Optimal Design of High-Power Medium-Frequency Transformer Using Hollow Conductors with Consideration of Multi-Objective Parameters

Abstract

:1. Introduction

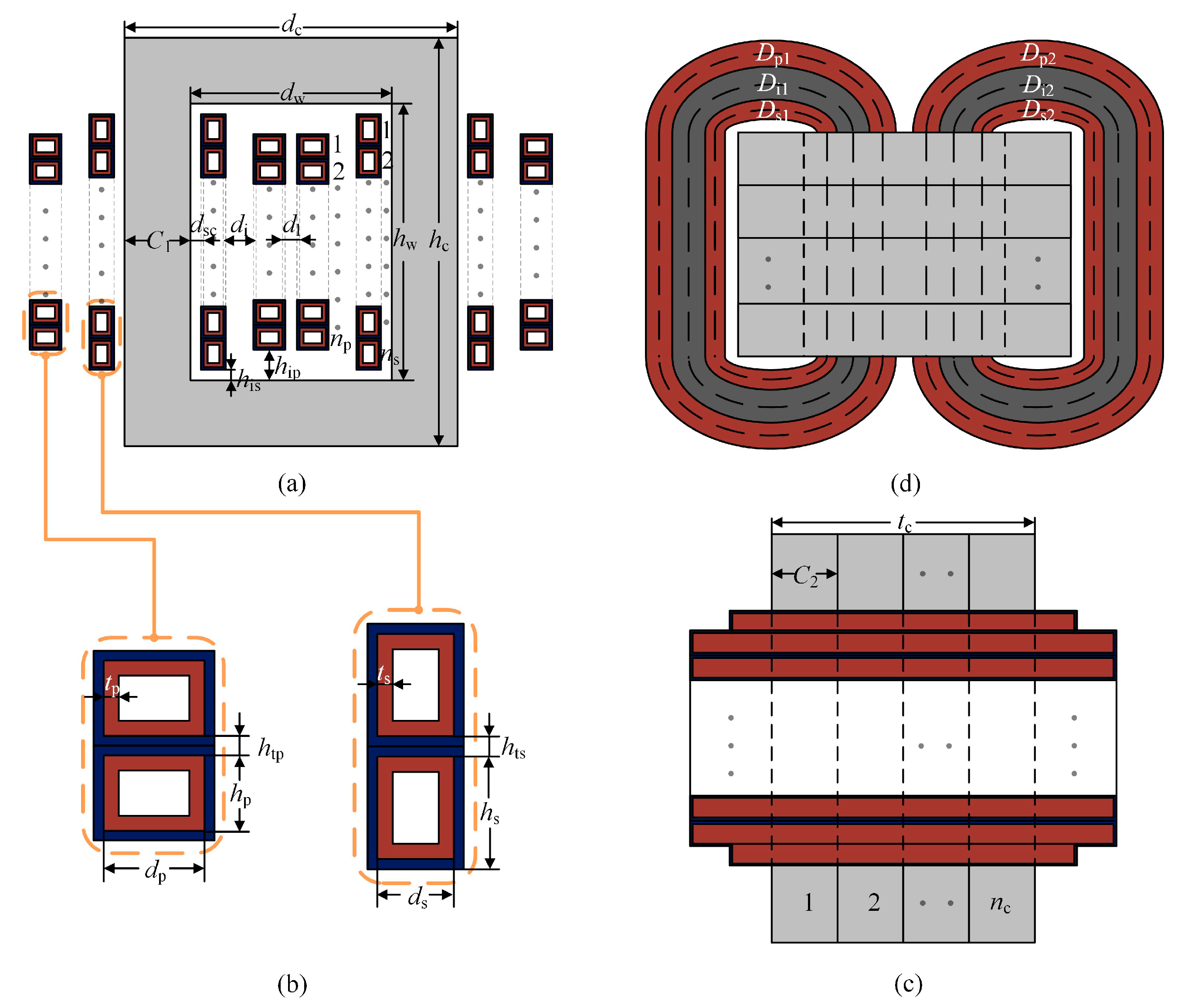

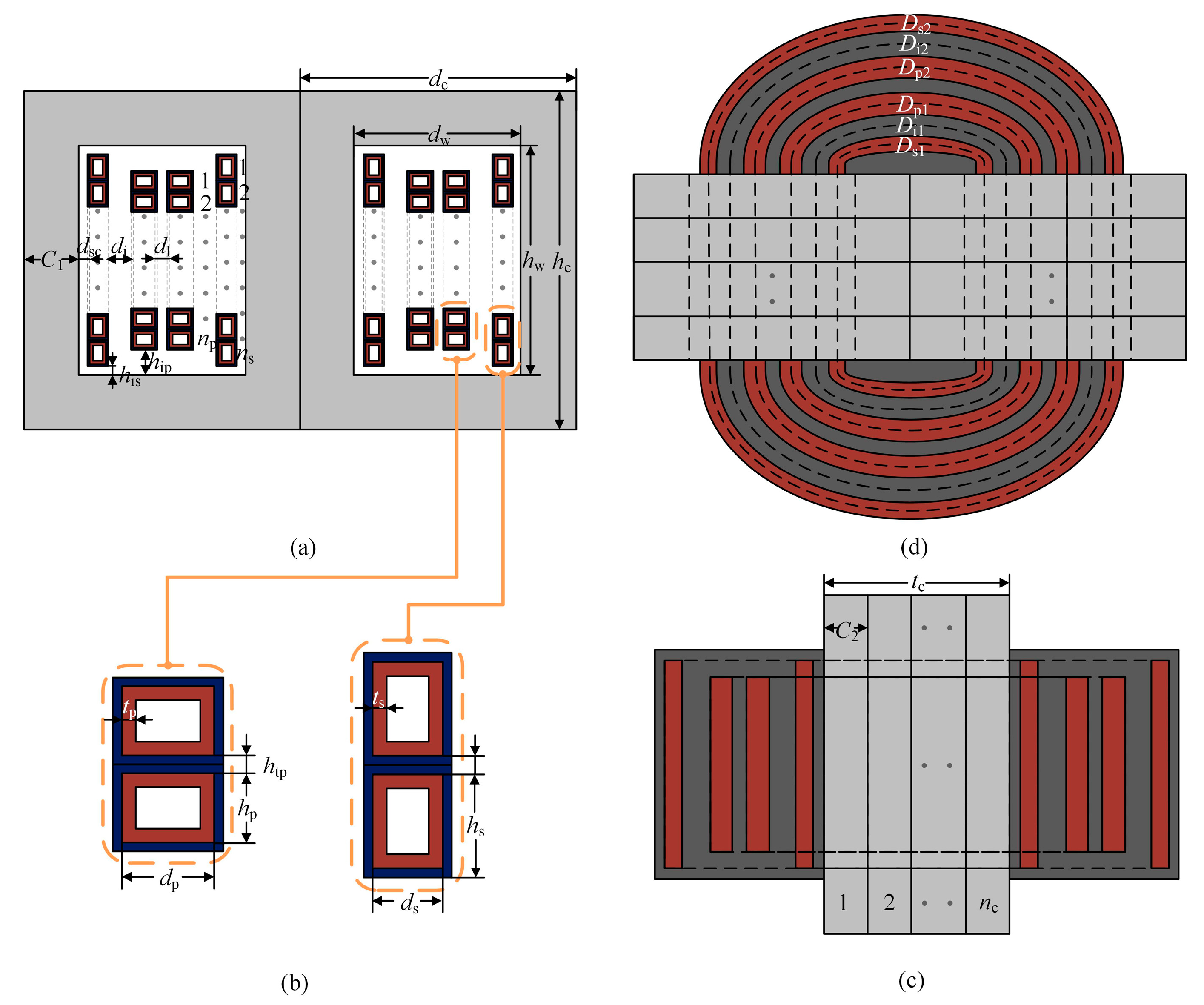

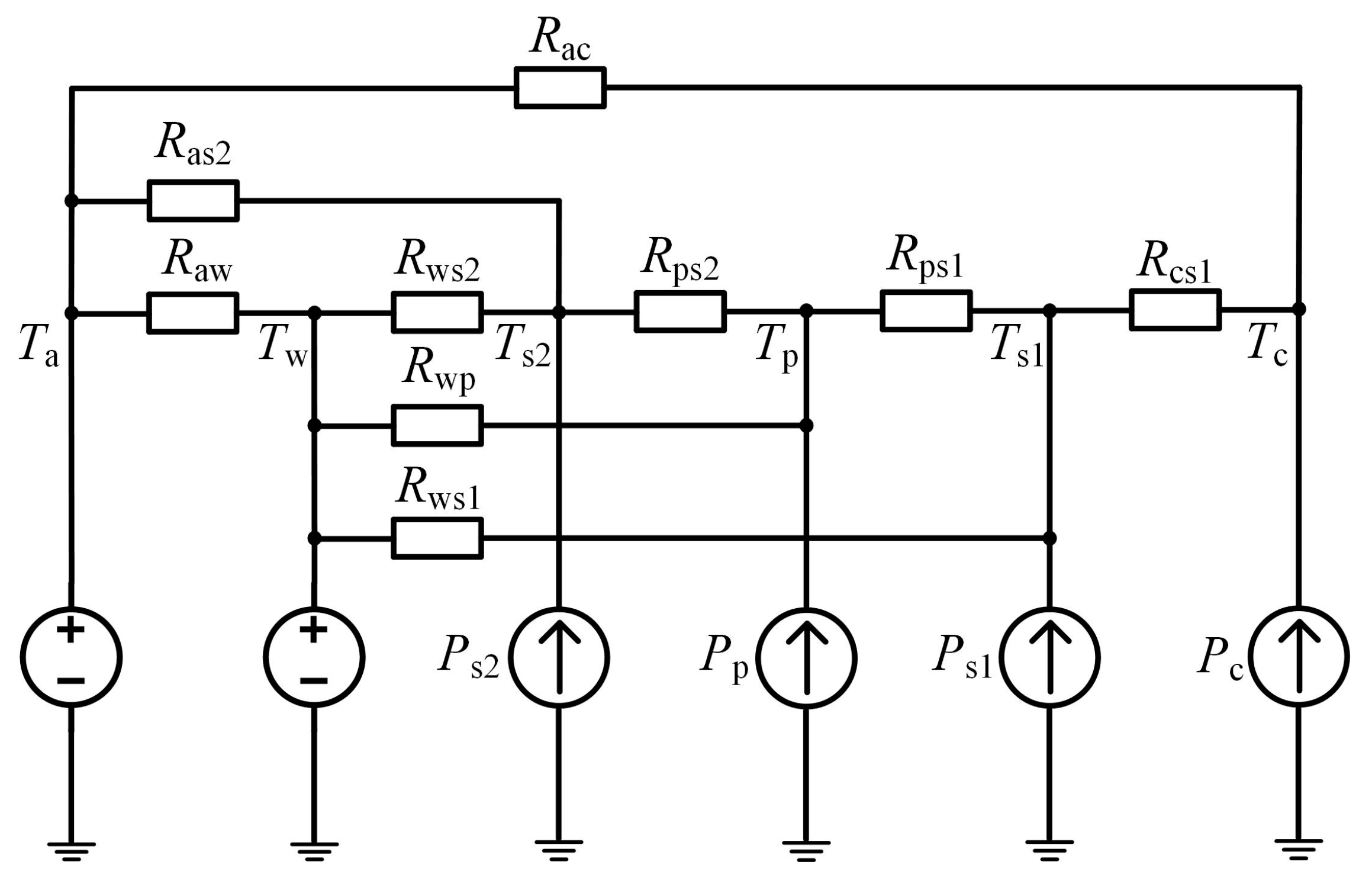

2. System Structure of PET and Design Parameters of HPMFT

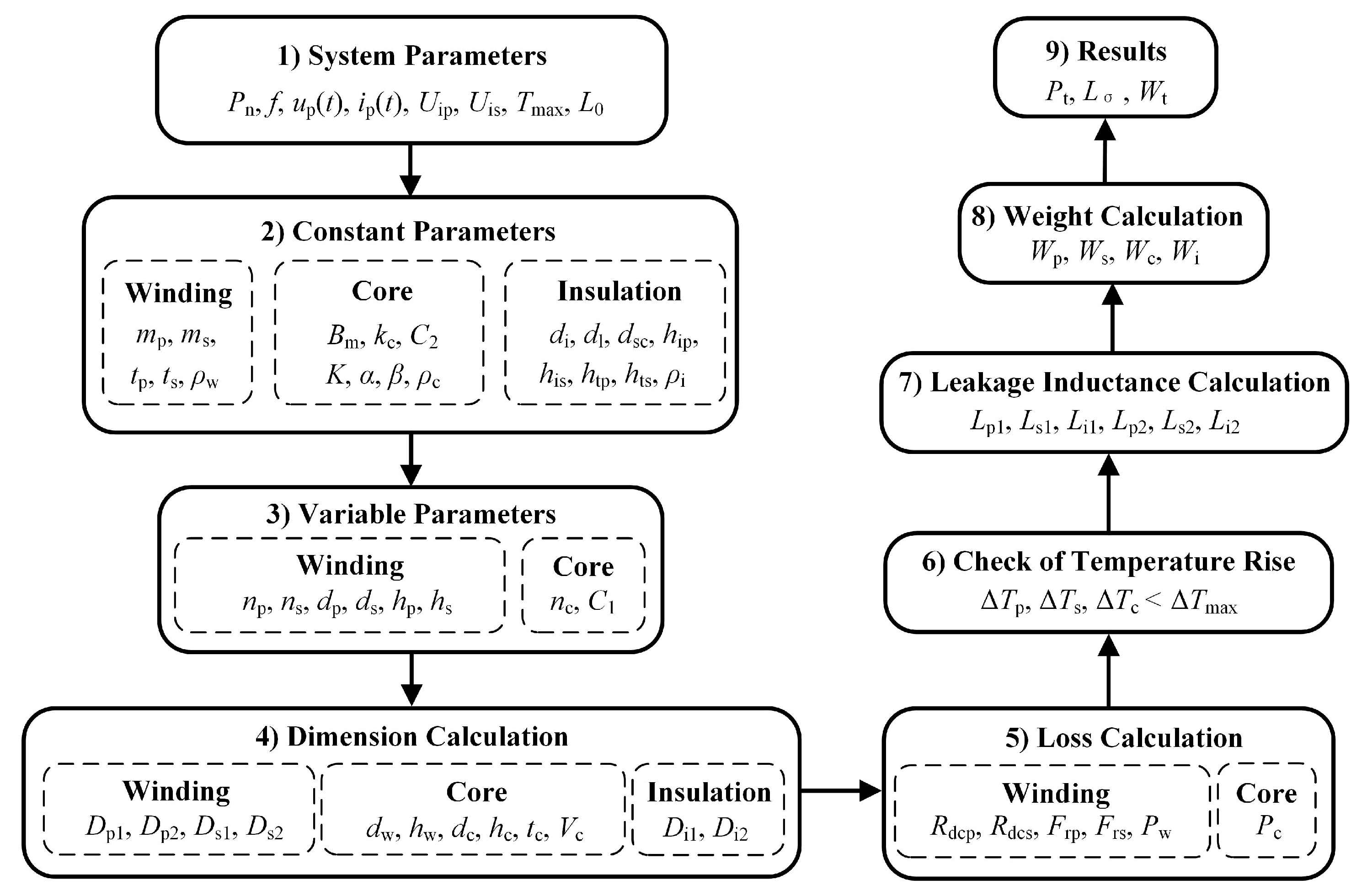

3. Design Process

3.1. Constant Parameters

3.1.1. Constant Parameters of the Winding

