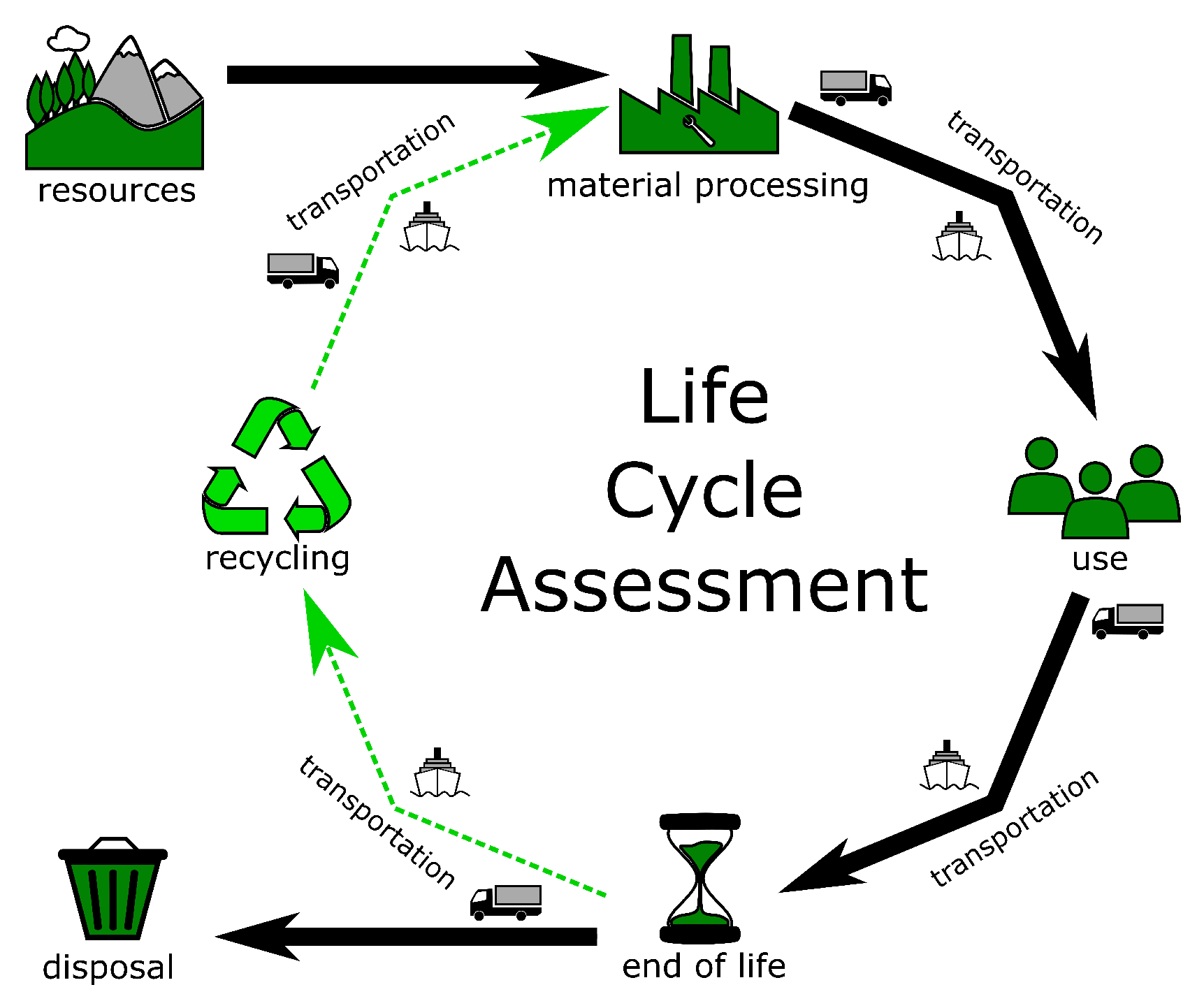

In this section, the general approach of an LCA is further detailed. After that, the methods of an LCA are applied to geothermal stations and the heat storage system.

