Performance Indexes of an Air-Water Heat Pump Versus the Capacity Ratio: Analysis by Means of Experimental Data

Abstract

1. Introduction

2. Materials and Methods

2.1. Definition of the Parameters Employed into the Proposed Model

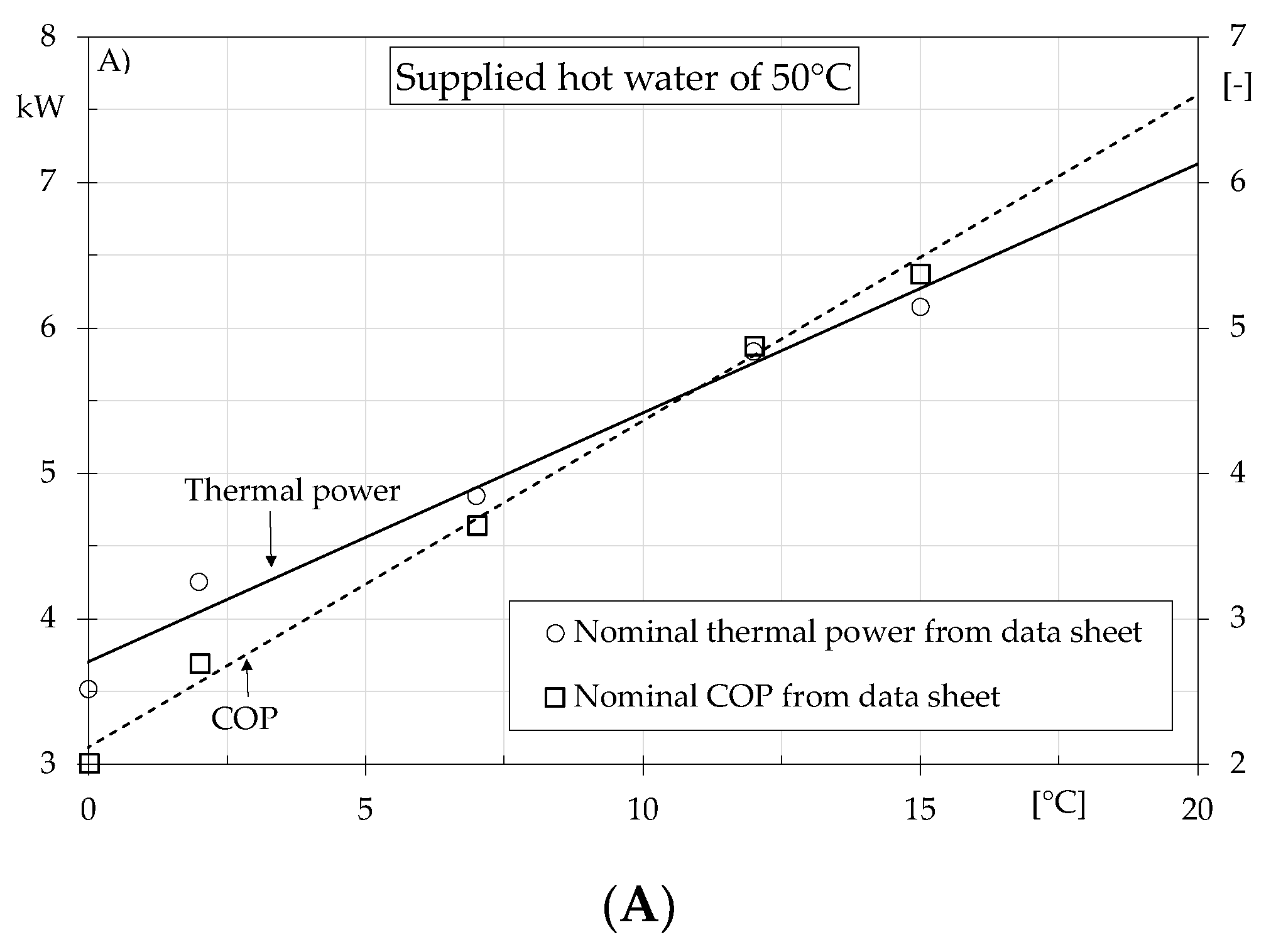

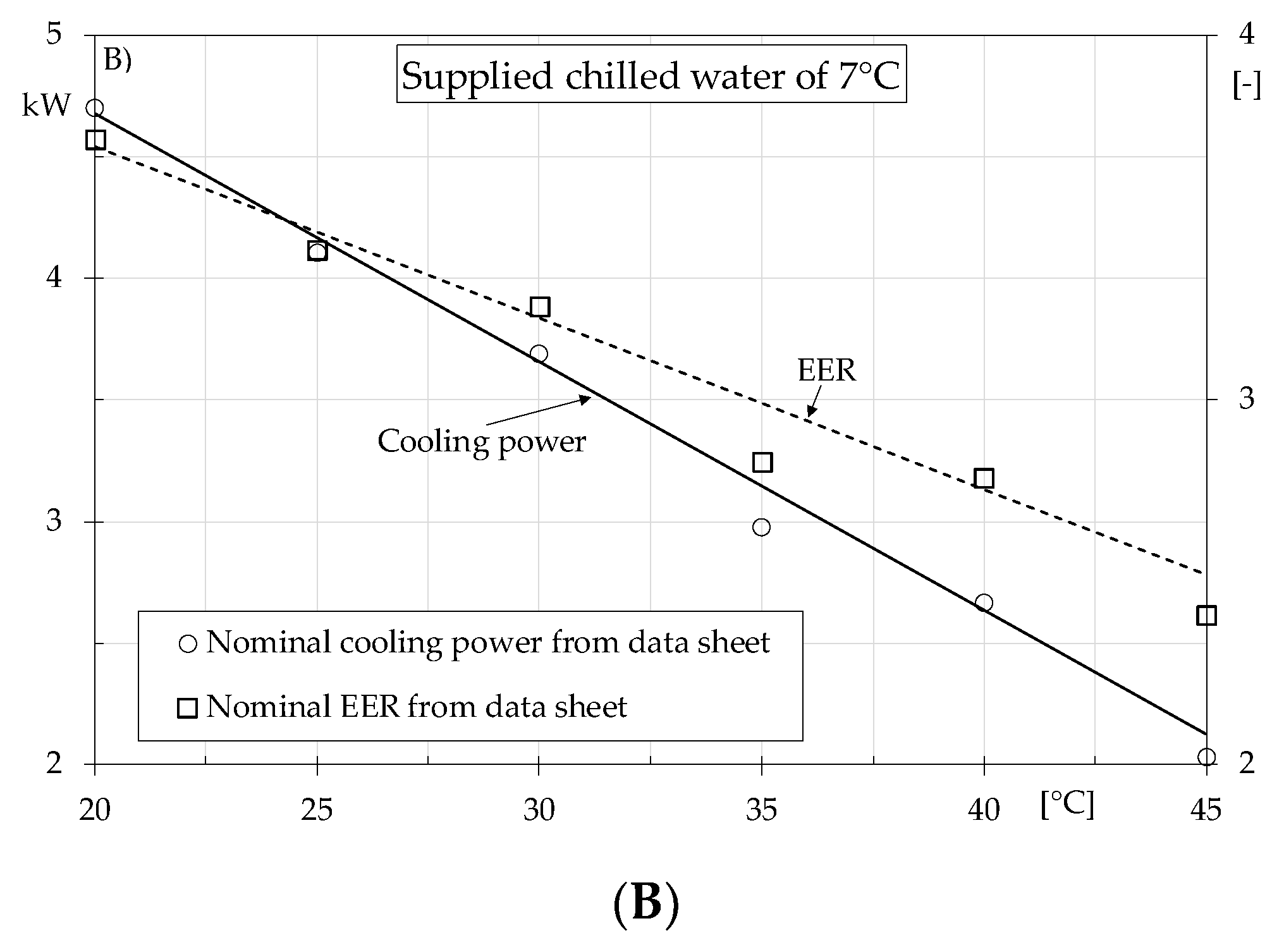

2.2. Experimental Set-Up Description

- N° 2 air-water heat pumps equipped with an inverter (Hitachi, Yutaki S series, RWM 2.0 model) and with a PV generator of 4 kWp,

- a cogenerative biomass boiler equipped with a Stirling engine as a back-up system,

- an 800-L thermal storage tank employed both for heating and cooling applications and

- radiant ceilings made by mineral fibers panel as the emission system.