3.1.2. Constant Parameters of the Core

3.1.3. Constant Parameters of the Insulation Distance

3.2. Variable Parameters

3.3. Dimensions Calculation

3.4. Loss Calculation

3.4.1. Winding Loss Calculation

3.4.2. Core Loss Calculation

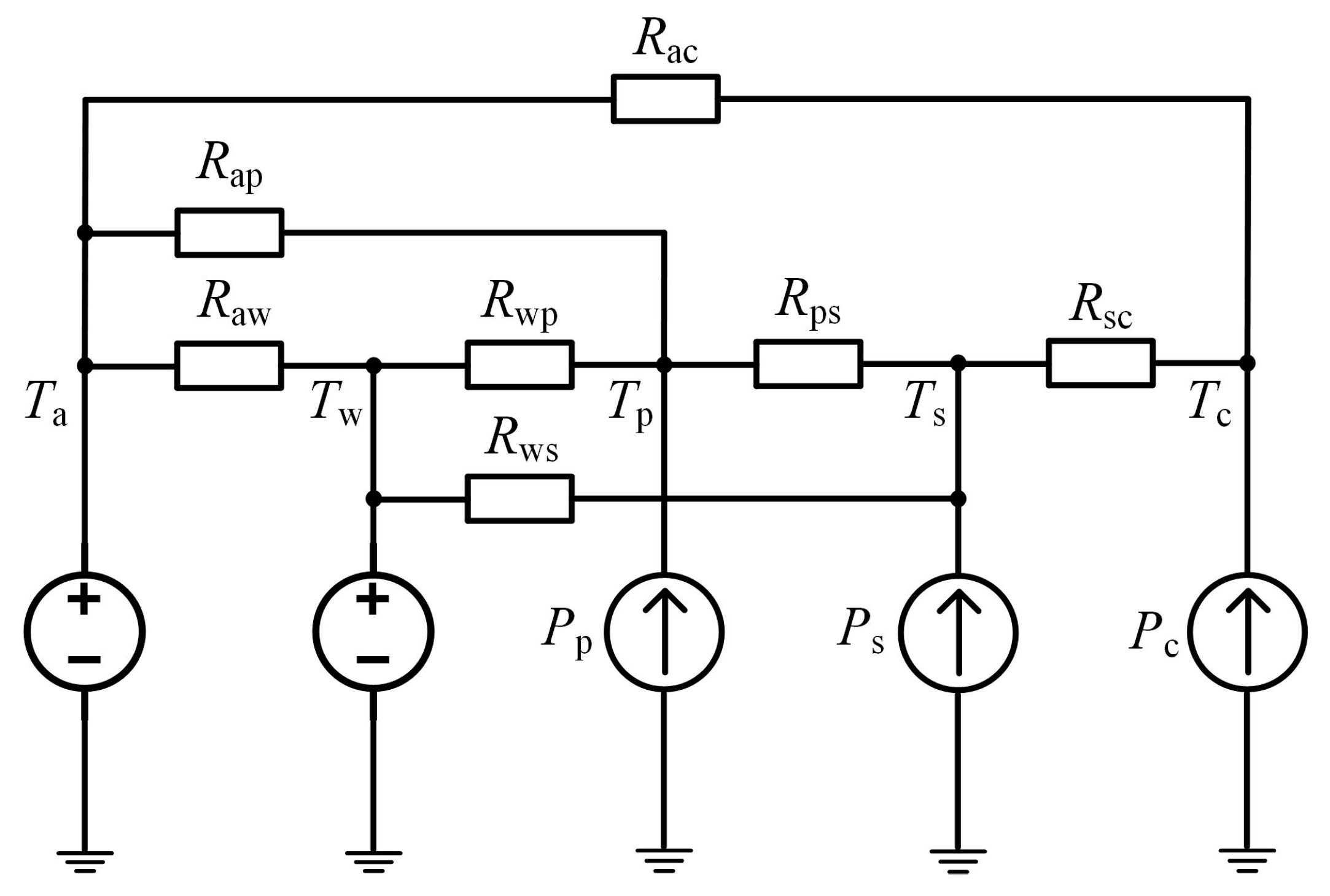

3.5. Check of Temperature Rise

3.6. Leakage Inductance Calculation

3.7. Weight Calculation

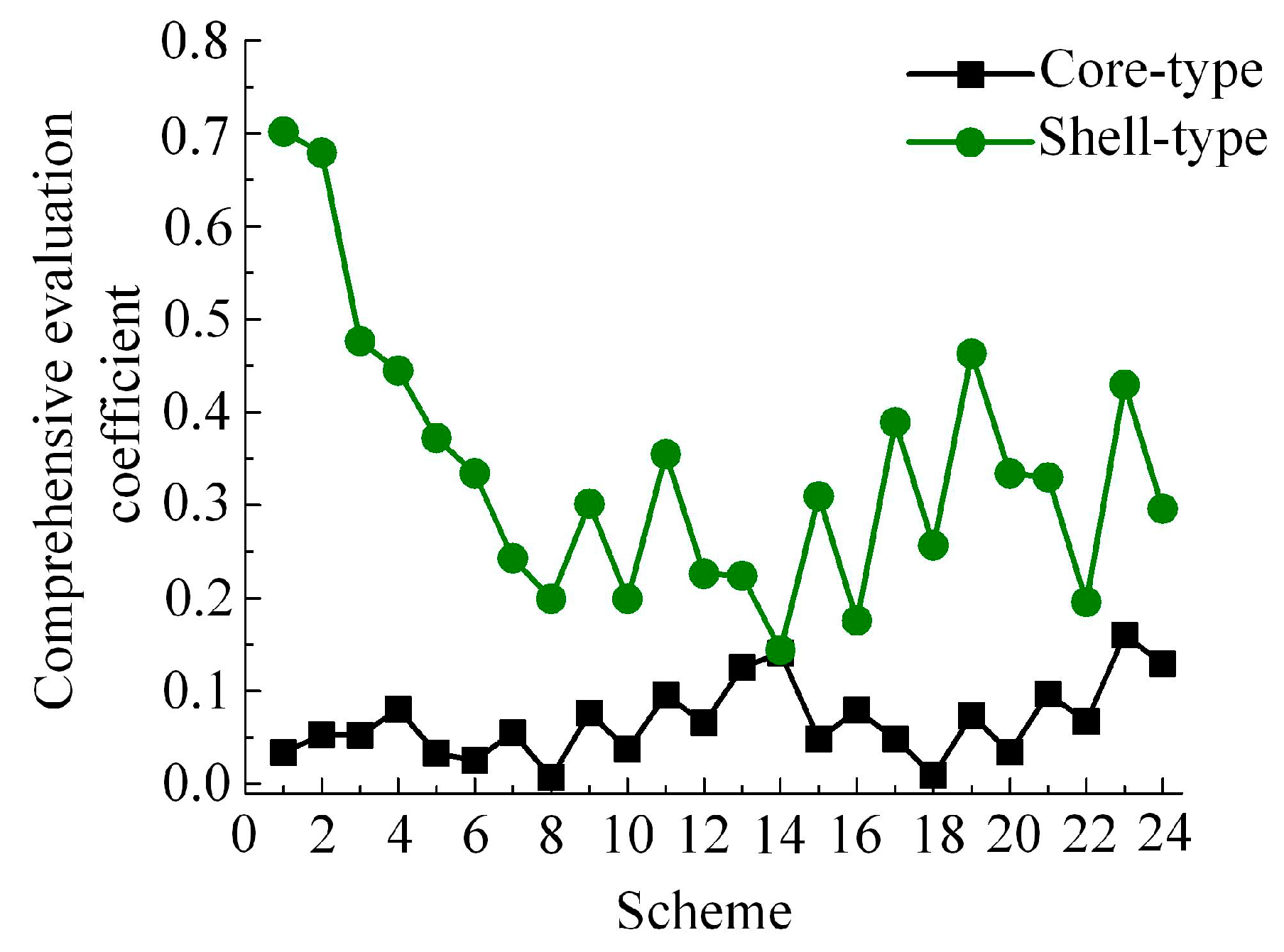

4. Design Results and Evaluation

