Systematic Investigation of Integrating Small Wind Turbines into Power Supply for Hydrocarbon Production

Abstract

:1. Introduction

2. Methodology

3. Target Oilfield

4. Meteorological Data

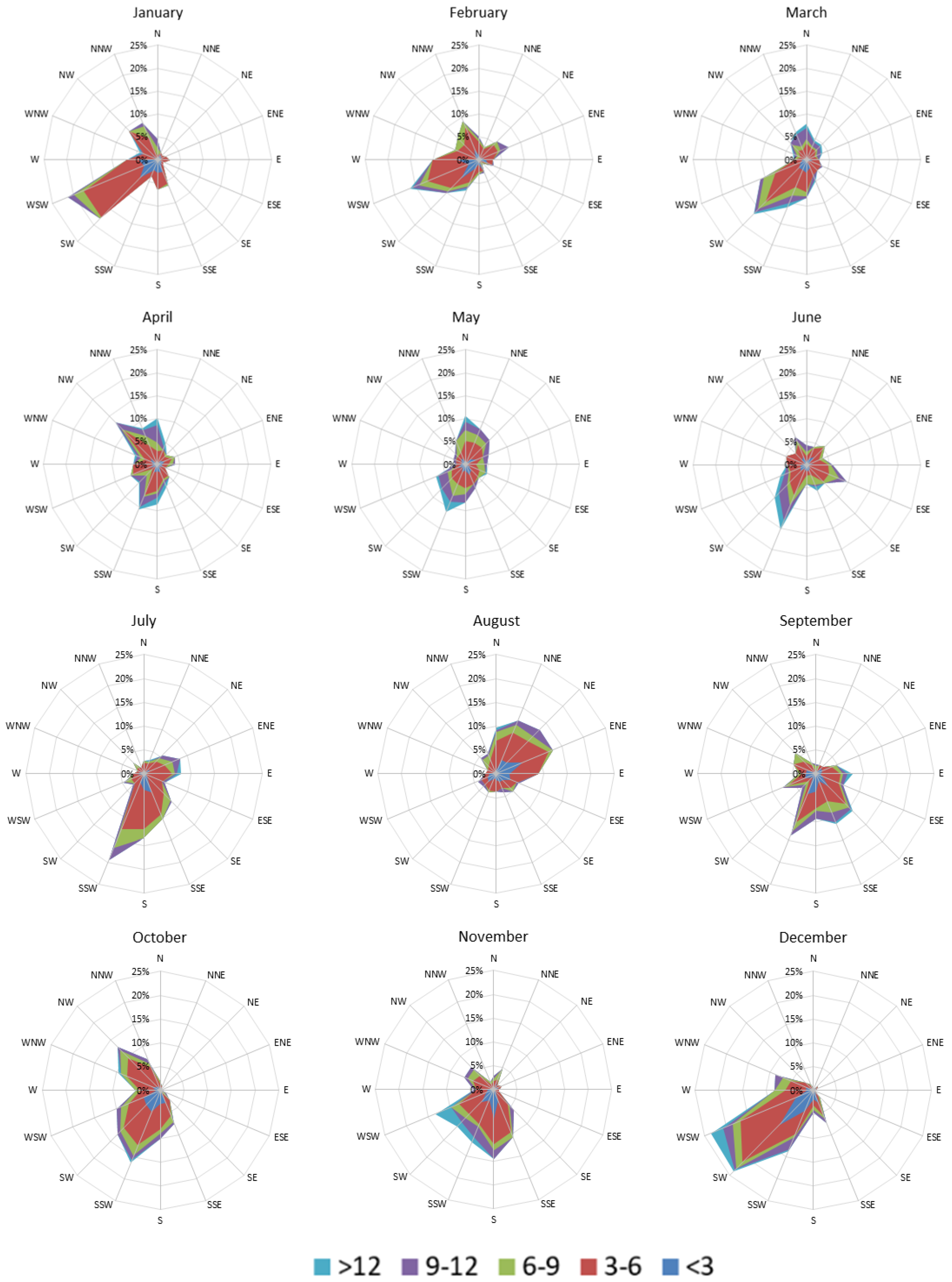