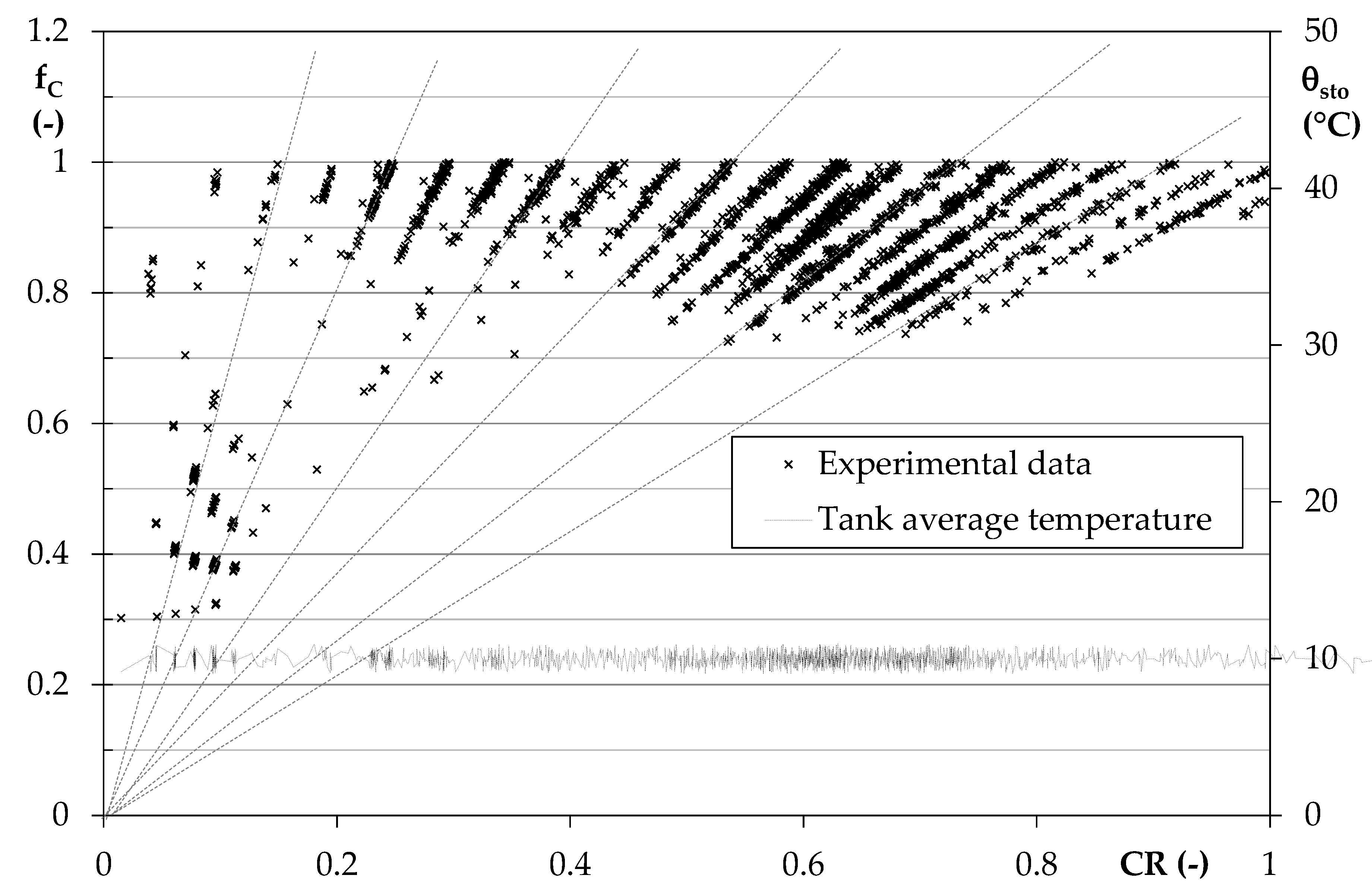

2.3. Calculation of the Actual CR and the Correspondent Correction Factor

- ⮚

- The linearization of the nominal COP produced an error in the fC evaluation further amplified when correlated to the correspondent CR, because the latter was also affected by the same error.

- ⮚

- The analyzed data referred to performances detected in the function of the hourly energies; however, in some operational situations, these energies were quantified also when the functioning occurred for some minutes by avoiding the attainment of the regime operative conditions, with a correspondent worsening of the device efficiency denoted by penalized COP and ERR values.

- ⮚

- Since the data were recorded at hourly levels, slight variations of the outdoor air were detected inside the same interval, whereas the nominal value referred to a constant hourly value.