Overall, an LCA can be divided into the following four phases: definition of the objective and scope of the study, life cycle inventory, impact assessment and, finally, the evaluation. At the beginning, the scope of the investigation and the objective of a project are described. For this purpose, a functional unit is defined which acts as a measurable reference value for standardisation. With this functional unit, a comparison to similar systems can be made. Furthermore, the system boundary is determined to consider all the contained processes. The life cycle inventory describes phase two, in which both input and output data are gathered for the entire life cycle. This includes material and energy flows as well as emissions. These values are standardised to the functional unit so that a comparison with other LCAs is possible in the impact assessment (phase three). For the impact assessment, so-called impact categories are defined according to [

27], since the EN ISO 14044 standard does not specify any requirements for this. These categories include for example climate change, ozone formation or acidification. Each category can thus be assigned an equivalent, for example a kg CO

2 equivalent for the global warming potential. Finally, the evaluation takes place in three steps. First, significant parameters are determined which have the biggest influence on the results. Then a sensitivity and consistency check is performed and finally a conclusion is drawn from the results.

In this paper an LCA was performed for geothermal stations and the heat storage system. All LCAs were created with the open source software OpenLCA (

www.openlca.org). Since there was no access to established, fee-based databases such as Ecoinvent, it was necessary to fall back on the free databases. In these free databases, not every single component was available. If this was the case, other datasets of similar materials were used which get as close as possible to the desired material. This means that the following results will change slightly when using a more detailed database but still provides a good insight into the environmental impacts per se. Furthermore, transport as well as recycling rates for components are included whenever possible. In general, recycling rates were only used if several literature sources made a similar statement, otherwise pessimistic calculations were made with a recycling rate of 0%. Likewise, the extraction and processing of raw materials was based entirely in Germany. As no usable data was available for transport by rail, all transport routes were planned with trucks.

The analysis of the environmental influences was limited to the four probably most important factors: Acidification Potential (AP), Global Warming Potential (GWP), Human Toxicity Potential (HTP) and the Cumulative Energy Demand (CED). The AP is expressed in kg SO2 equivalents and describes the promotion of acidification, which leads to acidification of lakes or soils. The GWP is a measure of the greenhouse gas potential of a gas and is converted into kg CO2 equivalents. The HTP represents the toxicity of substances to humans and refers to 1,4-dichlorobenzene equivalents in kg. The last considered influence is the CED, which describes the energy input for the production of the product in GJ.

4.1. Geothermal Station

Geothermal stations are a huge project in terms of planning and implementation, therefore the right location must be chosen carefully. Since the potential analysis already provides help for the choice of location, the goal is to develop a kind of simplified mathematical representation of LCA

geo. In principle, the LCA for geothermal stations can be represented as written in Equation (

2).

In addition to a static part (LCAstatic), there are also dependancies on the depth x (LCAdepth) and volume flow v (LCAthermal). With LCAstatic, influences are taken into account which remain mostly the same for each geothermal station. These include, for example, the building itself or the stimulation of the subsoil. The first variable part, LCAdepth, depends on the depth of the borehole. A deeper borehole inevitably means more wear of the drill bit and drill head as well as more pipes and cementing necessary for the borehole. However, the drilling depth is linearly included in the overall result, which allows a linear interpolation to be made. The second variable component, LCAthermal, describes the thermal power output. A larger volume flow rate results in a higher thermal output of the system but the pumping effort also increases.

To be able to perform the LCA, a few boundary conditions must be established. The first is an optimistic assumption, namely that two drillings per site can be carried out without complications. Furthermore, a new drilling rig is expected for each location and is assigned to the static part of the LCA. Although a drilling rig can be used several times, this pessimistic assumption takes into account a possible fluctuation in the static part, for example for a larger building or complications with the foundation. The observation period of the whole system and its corresponding operation phase is set to 30 years according to [

28].

For the static part, the most important materials with their necessary weigth are summarized in

Table 3. It includes the flushing pumps [

29], flushing tanks [

30], the building [

31], the deep drilling rig [

32], deconstruction [

33], stimulation [

31], power generators [

34] and the sealing of the well site [

33].

For the depth-dependent part of the LCA, the most important materials can be summarized as shown in

Table 4. For this purpose, the drilling [

35], drilling bit [

36], drilling fluid [

31] aswell as piping and cementation [

31] were taken into account. For the performance-dependent part, no simple representation can be made, since many individual components have a different influence. The filter change [

12], thermal water circuit [

31], feed pump [

37] as well as the injection pump [

38] were considered for that part.