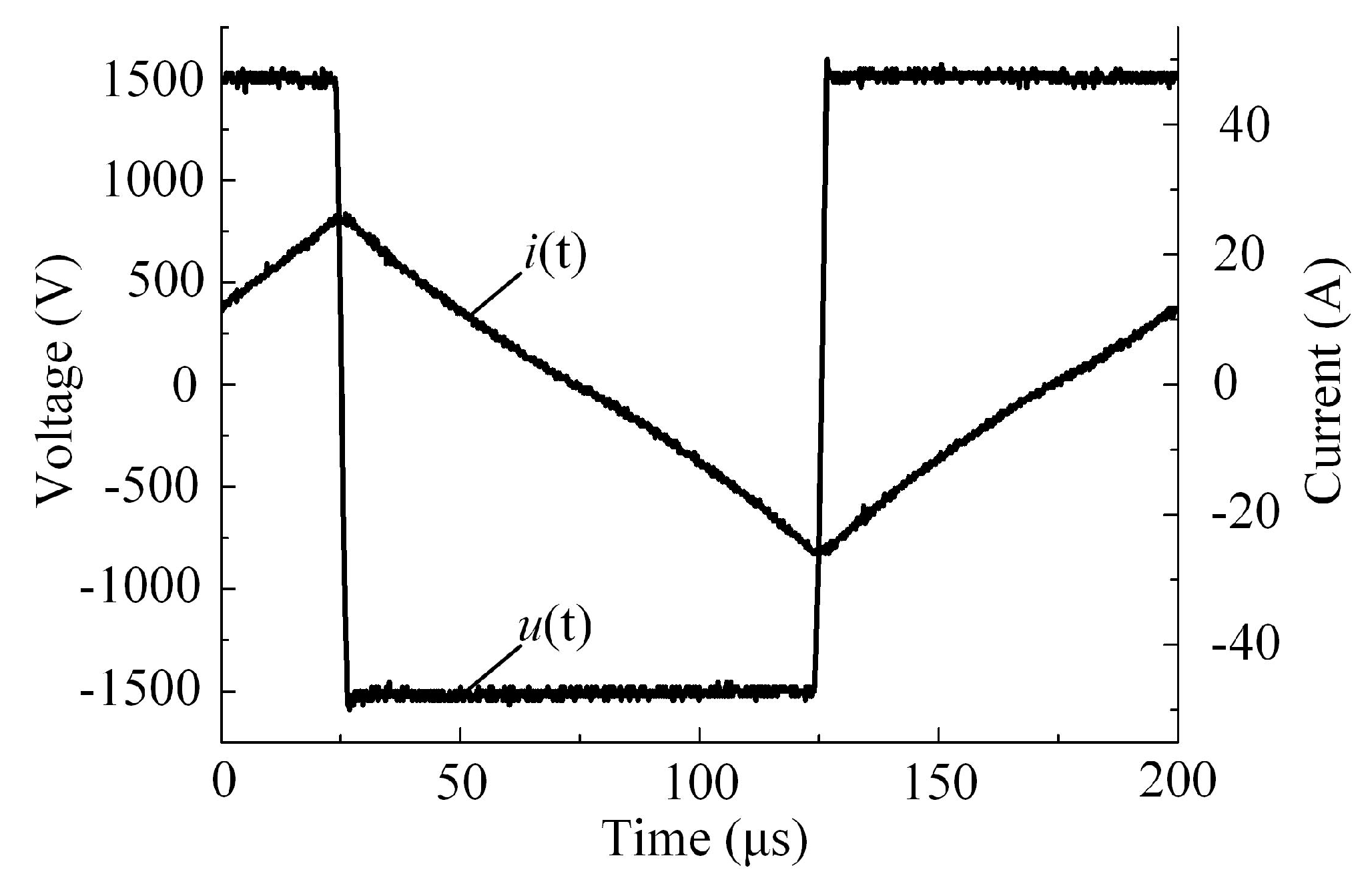

5. Experimental Validation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) | Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) | Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 14 | 2 | 60 | 12 | 10 | 9 | 10 | 3 | 55 | 12 | 10 | 17 | 10 | 4 | 40 | 12 | 10 |

| 2 | 14 | 2 | 60 | 10 | 8 | 10 | 10 | 3 | 55 | 10 | 8 | 18 | 10 | 4 | 40 | 10 | 8 |