4.1. Wind Rose

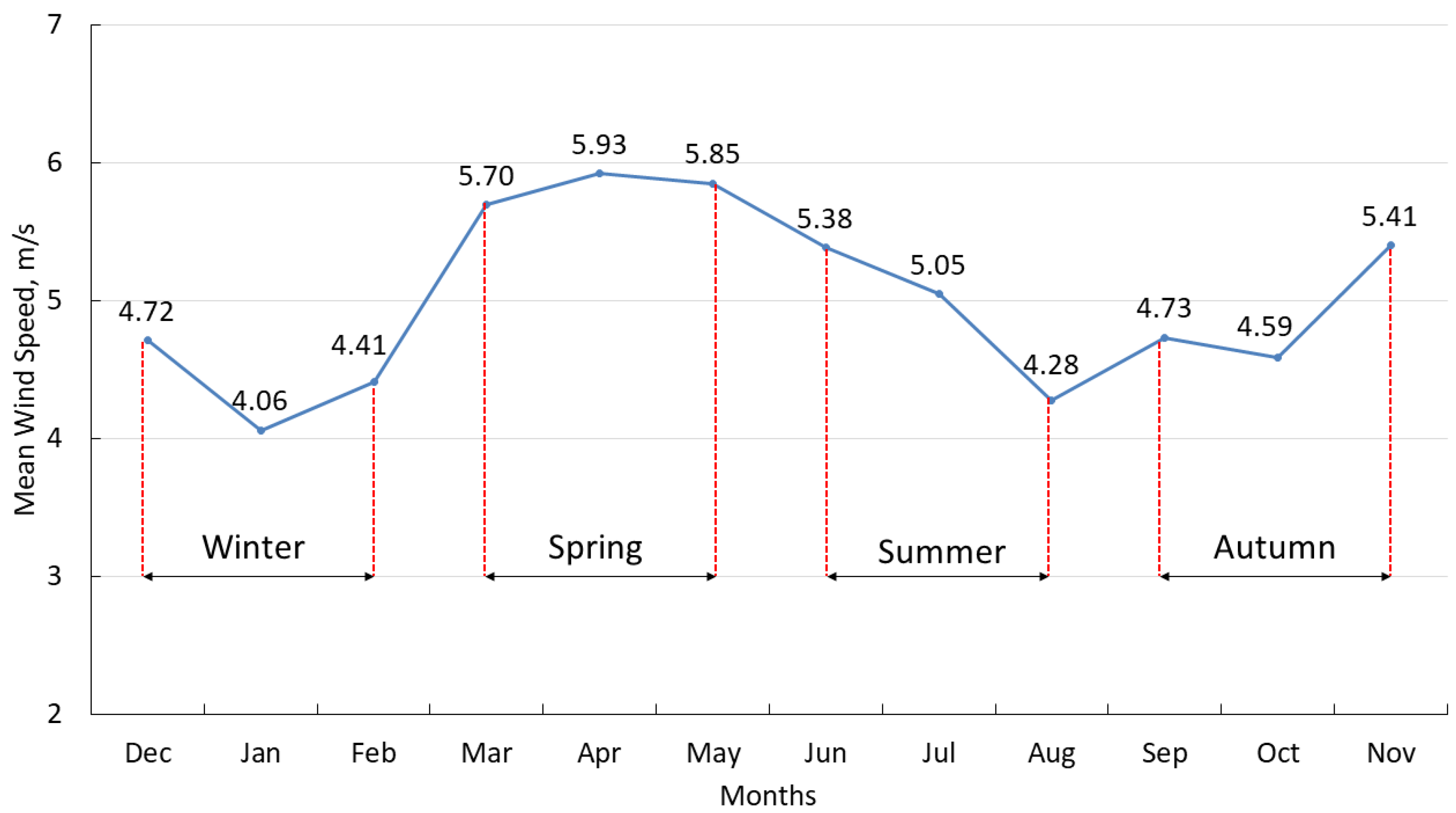

4.2. Wind Speeds

5. Wind Power Modeling

5.1. Wind Turbine Specification

5.2. Modelling Outputs

6. Economic Analysis

6.1. Current Annual Cost of Diesel Generator

