T’imani a Multifunctional Solar System to Provide Cooking and Water Heating Rural Energy Needs

Abstract

1. Introduction

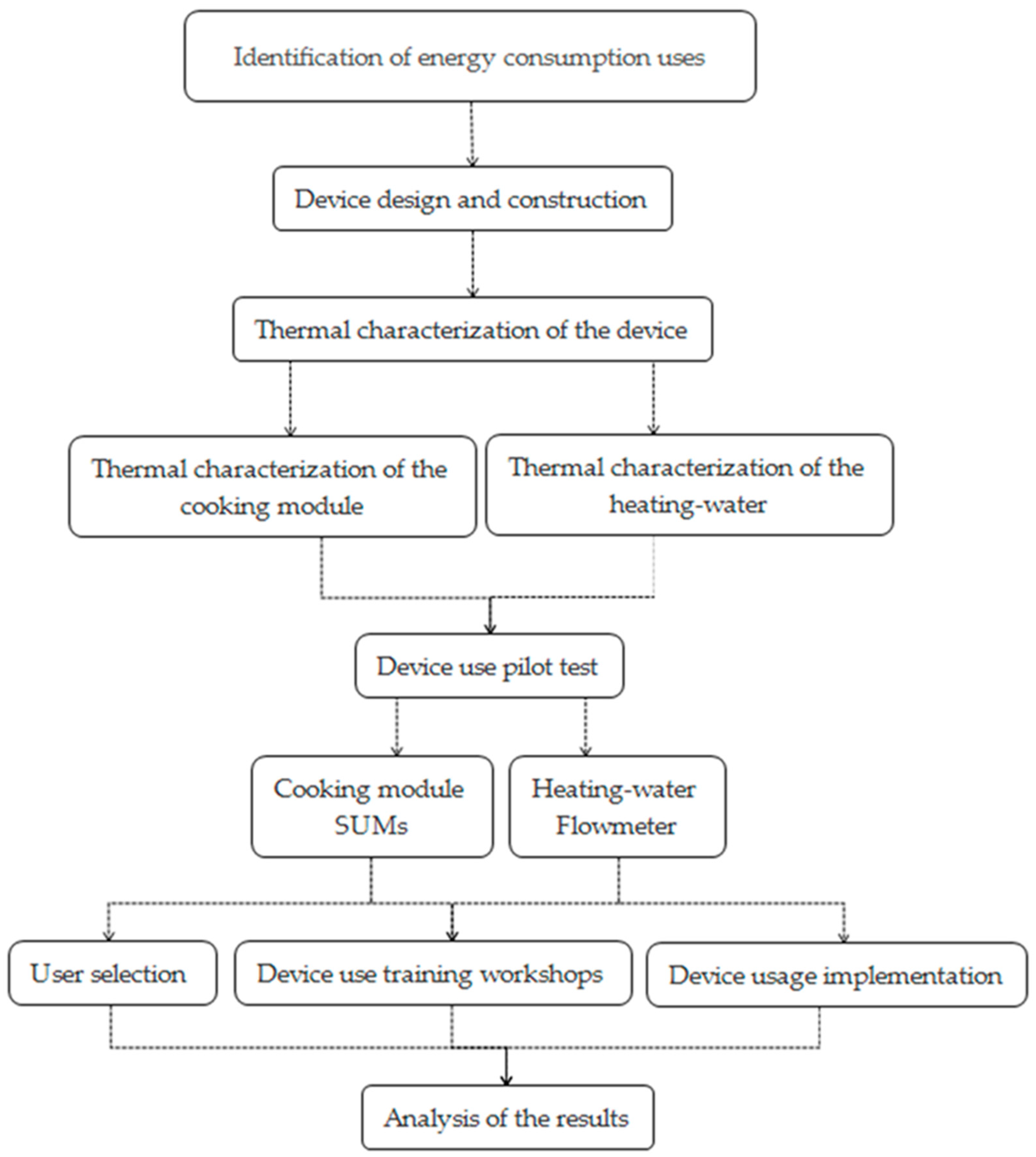

2. Materials and Methods

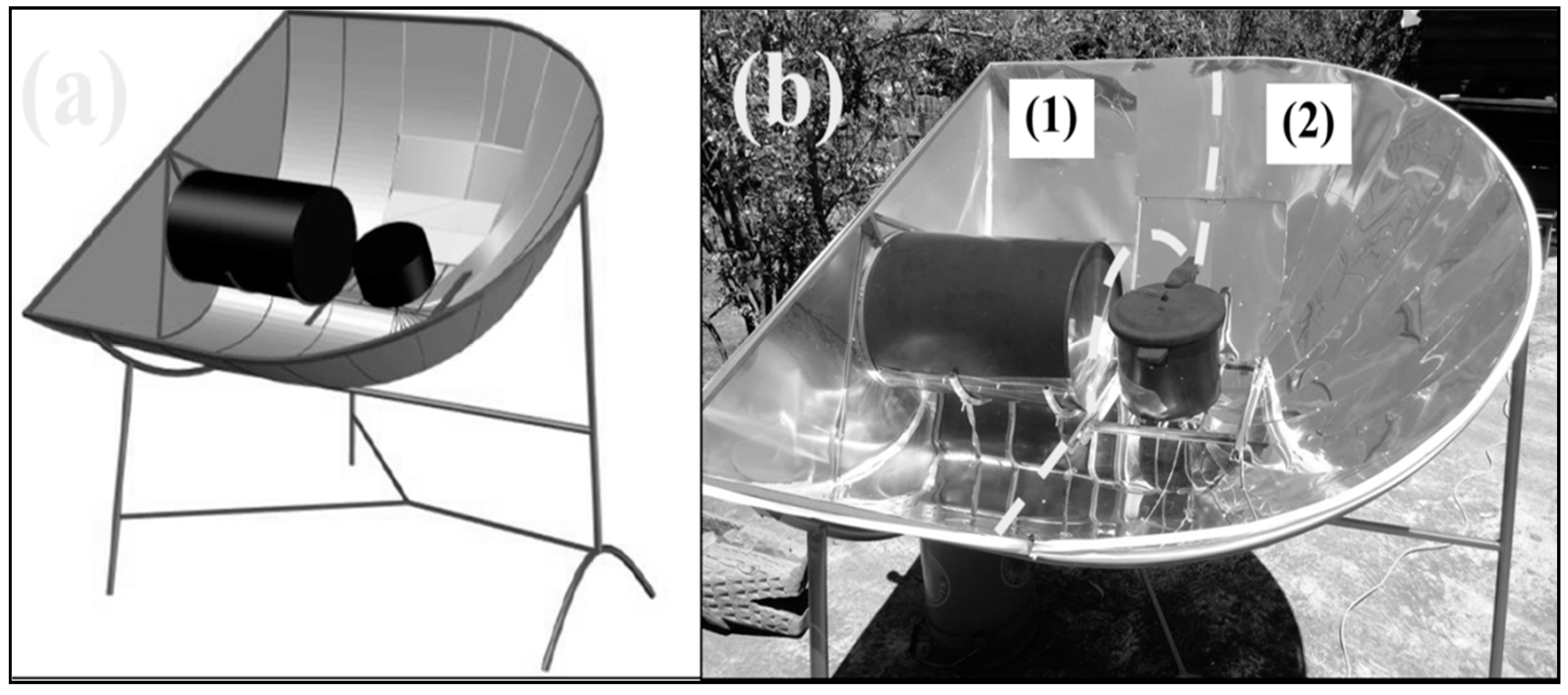

2.1. Design and Construction

- Metallic structure with reflective surface that forms the CPC: a frame made of 40-calibre polystyrene that serves as the base. It has a self-adhering, mirror-type silver–chrome vinyl film placed over a carbon-steel structure and a transparent glass cover placed over the structure to prevent heat loss due to convection.

- Heating tank and water storage tank: a 27-liter metallic recipient the outside of which is painted with a coating of absorbent forest–biomass soot [21] and then wrapped in absorbent sheeting optimized for the rest of the recipient.

- Cooking pot: a pressure cooker made of aluminum and painted black with the same soot-based coating (6-liter capacity).

- Hatch to access the cooking pot: allows access to the recipient where the food to be cooked is placed.

- Glass cover: a 6-mm-thick glass lid that covers the apparatus so that no airflow can enter or escape.

- Concentrator base: a carbon-steel structure that supports the collector.

- (1)

- Water-heating module (Figure 1(b-1)) made up of the compound parabolic channel and a flat wall with reflectors; the water storage tank with its inlet and outlet; and the support structure for the tank.

- (2)

- Food-cooking module (Figure 1(b-2)) showing the revolving CPC (3D) with solar reflectors, the pressure cooking pot and soot coating.

2.2. Thermal Characterization of The Device

2.2.1. Water-Heating Module

2.2.2. Food-Cooking Module

- Measurement and recording of average temperature of the water inside the container where the food, temperature, environment and irradiance are cooked at intervals 5 min;

- Strong wind conditions (greater than 2 m/s) for more than 5 min, high variation of insolation (+100 W/m2), low variation heat stroke (−100 W/m2) or low temperature environment (below 20 °C) the tests are invalidated.