| 3 | 14 | 3 | 40 | 12 | 10 | 11 | 9 | 3 | 60 | 12 | 10 | 19 | 9 | 4 | 45 | 12 | 10 |

| 4 | 14 | 3 | 40 | 10 | 8 | 12 | 9 | 3 | 60 | 10 | 8 | 20 | 9 | 4 | 45 | 10 | 8 |

| 5 | 12 | 3 | 45 | 12 | 10 | 13 | 14 | 4 | 30 | 12 | 10 | 21 | 8 | 4 | 50 | 12 | 10 |

| 6 | 12 | 3 | 45 | 10 | 8 | 14 | 14 | 4 | 30 | 10 | 8 | 22 | 8 | 4 | 50 | 10 | 8 |

| 7 | 11 | 3 | 50 | 12 | 10 | 15 | 12 | 4 | 35 | 12 | 10 | 23 | 7 | 4 | 60 | 12 | 10 |

| 8 | 11 | 3 | 50 | 10 | 8 | 16 | 12 | 4 | 35 | 10 | 8 | 24 | 7 | 4 | 60 | 10 | 8 |

| Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) | Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) | Scheme | np | nc | C1 (mm) | dp (mm) | ds (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 14 | 1 | 60 | 12 | 10 | 9 | 9 | 2 | 45 | 12 | 10 | 17 | 7 | 3 | 40 | 12 | 10 |

| 2 | 14 | 1 | 60 | 10 | 8 | 10 | 9 | 2 | 45 | 10 | 8 | 18 | 7 | 3 | 40 | 10 | 8 |

| 3 | 14 | 2 | 30 | 12 | 10 | 11 | 8 | 2 | 50 | 12 | 10 | 19 | 6 | 3 | 45 | 12 | 10 |

| 4 | 14 | 2 | 30 | 10 | 8 | 12 | 8 | 2 | 50 | 10 | 8 | 20 | 6 | 3 | 45 | 10 | 8 |

| 5 | 12 | 2 | 35 | 12 | 10 | 13 | 9 | 3 | 30 | 12 | 10 | 21 | 7 | 4 | 30 | 12 | 10 |

| 6 | 12 | 2 | 35 | 10 | 8 | 14 | 9 | 3 | 30 | 10 | 8 | 22 | 7 | 4 | 30 | 10 | 8 |

| 7 | 10 | 2 | 40 | 12 | 10 | 15 | 8 | 3 | 35 | 12 | 10 | 23 | 6 | 4 | 35 | 12 | 10 |

| 8 | 10 | 2 | 40 | 10 | 8 | 16 | 8 | 3 | 35 | 10 | 8 | 24 | 6 | 4 | 35 | 10 | 8 |