6.2. Annual Cost of Small Wind Turbines (SWT)

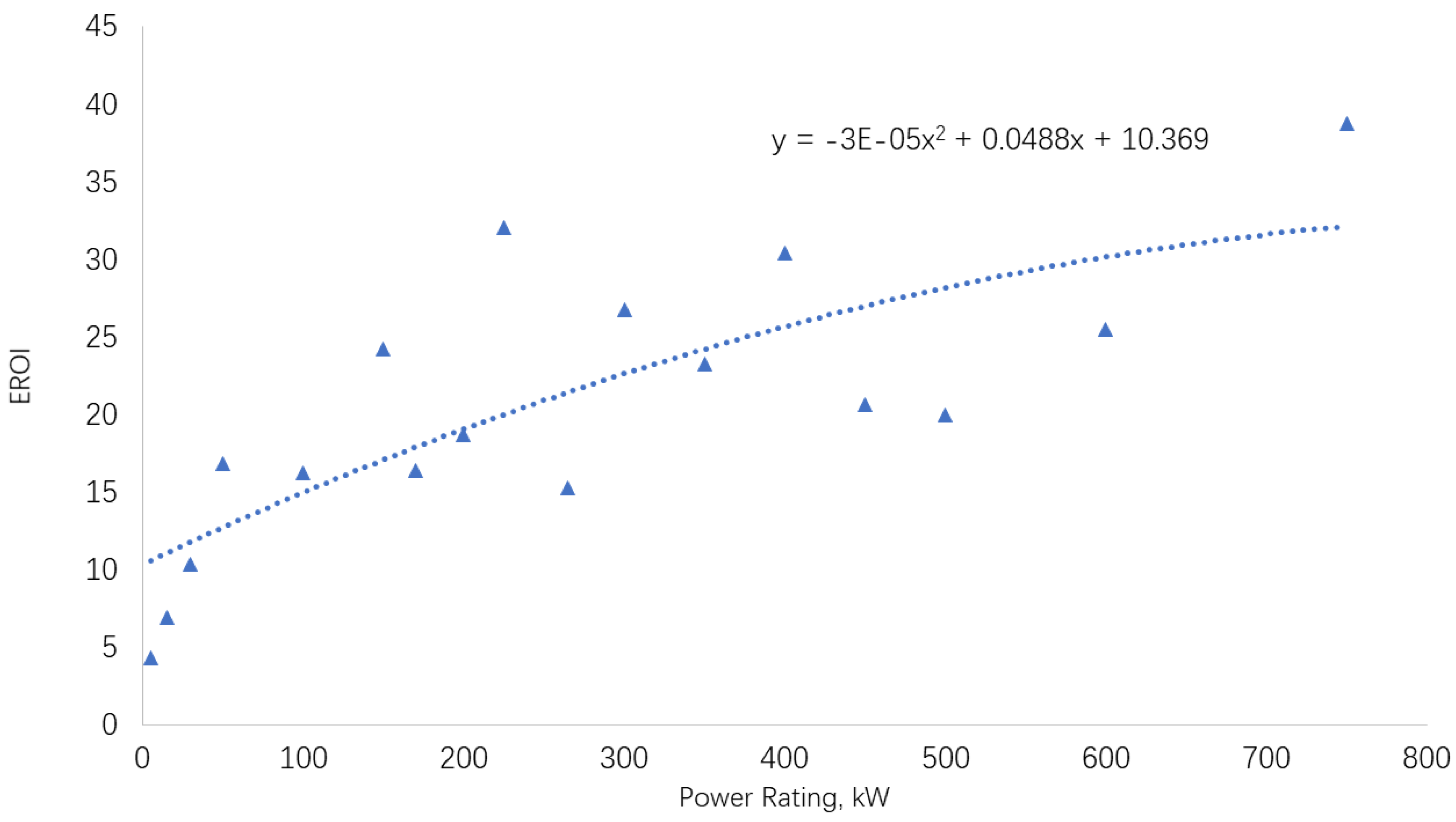

6.3. Energy Return on Investment (EROI)

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| a | Exponential constant that is related to standard wind speeds |