2.3. Energy Consumption Tests to Identify Needs

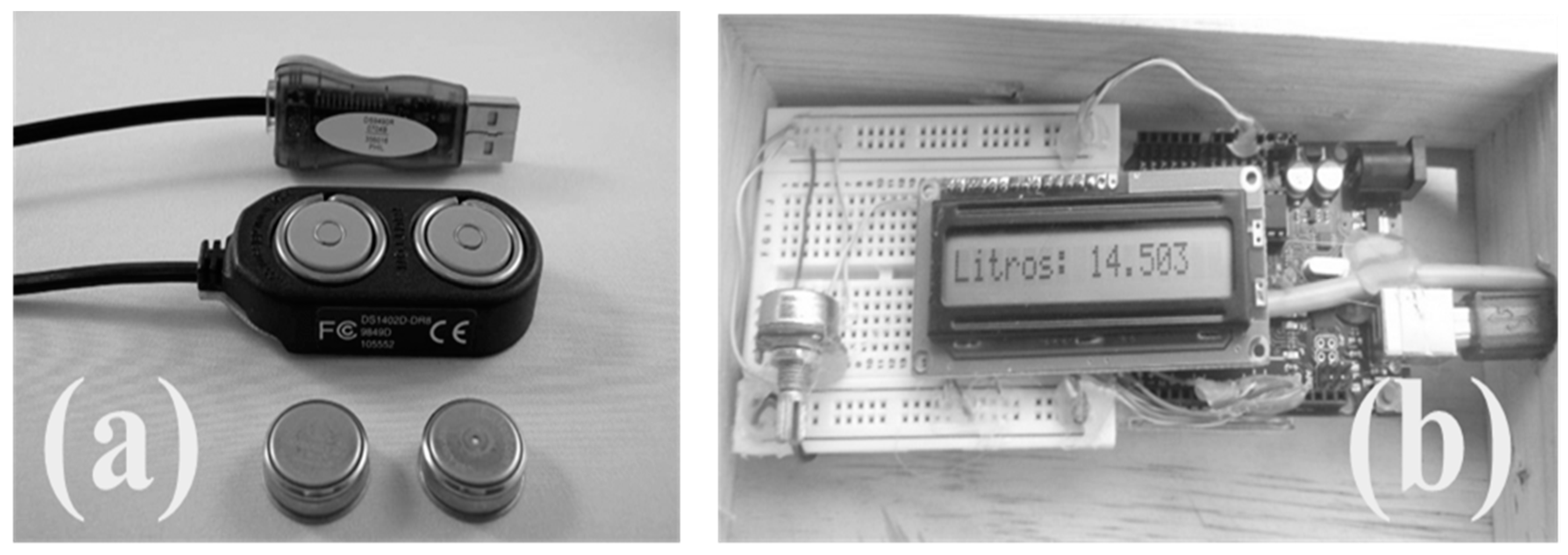

2.3.1. Monitoring the Technology

2.3.2. Analysis of the Adoption of the Multifunctional Solar Cooking System