Appendix B

| Symbol | Equation | Symbol | Equation |

|---|---|---|---|

| Dp1 | Di1 + 4(dp + di) | dc | dw + 2C1 |

| Dp2 | Di1 + 4(dp + di) | hc | hw + 2C1 |

| Ds1 | 2(C1 + ncC2 + 2ds + 4dsc) | tc | ncC2 |

| Ds2 | 2(C1 + ncC2 + 2ds + 4dsc) | Vc | (dchc − dwhw)tc |

| dw | 2(dp + ds + di + dsc) + dl | Di1 | Ds1 + 4(ds + di) |

| hw | nshs + (ns − 1) hts + 2his | Di2 | Ds1 + 4(ds + di) |

| Dp1 | Di1 + 4(dp+di) | dc | dw + 2C1 |

| Dp2 | Di1 + 4(dp + di) | hc | hw + 2C1 |

| Symbol | Equation | Symbol | Equation |

|---|---|---|---|

| Dp1 | Di1 + 4(dp + di) | dc | dw + 2C1 |

| Dp2 | Dp1 + 8(dp + dl) | hc | hw + 2C1 |

| Ds1 | 2(2C1 + ncC2 + 2ds + 4dsc) | tc | ncC2 |

| Ds2 | Di2 + 4(ds + di) | Vc | 2(dchc − dwhw)tc |

| dw | 2(dp + ds + di + dsc) + dl | Di1 | Ds1 + 4(ds + di) |

| hw | nshs + (ns − 1)hts + 2his | Di2 | Dp2 + 4(dp + di) |

| Dp1 | Di1 + 4(dp + di) | dc | dw + 2C1 |

| Dp2 | Dp1 + 8(dp + dl) | hc | hw + 2C1 |

References

- Shamshuddin, M.A.; Rojas, F.; Cardenas, R.; Pereda, J.; Diaz, M.; Kennel, R. Solid State Transformers: Concepts, Classification, and Control. Energies 2020, 13, 2319. [Google Scholar] [CrossRef]

- Huber, J.E.; Kolar, J.W. Applicability of Solid-State Transformers in Today’s and Future Distribution Grids. IEEE Trans. Smart Grid 2017, 10, 317–326. [Google Scholar] [CrossRef]

- Duan, Q.; Ma, C.; Sha, G.; Zhao, C.; Li, Z. Research on flexible power distribution unit and its key technologies for energy internet. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 2660–2665. [Google Scholar]

- Bahmani, M.A.; Thiringer, T.; Rabiei, A.; Abdulahovic, T. Comparative Study of a Multi-MW High-Power Density DC Transformer with an Optimized High-Frequency Magnetics in All-DC Offshore Wind Farm. IEEE Trans. Power Deliv. 2016, 31, 857–866. [Google Scholar] [CrossRef]

- Feng, J.; Chu, W.Q.; Zhang, Z.; Zhu, Z.Q. Power Electronic Transformer-Based Railway Traction Systems: Challenges and Opportunities. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 1237–1253. [Google Scholar] [CrossRef]

- Villar, I.; Mir, L.; Etxeberria-Otadui, I.; Colmenero, J.; Agirre, X.; Nieva, T. Optimal Design and Experimental Validation of a Medium-Frequency 400kVA Power Transformer for Railway Traction Applications. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 684–690. [Google Scholar]

- Hannan, M.; Ker, P.J.; Lipu, M.S.H.; Choi, Z.H.; Rahman, M.S.A.; Muttaqi, K.M.; Blaabjerg, F. State of the Art of Solid-State Transformers: Advanced Topologies, Implementation Issues, Recent Progress and Improvements. IEEE Access 2020, 8, 19113–19132. [Google Scholar] [CrossRef]

- Lü, F.; Li, D.; Guo, Y.; Fu, C.; Wang, H. Optimal design of compact main insulation structure of PETT. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 303–306. [Google Scholar]

- Yue, Q.; Li, C.; Cao, Y.; He, Y.; Cai, B.; Wu, Q.; Zhou, B. Comprehensive Power Losses Model for Electronic Power Transformer. IEEE Access 2018, 6, 14926–14934. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, J.; Zhu, L. Accurate Calculation of Eddy Current Loss in Litz-Wired High-Frequency Transformer Windings. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Chen, B.; Li, L. Semi-Empirical Model for Precise Analysis of Copper Losses in High-Frequency Transformers. IEEE Access 2018, 6, 3655–3667. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Griffo, A.; Spagnolo, A. Thermal Modeling of Hollow Conductors for Direct Cooling of Electrical Machines. IEEE Trans. Ind. Electron. 2020, 67, 895–905. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Islam, R.; Lei, G.; Liu, C.; Zhu, J. Comparison of electromagnetic performances of amorphous and nanocrystalline core-based high frequency transformers. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS); Institute of Electrical and Electronics Engineers (IEEE), Hangzhou, China, 22–25 October 2014; pp. 2028–2032. [Google Scholar]

