Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value

Abstract

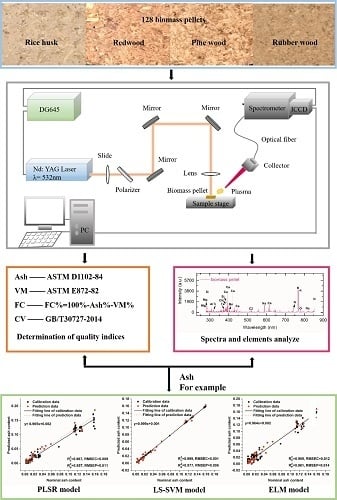

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Determination of Quality Indexes

2.3. Experimental Apparatus and LIBS Measurement

2.4. Data Pretreatment and Analyze

2.5. Chemometrics for Data Analyze

3. Results and Discussion

3.1. Quality Indexes Statistics

3.2. Spectral Analysis

3.3. Prediction of Quality Indexes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Keles, S.; Kar, T.; Bahadır, A.; Kaygusuz, K. Renewable energy from woody biomass in Turkey. J. Eng. Res. Appl. Sci. 2017, 6, 652–661. [Google Scholar]

- David, E.; Kopac, J.; Armeanu, A.; Niculescu, V.; Sandru, C.; Badescu, V. Biomass—Alternative renewable energy source and its conversion for hydrogen rich gas production. E3S Web Conf. 2019, 122, 01001. [Google Scholar] [CrossRef]

- Kaygusuz, K.; Toksoy, D.; Bayramoğlu, M.M. Global utilization of wood pellet for residential heating. J. Eng. Res. Appl. Sci. 2017, 6, 688–697. [Google Scholar]

- Kiss, I.; Alexa, V.; Sárosi, J. Biomass from Wood Processing Industries as an Economically Viable and Environmentally Friendly Solution. Analecta Tech. Szeged. 2016, 10, 1–6. [Google Scholar] [CrossRef]

- Feng, X.; Yu, C.; Liu, X.; Chen, Y.; Zhen, H.; Sheng, K.; He, Y. Nondestructive and rapid determination of lignocellulose components of biofuel pellet using online hyperspectral imaging system. Biotechnol. Biofuels 2018, 11, 88. [Google Scholar] [CrossRef]

- Nazari, M.M.; San, C.P.; Atan, N.A. Combustion Performance of Biomass Composite Briquette from Rice Husk and Banana Residue. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 455–460. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Sandoval-Salas, F.; Soreanu, G.; Valverde, J.L.; Silva, M.L.S. Valorization of Mexican biomasses through pyrolysis, combustion and gasification processes. Renew. Sustain. Energy Rev. 2017, 71, 509–522. [Google Scholar] [CrossRef]

- Li, J.; Paul, M.C.; Younger, P.; Watson, I.; Hossain, M.; Welch, S. Prediction of high-temperature rapid combustion behaviour of woody biomass particles. Fuel 2016, 165, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Oladejo, J.; Adegbite, S.; Gao, X.; Liu, H.; Wu, T. Catalytic and non-catalytic synergistic effects and their individual contributions to improved combustion performance of coal/biomass blends. Appl. Energy 2018, 211, 334–345. [Google Scholar] [CrossRef]

- Sarikaya, A.C.; Acma, H.H.; Yaman, S.; Sarikaya, A.C.; Haykiri-Acma, H.; Serdar, Y. Synergistic Interactions During Cocombustion of Lignite, Biomass, and Their Chars. J. Energy Resour. Technol. 2019, 141, 12. [Google Scholar] [CrossRef]

- Estiati, I.; Freire, F.B.; Freire, J.T.; Aguado, R.; Olazar, M. Fitting performance of artificial neural networks and empirical correlations to estimate higher heating values of biomass. Fuel 2016, 180, 377–383. [Google Scholar] [CrossRef]

- Feng, X.; Yu, C.; Shu, Z.; Liu, X.; Yan, W.; Zheng, Q.; Sheng, K.; He, Y. Rapid and non-destructive measurement of biofuel pellet quality indices based on two-dimensional near infrared spectroscopic imaging. Fuel 2018, 228, 197–205. [Google Scholar] [CrossRef]

