Evaluation of Illuminance Measurement Data through Integrated Automated Blinds and LED Dimming Controls in a Full-Scale Mock-Up

Abstract

:1. Introduction

1.1. Background and Purpose

1.2. Literature Review

2. Materials and Methods

2.1. Study Methods

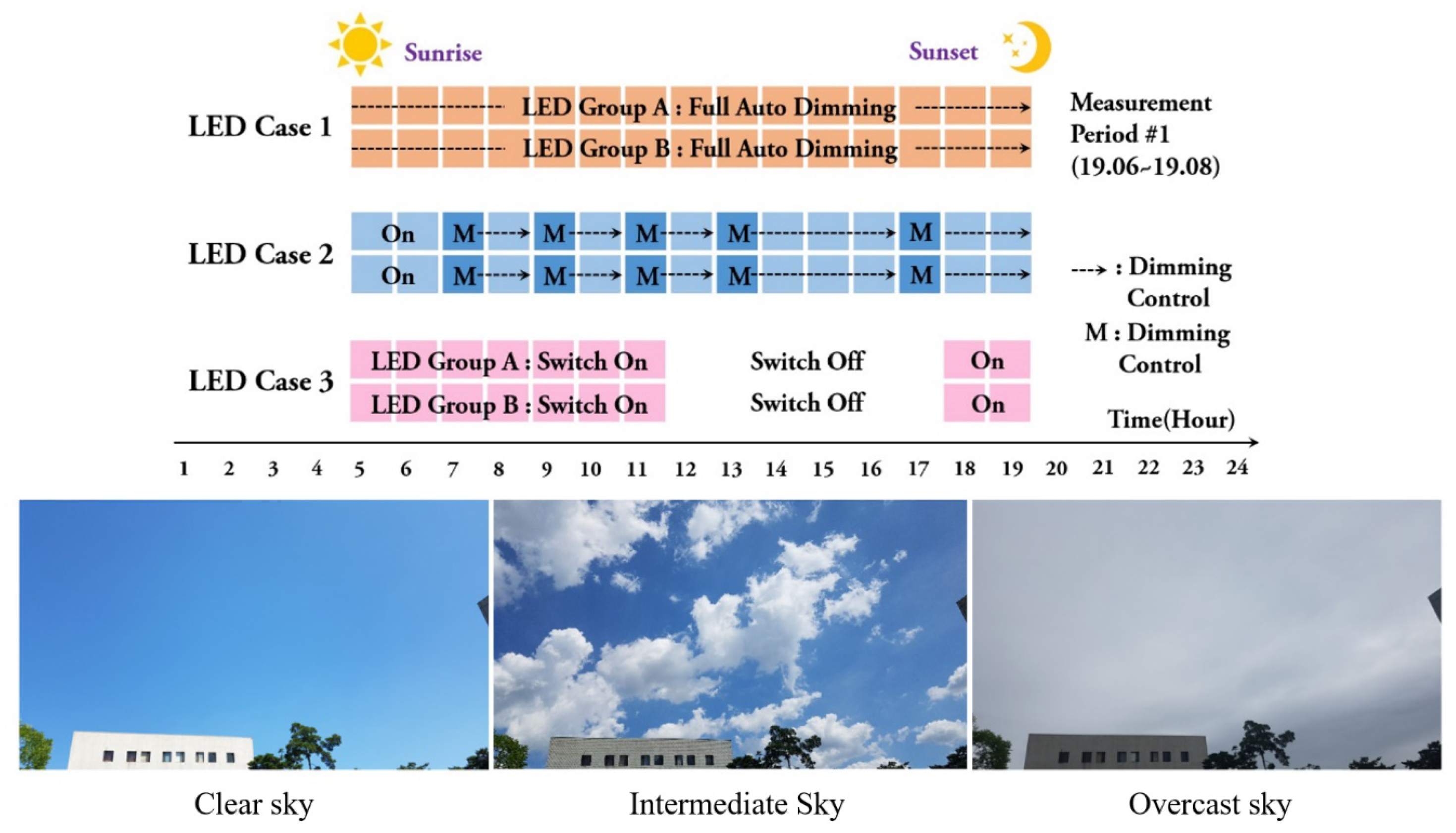

2.1.1. Measuring Period #1 (No Blinds + LED Dimming Controls)

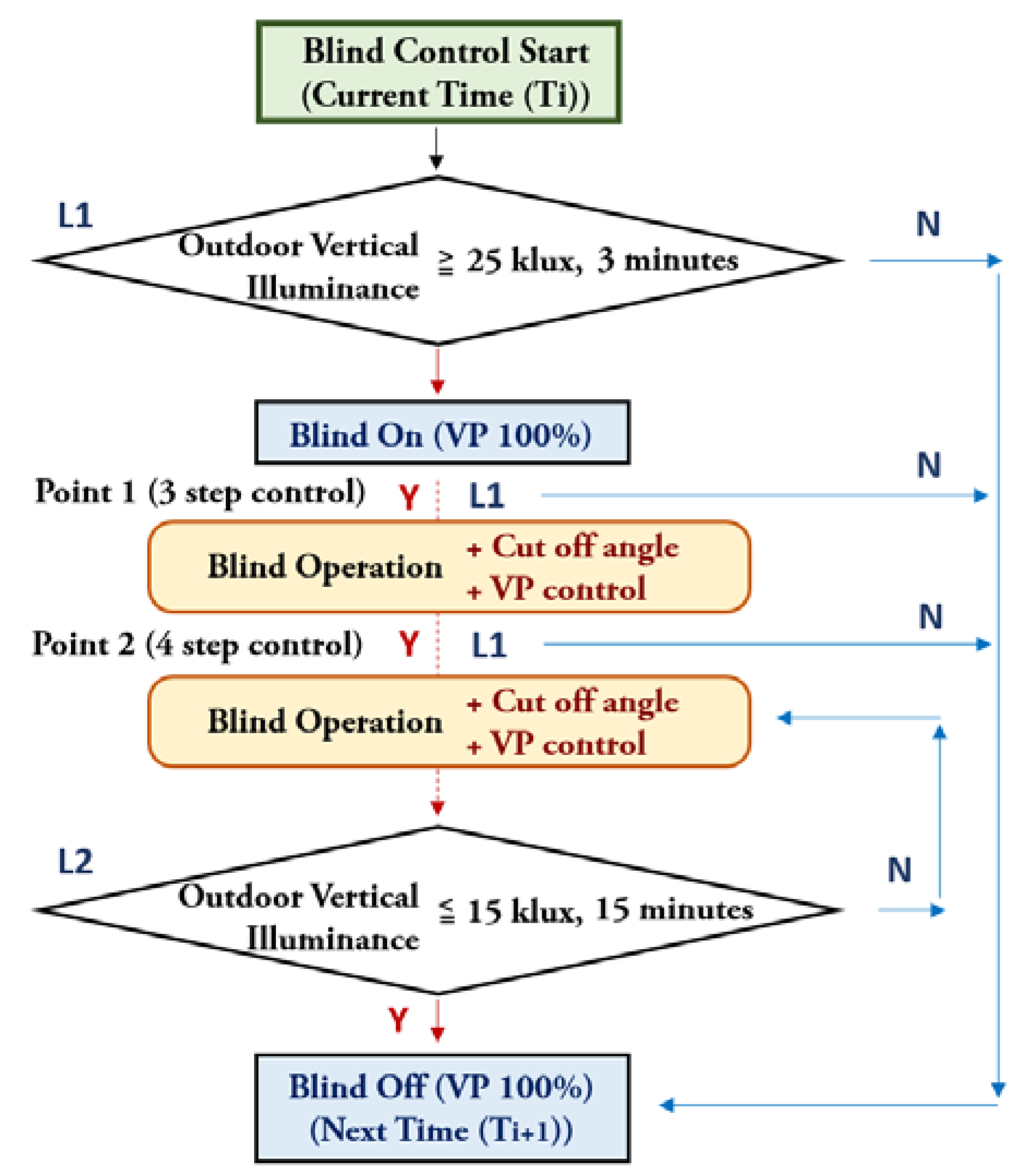

2.1.2. Measuring Period #2 (Integrated Automated Blinds and LED Dimming Controls)

2.2. Theories

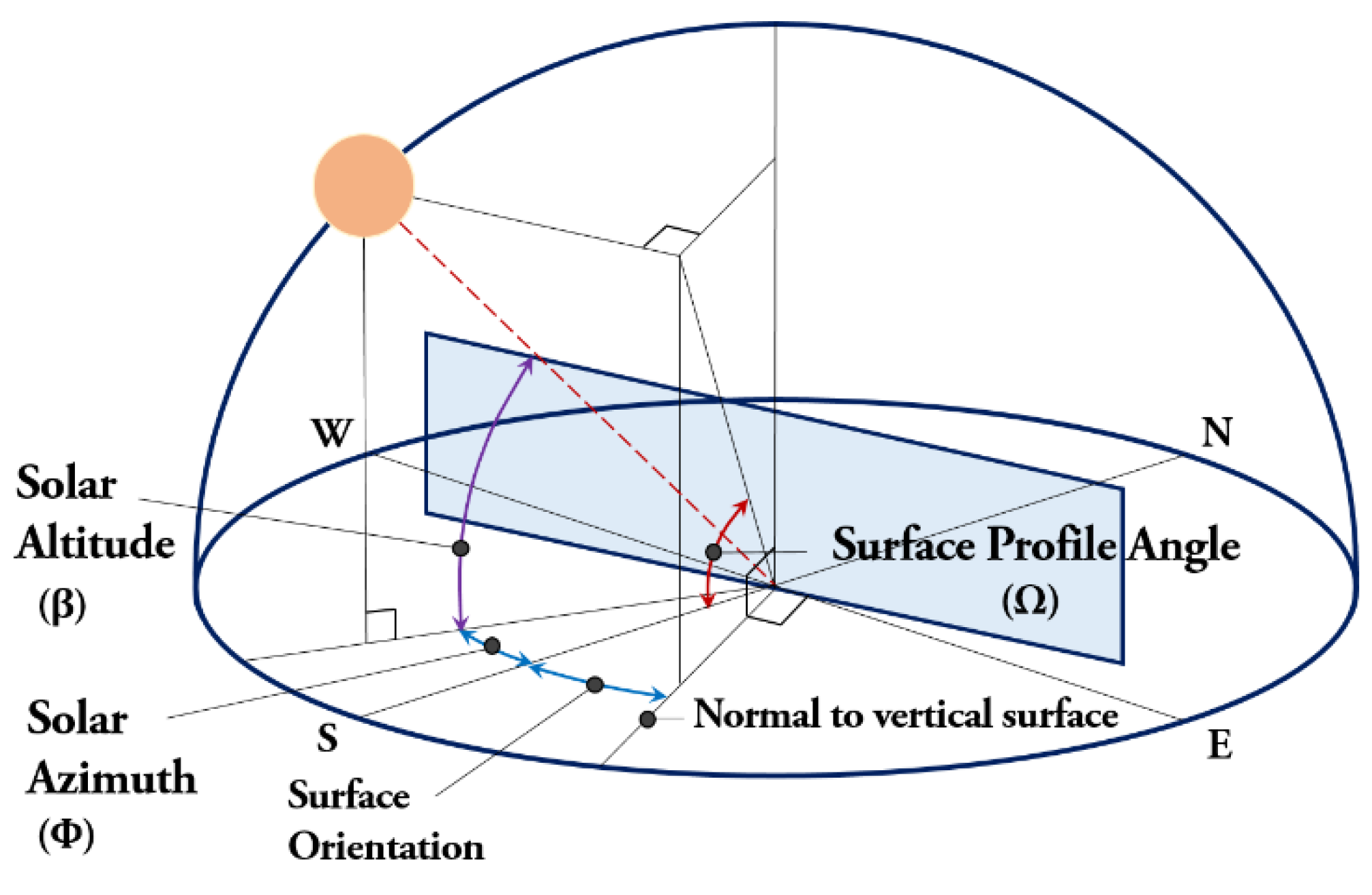

2.2.1. Solar Altitude and Azimuth

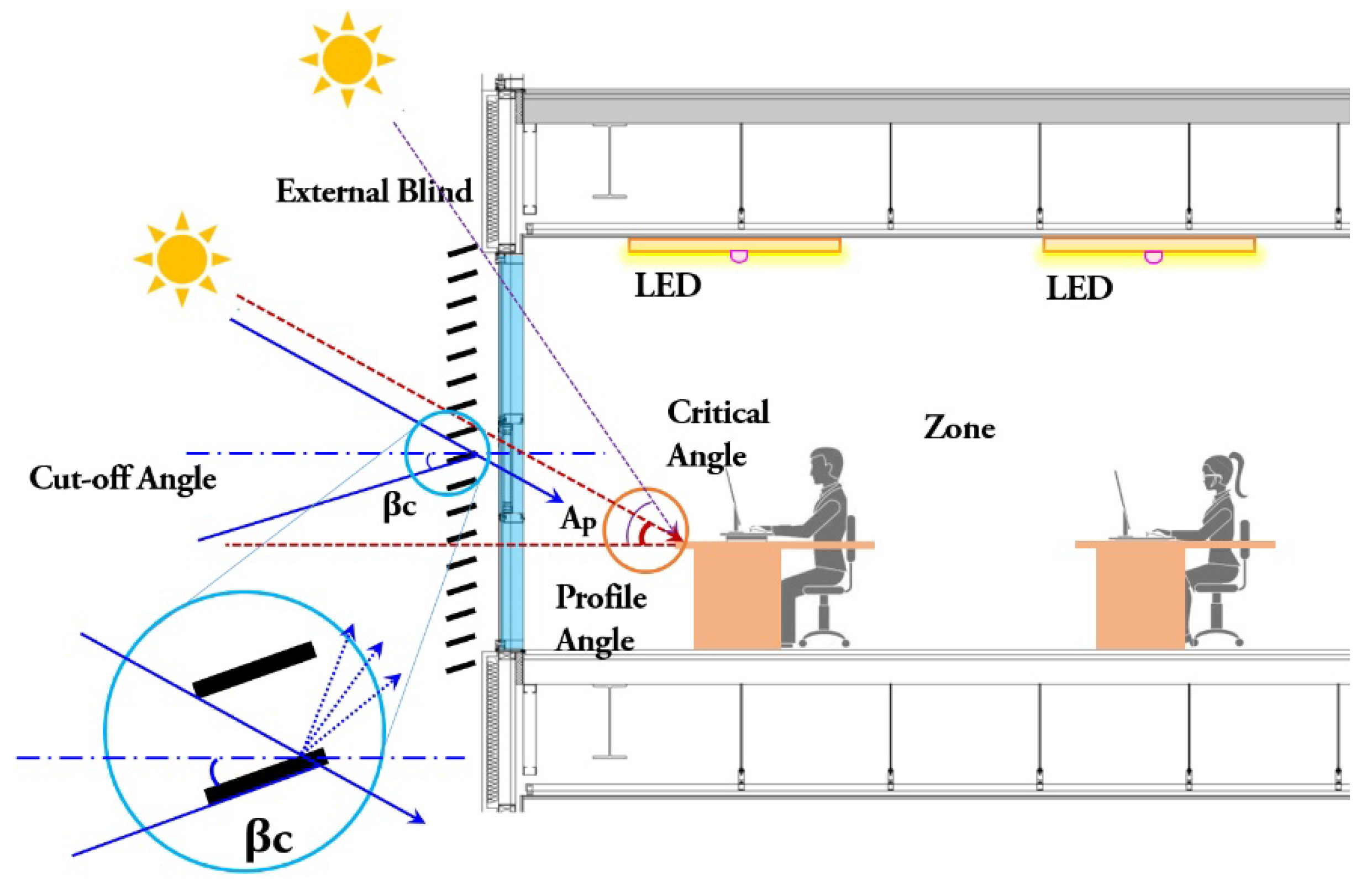

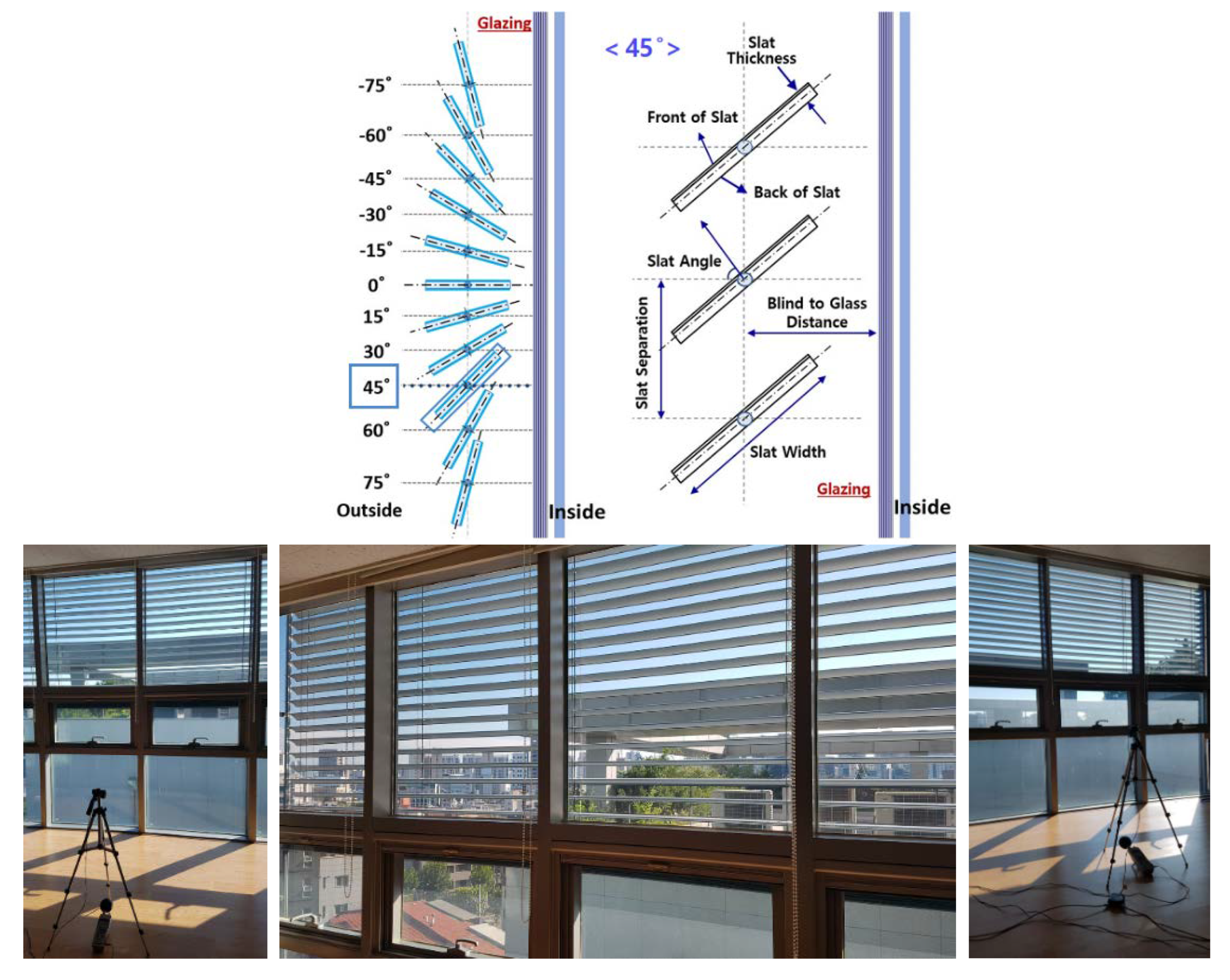

2.2.2. Blind Slat Angle and Vertical Position (VP) Control