Due to the geological conditions in Germany there are currently far more petrothermal hotspots known than hydrothermal ones, which is why the focus is shifted to them for the detailed LCA analysis. In order to make a statement that is as representative as possible, the LCA is not carried out for the top candidates in the Rhine Valley but for Perleberg in the North German Basin. Perleberg is neither a good nor bad candidate compared to the other locations of that region, which allows a more general statement. The required depth for 150 °C is about 4200 m. Furthermore a thermal power of 38 MW was selected, which corresponds to a thermal volume flow of approx. 241 m

/h. This represents the average thermal power of a new geothermal plant. In

Figure 4 the results of the LCA for the four investigated environmental influences are compared.

When comparing the results from

Figure 4 with each other, it is obvious that the components feed pump, piping and cementation, drilling and drilling rig have the greatest environmental impact. As already mentioned, the drilling rig is based on the pessimistic assumption so its actual influence should be lower. As it is the biggest impact in the static part, influences of a bigger building can therefore be neglected. The strong influence of the feed pump can be explained by its short life time during continuous operation for geothermal stations, which makes it a component that has to be replaced regularly during the 30 years of operation. Piping and cementation mainly occur at the beginning of the project but represent enormous material expenses. The drilling process itself is by far the biggest part in the CED but has a much smaller part in the GWP. This is due to the excessive energy necessary (converted to diesel) which results in equally high values for AP and HTP. Furthermore, components like pressurized tanks or noise barriers were also not included in the figures but included in the final results for Perleberg shown in

Table 5.

The results from

Table 5 are splitted in the mentioned static and variable parts and displayed in

Table 6.

To get a first rough approximation for different locations, mathematical equations were developed based on the results of Perleberg in

Table 6. The goal was to shape the equations like Equation (

2) with a static part and two variable parts, dependant on the depth

x and the volume flow

v. For each variable part, a different curve is fitted according to the LCA results. The LCA results dependant on the depth x are linear interpolated, contrary to the volume flow dependant values. The power equation of a pump is a third degree polynomial, which represents the second variable part in Equation (

2). The results after fitting the seperate parts to a curve and combining them into one equation are displayed in Equations (

3)–(

7), with the different parts separated in brackets. With these equations the effects of a geothermal station can be roughly calculated depending on the drilling depth and desired thermal output. For a simpler overview, a part of the volume flow dependent equation was summarized in

.

- -

- -

Acidification in kg SO

eq

- -

Global Warming in kg CO

eq

- -

Human Toxicity in kg 1,4-db eq

- -

Cumulative Energy Demand in MJ

First, the necessary depth for 150 °C is determined for the desired location. Then the depth in meters is used for x and the wanted flow rate in m/h for v.

The results of the equations are compared with the results determined in OpenLCA and examined for their deviation from one another (

Table 7).

A direct comparison was made between the already existing results of Perleberg (4.1 km and 241 m/h) and the results of the equations. The error of about 0.1% is due to possible rounding errors. To illustrate the influence of x, the depth was reduced by almost 1 kilometer while maintaining the same volume flow. Although the deviation increases minimally, it still remains at roughly 0.1%. The same was done for v, with only the flow rate being reduced from 241 to 95. A greater influence on the error can be seen with deviations between 1 and 1.5%. Finally, the equations were compared with the results for another potential location. The LCA for Rheinau in the Rhine Valley is calculated with OpenLCA and the estimations for a depth of 3192 m and a flow rate of 95. Overall, the error is less than 2%. Therefore it is shown that the equations designed allow the results of the LCA to be calculated relatively well and accurately. For a first estimation of the results a deviation of about 2% is acceptable.

4.2. Pumped Thermal Energy Storage

The basic aim of the pumped thermal energy storage is its use as a base load storage unit. This means that the storage tank can be constantly charged and discharged over a period of several hours. For this purpose, the components of the heat pump and the ORC are designed so that a period of 10 hours of constant charging or discharging is guaranteed. For the determination of the COP of the HP and efficiency of the ORC, the model provided in [

4] was used. The following assumptions for the boundary conditions are involved: a heat source inlet temperature of 85 °C, an outlet temperature of 70 °C after the heat pump evaporator, an evaporation temperature of 65 °C in the heat pump evaporator for the working fluid cyclopentane and a condensation temperature of 121 °C in the heat storage. Together with an isentropic efficiency of 0.7 for the compressor and a pinch point of 5 K in all heat exchangers, this results in a COP of 4.88. For the ORC an evaporation temperature of 91.8 °C and a condensation temperature of 30 °C achieved the best results with an efficiency of 10.25%. The isentropic efficiency is again 0.7. The P2P efficiency is therefore 50.02% for the entire system. In

Figure 5 the heat storage heat exchanger is shown in detail with a t-Q-diagram providing the exact temperatures along both ways for the charging and discharging process.