- De Oliveira, D.M.; Fontes, L.M.; Pasquini, C. Comparing laser induced breakdown spectroscopy, near infrared spectroscopy, and their integration for simultaneous multi-elemental determination of micro- and macronutrients in vegetable samples. Anal. Chim. Acta 2019, 1062, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Moncayo, S.; Manzoor, S.; Rosales, J.; Anzano, J.; Cáceres, J. Qualitative and quantitative analysis of milk for the detection of adulteration by Laser Induced Breakdown Spectroscopy (LIBS). Food Chem. 2017, 232, 322–328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gondal, M.; Habibullah, Y.; Baig, U.; Oloore, L. Direct spectral analysis of tea samples using 266 nm UV pulsed laser-induced breakdown spectroscopy and cross validation of LIBS results with ICP-MS. Talanta 2016, 152, 341–352. [Google Scholar] [CrossRef]

- Peng, J.; He, Y.; Jiang, J.; Zhao, Z.; Zhou, F.; Liu, F. High-accuracy and fast determination of chromium content in rice leaves based on collinear dual-pulse laser-induced breakdown spectroscopy and chemometric methods. Food Chem. 2019, 295, 327–333. [Google Scholar] [CrossRef]

- Sun, C.; Tian, Y.; Gao, L.; Niu, Y.-S.; Zhang, T.; Li, H.; Zhang, Y.; Yue, Z.; Delepine-Gilon, N.; Yu, J. Machine Learning Allows Calibration Models to Predict Trace Element Concentration in Soils with Generalized LIBS Spectra. Sci. Rep. 2019, 9, 1–18. [Google Scholar] [CrossRef]

- Bonta, M.; Quarles, C.D.; Russo, R.; Gonzalez, J.J.; Hegedus, B.; Limbeck, A. Elemental mapping of biological samples by the combined use of LIBS and LA-ICP-MS. J. Anal. At. Spectrom. 2016, 31, 252–258. [Google Scholar] [CrossRef]

- Cui, M.; Deguchi, Y.; Wang, Z.; Tanaka, S.; Fujita, Y.; Zhao, S. Improved Analysis of Manganese in Steel Samples Using Collinear Long-Short Double Pulse Laser-Induced Breakdown Spectroscopy (LIBS). Appl. Spectrosc. 2018, 73, 152–162. [Google Scholar] [CrossRef]

- Li, W.; Lu, J.; Dong, M.; Lu, S.; Yu, J.; Li, S.; Huang, J.; Liu, J. Quantitative Analysis of Calorific Value of Coal Based on Spectral Preprocessing by Laser-Induced Breakdown Spectroscopy (LIBS). Energy Fuels 2017, 32, 24–32. [Google Scholar] [CrossRef]

- Yao, S.; Mo, J.; Zhao, J.; Li, Y.; Zhang, X.; Lu, W.; Lu, Z. Development of a Rapid Coal Analyzer Using Laser-Induced Breakdown Spectroscopy (LIBS). Appl. Spectrosc. 2018, 72, 1225–1233. [Google Scholar] [CrossRef] [PubMed]

- Dong, M.; Wei, L.; Lu, J.; Li, W.; Lu, S.; Li, S.; Liu, C.; Yoo, J.H.; Li, W. A comparative model combining carbon atomic and molecular emissions based on partial least squares and support vector regression correction for carbon analysis in coal using LIBS. J. Anal. At. Spectrom. 2019, 34, 480–488. [Google Scholar] [CrossRef]

- Aints, M.; Paris, P.; Tufail, I.; Jõgi, I.; Aosaar, H.; Riisalu, H.; Laan, M. Determination of the calorific value and moisture content of crushed oil shale by libs. Oil Shale 2018, 35, 339. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.; Yao, S.; Qin, H.; Zhang, L.; Yao, X.; Yu, Z.; Lu, J. Feasibility study of gross calorific value, carbon content, volatile matter content and ash content of solid biomass fuel using laser-induced breakdown spectroscopy. Fuel 2019, 258, 116150. [Google Scholar] [CrossRef]