3. Experiment Overview

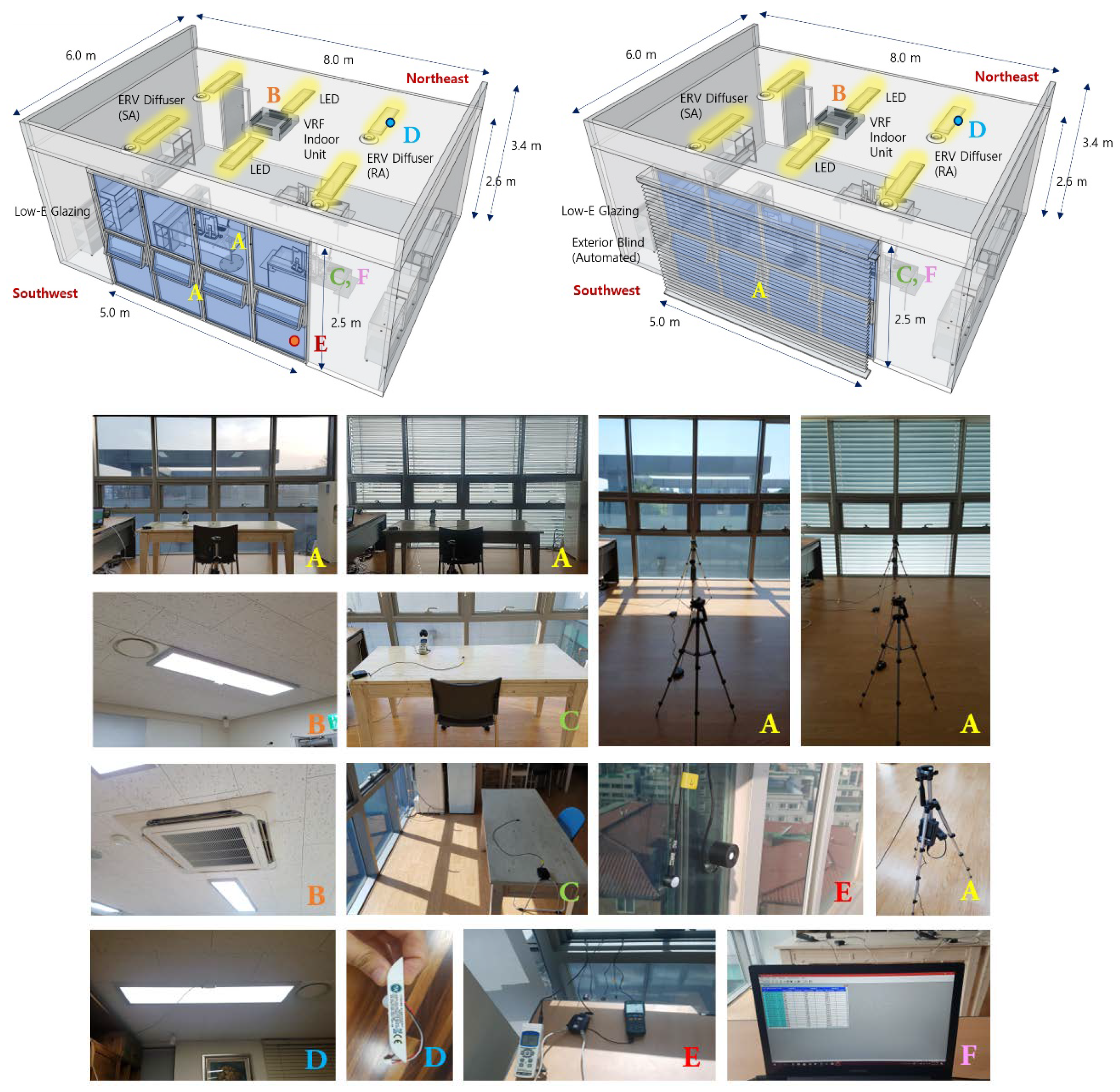

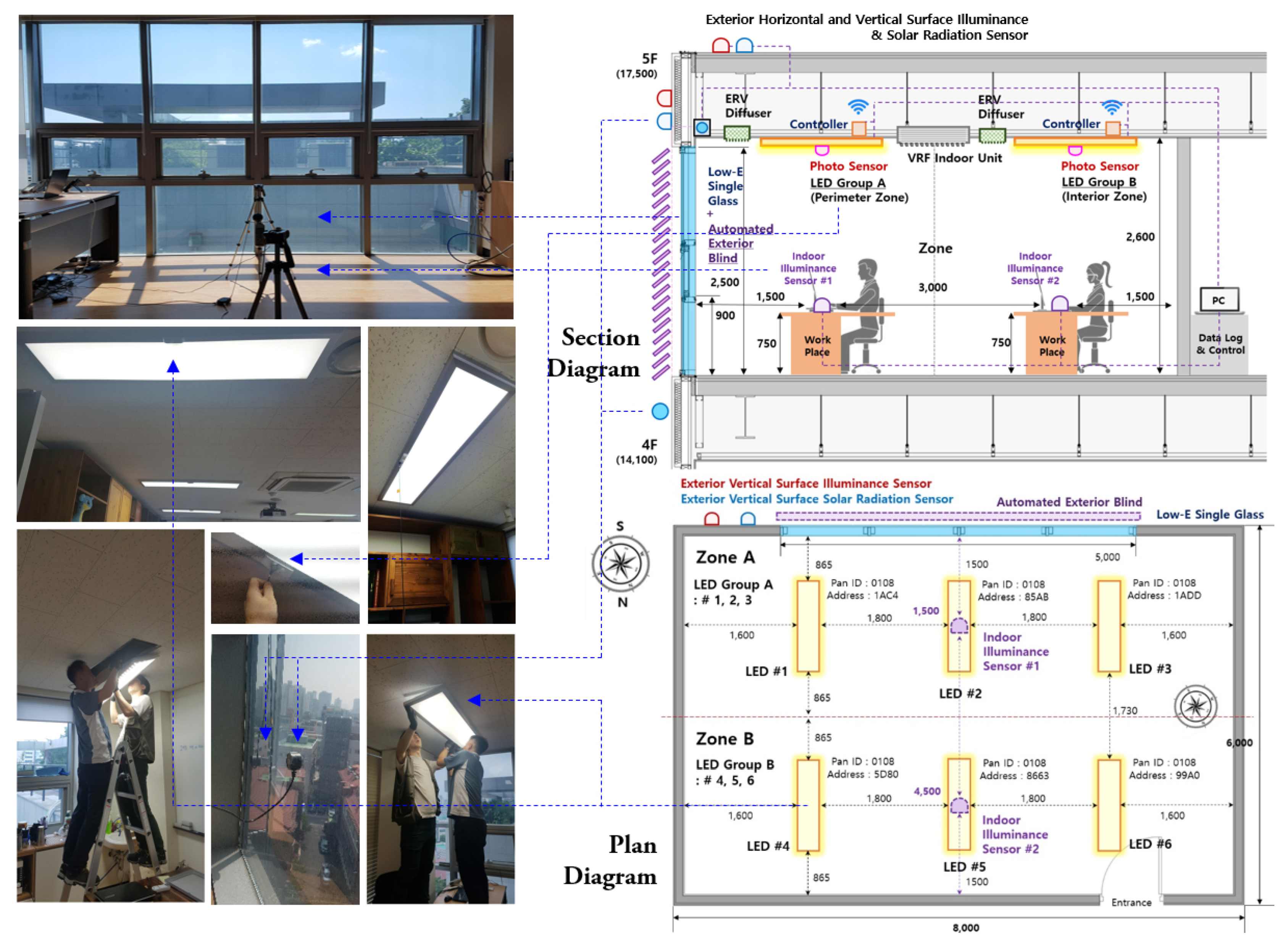

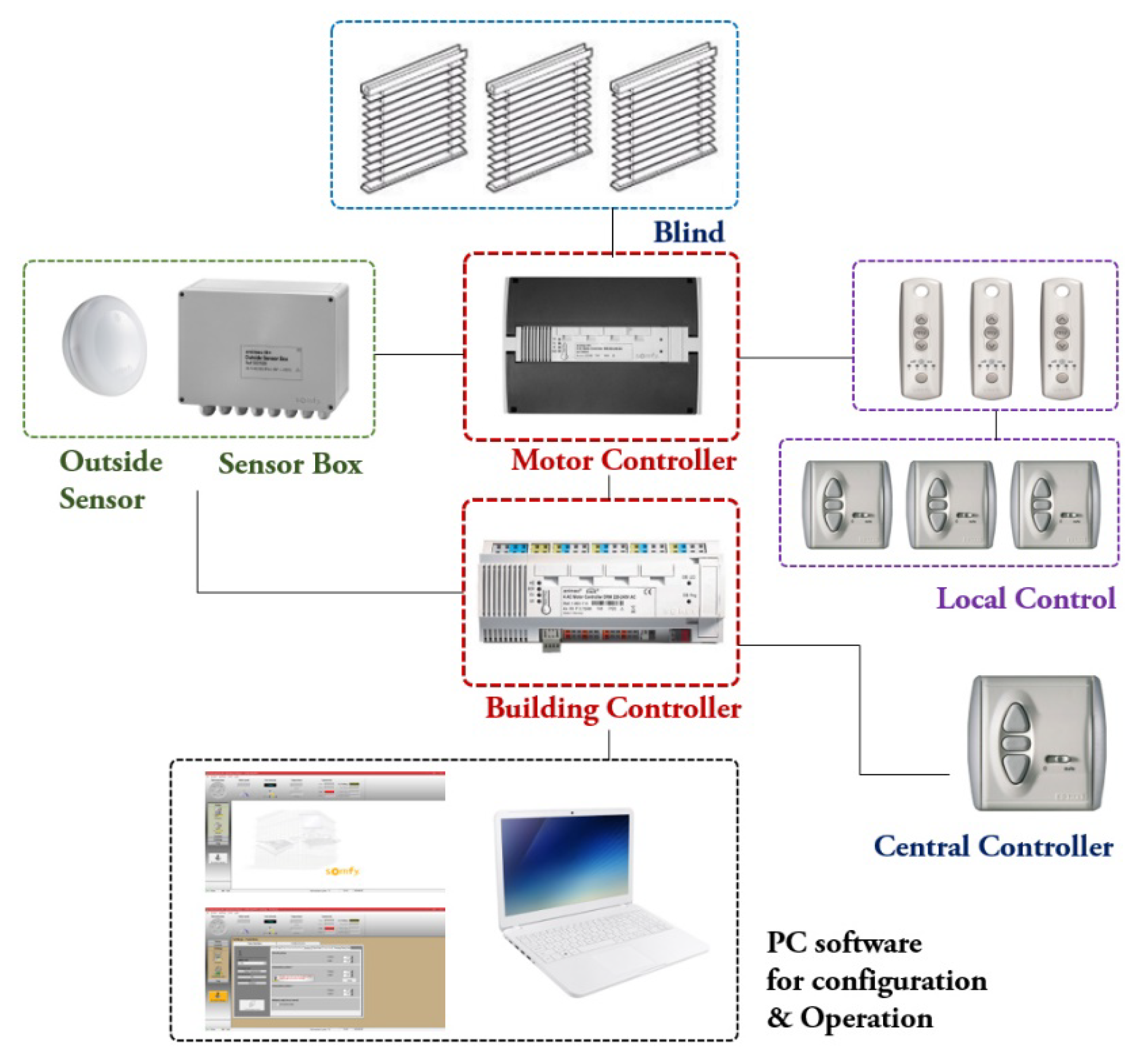

3.1. Target Full-Scale Mock-Up and Experimental Setup

3.2. Case Selection for Measurement and Simulation

3.2.1. Case Selection for the Measuring Period #1 (June to August 2019) Experiment

3.2.2. Case Selection for the Measuring Period #2 (September to October 2019) Experiment

4. Experimental Results

4.1. Illuminometer Calibration

4.2. No Blinds + LED Dimming Control (Measuring Period #1)

4.3. Blind Manual Controls + LED Dimming Controls (Measuring Period #2)

4.4. Blind Automated Controls + LED Dimming Controls (Measuring Period #2)

5. Conclusions

- (1)

- The illuminance of the LED photo sensor was expressed as Pulse with Modulation (PWM) in the dimming control software of company A. To convert this into lx, an illuminance unit, the illuminance (lx) was measured by installing a Minolta illuminance sensor that measures the work plane illuminance at the same position as that of the LED photo sensor. The correlations between the lx values of the Minolta sensors (Locations #1–4) and the LED photo sensor PWM were derived according to the dimming rate 0–100%. The relationships between the LED photo sensor and the illuminance sensors at each position were higher than 0.9 (Location #1: 0.9936, Location #2: 0.9966, Location #3: 0.9934), thereby exhibiting close relationships.

- (2)