3. Results

3.1. Evaluation of the Functionality of the Technology

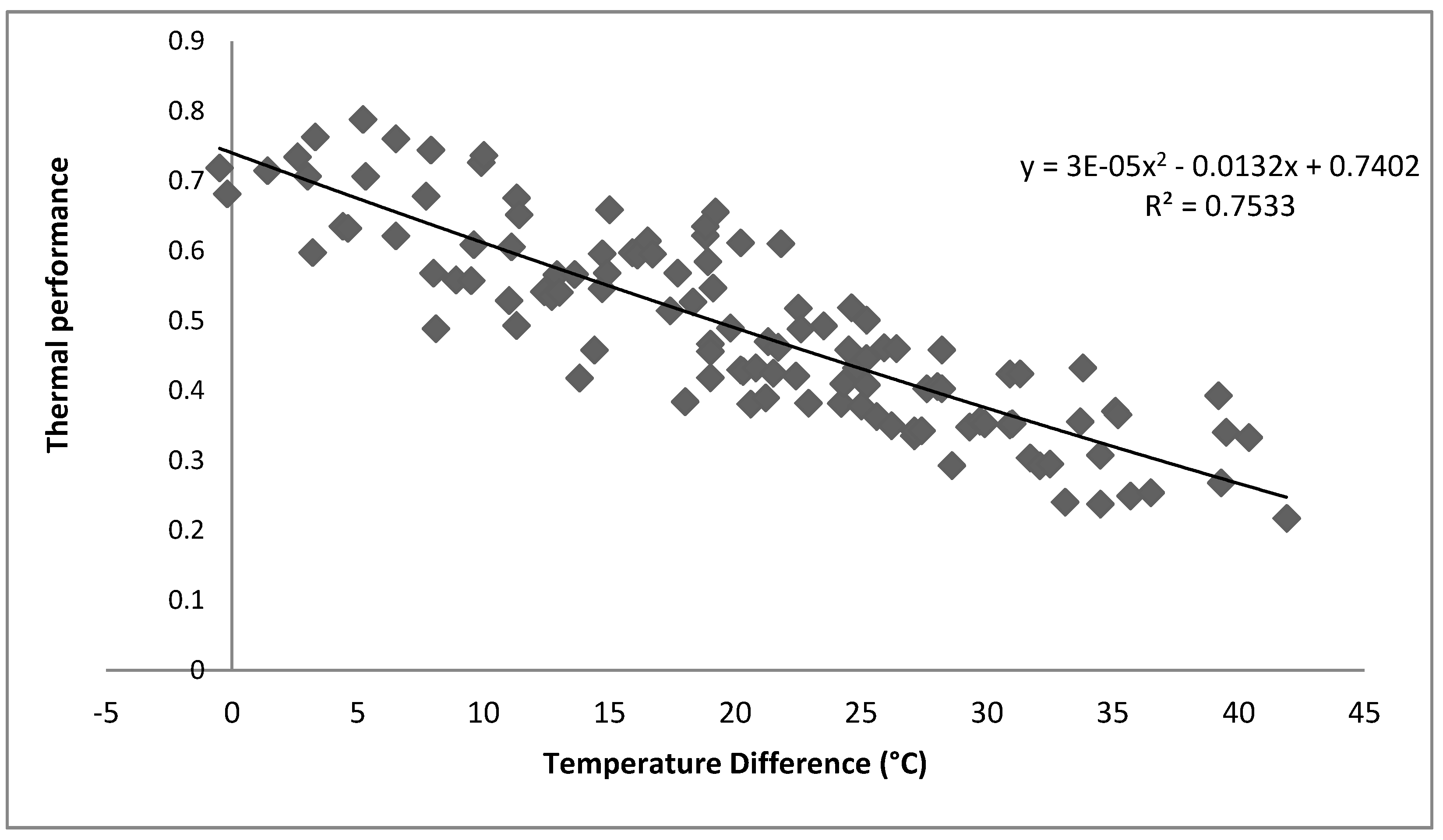

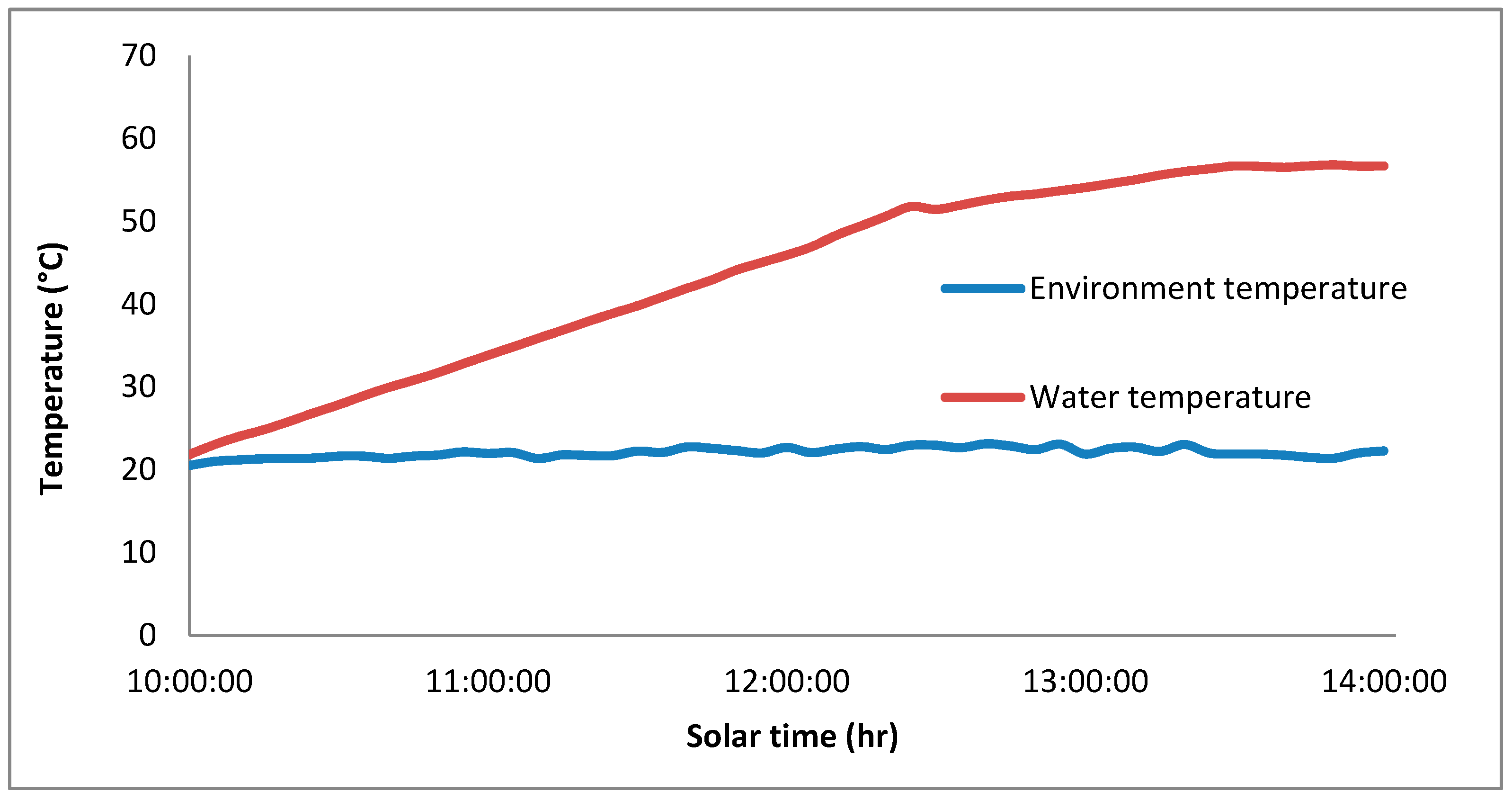

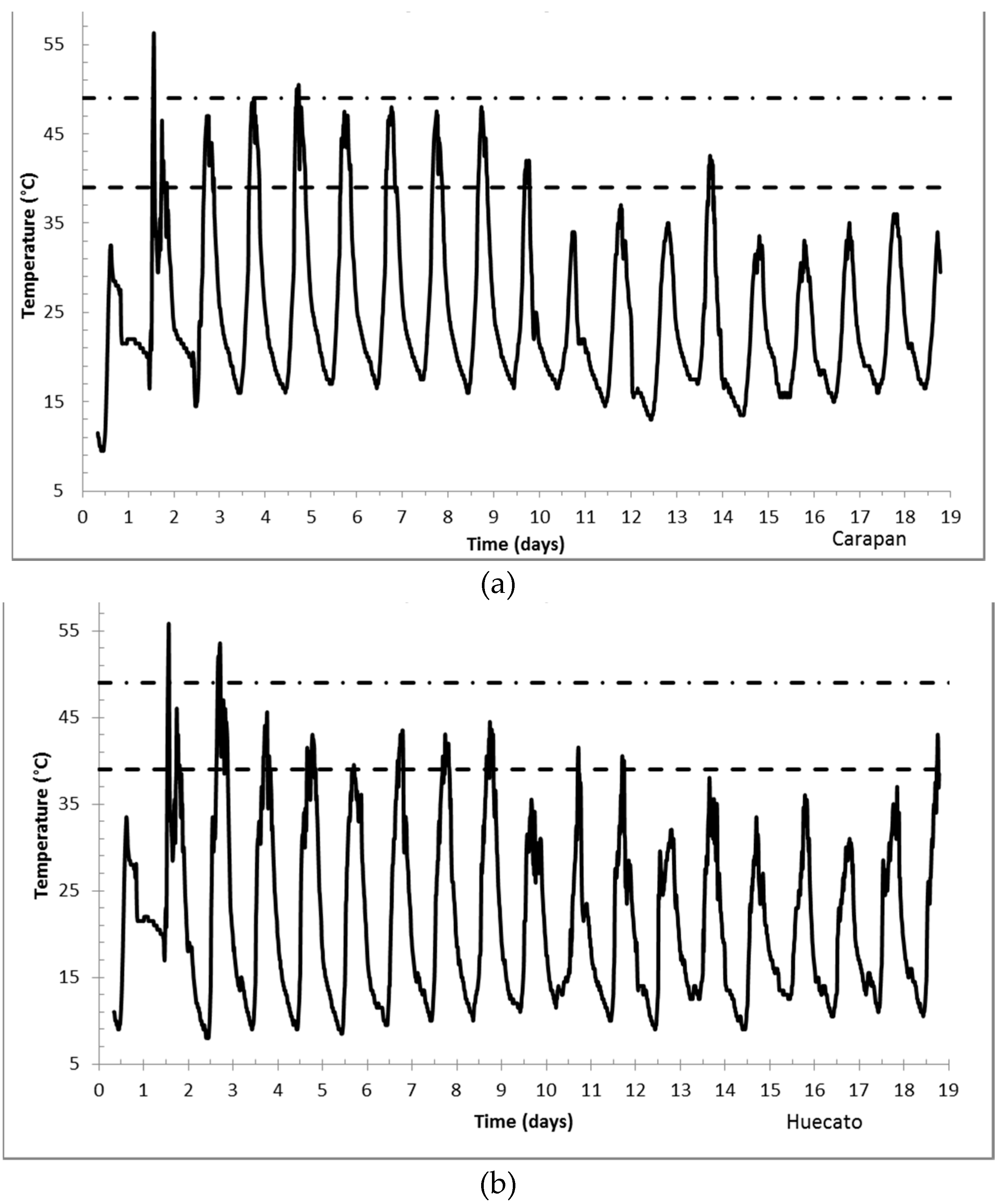