- Galvão, R.K.H.; De Araújo, M.C.U.; José, G.E.; Pontes, M.J.; Silva, E.C.; Saldanha, T.C.B. A method for calibration and validation subset partitioning. Talanta 2005, 67, 736–740. [Google Scholar] [CrossRef]

- Yan, W.; Perez, S.; Sheng, K. Upgrading fuel quality of moso bamboo via low temperature thermochemical treatments: Dry torrefaction and hydrothermal carbonization. Fuel 2017, 196, 473–480. [Google Scholar] [CrossRef]

- Liu, X.; Feng, X.; Liu, F.; Peng, J.; He, Y. Rapid Identification of Genetically Modified Maize Using Laser-Induced Breakdown Spectroscopy. Food Bioprocess Technol. 2018, 12, 347–357. [Google Scholar] [CrossRef]

- Guo, G.; Niu, G.; Shi, Q.; Lin, Q.; Tian, D.; Duan, Y. Multi-element quantitative analysis of soils by laser induced breakdown spectroscopy (LIBS) coupled with univariate and multivariate regression methods. Anal. Methods 2019, 11, 3006–3013. [Google Scholar] [CrossRef]

- Xiao, S.; He, Y. Application of Near-infrared Spectroscopy and Multiple Spectral Algorithms to Explore the Effect of Soil Particle Sizes on Soil Nitrogen Detection. Molecules 2019, 24, 2486. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Jiang, H.; Liu, F.; He, Y. Application of Near-Infrared Hyperspectral Imaging with Variable Selection Methods to Determine and Visualize Caffeine Content of Coffee Beans. Food Bioprocess Technol. 2016, 10, 213–221. [Google Scholar] [CrossRef]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Martín, M.; Hernández, O.; Jiménez, A.; Arias, J.; Jiménez, F. Partial least-squares method in analysis by differential pulse polarography. Simultaneous determination of amiloride and hydrochlorothiazide in pharmaceutical preparations. Anal. Chim. Acta 1999, 381, 247–256. [Google Scholar] [CrossRef]

- Sjöström, M.; Wold, S.; Lindberg, W.; Persson, J.-Å.; Martens, H. A multivariate calibration problem in analytical chemistry solved by partial least-squares models in latent variables. Anal. Chim. Acta 1983, 150, 61–70. [Google Scholar] [CrossRef]

- Rapid Identification of Varieties of Walnut Powder Based on Laser-Induced Breakdown Spectroscopy. Trans. ASABE 2017, 60, 19–28. [CrossRef]

- Morellos, A.; Pantazi, X.E.; Moshou, D.; Alexandridis, T.; Whetton, R.; Tziotzios, G.; Wiebensohn, J.; Bill, R.; Mouazen, A.M. Machine learning based prediction of soil total nitrogen, organic carbon and moisture content by using VIS-NIR spectroscopy. Biosyst. Eng. 2016, 152, 104–116. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Yang, J.; Ma, J. Sparse Least Squares Support Vector Machine With Adaptive Kernel Parameters. Int. J. Comput. Intell. Syst. 2020, 13, 212–222. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y.; Liu, F.; Kong, W.; Sun, D.; He, Y.; Qiu, Z. Measurement of Soluble Solid Contents and pH of White Vinegars Using VIS/NIR Spectroscopy and Least Squares Support Vector Machine. Food Bioprocess Technol. 2013, 7, 54–61. [Google Scholar] [CrossRef]

- Wang, H.-Q.; Sun, F.; Cai, Y.-N.; Ding, L.-G.; Chen, N. An unbiased LSSVM model for classification and regression. Soft Comput. 2009, 14, 171–180. [Google Scholar] [CrossRef]

- He, Y.; Liu, X.; Lv, Y.; Liu, F.; Peng, J.; Shen, T.; Zhao, Y.; Tang, Y.; Luo, S. Quantitative Analysis of Nutrient Elements in Soil Using Single and Double-Pulse Laser-Induced Breakdown Spectroscopy. Sensors 2018, 18, 1526. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.S.; Wang, R.J.; Lu, C.P.; Wang, J.; Huang, W.; Jian, Q.; Wang, Y.B.; Lin, L.Z.; Song, L.T. Quantitative Analysis of Total Nitrogen Content in Monoammonium Phosphate Fertilizer Using Visible-Near Infrared Spectroscopy and Least Squares Support Vector Machine. J. Appl. Spectrosc. 2019, 86, 465–469. [Google Scholar] [CrossRef]