The storage capacity is thus chosen as the functional unit, as the necessary parameters of individual components can be determined based on the storage size. The following components were included in the analysis: generator [

34], compressor [

39], pump [

40], turbine, piping and apparatuses [

41], heat exchanger [

42], water reservoir [

30] as well as the working fluid [

43].

In

Table 8 an overview of the different compositions for the working machines is given. An identical composition was used for both the compressor and the turbine as they are very similar in their construction but separate machines were considered for the setup. For the required heat exchangers it was assumed that they are mainly made of steel. Therefore, the heat exchangers of the pilot plant were weighed and normalized for their power. The plant section “piping and accessories” is split into two parts for better clarity. The first part describes the pipes themselves, for which estimates of the required overall length are also made based on the pilot plant. The second part describes the accessories which can be described in a simplified way as part of the pipe, for example the throttle or valves. The heat storage is by far the largest component of the system. With a storage capacity of 1 MWh and a temperature difference of 30 °C between charging and discharging, about 28,500 litres of water are required. Assuming a cylindrical water storage tank, the necessary amount of insulating material (rock wool) is calculated in addition to steel. The working fluid of the heat pump and the ORC is cyclopentane.

The results of the LCA are shown in

Figure 6. It can be clearly seen that the heat storage system has by far the greatest impact on the environment. The mass of steel to be melted, water to be purified and insulation to be produced exceeds the impact of all other plant components by far. In second place is the compressor, which is twice as large as the turbine of the plant. Throttle, valves and other accessories in the piping show that they also make up a proportion not to be underestimated compared to the working machines. Since the P2P efficiency is specified as 50%, the choice of the working fluid does not enter in the LCA as a function of operating parameters, but in those of the construction of the plant. The energy required for the production of cyclopentane was calculated based on [

43]. For the calculation of the GWP, an equivalent of 11 kg carbon dioxide per 1 kg of cyclopentane was included in the calculations.

Many results depend on the provider used for steel in the software OpenLCA. A provider contains necessary data of a material to calculate the environmental impact of a process. With another provider available for steel in the free databases used, a sensitivity analysis is recommended. The results of both providers are displayed in

Figure 7 and show that there are hardly any differences across the storage components between the two providers. Only for the heat storage unit itself are small differences visible. As the differences between the providers are unknown, the more pessimistic provider 2 was used for the calculations due to the many simplifications already made.

In summary, it can be said that, with regard to the production of the storage system, the heat storage is the decisive component for environmental pollution. In addition to its production, the operation of the storage system must also be examined. According to the sources cited, all components have a service life of 15 to 30 years, therefore the service life of the entire system is set at 20 years for further consideration. For the analysis of the operation, three different power-mix scenarios were examined and compared. The first one represents a mix of renewable and fossil energy sources according to ELCD database 2.0. The next is photovoltaic electricity from monocrystalline silicon modules, based on the NEEDS database of 2003. The last case considers electricity from wind power, also according to ELCD database 2.0. According to [

44], a stationary energy storage system for the integration of renewable energies experiences 400 full storage cycles per year. At a P2P efficiency of 50% and a storage capacity of 1 MWh, the electricity input amounts to 800 MWh per year. The output and the losses are both 400 MWh each. In

Table 9 the environmental factors for the production as well as for the operation with different power sources are compared. It can be clearly seen that the production of the storage system is surpassed by its operation in one year. As expected, the electricity mix shows the worst results, as it still contains a high proportion of fossil fuels. Since the data for photovoltaic electricity is based on a dataset from 2003, better values are very likely to be expected with the current state of the art, but it is unlikely that the values from wind power can be surpassed. This can be explained by the fact that the energy-intensive production and processing of silicon is not comparable to the construction of a wind turbine.