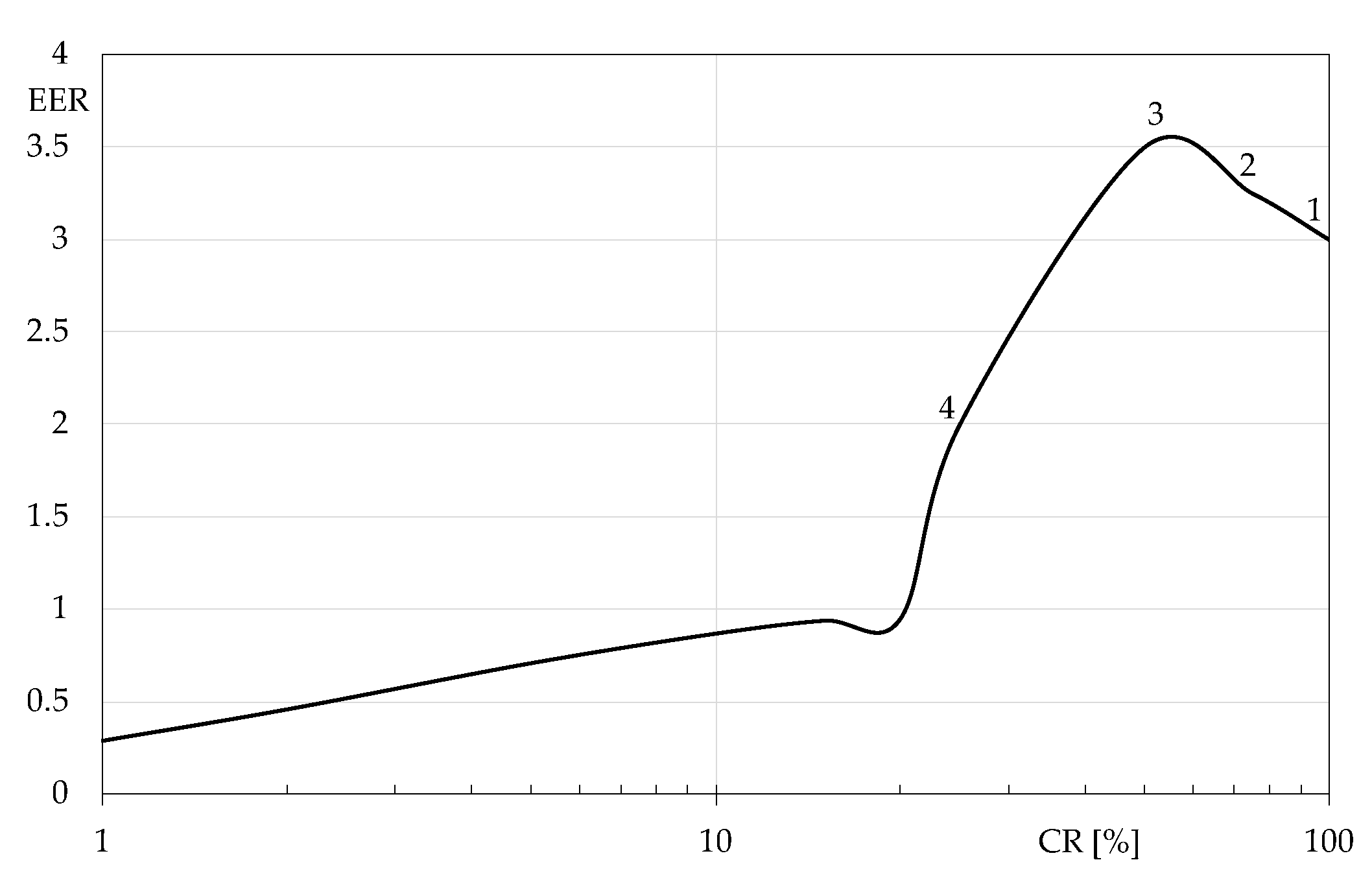

3. Results and Discussion

3.1. Data analysis and Proposed Correlations

3.2. Results Validation

- ⮚

- The root mean square error (RMSE) that measures the standard deviation of the residual calculated between the modeled (m) and observed (oB) data. On a data sample of N elements, more limited is the RMSE value, and more reliable will be the modeled value:

- ⮚

- The mean bias error (MBE) used to determine if the modeled values are overestimated (positive MBE) or underestimated (negative MBE) compared to the observed data. When the MBE is null, the model is ideal and is not affected by errors:

- ⮚

- The correlation factor R describes how the modeled data follows the variations of the observed values, and it ranges between −1 and 1:

4. Conclusions

- ⮚

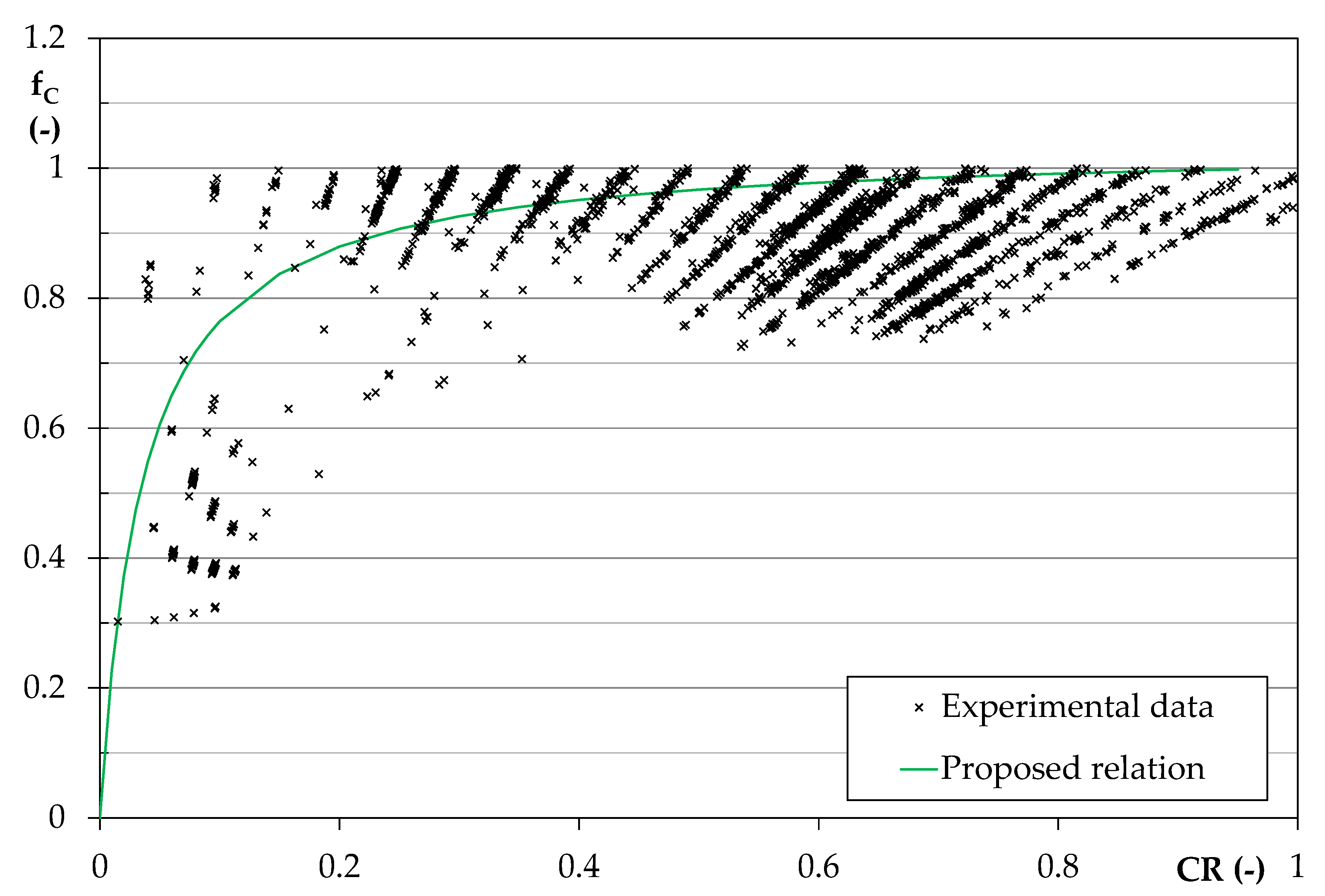

- In the winter, the penalization of the nominal COP due to the part-load mode can be taken into account by the correction factor fC, indicated by the EN 14825 standard, quite well. However, when the heat pump is connected to a storage tank maintained at a set-point temperature, the procedure suggested for ON/OFF functioning seems to be more appropriate than that indicated for modulating units.

- ⮚

- In the winter, the experimental data were interpolated with the same relation indicated by the EN 14825 in order to find the penalization factor CC that better fits these data. The obtained value is close to the default value of 0.9 to use in the absence of manufacturer indications; however, little variations of this coefficient produce noticeable correction factor deviations, especially in the presence of a limited capacity ratio. For instance, by applying the penalization factor of 0.9671 determined by the fit, deviations in the calculation of the real COP of about 0.12 was detected for CR = 0.5, whereas the difference increased to 0.40 for CR = 0.25.

- ⮚

- In the summer, a similar form of the correlation employed to determine the winter fC was analytically found also for the cooling mode by exploiting the dependence of the experimental data from the dimensionless ratio between the nominal and actual absorbed electricity. The EERs calculated with the proposed procedure for different real CR have shown a good agreement with the results determined experimentally. For instance, with a CR = 0.3 and outdoor air at 31.1 °C, a correction factor of 0.925 was calculated, whereas the correspondent experimental value was 0.919.

- ⮚

- In order to evaluate the distances between the proposed correlations and the experimental data, three statistical indexes were used to relate the modeled fC values to those observed. All the indicators provided satisfactory values, with an RMSE slightly greater than 0.12, an MBE that denotes a slight overestimation produced by the proposed relations and a correlation factor greater than 0.7, both in heating and cooling modes.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Units | |