- Boukhari, Y.; Boucherit, M.N.; Zaabat, M.; Amzert, S.; Brahimi, K. Optimization of learning algorithms in the prediction of pitting corrosion. J. Eng. Sci. Technol. 2018, 13, 1153–1164. [Google Scholar]

- Liu, F.; Wang, W.; Shen, T.; Peng, J.; Kong, W. Rapid Identification of Kudzu Powder of Different Origins Using Laser-Induced Breakdown Spectroscopy. Sensors 2019, 19, 1453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, G.-B.; Zhou, H.; Ding, X.; Zhang, R. Extreme Learning Machine for Regression and Multiclass Classification. IEEE Trans. Syst. Man Cybern. Part B 2011, 42, 513–529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, Y.; Yan, F.; Yang, G.; Chen, H.; Song, Z. Quantitative analysis of sinters using laser-induced breakdown spectroscopy (LIBS) coupled with kernel-based extreme learning machine (K-ELM). Anal. Methods 2018, 10, 1074–1079. [Google Scholar] [CrossRef]

- Bian, X.; Fan, M.-R.; Guo, Y.; Wang, J.-J.; Li, S.-J.; Chang, N. Spectral quantitative analysis of complex samples based on the extreme learning machine. Anal. Methods 2016, 8, 4674–4679. [Google Scholar] [CrossRef]

- Abuassba, A.O.M.; Zhang, D.; Luo, X.; Shaheryar, A.; Ali, H. Improving Classification Performance through an Advanced Ensemble Based Heterogeneous Extreme Learning Machines. Comput. Intell. Neurosci. 2017, 2017, 1–11. [Google Scholar] [CrossRef]

- Gillespie, G.; Everard, C.D.; McDonnell, K. Prediction of biomass pellet quality indices using near infrared spectroscopy. Energy 2015, 80, 582–588. [Google Scholar] [CrossRef]

- Singh, S.; Ram, L.C.; Masto, R.E.; Verma, S.K. A comparative evaluation of minerals and trace elements in the ashes from lignite, coal refuse, and biomass fired power plants. Int. J. Coal Geol. 2011, 87, 112–120. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.-C.; Li, W.-Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Mlonka-Medrala, A.; Magdziarz, A.; Gajek, M.; Nowińska, K.; Nowak, W. Alkali metals association in biomass and their impact on ash melting behaviour. Fuel 2020, 261, 116421. [Google Scholar] [CrossRef]

- Ren, X.Y.; Cai, H.Z.; Chang, J.M.; Fan, Y.M. TG-FTIR Study on the Pyrolysis Properties of Lignin from Different Kinds of Woody Biomass. Paper Biomater. 2018, 3, 1–7. [Google Scholar]

- Li, R.; Konnov, A.A.; He, G.; Qin, F.; Zhang, D. Chemical mechanism development and reduction for combustion of NH3/H2/CH4 mixtures. Fuel 2019, 257, 116059. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Vassilev, V.S. Advantages and disadvantages of composition and properties of biomass in comparison with coal: An overview. Fuel 2015, 158, 330–350. [Google Scholar] [CrossRef]

- Zuo, Z.; Yu, Q.; Xie, H.; Duan, W.; Liu, S.; Qin, Q. Thermogravimetric analysis of the biomass pyrolysis with copper slag as heat carrier. J. Therm. Anal. Calorim. 2017, 129, 1233–1241. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, L.; Xu, J.; Yu, Z.; Lu, Z. Data Processing Method for the Measurement of Unburned Carbon in Fly Ash by PF-SIBS. Energy Fuels 2017, 31, 12093–12099. [Google Scholar] [CrossRef]

- Atan, N.A.; Nazari, M.M.; Azizan, F.A. Effect of torrefaction pre-treatment on physical and combustion characteristics of biomass composite briquette from rice husk and banana residue. MATEC Web Conf. 2018, 150, 06011. [Google Scholar] [CrossRef] [Green Version]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Kok, M.V.; Ozgur, E. Thermal analysis and kinetics of biomass samples. Fuel Process. Technol. 2013, 106, 739–743. [Google Scholar] [CrossRef]