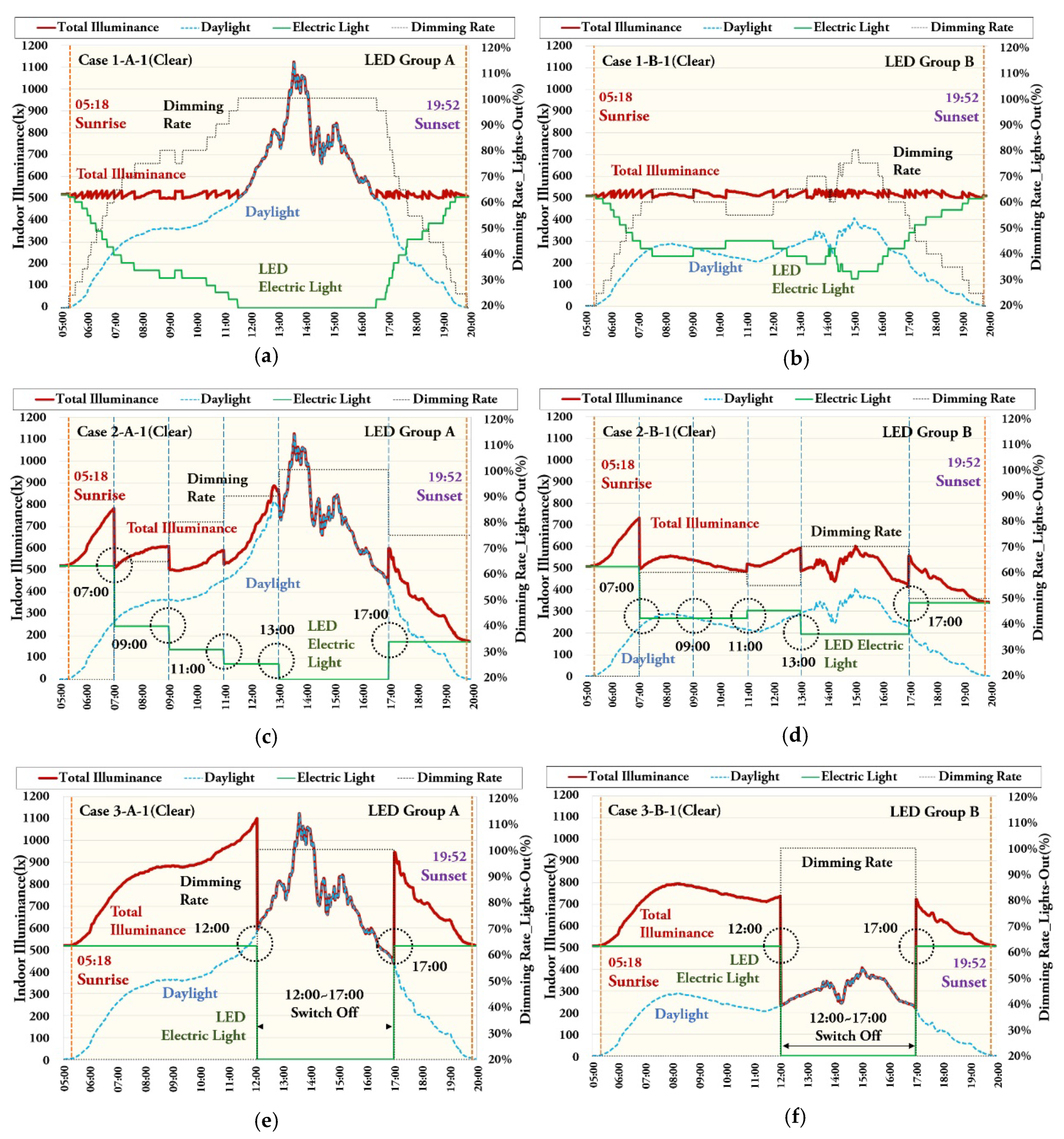

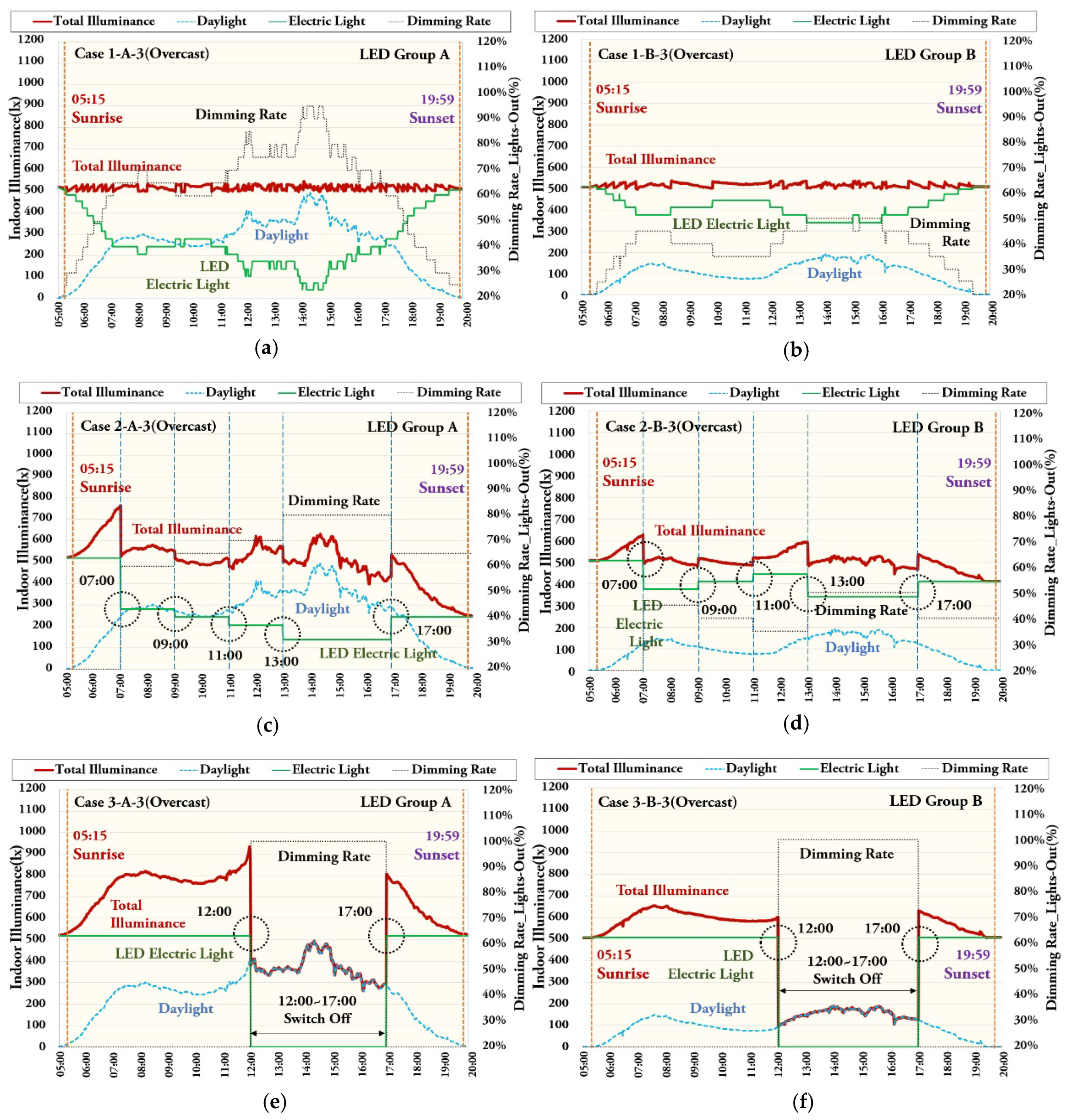

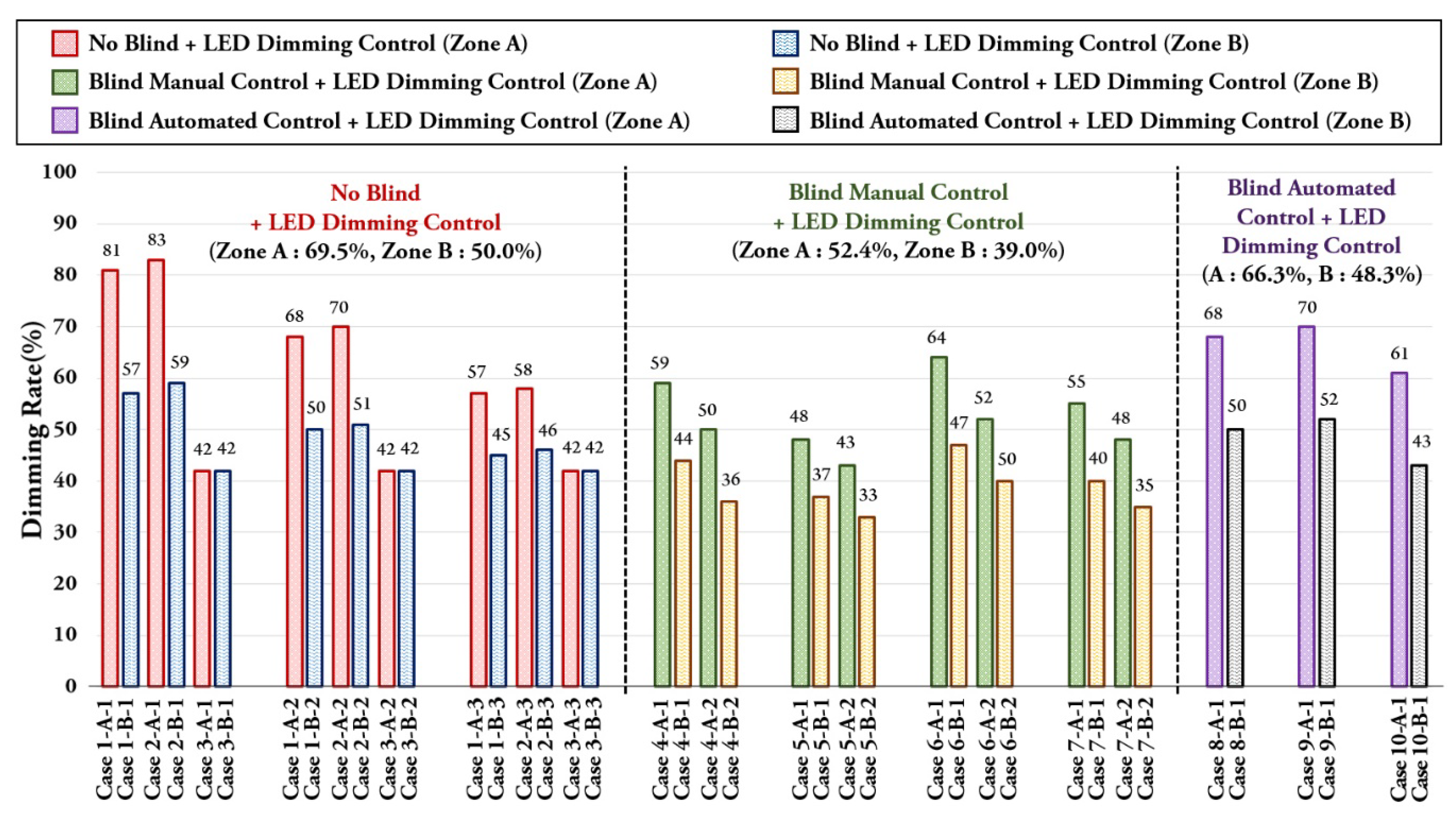

- During measuring period #1 (June to August 2019), the standard illuminance (500 lx) was set based on the basic envelope conditions (low-E glazing) with no blinds in the target space prior to integrated blind controls. When dimming control was conducted under each sky condition, the indoor work plane illuminance was constantly maintained at 500 lx (±30 lx) by daylight and artificial lighting. The average dimming rates of 82% (window side) and 58% (indoor side) were observed under clear sky, and those of 69% (window side) and 51% (indoor side) were observed under intermediate sky. Under overcast sky, the average dimming rates of 57% (window side) and 46% (indoor side) were observed. These results indicate that dimming control was effective for reducing lighting energy.

- (3)

- However, during measuring period #2 (September to October 2019), solar radiation cut-off was required, because excessive direct sunlight was introduced to the work plane. Excessive daylight only for lighting energy reduction may cause unpleasant thermal and light environments in an indoor space. The maximum daylight illuminance of the work plane