| CC | penalization factor (-) |

| COP | coefficient of performances (-) |

| CR | capacity ratio (-) |

| E | electric energy (Wh) |

| fC | correction factor of the nominal value (-) |

| i | i-th data |

| m | modelled data (-) |

| MBE | Mean Bias Error (-) |

| N | number of sample (-) |

| oB | observed data (-) |

| P | specific parameter (-) |

| Q | thermal/cooling energy (Wh) |

| R | correlation index (-) |

| RMSE | Root Mean Square Error (-) |

| θ | temperature (°C) |

| Subscripts/Superscripts | |

| extr | thermal energy extracted from the storage tank |

| NOM | nominal conditions concerning the heat pump functioning |

| oa | outdoor air |

| prov | thermal energy provided to the storage tank |

| real | actual value evaluated starting from experimental data |

| sto | storage tank system |

| Acronyms | |

| DAQ | Data Acquisition |

| GUI | Graphical User Interface |

| GWP | Global Warming Potential |

| HVAC | Heating, Ventilation and Air-Conditioning |

| nZEB | Near-Zero Energy Building |

| PLR | Part-Load Ratio |

| PV | Photovoltaic |

| SEPR | Seasonal Energy Performance Ratio |

References

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Green roofs in a Mediterranean climate: Energy performances based on in-situ experimental data. Renew. Energy 2020, 152, 1414–1430. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Benevento, F.; Bruno, R.; Arcuri, N. Are Trombe walls suitable passive systems for the reduction of the yearly building energy requirements? Energy 2019, 185, 554–566. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Cuconati, T.; Arcuri, N. Energy evaluations of an innovative multi-storey wooden near Zero Energy Building designed for Mediterranean areas. Appl. Energy 2019, 238, 929–941. [Google Scholar] [CrossRef]

- Bruno, R.; Arcuri, N.; Carpino, C. The Passive House in Mediterranean Area: Parametric Analysis and Dynamic Simulation of the Thermal Behaviour of an Innovative Prototype. Energy Procedia 2015, 82, 533–539. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Longo, L.; Arcuri, N. Small size single-axis PV trackers: Control strategies and system layout for energy optimization. Energy Procedia 2015, 82, 737–743. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Comparing the performances of different cooling strategies to increase photovoltaic electric performance in different meteorological conditions. Energy 2020, 195, 116950. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in heat pump systems: A review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Hepbasli, A.; Kalinci, Y. A review of heat pump water heating systems. Renew. Sustain. Energy Rev. 2009, 13, 1211–1229. [Google Scholar] [CrossRef]

- Arcuri, N.; Bruno, R.; Bevilacqua, P.; Carpino, C. Strategies for The Reduction of Electricity Consumptions in Heat Pumps: The Role of the Thermal Inertia in Buildings Equipped with Radiant Systems. In Proceedings of the BS2019, Rome, Italy, 2–3 September 2019; pp. 1724–1731. [Google Scholar]

- Arcuri, N.; Bruno, R.; Carpino, C. PV Driven Heat Pumps for the Electric Demand-Side Management: Experimental Results of a Demonstrative Plant. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Italian Republic. Implementation of Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources, Amending and Subsequently Repealing the Directives. 2011. Available online: https://www.gazzettaufficiale.it/ (accessed on 18 May 2020).

- Hong, J.; Kelly, N.J.; Richardson, I.; Thomson, M. Assessing heat pumps as flexible load. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013. [Google Scholar] [CrossRef]

- IEA. Tracking Buildings 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/tracking-buildings-2019 (accessed on 18 May 2020).

- Hu, B.; Li, Y.; Cao, F.; Xing, Z. Extremum seeking control of COP optimization for air-source transcritical CO2 heat pump water heater system. Appl. Energy 2015, 147, 361–372. [Google Scholar] [CrossRef]

- Tammaro, M.; Montagud, C.; Corberán, J.M.; Mauro, A.W.; Mastrullo, R. A propane water-to-water heat pump booster for sanitary hot water production: Seasonal performance analysis of a new solution optimizing COP. Int. J. Refrig. 2015, 51, 59–69. [Google Scholar] [CrossRef]

- Willem, H.; Lin, Y.; Lekov, A. Review of energy efficiency and system performance of residential heat pump water heaters. Energy Build. 2017, 143, 191–201. [Google Scholar] [CrossRef]

- Fernandez, N.; Hwang, Y.; Radermacher, R. Comparison of CO2 heat pump water heater performance with baseline cycle and two high COP cycles. Int. J. Refrig. 2010, 33, 635–644. [Google Scholar] [CrossRef]

- Sarkar, J.; Bhattacharyya, S. Operating characteristics of transcritical CO2 heat pump for simultaneous water cooling and heating. Arch. Thermodyn. 2012, 33, 23–40. [Google Scholar] [CrossRef]

- Shuxue, X.; Guoyuan, M. Research on air-source heat pump coupled with economized vapor injection scroll compressor and ejector. Int. J. Refrig. 2011, 34, 1587–1595. [Google Scholar] [CrossRef]