3.1.1. Thermal Analysis of the Water-Heating Module

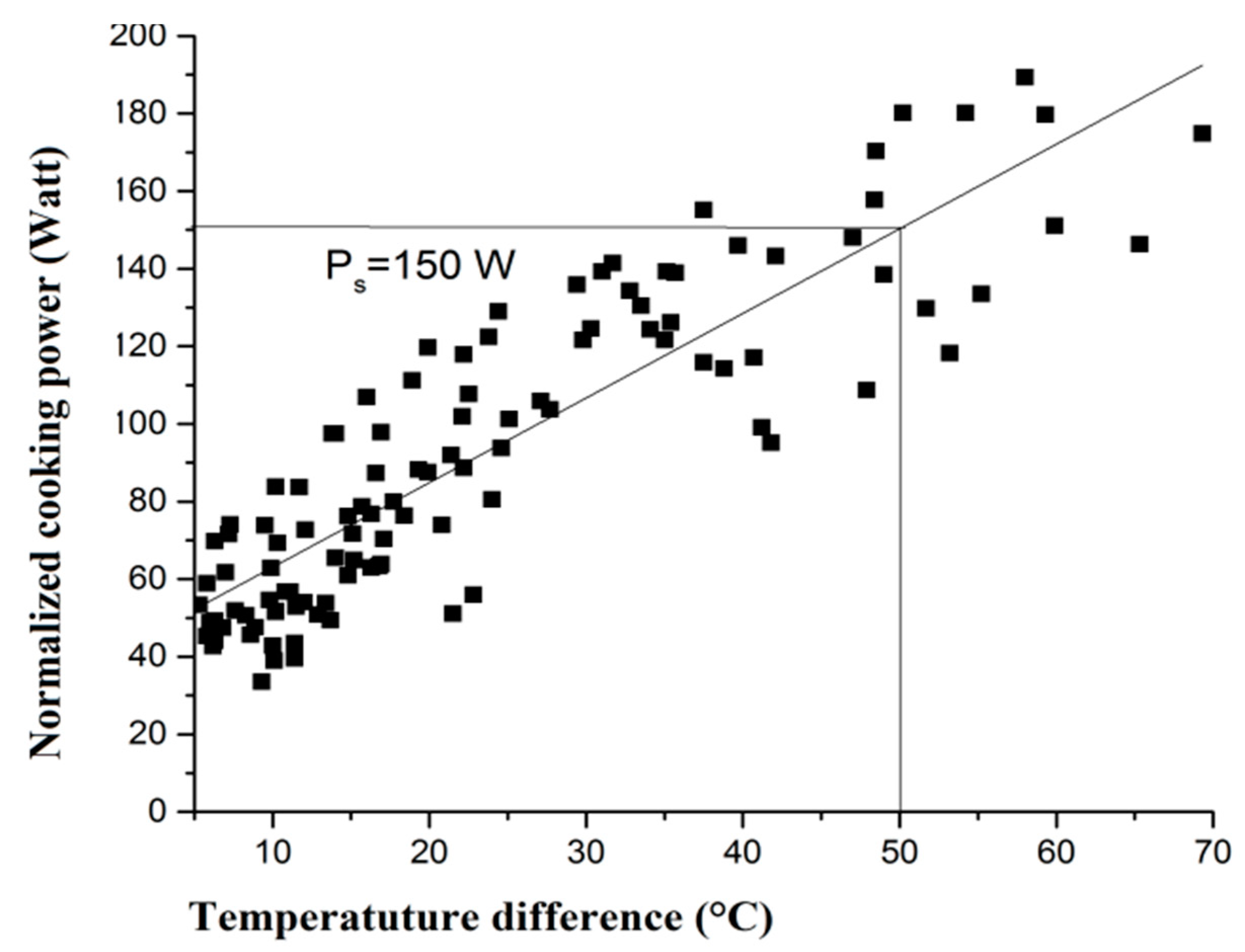

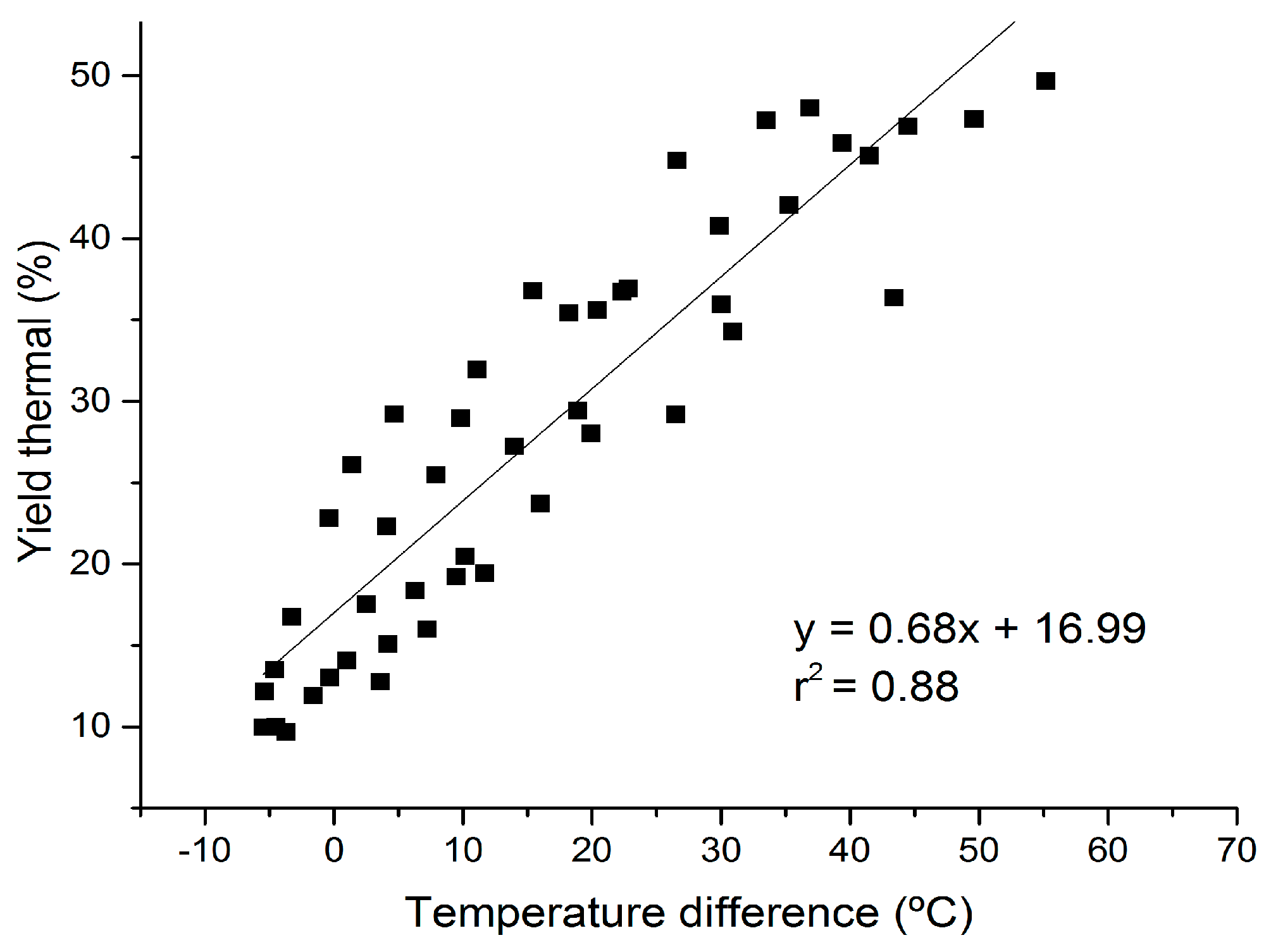

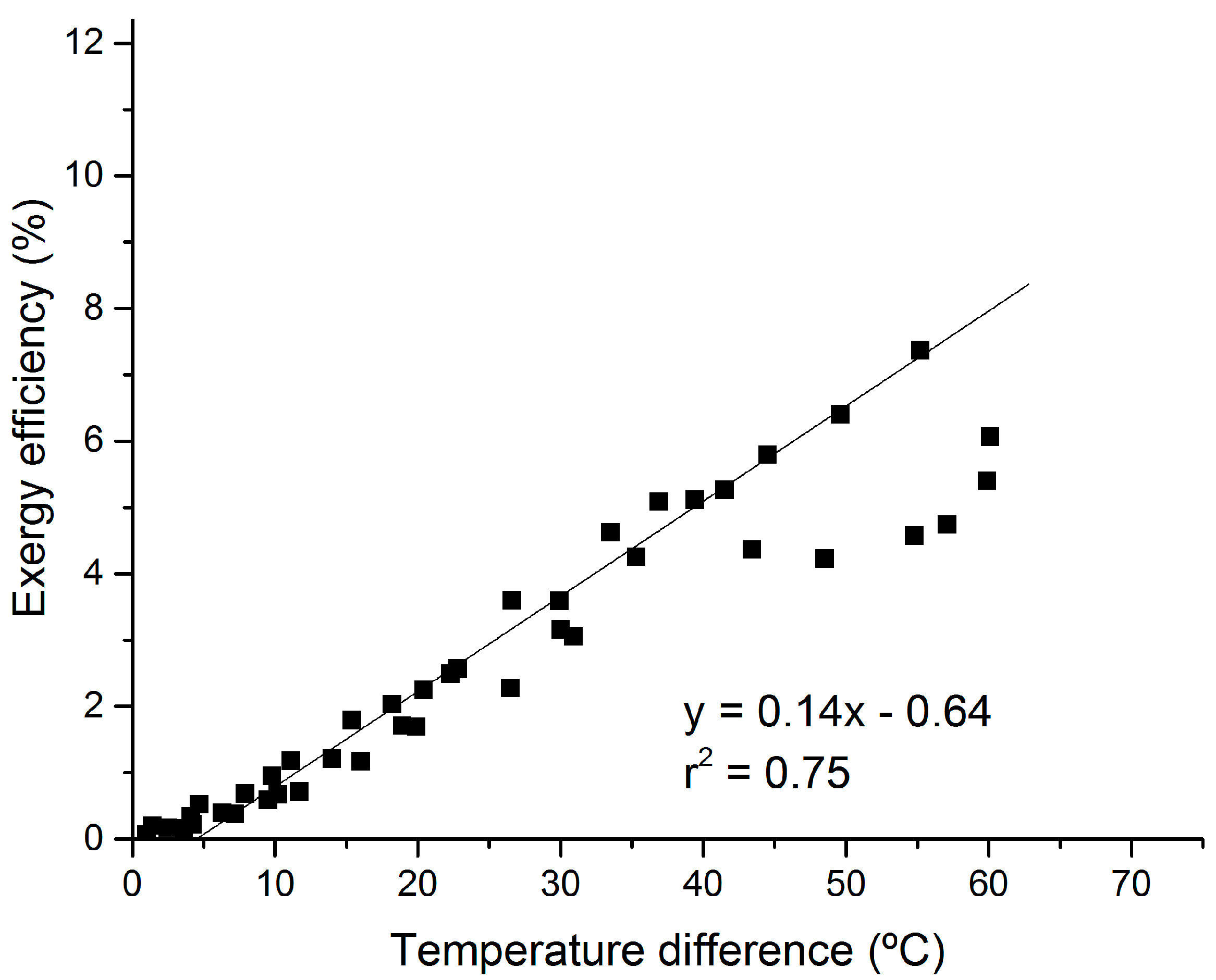

3.1.2. Thermal Analysis of the Solar Cooking Module

3.1.3. Multifunctional Solar Cooking System

- The households surveyed depend primarily on firewood, followed by LPG;

- The main end-uses that require energy were cooking food and heating water.