was measured to be 2860 lx. To address this problem, blinds that can cut off solar heat were required. Therefore, LED dimming controls integrated with blind controls were used in measuring period #2.

- (4)

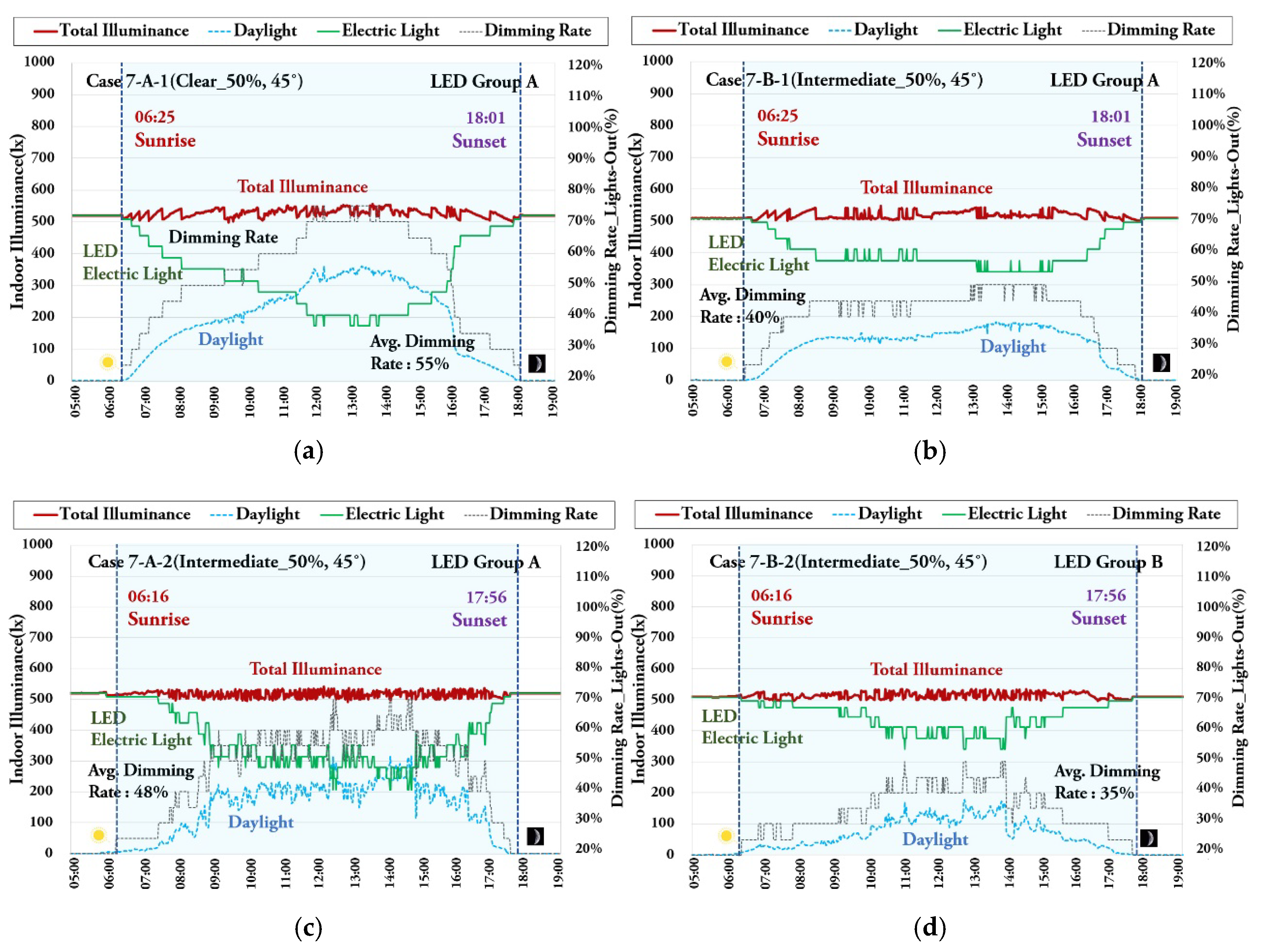

- When integrated LED dimming control was conducted after the vertical position of the blind was set to 100% and its slat angle was set to 0° under clear and intermediate sky, the average dimming rates were evaluated to be 55% (window side) and 40% (indoor side). When the VP was 100% and the slat angle was 45°, the dimming rates were evaluated to be 46% (window side) and 35% (indoor side), which were the lowest dimming rates among all experimental cases. When integrated LED dimming control was performed after setting the VP to 50% and the slat angle to 0°, the average dimming rates were evaluated to be 58% (window side) and 44% (indoor side). When integrated LED dimming control was conducted after setting the VP to 50% and the slat angle to 45°, the average dimming rates were evaluated to be 52% (window side) and 38% (indoor side). It was found that manual blind control had the effect of cutting off solar radiation, but because the angle and VP were fixed, daylight could not be effectively used.