- Mattinen, M.K.; Nissinen, A.; Hyysalo, S.; Juntunen, J.K. Energy Use and Greenhouse Gas Emissions of Air-Source Heat Pump and Innovative Ground-Source Air Heat Pump in a Cold Climate. J. Ind. Ecol. 2015, 19, 61–70. [Google Scholar] [CrossRef]

- Lucia, U.; Simonetti, M.; Chiesa, G.; Grisolia, G. Ground-source pump system for heating and cooling: Review and thermodynamic approach. Renew. Sustain. Energy Rev. 2017, 70, 867–874. [Google Scholar] [CrossRef]

- Girard, A.; Gago, E.J.; Muneer, T.; Caceres, G. Higher ground source heat pump COP in a residential building through the use of solar thermal collectors. Renew. Energy 2015, 80, 26–39. [Google Scholar] [CrossRef]

- Zhu, C.; Gluesenkamp, K.R.; Yang, Z.; Blackman, C. Unified thermodynamic model to calculate COP of diverse sorption heat pump cycles: Adsorption, absorption, resorption, and multistep crystalline reactions. Int. J. Refrig. 2019, 99, 382–392. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Klemeš, J.J.; Walmsley, M.R.W.; Atkins, M.J.; Varbanov, P.S. Innovative hybrid heat pump for dryer Process Integration. Chem. Eng. Trans. 2017, 57, 1039–1044. [Google Scholar] [CrossRef]

- Torregrosa-Jaime, B.; Corberán, J.M.; Vasile, C.; Muller, C.; Risser, M.; Payá, J. Sizing of a reversible magnetic heat pump for the automotive industry. Int. J. Refrig. 2014, 37, 156–164. [Google Scholar] [CrossRef]

- Ferrara, G.; Ferrari, L.; Fiaschi, D.; Galoppi, G.; Karellas, S.; Secchi, R.; Tempesti, D. A Small Power Recovery Expander for Heat Pump COP Improvement. Energy Procedia 2015, 81, 1151–1159. [Google Scholar] [CrossRef]

- Bi, Y.; Chen, L.; Sun, F. Heating load, heating-load density and COP optimizations of an endoreversible air heat-pump. Appl. Energy 2008, 85, 607–617. [Google Scholar] [CrossRef]

- Feng, X.; Berntsson, T. Critical COP for an economically feasible industrial heat-pump application. Appl. Therm. Eng. 1997, 17, 93–101. [Google Scholar] [CrossRef]

- Di Pretoro, A.; Manenti, F. Heat Pumps. In SpringerBriefs in Applied Sciences and Technology; Springer Nature: Basel, Switzerland, 2020; Available online: https://www.springer.com/series/8884 (accessed on 18 May 2020).

- Madonna, F.; Bazzocchi, F. Annual performances of reversible air-to-water heat pumps in small residential buildings. Energy Build. 2013, 65, 299–309. [Google Scholar] [CrossRef]

- Piechurski, K.; Szulgowska-Zgrzywa, M.; Danielewicz, J. The impact of the work under partial load on the energy efficiency of an air-to-water heat pump. E3S Web Conf. 2017, 17, 00072. [Google Scholar] [CrossRef]

- Ertesvåg, I.S. Uncertainties in heat-pump coefficient of performance (COP) and exergy efficiency based on standardized testing. Energy Build. 2011, 43, 1937–1946. [Google Scholar] [CrossRef]

- In, S.; Cho, K.; Lim, B.; Lee, C. Partial load performance test of residential heat pump system with low-GWP refrigerants. Appl. Therm. Eng. 2015, 85, 179–187. [Google Scholar] [CrossRef]

- Tassou, S.A.; Votsis, P. Transient response and cycling losses of air-to-water heat pump systems. Heat Recover. Syst. CHP 1992, 12, 123–129. [Google Scholar] [CrossRef]

- Dongellini, M.; Morini, G.L. On-off cycling losses of reversible air-to-water heat pump systems as a function of the unit power modulation capacity. Energy Convers. Manag. 2019, 196, 966–978. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M. On-field validation of a seasonal performance calculation method for chillers in buildings. Energy Convers. Manag. 2014, 85, 62–69. [Google Scholar] [CrossRef]

- European Normalization Standard EN 14825. Air Conditioners, Liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling-Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance. 2019. Available online: https://standards.globalspec.com/std/13134222/EN%2014825 (accessed on 18 May 2020).