- Dalólio, F.S.; Da Silva, J.N.; De Oliveira, A.C.C.; Ferreira-Tinôco, I.D.F.; Barbosa, R.C.; Resende, M.D.O.; Albino, L.F.T.; Coelho, S. Poultry litter as biomass energy: A review and future perspectives. Renew. Sustain. Energy Rev. 2017, 76, 941–949. [Google Scholar] [CrossRef]

| Quality Indexes | Maximum | Minimum | Mean | Standard Deviation |

|---|---|---|---|---|

| Ash content (%) | 15.94 | 0.26 | 4.43 | 5.10 |

| Volatile matter (%) | 88.99 | 74.96 | 80.22 | 2.71 |

| Fixed carbon (%) | 21.22 | 10.39 | 15.83 | 2.63 |

| Calorific value | 19.54 | 15.10 | 17.71 | 1.10 |

| Quality Indexes | Ash | VM | FC | CV |

|---|---|---|---|---|

| Ash | 1 | −0.923 ** | 0.292 ** | −0.903 ** |

| Volatile matter | −0.923 ** | 1 | −0.636 ** | 0.751 ** |

| Fixed carbon | 0.292 ** | −0.636 ** | 1 | −0.063 ns |

| Calorific value | −0.903 ** | 0.751 ** | −0.063 ns | 1 |

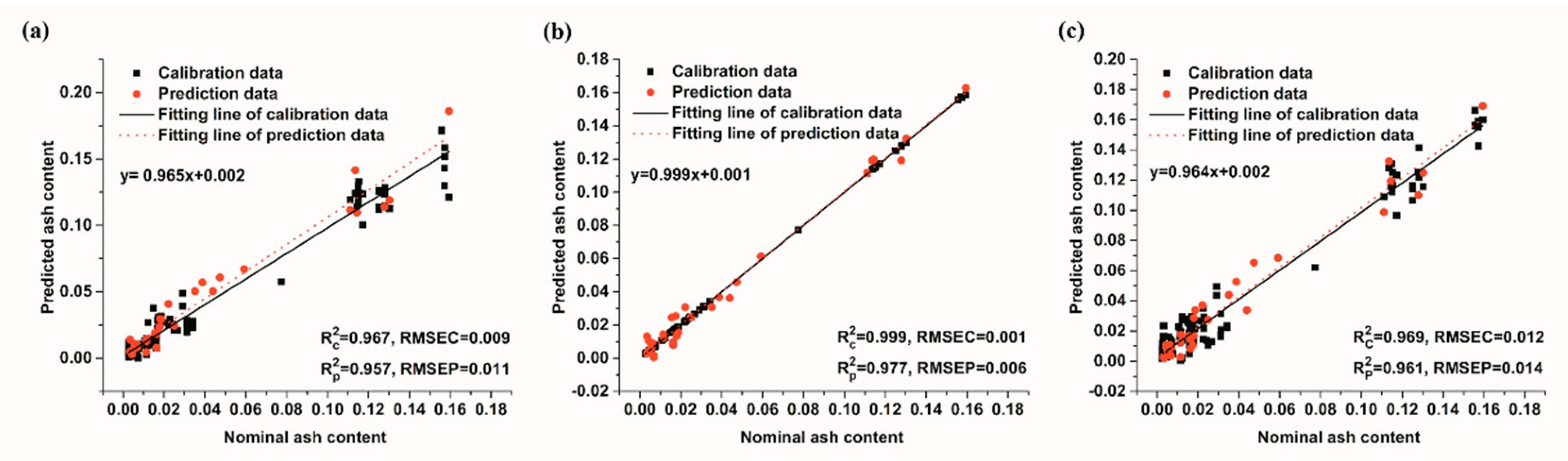

| Quality Indexes | Model | Parameter | R2C | RMSEC | R2P | RMSEP |

|---|---|---|---|---|---|---|

| PLSR | 6 | 0.967 | 0.009 | 0.957 | 0.011 | |

| Ash (wt.%) | LS-SVM | (4.377 × 105, 1 × 105) | 0.999 | 0.001 | 0.977 | 0.006 |

| ELM | 15 | 0.969 | 0.012 | 0.961 | 0.014 | |

| PLSR | 7 | 0.943 | 0.006 | 0.924 | 0.007 | |