- Villar, I.; Viscarret, U.; Etxeberria-Otadui, I.; Rufer, A. Global Loss Evaluation Methods for Nonsinusoidally Fed Medium-Frequency Power Transformers. IEEE Trans. Ind. Electron. 2009, 56, 4132–4140. [Google Scholar] [CrossRef]

- Shen, W.; Wang, F.; Boroyevich, D.; Tipton, C. Loss Characterization and Calculation of Nanocrystalline Cores for High-Frequency Magnetics Applications. IEEE Trans. Power Electron. 2008, 23, 475–484. [Google Scholar] [CrossRef]

- Garcia-Bediaga, A.; Villar, I.; Rujas, A.; Mir, L.; Rufer, A. Multiobjective Optimization of Medium-Frequency Transformers for Isolated Soft-Switching Converters using a Genetic Algorithm. IEEE Trans. Power Electron. 2016, 32, 1. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Q.; Qin, D.; Cheng, K.; Li, Z. Power Control of a Modular Three-Port Solid-State Transformer With Three-Phase Unbalance Regulation Capabilities. IEEE Access 2020, 8, 72859–72869. [Google Scholar] [CrossRef]

- Huang, P.; Mao, C.; Wang, D.; Wang, L.; Duan, Y.; Qiu, J.; Xu, G.; Cai, H. Optimal Design and Implementation of High-Voltage High-Power Silicon Steel Core Medium-Frequency Transformer. IEEE Trans. Ind. Electron. 2017, 64, 4391–4401. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D.; Shui, H.; Yuan, Y.; Pei, Q.; Zhu, J. Optimisation design of medium frequency transformer for the offshore dc grid based on multi-objective genetic algorithm. IET Power Electron. 2017, 10, 2157–2162. [Google Scholar] [CrossRef]

- Drofenik, U. A 150kW Medium Frequency Transformer Optimized for Maximum Power Density. In Proceedings of the 2012 7th International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012; pp. 1–6. [Google Scholar]

- Du, Y.; Baek, S.; Bhattacharya, S.; Huang, A.Q. High-voltage high-frequency transformer design for a 7.2kV to 120V/240V 20kVA solid state transformer. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 493–498. [Google Scholar]

- Du, S.B.Y.; Wang, G.; Bhattacharya, S. Design considerations of high voltage and high frequency transformer for solid state transformer application. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 421–426. [Google Scholar]

- Lü, F.; Guo, Y.; Wang, Y.; Yu, D.; Li, P. AC resistance calculation method for hollow conductor windings in high power medium frequency transformers. Proc. CSEE 2016, 23, 6552–6559. [Google Scholar]

- Steinmetz, C. On the law of hysteresis. Proc. IEEE 1984, 72, 196–221. [Google Scholar] [CrossRef]

- Dowell, P. Effects of eddy currents in transformer windings. Proc. Inst. Electr. Eng. 1966, 8, 1387–1394. [Google Scholar] [CrossRef]

| Description | Symbol | Value |

|---|---|---|

| rated output | Pn | 300 kW |

| frequency | f | 5 kHz |

| voltage amplitude of primary winding | Upm | 1.5 kV |

| insulation voltage of primary winding | Uip | 27.5 kV |

| insulation voltage of secondary winding | Uis | 1.7 kV |

| turn ratio | k | 1:1 |

| maximum temperature rise | ΔTmax | 70 °C |

| expected leakage inductance | L0 | 12 μH |

| Region | Symbol | Equation |

|---|---|---|

| first layer of the primary winding | Lp1 | |

| first layer of the secondary winding | Ls1 | |

| insulation area between the first layer of the winding | Li1 | |

| second layer of the primary winding | Lp2 | |

| second layer of the secondary winding | Ls2 | |

| insulation area between the second layer of the winding | Li2 | |

| first layer of the primary winding | Lp1 | |

| first layer of the secondary winding | Ls1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Lu, C.; Hua, L.; Zhang, X. Optimal Design of High-Power Medium-Frequency Transformer Using Hollow Conductors with Consideration of Multi-Objective Parameters. Energies 2020, 13, 3654. https://doi.org/10.3390/en13143654

Guo Y, Lu C, Hua L, Zhang X. Optimal Design of High-Power Medium-Frequency Transformer Using Hollow Conductors with Consideration of Multi-Objective Parameters. Energies. 2020; 13(14):3654. https://doi.org/10.3390/en13143654

Chicago/Turabian StyleGuo, Yunxiang, Cheng Lu, Liang Hua, and Xinsong Zhang. 2020. "Optimal Design of High-Power Medium-Frequency Transformer Using Hollow Conductors with Consideration of Multi-Objective Parameters" Energies 13, no. 14: 3654. https://doi.org/10.3390/en13143654

APA StyleGuo, Y., Lu, C., Hua, L., & Zhang, X. (2020). Optimal Design of High-Power Medium-Frequency Transformer Using Hollow Conductors with Consideration of Multi-Objective Parameters. Energies, 13(14), 3654. https://doi.org/10.3390/en13143654