossRef]

- Vaniman, D.T.; Bish, D.L.; Ming, D.W.; Bristow, T.F.; Morris, R.V.; Blake, D.F.; Chipera, S.J.; Morrison, S.M.; Treiman, A.H.; Rampe, E.B.; et al. Mineralogy of a mudstone at Yellowknife Bay, Gale crater, Mars. Science 2014, 343, 1243480. [Google Scholar] [CrossRef]

- Wang, S.; Han, L.; Meng, Q.; Jin, Y.; Zhao, W. Investigation of Pore Structure and Water Imbibition Behavior of Weakly Cemented Silty Mudstone. Adv. Civ. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Lenoir, N.; Bornert, M.; Desrues, J.; Bésuelle, P.; Viggiani, G. Volumetric Digital Image Correlation Applied to X-ray Microtomography Images from Triaxial Compression Tests on Argillaceous Rock. Strain 2007, 43, 193–205. [Google Scholar] [CrossRef]

- Pujiyanto, E.; Widyo Laksono, P.; Triyono, J. Synthesis and Characterization of Hydroxyapatite Powder from Natural Gypsum Rock. Adv. Mater. Res. 2014, 893, 56–59. [Google Scholar] [CrossRef]

- Kılıç, A.; Teymen, A. Determination of mechanical properties of rocks using simple methods. Bull. Eng. Geol. Environ. 2008, 67, 237–244. [Google Scholar] [CrossRef]

- Hassanzadeh, M. Fracture Mechanical Properties of Rocks and Mortar/Rock Interfaces. MRS Proc. 2011, 370. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Zhao, B.; Song, Z.; Lai, J. Experimental investigation and constitutive model for lime mudstone. Springerplus 2016, 5, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Zhang, B.; Forrestal, M.J. A split Hopkinson bar technique for low-impedance materials. Exp. Mech. 1999, 39, 81–85. [Google Scholar] [CrossRef]

- Gama, B.A.; Lopatnikov, S.L.; Gillespie, J.W. Hopkinson bar experimental technique: A critical review. Appl. Mech. Rev. 2004, 57, 223–250. [Google Scholar] [CrossRef]

- Zwiessler, R.; Kenkmann, T.; Poelchau, M.H.; Nau, S.; Hess, S. On the use of a split Hopkinson pressure bar in structural geology: High strain rate deformation of Seeberger sandstone and Carrara marble under uniaxial compression. J. Struct. Geol. 2017, 97, 225–236. [Google Scholar] [CrossRef]

- Shi, X.; Jing, H.; Yin, Q.; Zhao, Z.; Han, G.; Gao, Y. Investigation on physical and mechanical properties of bedded sandstone after high-temperature exposure. Bull. Eng. Geol. Environ. 2020. [Google Scholar] [CrossRef]

| Axial Loads/MPa | Load Classification | |||||

|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | Ⅵ | |

| 5 | 2.5 | 5 | ||||

| 10 | 2.5 | 5 | 7.5 | 10 | ||

| 15 | 2.5 | 5 | 7.5 | 10 | 12.5 | 15 |

| Identifier | Recombination Load/MPa | Impact Pressure/MPa | Water Content |

|---|---|---|---|

| Sel2-1~3 | 5 | 0.5 | 15% |

| Sel2-4~6 | 10 | 0.5 | 15% |

| Sel2-7~9 | 15 | 0.5 | 15% |

| Identifier | Recombination Load/MPa | Impact Pressure/MPa | Water Content |

|---|---|---|---|

| Sel3-1~3 | 10 | 0.3 | 15% |

| Sel3-4~6 | 10 | 0.4 | 15% |

| Sel3-7~9 | 10 | 0.5 | 15% |

| Sel3-10~12 | 10 | 0.6 | 15% |

| Identifier | Reorganization Loads/MPa | Average Diameter/mm | Average Height/mm |

|---|---|---|---|

| Sel2-1~3 | 5 | 60 | 32 |

| Sel2-4~6 | 10 | 58 | 37 |

| Sel2-7~9 | 15 | 54 | 41 |

| Identifier | Impact Pressure/MPa | Impact Speed/m/s | Average Diameter/mm | Average Height/mm |

|---|---|---|---|---|

| Sel3-1~3 | 0.3 | 11.75 | 52 | 48 |

| Sel3-7~9 | 0.4 | 14.18 | 56 | 37 |

| Sel3-13~15 | 0.5 | 16.01 | 58 | 31 |

| Sel3-19~21 | 0.6 | 18.99 | 59 | 27 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, L.; Han, L.; Meng, Q.; Liu, K.; Tian, M.; Zhu, H. Study on Characteristic and Energy of Argillaceous Weakly Cemented Rock under Dynamic Loading by Hopkinson Bar Experiment. Energies 2020, 13, 3215. https://doi.org/10.3390/en13123215

Meng L, Han L, Meng Q, Liu K, Tian M, Zhu H. Study on Characteristic and Energy of Argillaceous Weakly Cemented Rock under Dynamic Loading by Hopkinson Bar Experiment. Energies. 2020; 13(12):3215. https://doi.org/10.3390/en13123215

Chicago/Turabian StyleMeng, Lingdong, Lijun Han, Qingbin Meng, Kexiang Liu, Maolin Tian, and Hexuan Zhu. 2020. "Study on Characteristic and Energy of Argillaceous Weakly Cemented Rock under Dynamic Loading by Hopkinson Bar Experiment" Energies 13, no. 12: 3215. https://doi.org/10.3390/en13123215

APA StyleMeng, L., Han, L., Meng, Q., Liu, K., Tian, M., & Zhu, H. (2020). Study on Characteristic and Energy of Argillaceous Weakly Cemented Rock under Dynamic Loading by Hopkinson Bar Experiment. Energies, 13(12), 3215. https://doi.org/10.3390/en13123215