- (5)

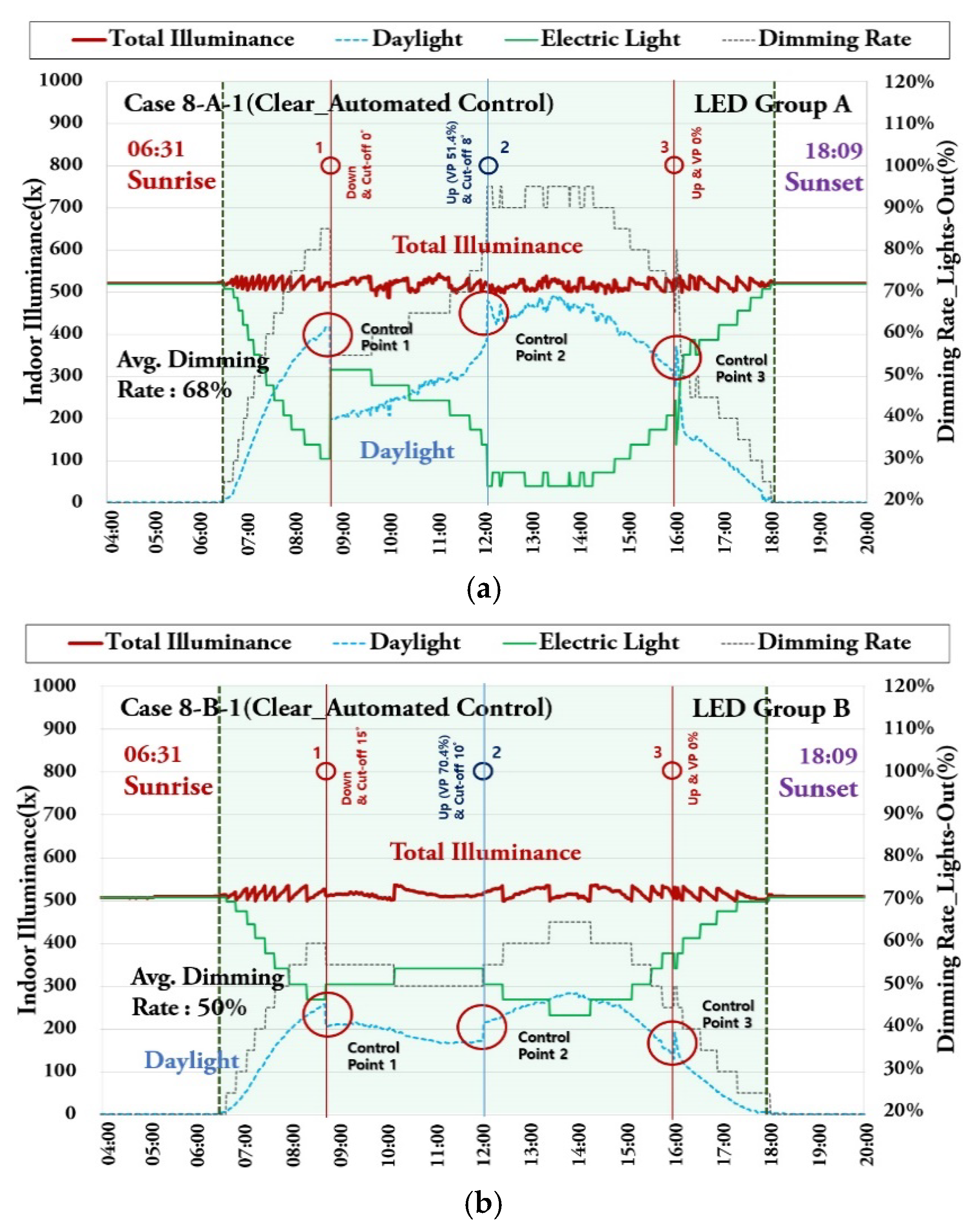

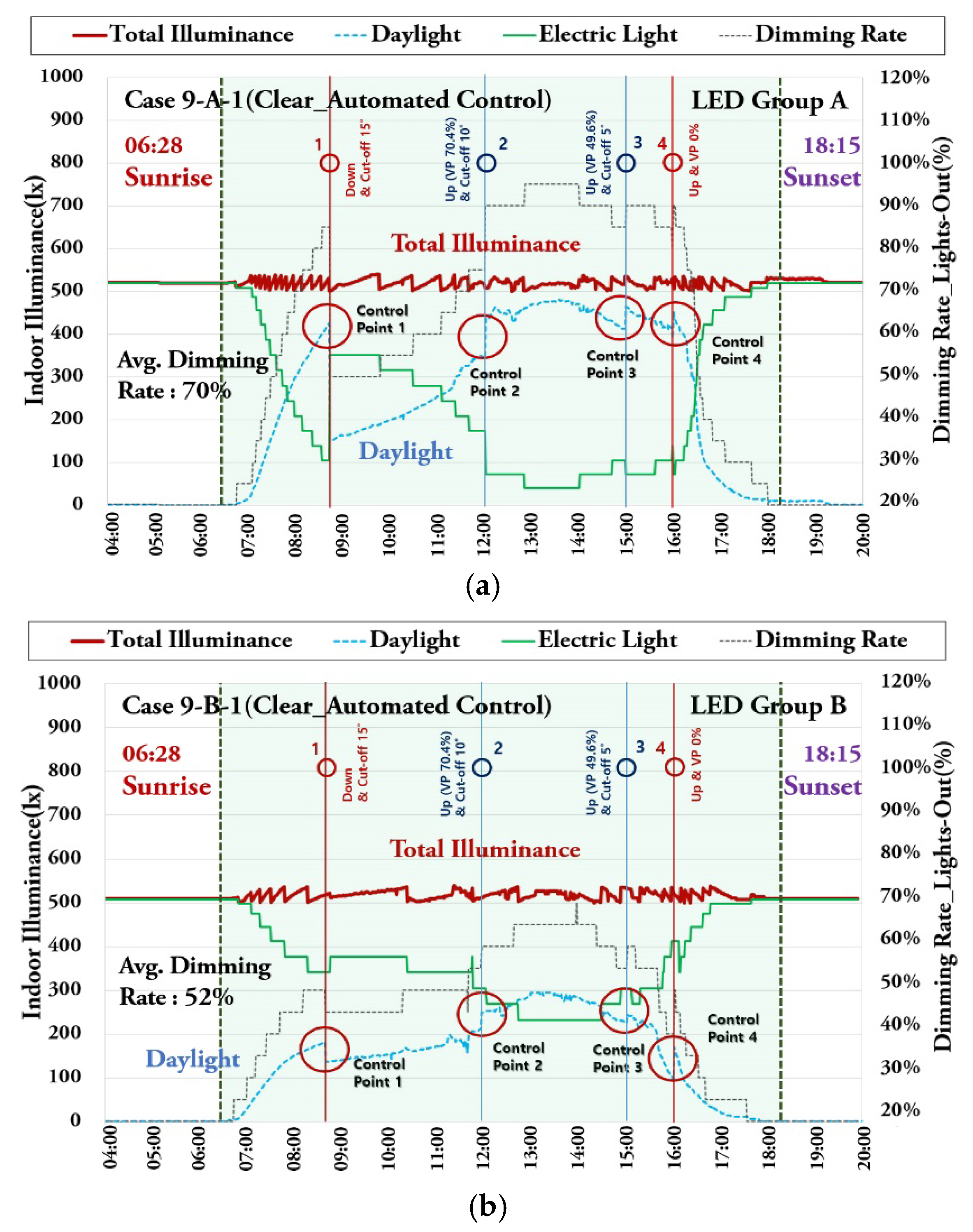

- When the blinds were subjected to three-step automatic control based on the exterior vertical illuminance and LED dimming control was performed at the same time under clear sky, the indoor work plan illuminance was constantly maintained at 500 lx (±30 lx) by daylight and artificial lighting, and the dimming rates of Zone A and Zone B were found to be 68 and 50%, respectively. When both four-step automatic control and LED dimming control were utilized, the dimming rates of Zone A and Zone B were found to be 70 and 52%, respectively. Under intermediate sky, the dimming rates of Zone A and Zone B were found to be 64 and 43%, respectively. When LED dimming control integrated with automatic blind control was used, the average dimming rate was 2.1% lower in Zone A and 1.7% lower in Zone B compared to when automatic and manual LED dimming control was conducted for low-E glazing with no blinds, but excessive solar radiation could be blocked. In addition, because the dimming rate was 14.9% higher in Zone A and 9.3% higher in Zone B compared to when manual blind control was performed, it was possible to utilize more daylight, and thus to reduce lighting energy.

- (6)

- The experimental results showed that because the LED dimming rate changed when daylight was introduced under various external weather conditions, it was possible to secure the uniform illuminance required for the indoor space in all cases. If the VP and the slat angle can be adjusted without lowering all the blinds, considering the work plane reference position, occupants may have more external views and a better sense of openness. Moreover, because the inflow of daylight increases without the direct impact of direct sunlight and glare, it is possible to secure the work plane illuminance. It was found that integrated blinds and LED dimming controls contributed to maintaining the standard illuminance and saving lighting energy using daylight. Based on the results of this study, further research will be conducted on the comfort indicators (thermal comfort and visual comfort) and thermal environment of buildings, as well as the cooling and heating energy.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amasyali, K.; El–Gohary, N.M. A review of data–driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 81, 1192–1205. [Google Scholar] [CrossRef]

- Kaminska, A.; Ożadowicz, A. Lighting Control Including Daylight and Energy Efficiency Improvements Analysis. Energies 2018, 11, 2166. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.H.; Lee, S.E.; Kim, K.S. Analysis of Energy Saving Potential in High–Performance Building Technologies under Korean Climatic Conditions. Energies 2018, 11, 884. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Land, Infrastructure and Transport (MOLIT); Korea Energy Agency (KEA). Building Energy Saving Design Standards of Korea; KEA: Gyeonggi-Do, Korea, 2018.