| Cs | Special cost |

| Cv | Variable capital cost |

| Ic | Interest rate |

| M | Variable O&M cost |

| n | Lifespan of the selected SWT |

| p | Pressure |

| Pr | Rated power |

| R | Specific gas constant of dry air |

| t | Temperature |

| v | Wind speed |

| z | Height |

| ρ | Air density |

| Abbreviation | |

| AEO | Annual Energy Output |

| AWEA | American Wind Energy Association |

| CanWEA | Canadian Wind Energy Association |

| CNPC | China National Petroleum Corporation |

| EOR | Enhanced Oil Recovery |

| EROI | Energy Return On Investment |

| IEC | International Electrotechnical Commission |

| LCOE | Levelized Cost Of Electricity |

| NOAA | National Oceanic and Atmospheric Administration |

| NREL | National Renewable Energy Laboratory |

| NSAI | National Standards Authority of Ireland |

| O&M | Operation and Maintenance |

| SWTs | Small Wind Turbines |

| WWEA | World Wind Energy Association |

References

- Feng, Z.M.; Tan, J.J.; Li, Q.; Fang, X. A review of beam pumping energy-saving technologies. J. Pet. Explor. Prod. Technol. 2018, 8, 299–311. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Falcone, G.; Alimonti, C. A systematic study of harnessing low-temperature geothermal energy from oil and gas reservoirs. Energy 2018, 142, 346–355. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Liu, X. Wind power forecasting of an offshore wind turbine based on high-frequency SCADA data and deep learning neural network. Energy 2020. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, X. Assessment of wind turbine aero-hydro-servo-elastic modelling on the effects of mooring line tension via deep learning. Energies 2020, 13, 2264. [Google Scholar] [CrossRef]

- Lin, Z.; Sayer, P. An enhanced stiffness model for elastic lines and its application to the analysis of a moored floating offshore wind turbine. Ocean Eng. 2015, 109, 444–453. [Google Scholar] [CrossRef] [Green Version]

- He, W.; Jacobsen, G.; Anderson, T.; Olsen, F.; Hanson, T.D.; Korpås, M.; Toftevaag, T.; Eek, J.; Uhlen, K.; Johansson, E. The Potential of Integrating Wind Power with Offshore Oil and Gas Platforms. Wind Eng. 2010, 34, 125–137. [Google Scholar] [CrossRef]

- Hu, D.; Zhao, X.; Cai, X.; Wang, J. Impact of wind power on distribution system reliability. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008. [Google Scholar]

- Haruni, A.M.O.; Gargoom, A.; Haque, M.E.; Negnevitsky, M. Dynamic operation and control of a hybrid wind-diesel stand alone power systems. In Proceedings of the 2010 Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition—APEC, Palm Springs, CA, USA, 21–25 February 2010; pp. 162–169. [Google Scholar]

- Kariniotakis, G.N.; Stavrakakis, G.S. A General Simulation Algorithm For The Accurate Assessment Of Isolated Diesel—Wind Turbines Systems Interaction, PART 2. IEEE Trans. Energy Convers. 1995, 10, 584–590. [Google Scholar] [CrossRef]

- Pierobon, L.; Benato, A.; Scolari, E.; Haglind, F.; Stoppato, A. Waste heat recovery technologies for offshore platforms. Appl. Energy 2014, 136, 228–241. [Google Scholar] [CrossRef] [Green Version]

- Kazak, J.; Van Hoof, J.; Szewranski, S. Challenges in the wind turbines location process in Central Europe—The use of spatial decision support systems. Renew. Sustain. Energy Rev. 2017, 76, 425–433. [Google Scholar] [CrossRef]

- Bugała, A.; Roszyk, O. Investigation of an Innovative Rotor Modification for a Small-Scale Horizontal Axis Wind Turbine. Energies 2020, 13, 2649. [Google Scholar] [CrossRef]

- NSAI Standards. Wind Turbines—Part 2: Small Wind Turbines; Irish Standard: Santry, Ireland, 2014.

- Canadian Wind Energy Association. Small Wind Turbine Purchasing Guide (Off-grid, Residential, Darm & Small Business Applications); CANWEA: Ottawa, ON, Canada, 2015. [Google Scholar]

- Olsen, T.; Preus, R. Small Wind Site Assessment Guidelines; NREL: Golden, CO, USA, 2015.

- American Wind Energy Association. Basics of Wind Energy. Available online: https://www.awea.org/wind-101/basics-of-wind-energy (accessed on 18 March 2019).

- Pitteloud, J.-D.; Gsanger, S. Small Wind World Report. WWEA: Bonn, Germany, 2017. [Google Scholar]

- Renewables UK Wind Energy. Available online: https://www.renewableuk.com/page/WindEnergy (accessed on 7 May 2019).

- Bortolini, M.; Gamberi, M.; Graziani, A.; Manzini, R.; Pilati, F. Performance and viability analysis of small wind turbines in the European Union. Renew. Energy 2014, 62, 629–639. [Google Scholar] [CrossRef]

- Tummala, A.; Kishore, R.; Kumar, D.; Indraja, V.; Krishna, V.H. A review on small scale wind turbines. Renew. Sustain. Energy Rev. 2016, 56, 1351–1371. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, X.; Collu, M. Wind power prediction based on high-frequency SCADA data along with isolation forest and deep learning neural networks. Int. J. Electr. Power Energy Syst. 2020, 118, 105835. [Google Scholar] [CrossRef]