| VM (wt.%) | LS-SVM | (3.375 × 104, 206) | 0.999 | 0.001 | 0.974 | 0.006 |

| ELM | 43 | 0.952 | 0.006 | 0.932 | 0.007 | |

| PLSR | 11 | 0.947 | 0.006 | 0.937 | 0.007 | |

| FC (wt.%) | LS-SVM | (2.133 × 104, 3.589 × 103) | 0.979 | 0.001 | 0.953 | 0.009 |

| ELM | 32 | 0.874 | 0.009 | 0.836 | 0.015 | |

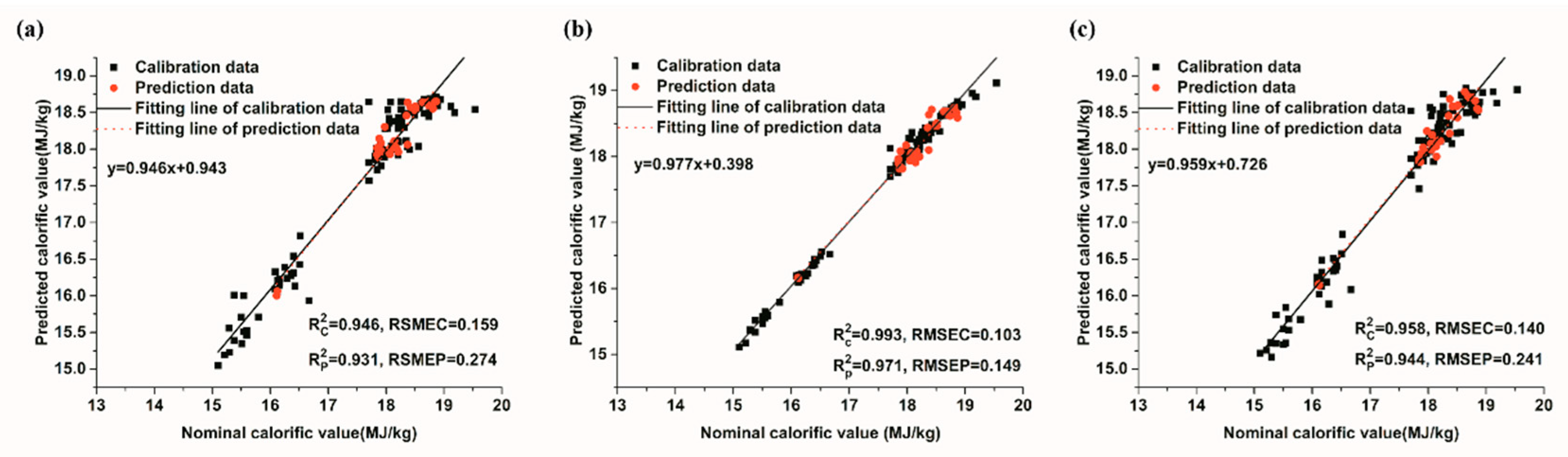

| PLSR | 4 | 0.946 | 0.159 | 0.931 | 0.274 | |

| CV (MJ·kg−1) | LS-SVM | (6.656 × 107, 6.349 × 104) | 0.993 | 0.103 | 0.971 | 0.149 |

| ELM | 18 | 0.958 | 0.140 | 0.944 | 0.241 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Feng, X.; Huang, L.; He, Y. Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value. Energies 2020, 13, 3741. https://doi.org/10.3390/en13143741

Liu X, Feng X, Huang L, He Y. Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value. Energies. 2020; 13(14):3741. https://doi.org/10.3390/en13143741

Chicago/Turabian StyleLiu, Xiaodan, Xuping Feng, Lingxia Huang, and Yong He. 2020. "Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value" Energies 13, no. 14: 3741. https://doi.org/10.3390/en13143741

APA StyleLiu, X., Feng, X., Huang, L., & He, Y. (2020). Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value. Energies, 13(14), 3741. https://doi.org/10.3390/en13143741