- Fontoynont, M.; Ramananarivo, K.; Soreze, T.; Fernez, G.; Skov, K.G. Economic feasibility of maximising daylighting of a standard office building with efficient electric lighting. Energy Build. 2016, 110, 435–442. [Google Scholar] [CrossRef] [Green Version]

- Mettanant, V.; Chaiwiwatworakul, P. Automated vertical blinds for daylighting in tropical region. Energy Procedia 2014, 52, 278–286. [Google Scholar] [CrossRef] [Green Version]

- Chaiwiwatworakul, P.; Chirarattananon, S.; Rakkwamsuk, P. Application of automated blind for daylighting in tropical region. Energy Convers. Manag. 2009, 50, 2927–2943. [Google Scholar] [CrossRef]

- Bodart, M.; De Herde, A. Global energy savings in offices buildings by the use of daylighting. Energy Build. 2002, 34, 421–429. [Google Scholar] [CrossRef]

- Shen, E.; Hu, J.; Patel, M. Energy and visual comfort analysis of lighting and daylight control strategies. Build. Environ. 2014, 78, 155–170. [Google Scholar] [CrossRef]

- Reinhart, C.F. Lightswitch-2002: A model for manual and automated control of electric lighting and blinds. Sol. Energy 2004, 77, 15–28. [Google Scholar] [CrossRef] [Green Version]

- Babu, S.; Zhou, J.; Wan, M.P.; Lamano, A.S.; Sarvaiya, J.N.; Zhang, Z.; Kumar, D.K.; Gao, C.P.; Valliappan, S.; Goh, A. et al.; et al. Investigation of an integrated automated blinds and dimmable lighting system for tropical climate in a rotatable testbed facility. Energy Build. 2019, 183, 356–376. [Google Scholar] [CrossRef]

- Meerbeek, B.W.; de Bakker, C.; De Kort, Y.A.W.; Van Loenen, E.J.; Bergman, T. Automated blinds with light feedback to increase occupant satisfaction and energy saving. Build. Environ. 2016, 103, 70–85. [Google Scholar] [CrossRef]

- Kim, C.H.; Lee, S.E.; Kim, K.S. Comprehensive Analysis of Energy Consumption Rate and New Technology Trend in High-Performance Buildings related with Different Climatic Zones. J. Arch. Inst. Korea Struct. Constr. 2018, 34, 63–72. [Google Scholar]

- Williams, A.; Atkinson, B.; Garbesi, K.; Page, E.; Rubinstein, F. Lighting controls in commercial buildings. LEUKOS J. Illum. Eng. Soc. 2012, 8, 161–180. [Google Scholar] [CrossRef]

- Galasiu, A.D.; Atif, M.R.; MacDonald, R.A. Impact of window blinds on daylight-linked dimming and automatic on/off lighting controls. Sol. Energy 2004, 76, 523–544. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, L.L.; Lee, E.S.; DiBartolomeo, D.L.; McNeil, A. Monitored lighting energy savings from dimmable lighting controls in The New York Times Headquarters Building. Energy Build. 2014, 68, 498–514. [Google Scholar] [CrossRef] [Green Version]

- Richman, E.E.; Kinzey, B.R.; Miller, N.J. Laboratory Evaluation of LED T8 Replacement Lamp Products (No. PNNL-20404); Pacific Northwest National Lab.(PNNL): Richland, WA, USA, 2011.

- Al-Ashwal, N.T.; Budaiwi, I.M. Energy savings due to daylight and artificial lighting integration in office buildings in hot climate. Int. J. Energy Environ. 2011, 2, 999–1012. [Google Scholar]

- Caicedo, D.; Pandharipande, A.; Willems, F.M. Daylight-adaptive lighting control using light sensor calibration prior-information. Energy Build. 2014, 73, 105–114. [Google Scholar] [CrossRef]

- Yoo, S.; Kim, J.; Jang, C.Y.; Jeong, H. A sensor-less LED dimming system based on daylight harvesting with BIPV systems. Opt. Express 2014, 22, A132–A143. [Google Scholar] [CrossRef]

- Parise, G.; Martirano, L. Daylight impact on energy performance of internal lighting. IEEE Trans. Ind. Appl. 2012, 49, 242–249. [Google Scholar] [CrossRef]

- Gentile, N.; Dubois, M.C. Field data and simulations to estimate the role of standby energy use of lighting control systems in individual offices. Energy Build. 2017, 155, 390–403. [Google Scholar] [CrossRef]

- Gentile, N.; Laike, T.; Dubois, M.C. Lighting control systems in individual offices rooms at high latitude: Measurements of electricity savings and occupants’ satisfaction. Sol. Energy 2016, 127, 113–123. [Google Scholar] [CrossRef]

- Nagy, Z.; Yong, F.Y.; Frei, M.; Schlueter, A. Occupant centered lighting control for comfort and energy efficient building operation. Energy Build. 2015, 94, 100–108. [Google Scholar] [CrossRef]

- Gagne, J.M.; Andersen, M.; Norford, L.K. An interactive expert system for daylighting design exploration. Build. Environ. 2011, 46, 2351–2364. [Google Scholar] [CrossRef]

- Tzempelikos, A.; Athienitis, A.K. The impact of shading design and control on building cooling and lighting demand. Sol. Energy 2007, 81, 369–382. [Google Scholar] [CrossRef]

- Olbina, S.; Hu, J. Daylighting and thermal performance of automated split-controlled blinds. Build. Environ. 2012, 56, 127–138. [Google Scholar] [CrossRef]

- Chan, Y.C.; Tzempelikos, A. Efficient venetian blind control strategies considering daylight utilization and glare protection. Sol. Energy 2013, 98, 241–254. [Google Scholar] [CrossRef]

- Chan, Y.C.; Tzempelikos, A. A hybrid ray-tracing and radiosity method for calculating radiation transport and illuminance distribution in spaces with venetian blinds. Sol. Energy 2012, 86, 3109–3124. [Google Scholar] [CrossRef]

- Koo, S.Y.; Yeo, M.S.; Kim, K.W. Automated blind control to maximize the benefits of daylight in buildings. Build. Environ. 2010, 45, 1508–1520. [Google Scholar] [CrossRef]

- Kim, D.W.; Park, C.S. Comparative control strategies of exterior and interior blind systems. Light. Res. Technol. 2012, 44, 291–308. [Google Scholar] [CrossRef]

- Korean Standards Association. KS A 3011:1998, Recommended Levels of Illumination; Korean Standards Association: Seoul, Korea, 1998. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, Fourth Edition; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; ISBN 9781118671603. [Google Scholar]

- Kim, J.H. Automatic Control Strategy of Venetian Blind for Improvement of Environmental Performance in Office Buildings. Ph.D. Thesis, Seoul National University, Seoul, Korea, 2007. [Google Scholar]

- Aurora Design Lab. Product. Available online: http://auroradesignlab.com/main/ko/sub03_01.html?type=1 (accessed on 13 May 2020).

- SOMFY. Owners manual: Somfy Animeo® IB+ Operating PC Software—English 2.1; SOMFY SAS: Cluses, France, 2006. [Google Scholar]

- KONICA MINLOTAL. Product. Available online: https://www.konicaminolta.co.kr/instruments/products/light/t10a/index. html (accessed on 13 May 2020).

- LUTRON ELECTRONIC. Solar Power Meter. Available online: http://www.sunwe.com.tw/lutron/SPM-1116SD.pdf (accessed on 13 May 2020).

- TES Electrical Electrronic Corp. Solar Power Meter. Available online: http://www.tes.com.tw/en/product_detail.asp?seq= 284 (accessed on 13 May 2020).

- Kim, C.H.; Kim, K.S. Development of Sky Luminance and Daylight Illuminance Prediction Methods for Lighting Energy Saving in Office Buildings. Energies 2019, 12, 592. [Google Scholar] [CrossRef] [Green Version]

| Surface of Model. | Area(m2) | Reflection Rate (%) |

|---|---|---|

| Floor | 48 | 20 |

| Back Wall | 27.2 | 55 |

| Right Side Wall | 20.4 | 55 |

| Left Side Wall | 20.4 | 55 |

| Ceiling | 48 | 85 |

| Front Wall (Top) | 14.7 | 55 |

| Window | 12.5 | 5 |

| Total | 178.7 | – |

| Average | – | 54.1 |

| Lamp | Size (mm) | Activity Power (W) | Luminous Flux (lm) | Efficiency (lm/W) | Color Temperature (K) | Color Rendering Index (CRI) |

|---|---|---|---|---|---|---|

| Fluorescent Lamp | 1275 × 310 × 40 | 64 W | 4800 | 75 | 8000 | 70 |

| LED Lamp | 1275 × 310 × 45 | 35 W | 3325 | 95 | 6000 | 80 |

| Device | Parameter | Data Management | Range | Accuracy | Shape |

|---|---|---|---|---|---|

| T-10MA (Konica Minolta) [37] | Vertical Surface & Indoor Illuminance | Universal Serial Bus (USB) cable with PC | (0.01–299,900) lx or (0.001–29,990) fcd | ±3~5% |  |

| SPM-1116SD (Lutron Electronic) [38] | Exterior Solar Irradiation | Secure Digital (SD) Card with PC | (0–2000) W/m2 or (0–634) Btu/ft2 | ± 10 W/m2, ± 3 Btu/ft2 or ± 5% |  |

| TES-132 (TES Electronic) [39] | Solar Transmission & Irradiation | USB cable and SD Card with PC | (0–2000) W/m2 or (0–634) Btu/ft2 | ± 10 W/m2, ± 3 Btu/ft2 or ± 5% |  |

| LED Control Program [35] | LED dimming remote monitoring and control system (Company A, Korea), Dimming speed, Target illumination, Control mode management, LED channel and Pan ID address input |  | |||