- Shu, Z.R.; Li, Q.S.; Chan, P.W. Investigation of offshore wind energy potential in Hong Kong based on Weibull distribution function. Appl. Energy 2015, 156, 362–373. [Google Scholar] [CrossRef]

- Shu, Z.R.; Li, Q.S.; Chan, P.W. Statistical analysis of wind characteristics and wind energy potential in Hong Kong. Energy Convers. Manag. 2015, 101, 644–657. [Google Scholar] [CrossRef]

- Li, M.; Li, X. Investigation of wind characteristics and assessment of wind energy potential for Waterloo region, Canada. Energy Convers. Manag. 2005, 46, 3014–3033. [Google Scholar] [CrossRef]

- Li, Y.; Wu, X.; Li, Q.; Tee, K.F. Assessment of onshore wind energy potential under different geographical climate conditions in China. Energy 2018, 152, 498–511. [Google Scholar] [CrossRef]

- Jung, C.; Schindler, D. The role of air density in wind energy assessment—A case study from Germany. Energy 2019, 171, 385–392. [Google Scholar] [CrossRef]

- Lasse Svenningsen Power Curve Air Density Correction And Other Power Curve Options. In WindPRO; EMD International A/S: Aalborg, Denmark, 2010.

- Banuelos-Ruedas, F.; Angeles-Camacho, C.; Rios-Marcuello, S. Analysis and validation of the methodology used in the extrapolation of wind speed data at different heights. Renew. Sustain. Energy Rev. 2010, 14, 2383–2391. [Google Scholar] [CrossRef]

- Oemof Developer Group. Windpowerlib Documentation; Oemof Developer Group: Flensburg, Germany, 2019. [Google Scholar]

- Tang, X.; Zhang, B.; Höök, M.; Feng, L. Forecast of oil reserves and production in Daqing oilfield of China. Energy 2010, 35, 3097–3102. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Feng, L.; Wei, W.X.; Hu, Y.; Wang, J. A preliminary forecast of the production status of China’s daqing oil field from the perspective of EROI. Sustainability 2014, 6, 8262–8282. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Feng, L.; Hall, C.C.S.; Tian, D. Analysis of the energy return on investment (EROI) of the huge daqing oil field in China. Sustainability 2011, 3, 2323–2338. [Google Scholar] [CrossRef] [Green Version]

- Lee Kwan, C. The Inner Mongolia Autonomous Region: A major role in China’s renewable energy future. Util. Policy 2010, 18, 46–52. [Google Scholar] [CrossRef]

- National Oceanic and Atmospheric Administration NCEI Map Viewer. Available online: https://gis.ncdc.noaa.gov/maps/ncei#app=clim&cfg=cdo&theme=hourly&layers=1&node=gis (accessed on 8 May 2019).

- Infield, D. Chapter 15—Wind Energy. In Future Energy, 2nd ed.; Letcher, T.M., Ed.; Elsevier: Boston, MA, USA, 2014; pp. 313–333. ISBN 978-0-08-099424-6. [Google Scholar]

- Haas, S.; Schachler, B.; Krien, U.; Bosch, S. Windpowerlib: A Python Library to Model Wind Power Plants (v0.1.1); Oemof Developer Group: Flensburg, Germany, 2019. [Google Scholar]

- Hilpert, S.; Kaldemeyer, C.; Krien, U.; Günther, S.; Wingenbach, C.; Plessmann, G. The Open Energy Modelling Framework (oemof)—A new approach to facilitate open science in energy system modelling. Energy Strategy Rev. 2018, 22, 16–25. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Duepmeier, C.; Hagenmeyer, V. A New Concept of a Generic Co-Simulation Platform for Energy Systems Modeling. In Proceedings of the Future Technologies Conference (FTC), Pan Pacific Hotel Vancouver, BC, Canada, 29–30 November 2017. [Google Scholar]

- Sherry, M.; Rival, D. Meteorological phenomena associated with wind-power ramps downwind of mountainous terrain. J. Renew. Sustain. Energy 2015, 7, 033101. [Google Scholar] [CrossRef] [Green Version]

- Che, Y.; Xiao, F. An integrated wind-forecast system based on the weather research and forecasting model, Kalman filter, and data assimilation with nacelle-wind observation. J. Renew. Sustain. Energy 2016, 8, 053308. [Google Scholar] [CrossRef]

- Anhui Hummer Dynamo Co., Ltd. H19.2-100KW Off Grid Wind Turbine. Available online: http://www.allwindturbine.com/products_info/H19-2-100KW-Off-Grid-Wind-Turbine-230240.html (accessed on 30 April 2019).