- Minetto, S.; Rossetti, A.; Marinetti, S. Seasonal energy efficiency ratio for remote condensing units in commercial refrigeration systems. Int. J. Refrig. 2018, 85, 85–96. [Google Scholar] [CrossRef]

- Perers, B.; Anderssen, E.; Nordman, R.; Kovacs, P. A Simplified Heat Pump Model for use in Solar Plus Heat Pump System Simulation Studies. Energy Procedia 2012, 30, 664–667. [Google Scholar] [CrossRef][Green Version]

- Dongellini, M.; Naldi, C.; Morini, G.L. Annual Performances of Reversible Air Source Heat Pumps for Space Conditioning. Energy Procedia 2015, 78, 1123–1128. [Google Scholar] [CrossRef]

- Song, K.; Jeon, Y.; Park, K.; Kim, Y. Dynamic performance characteristics of R410A heat pump with consideration of energy efficiency and thermal comfort at various compressor frequencies and outdoor fan speeds. Appl. Therm. Eng. 2020, 165, 114499. [Google Scholar] [CrossRef]

- Palmiter, L.; Kim, J.H.; Larson, B.; Francisco, P.W.; Groll, E.A.; Braun, J.E. Measured effect of airflow and refrigerant charge on the seasonal performance of an air-source heat pump using R-410A. Energy Build. 2011, 43, 1802–1810. [Google Scholar] [CrossRef]

- Italian Unification Institution. UNI TS 11300-4. Energy Performances of Building: Renewable Rnergy and Other Generation Systems for Space Heating and Domestic Hot Water Production. 2016. Available online: https://www.uni.com/ (accessed on 24 June 2020).

- Italian Unification Institution. UN TS 11300-3. Energy performance of buildings: Evaluation of Primary Energy and System Efficiencies for Space Cooling. 2010. Available online: https://www.uni.com/ (accessed on 24 June 2020).

- Fuentes, E.; Waddicor, D.; Fannan, M.O.; Salom, J. Improved methodology for testing the part load performance of water-to-water heat pumps. In Proceedings of the 12th IEA Heat Pump Conference, Rotterdam, The Netherlands, 15–18 May 2017; pp. 1–11. Available online: http://hpc2017.org/wp-content/uploads/2017/05. (accessed on 24 June 2020).

- Asloune, H.; Riviere, P. A Simplified Model For Assessing Improvement Potential Of Air-To-Air Conditioners And Heat Pumps. Int. Refrig. Air Cond. Conf. 2018, 1–10. Available online: https://docs.lib.purdue.edu/iracc/1878. (accessed on 24 June 2020).

- Mooney, T.; Martin, D. Increasing Metering Accuracy by Optimizing the Analog to Digital Converter Characteristics. In Proceedings of the 2006 Power Systems Conference: Advanced Metering, Protection, Control, Communication, and Distributed Resources, Clemson, SC, USA, 14–17 March 2006; pp. 96–98. [Google Scholar] [CrossRef]

| Test Number | CR | Outdoor Air Temperature (°C) | Outlet and Inlet Temperatures of the Chilled Water with Full Water Flow Rate (°C) |

|---|---|---|---|

| 1 | 1.00 | 35 | 12/7 |

| 2 | 0.75 | 30 | 12/7 |

| 3 | 0.50 | 25 | 12/7 |

| 4 | 0.25 | 20 | 12/7 |

| Temperature | Flow Rate | AC Electric Power | |

|---|---|---|---|

| Sensor | Pt100 | Pulse generator | Programmable Current transducer |

| Range | −50–70 °C | Up to 1.5 m3/h | Up to 200 MW |

| Accuracy | ±0.15 °C (at 0 °C) | Class 3 (EN 1434) | Class 0.2 |

| INDEXES | Winter fC Deviances | Summer fC Deviances |

|---|---|---|

| RMSE | 0.12487 | 0.12336 |

| MBE | 0.066 | 0.070 |

| Correlation Factor (R) | 0.88346 | 0.70467 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bruno, R.; Nicoletti, F.; Cuconati, G.; Perrella, S.; Cirone, D. Performance Indexes of an Air-Water Heat Pump Versus the Capacity Ratio: Analysis by Means of Experimental Data. Energies 2020, 13, 3391. https://doi.org/10.3390/en13133391

Bruno R, Nicoletti F, Cuconati G, Perrella S, Cirone D. Performance Indexes of an Air-Water Heat Pump Versus the Capacity Ratio: Analysis by Means of Experimental Data. Energies. 2020; 13(13):3391. https://doi.org/10.3390/en13133391

Chicago/Turabian StyleBruno, Roberto, Francesco Nicoletti, Giorgio Cuconati, Stefania Perrella, and Daniela Cirone. 2020. "Performance Indexes of an Air-Water Heat Pump Versus the Capacity Ratio: Analysis by Means of Experimental Data" Energies 13, no. 13: 3391. https://doi.org/10.3390/en13133391

APA StyleBruno, R., Nicoletti, F., Cuconati, G., Perrella, S., & Cirone, D. (2020). Performance Indexes of an Air-Water Heat Pump Versus the Capacity Ratio: Analysis by Means of Experimental Data. Energies, 13(13), 3391. https://doi.org/10.3390/en13133391