| Blind Control Program [36] | Animeo IB+ Operating Software (Company S, France), Manual and automatic control mode selection, Blind control criteria and control schedule management |  | |||

| Blind Conditions | Exterior Blind |

|---|---|

| Slat Material and Color | Aluminum Silver (A5754-H19) |

| Slat Width and Separation (mm) | 86 |

| Slat Thickness (mm) | 2 |

| Slat Conductivity (W/mk) | 221 |

| Slat Beam Diffuse Solar Reflectance | 0.7 |

| Slat Infrared Emissivity | 0.9 |

| Blind to Glass Distance (mm) | 64 |

| Zone A | Glazing Systems | LED Group A (Zone A) | Zone B | Glazing Systems | LED Group B (Zone B) | ||||

|---|---|---|---|---|---|---|---|---|---|

| LED #1 | LED #2 | LED #3 | LED #4 | LED #5 | LED #6 | ||||

| Case 1-A-1 (Clear Sky) | Low-E Glass + No Blind | Full Auto Dimming | Case 1-B-1 (Clear Sky) | Low-E Glass + No Blind | Full Auto Dimming | ||||

| Case 2-A-1 (Clear Sky) | Manual Dimming (5 Times in 1 Day) 07:00, 09:00, 11:00, 13:00, 17:00 | Case 2-B-1 (Clear Sky) | Manual Dimming (5 Times in 1 Day) 07:00, 09:00, 11:00, 13:00, 17:00 | ||||||

| Case 3-A-1 (Clear Sky) | Switch Control 12:00–17:00 (Off) | Case 3-B-1 (Clear Sky) | Switch Control 12:00–17:00 (Off) | ||||||

| Case 1-A-2 (Intermediate Sky) | Low-E Glass + No Blind | Full Auto Dimming | Case 1-B-2 (Intermediate Sky) | Low-E Glass + No Blind | Full Auto Dimming | ||||

| Case 2-A-2 (Intermediate Sky) | Manual Dimming (5 Times in 1 Day) 07:00, 09:00, 11:00, 13:00, 17:00 | Case 2-B-2 (Intermediate Sky) | Manual Dimming (5 Times in 1 Day) 07:00, 09:00, 11:00, 13:00, 17:00 | ||||||

| Case 3-A-2 (Intermediate Sky) | Switch Control 12:00–17:00 (Off) | Case 3-B-2 (Intermediate Sky) | Switch Control 12:00–17:00 (Off) | ||||||

| Case 1-A-3 (Overcast Sky) | Low-E Glass + No Blind | Full Auto Dimming | Case 1-B-3 (Overcast Sky) | Low-E Glass + No Blind | Full Auto Dimming | ||||

| Case 2-A-3 (Overcast Sky) | Manual Dimming (5 Times in 1 Day) 07:00, 09:00, 11:00, 13:00, 17:00 | Case 2-B-3 (Overcast Sky) | Manual Dimming (5 Times in 1 Day)07:00, 09:00, 11:00, 13:00, 17:00 | ||||||

| Case 3-A-3 (Overcast Sky) | Switch Control 12:00–17:00 (Off) | Case 3-B-3 (Overcast Sky) | Switch Control 12:00–17:00 (Off) | ||||||

| Zone A | Glazing & Blind Manual Control | LED Group A (Zone A) | Zone B | Glazing & Blind Manual Control | LED Group B (Zone B) | ||||

|---|---|---|---|---|---|---|---|---|---|

| LED #1 | LED #2 | LED #3 | LED #4 | LED #5 | LED #6 | ||||

| Case 4-A-1 (Clear Sky) | Low-E Glass + Blind (100%, 0°) | Full Auto Dimming | Case 4-B-1 (Clear Sky) | Low-E Glass + Blind (100%, 0°) | Full Auto Dimming | ||||

| Case 4-A-2 (Intermediate Sky) | Case 4-B-2 (Intermediate Sky) | ||||||||

| Case 5-A-1 (Clear Sky) | Low-E Glass + Blind (100%, 45°) | Full Auto Dimming | Case 5-B-1 (Clear Sky) | Low-E Glass + Blind (100%, 45°) | Full Auto Dimming | ||||

| Case 5-A-2 (Intermediate Sky) | Case 5-B-2 (Intermediate Sky) | ||||||||

| Case 6-A-1 (Clear Sky) | Low-E Glass + Blind (50%, 0°) | Full Auto Dimming | Case 6-B-1 (Clear Sky) | Low-E Glass + Blind (50%, 0°) | Full Auto Dimming | ||||

| Case 6-A-2 (Intermediate Sky) | Case 6-B-2 (Intermediate Sky) | ||||||||

| Case 7-A-1 (Clear Sky) | Low-E Glass + Blind (50%, 45°) | Full Auto Dimming | Case 7-B-1 (Clear Sky) | Low-E + Blind (50%, 45°) | Full Auto Dimming | ||||

| Case 7-A-2 (Intermediate Sky) | Case 7-B-2 (Intermediate Sky) | ||||||||

| Zone A | Glazing & Blind Automated Control | LED Group A (Zone A) | Zone B | Glazing & Blind Automated Control | LED Group B (Zone B) | ||||

|---|---|---|---|---|---|---|---|---|---|

| LED #1 | LED #2 | LED #3 | LED #4 | LED #5 | LED #6 | ||||

| Case 8-A-1 (Clear Sky) | Low-E Glass + Blind (three step automated control) | Full Auto Dimming | Case 8-B-1 (Clear Sky) | Low-E Glass + Blind (three step automated control) | Full Auto Dimming | ||||

| Case 9-A-1 (Clear Sky) | Low-E Glass + Blind (four step automated control) | Full Auto Dimming | Case 9-B-1 (Clear Sky) | Low-E Glass + Blind (four step automated control) | Full Auto Dimming | ||||

| Case 10-A-1 (Intermediate Sky) | Low-E Glass + Blind (automated control) | Full Auto Dimming | Case 10-B-1 (Intermediate Sky) | Low-E Glass + Blind (automated control) | Full Auto Dimming | ||||

| Sky Condition | LED Group A (Zone A) | LED Group B (Zone B) | Total Avg.1 | Total Avg.2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Case 1-A | Case 2-A | Case 3-A | Avg.1 | Avg.2 | Case 1-B | Case 2-B | Case 3-B | Avg.1 | Avg.2 | |||

| Clear Sky (1) | 81 | 83 | 42 | 82 | 69 | 57 | 59 | 42 | 58 | 53 | 70 | 61 |

| Intermediate Sky (2) | 68 | 70 | 42 | 69 | 60 | 50 | 51 | 42 | 51 | 48 | 60 | 54 |

| Overcast Sky (3) | 57 | 58 | 42 | 57 | 52 | 45 | 46 | 42 | 46 | 44 | 51 | 48 |

| Avg. | 69 | 70 | 42 | 69 | 60 | 41 | 42 | 42 | 51 | 48 | 60 | 54 |

| Blind VP and Angle | Sky Condition | Case | Dimming Rate (%) | Case | Dimming Rate (%) | Avg |

|---|---|---|---|---|---|---|

| 100%, 0° (4-A, B) | Clear Sky (1) | Case 4-A-1 | 59 | Case 4-B-1 | 44 | 51.5 |

| Intermediate Sky (2) | Case 4-A-2 | 50 | Case 4-B-2 | 36 | 43 | |

| Avg | 54.5 | 40 | 47.3 | |||

| 100%,45° (5-A, B) | Clear Sky (1) | Case 5-A-1 | 48 | Case 5-B-1 | 37 | 42.5 |

| Intermediate Sky (2) | Case 5-A-2 | 43 | Case 5-B-2 | 33 | 38 | |

| Avg | 45.5 | 35 | 40.3 | |||

| 50%, 0° (6-A, B) | Clear Sky (1) | Case 6-A-1 | 64 | Case 6-B-1 | 47 | 55.5 |

| Intermediate Sky (2) | Case 6-A-2 | 52 | Case 6-B-2 | 40 | 46 | |

| Avg | 58 | 43.5 | 50.8 | |||

| 50%, 45° (7-A, B) | Clear Sky (1) | Case 7-A-1 | 55 | Case 7-B-1 | 40 | 47.5 |

| Intermediate Sky (2) | Case 7-A-2 | 48 | Case 7-B-2 | 35 | 41.5 | |

| Avg | 51.5 | 37.5 | 44.5 | |||

| Avg. | 52.4 | 39 | 45.7 | |||

| Blind Control | Sky Condition | Case | Dimming Rate (%) | Case | Dimming Rate (%) | Avg |

|---|---|---|---|---|---|---|

| Automated control (3 step in clear sky) | Clear Sky | Case 8-A-1 | 68 | Case 8-B-1 | 50 | 59 |

| Automated control (4 step in clear sky) | Clear Sky | Case 9-A-1 | 70 | Case 9-B-1 | 52 | 42.5 |

| Automated control in intermediate sky | Intermediate Sky | Case 10-A-1 | 61 | Case 10-B-1 | 43 | 46 |

| Avg. | 66.3 | 48.3 | 49.2 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.-H.; Lee, K.-H.; Kim, K.-S. Evaluation of Illuminance Measurement Data through Integrated Automated Blinds and LED Dimming Controls in a Full-Scale Mock-Up. Energies 2020, 13, 3238. https://doi.org/10.3390/en13123238

Kim C-H, Lee K-H, Kim K-S. Evaluation of Illuminance Measurement Data through Integrated Automated Blinds and LED Dimming Controls in a Full-Scale Mock-Up. Energies. 2020; 13(12):3238. https://doi.org/10.3390/en13123238

Chicago/Turabian StyleKim, Chul-Ho, Kwang-Ho Lee, and Kang-Soo Kim. 2020. "Evaluation of Illuminance Measurement Data through Integrated Automated Blinds and LED Dimming Controls in a Full-Scale Mock-Up" Energies 13, no. 12: 3238. https://doi.org/10.3390/en13123238