- Regarding the use of fuels for cooking tasks and heating water, 54.5% of the families surveyed responded that they use only firewood, while only 3.6% indicated that they used LPG for these two purposes;

- In 22% of homes, both fuels—firewood and LPG are used simultaneously for cooking. Firewood is the fuel used most often used to heat water (58.2%), while 27.3% use LPG and 12.7% utilized other fuels to satisfy this need;

- In summary, 94.5% of all families surveyed use firewood to satisfy their basic energy needs, in particular, cooking of food and heating of water.

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Month | No. of Days in the Month | Total Radiation | Percentage of Hours of Sunlight, Monthly (%) | Mean Daily Hours of Sunlight | |||

|---|---|---|---|---|---|---|---|

| January | 31 | 339.54 | 26,940 | 15,300 | 121.49 | 35.78 | 3.92 |

| February | 28 | 318.39 | 31,103 | 17,700 | 115.10 | 36.15 | 4.11 |

| March | 31 | 368.43 | 35,336 | 19,500 | 121.30 | 32.93 | 3.91 |

| April | 30 | 373.59 | 38,723 | 21,300 | 122.34 | 32.75 | 4.08 |

| May | 31 | 400.88 | 38,916 | 22,100 | 142.51 | 35.55 | 4.60 |

| June | 30 | 395.06 | 39,182 | 18,900 | 85.37 | 21.61 | 2.85 |

| July | 31 | 404.91 | 38,927 | 18,000 | 73.86 | 18.24 | 2.38 |

| August | 31 | 392.28 | 37,905 | 18,300 | 84.88 | 21.64 | 2.74 |

| September | 30 | 363.17 | 35,391 | 17,500 | 85.43 | 23.52 | 2.85 |

| October | 31 | 357.67 | 32,273 | 16,200 | 89.48 | 25.02 | 2.89 |

| November | 30 | 331.86 | 27,947 | 15,600 | 112.50 | 33.90 | 3.75 |

| December | 31 | 335.84 | 25,662 | 13,500 | 96.38 | 28.70 | 3.11 |

Appendix B

| Time (Min) | T-H2O pot (°C) | I (W/m2) | Ps (W) |

|---|---|---|---|

| 0 | 18.8 | 968 | 87.6899504 |

| 5 | 20.7 | 979 | 101.574776 |

| 10 | 22.9 | 990 | 100.806821 |

| 15 | 24.8 | 994 | 107.478685 |

| 20 | 27.3 | 1003 | 114.291692 |

| 25 | 29.5 | 1003 | 113.443411 |

| 30 | 32 | 1018 | 143.075558 |

| 35 | 34.8 | 789 | 143.23409 |

| 40 | 37.3 | 1016 | 132.607638 |

| 45 | 40.4 | 1044 | 147.607205 |

| 50 | 43.6 | 1038 | 152.806908 |

| 55 | 46.9 | 1037 | 171.945373 |

| 60 | 50.9 | 1034 | 170.000387 |

| 65 | 54.1 | 1032 | 174.216667 |

| 70 | 58.3 | 1040 | 197.82236 |

| 75 | 62.6 | 1056 | 193.190759 |

| 80 | 66.7 | 1065 | 193.281887 |

| 85 | 71 | 1055 | 199.104762 |

| 90 | 75.3 | 1052 | 203.445434 |

| 95 | 79.8 | 1058 | 185.919644 |

| 100 | 83.3 | 1041 | 268.15376 |

References

- Díaz, R.; Berrueta, V.; Masera, O. Estufas de Leña; Red Mexicana de Bioenergía, A.C.: Morelia, Mexico, 2011. [Google Scholar]

- FAO. Evaluación de los Recursos Forestales Mundiales 2015; Segunda, Ed.; Organización de las Naciones Unidas para la Alimentación y la Agricultura: Roma, Italy, 2016. [Google Scholar]

- CEPAL, N.U. Informe Nacional de Monitoreo de la Eficiencia Energética de México, 2018; Comisión Económica para América Latina y el Caribe (CEPAL): Ciudad de México, Mexico, 2018. [Google Scholar]

- Masera, O.R.; Díaz, R.; Berrueta, V. From Cookstoves to Cooking Systems: The Integrated Program on Sustainable Household Energy Use in Mexico. Energy Sustain. Dev. 2005, 9, 25–36. [Google Scholar] [CrossRef]

- Caballero, M. La verdadera cosecha maderable en México. Rev. Mex. Cienc. For. 2010, 1, 5–16. [Google Scholar]

- Ghilardi, A.; Guerrero, G.; Masera, O. Spatial analysis of residential fuelwood supply and demand patterns in Mexico using the WISDOM approach. Biomass Bioenergy 2007, 31, 475–491. [Google Scholar] [CrossRef]

- SCI. Safe water and Solar Cookers. In SOLAR COOKER REVIEW; SCI: Sacramento, CA, USA, 2013; Volume 19. [Google Scholar]

- SCI. Solar Cookers International. 2016. Available online: http://www.solarcookers.org/index.php (accessed on 12 May 2020).

- Solar Inti. Solar Inti Argentina. 2016. Available online: http://solarinti.blogspot.com.es/ (accessed on 12 May 2020).