- Global Petrol Prices China Diesel Prices. Available online: https://www.globalpetrolprices.com/China/diesel_prices/ (accessed on 2 May 2019).

- Adaramola, M.S.; Paul, S.S.; Oyedepo, S.O. Assessment of electricity generation and energy cost of wind energy conversion systems in north-central Nigeria. Energy Convers. Manag. 2011, 52, 3363–3368. [Google Scholar] [CrossRef]

- Sathyajith, M. Wind Energy: Fundamentals, Resource Analysis and Economics; Springer: Berlin, Germany, 2006. [Google Scholar]

- International Renewable Energy Agency. Renewable Energy Technologies: Cost Analysis Series—Wind Power; IRENA: Bonn, Germany, 2012. [Google Scholar]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef] [Green Version]

- Trading Economics China Interest Rate. Available online: https://tradingeconomics.com/china/interest-rate (accessed on 1 May 2019).

- Kubiszewski, I.; Cleveland, C.J.; Endres, P.K. Meta-analysis of net energy return for wind power systems. Renew. Energy 2010, 35, 218–225. [Google Scholar] [CrossRef]

| Organization Name | Headquarter Location | Power Capacity |

|---|---|---|

| Canadian Wind Energy Association (CanWEA) | Canada | <1~300 kW |

| National Renewable Energy Laboratory (NREL) | USA | 1~100 kW |

| National Standards Authority of Ireland (NSAI) | Ireland | <50 kW |

| American Wind Energy Association (AWEA) | USA | <100 kW |

| World Wind Energy Association (WWEA) | Germany | 6 W~300 kW |

| RenewableUK | UK | 1.5~50 kW |

| Date | Time | Roughness Length, m | Atmospheric Pressure at Sea Level, Pa | Air Temperature at the Height of 10 m, K | Wind Speed at the Height of 10 m, m/s |

|---|---|---|---|---|---|

| 2018-04-01 | 00:00:00 | 0.15 | 1.01 × 105 | 280.60 | 7.30 |

| 2018-04-01 | 03:00:00 | 0.15 | 1.01 × 105 | 287.20 | 16.42 |

| 2018-04-01 | 06:00:00 | 0.15 | 1.00 × 105 | 291.90 | 10.94 |

| 2018-04-01 | 09:00:00 | 0.15 | 9.99 × 104 | 290.70 | 14.59 |

| 2018-04-01 | 12:00:00 | 0.15 | 9.98 × 104 | 288.70 | 12.77 |

| 2018-04-01 | 18:00:00 | 0.15 | 9.95 × 104 | 286.60 | 9.12 |

| 2018-04-01 | 21:00:00 | 0.15 | 9.97 × 104 | 284.70 | 7.30 |

| Parameters | Values |

|---|---|

| Configuration | horizontal axis; 3 Blades |

| Rated power, kW | 100 @ 12 m/s |

| Hub height, m | 18 |

| Rotor diameter, m | 20.8 |

| Swept area, m2 | 339.80 |

| Direction of rotation | clockwise looking upwind |

| Cut-in wind speed, m/s | 3 |

| Cut-out wind speed, m/s | 25 |

| Drivetrain | direct drive |

| Wind Turbine Size, kW | Micro (<20) | Small (20–200) | Medium (>200) |

|---|---|---|---|

| specific cost, 1/kW | 2200–3000 | 1250–2300 | 700–1600 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Liu, X.; Feng, Z. Systematic Investigation of Integrating Small Wind Turbines into Power Supply for Hydrocarbon Production. Energies 2020, 13, 3243. https://doi.org/10.3390/en13123243

Lin Z, Liu X, Feng Z. Systematic Investigation of Integrating Small Wind Turbines into Power Supply for Hydrocarbon Production. Energies. 2020; 13(12):3243. https://doi.org/10.3390/en13123243

Chicago/Turabian StyleLin, Zi, Xiaolei Liu, and Ziming Feng. 2020. "Systematic Investigation of Integrating Small Wind Turbines into Power Supply for Hydrocarbon Production" Energies 13, no. 12: 3243. https://doi.org/10.3390/en13123243

APA StyleLin, Z., Liu, X., & Feng, Z. (2020). Systematic Investigation of Integrating Small Wind Turbines into Power Supply for Hydrocarbon Production. Energies, 13(12), 3243. https://doi.org/10.3390/en13123243