- Inti Illimani. Asociación Inti Illimani. 2016. Available online: https://asointiillimani.wordpress.com (accessed on 12 May 2020).

- Anti Arequipa. 2016. Available online: https://intiarequipa.wordpress.com (accessed on 12 May 2020).

- González-Avilés, M.; López-Sosa, L.B.; Servín-Campuzano, H.; González-Pérez, D. Adoption of sustainable technology of solar cookers in indigenous and rural communities of Michoacán. Rev. Mex. Ing. Quim. 2017, 17, 273–282. [Google Scholar]

- GTZ. Here Comes the Sun: Options for Using Solar Cookers in Developing Countries; HERA—Household Energy Programme: Eschborn, Germany, 2007. [Google Scholar]

- Servín, H.; Peña, M.; Sobral, H.; González, M. Thermal and optical analysis of selective absorber coatings based on soot for applications in solar cookers. J. Phys. Conf. Ser. 2017, 792, 012095. [Google Scholar] [CrossRef]

- González-Avilés, M.; Urrieta, O.R.; Ruiz, I.; Masera, O. Design, manufacturing, thermal characterization of a solar cooker with compound parabolic concentrator and assessment of an integrated stove using a monitoring mechanism. Energy Sustain. Dev. 2018, 45, 135–141. [Google Scholar] [CrossRef]

- López-Sosa, L.B.; González-Avilés, M.; Hernández-Ramírez, L.M.; Medina-Flores, A.; López-Luke, T.; Bravo-Sánchez, M.; Zárate-Medina, J. Ecological solar absorber coating: A proposal for the use of residual biomass and recycled materials for energy conversion. Sol. Energy 2020, 202, 238–248. [Google Scholar] [CrossRef]

- Badran, A.A.; Yousef, I.A.; Joudeh, N.K.; Al Hamad, R.; Halawa, H.; Hassouneh, H.K. Portable solar cooker and water heater. Energy Convers. Manag. 2010, 51, 1605–1609. [Google Scholar] [CrossRef]

- Grupp, M.; Balmer, M.; Beall, B.; Bergler, H.; Cieslok, J.; Hancock, D.; Schröder, G. On-line recording of solar cooker use rate by a novel metering device: Prototype description and experimental verification of output data. Sol. Energy 2009, 83, 276–279. [Google Scholar] [CrossRef]

- Rabl, A. Comparison of solar concentrators. Sol Energy 1976, 18, 93–111. [Google Scholar] [CrossRef]

- Bauer, G. Evaluation of usage and fuel savings of solar ovens in Nicaragua. Energy Policy 2016, 97, 250–257. [Google Scholar] [CrossRef]

- Rabl, A. Optical and thermal properties of compound parabolic concentrators. SPIE Milest. Ser. 1993, 54, 229–243. [Google Scholar]

- ASAE, S. Testing and Reporting Solar Cooker Performance. ASAE 2003, 1, 824–826. [Google Scholar]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Kundapur, A.; Sudhir, C.V. Proposal for new world standard for testing solar cookers. Int. J. Eng. Sci. Technol. 2009, 4, 272–281. [Google Scholar]

- Pejack, E. Technology of Solar Cooking. Available online: http//solarcooking.org/Pejack-on-solar-cooker-technology.pdf (accessed on 12 May 2020).

- Pandey, A.K.; Tyagi, V.V.; Park, S.R.; Tyagi, S.K. Comparative experimental study of solar cookers using exergy analysis. J. Therm. Anal. Calorim. 2011, 109, 425–431. [Google Scholar] [CrossRef]

- Bailis, R.; Smith, K.R.; Edwards, R. Kitchen Performance Test (KPT); Univerisity of California: Berkeley, CA, USA, 2007. [Google Scholar]

- Ruiz-Mercado, I.; Canuz, E.; Smith, K.R. Temperature dataloggers as stove use monitors (SUMs): Field methods and signal analysis. Biomass Bioenergy 2012, 47, 459–468. [Google Scholar] [CrossRef]

- PROY-NOM-027-ENER/SCFI-2016. Proyecto de la Norma oficial para Calentadores Solares de Agua., Diario Oficial de la Federación. Ciudad de México, a 14 de julio de 2016.

- Duffie, J.A.; Beckman, W.A.; Blair, N. Solar Engineering of Thermal Processes, Photovoltaics and Wind; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Estrada-Cajigal, V.; Almanza, R. Irradiaciones global, directa y difusa, en superficies horizontales e inclinadas, así como irradiación directa normal, en la República Mexicana. Ser. Inst. Ing. 2005, 646. [Google Scholar]

- Burden, R.L.; Faires, J.D. Numerical Analysis–Theory and Applications; Cengage Learning, India Edition; IntechOpen: New Delhi, India, 2009. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez Morales, J.Á.; González-Avilés, M.; Servín Campuzano, H.; Masera, O. T’imani a Multifunctional Solar System to Provide Cooking and Water Heating Rural Energy Needs. Energies 2020, 13, 3429. https://doi.org/10.3390/en13133429

Rodríguez Morales JÁ, González-Avilés M, Servín Campuzano H, Masera O. T’imani a Multifunctional Solar System to Provide Cooking and Water Heating Rural Energy Needs. Energies. 2020; 13(13):3429. https://doi.org/10.3390/en13133429

Chicago/Turabian StyleRodríguez Morales, José Ángel, Mauricio González-Avilés, Hermelinda Servín Campuzano, and Omar Masera. 2020. "T’imani a Multifunctional Solar System to Provide Cooking and Water Heating Rural Energy Needs" Energies 13, no. 13: 3429. https://doi.org/10.3390/en13133429

APA StyleRodríguez Morales, J. Á., González-Avilés, M., Servín Campuzano, H., & Masera, O. (2020). T’imani a Multifunctional Solar System to Provide Cooking and Water Heating Rural Energy Needs. Energies, 13(13), 3429. https://doi.org/10.3390/en13133429