Maintenance Management through Intelligent Asset Management Platforms (IAMP). Emerging Factors, Key Impact Areas and Data Models

Abstract

1. Introduction

- The aggregate historical data of management, planning, and costs,

- The real-time status of equipment and its use, using alarms, thresholds and degradation patterns, and

- The predictions derived from reliability studies.

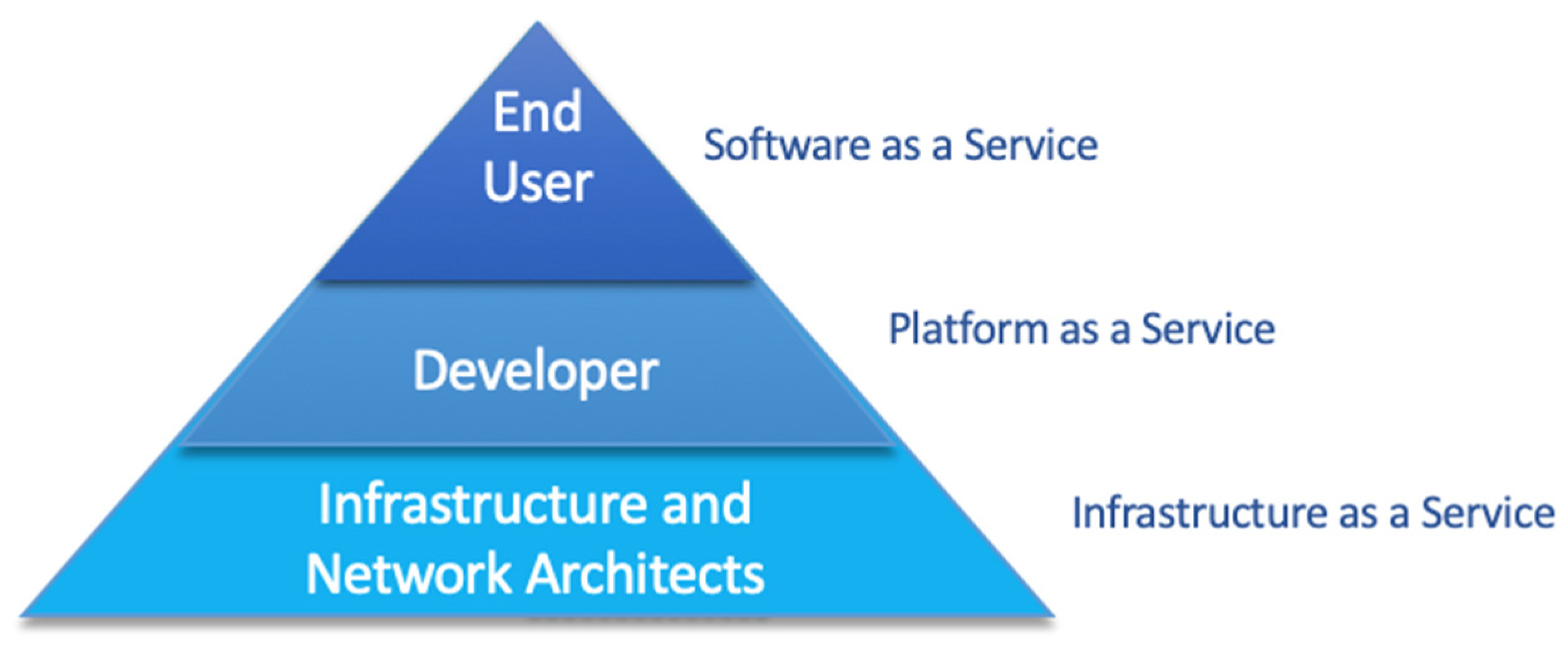

- Infrastructure as a service (IaaS): It is located at the lowest level of the pyramid and contains, among other capabilities, the operating systems, networks and storage.

- Platform as a service (PaaS): It is located at the medium level and includes services related to the development and implementation of applications.

- Software as a service (SaaS): It is located at the top of the pyramid and represents the applications (Apps) provided to end users.

- In the first level, the M number of modules can be found, each one referring to different domains within asset management. These modules are inter-dependent, in fact, their interrelation can be crucial. Examples of modules are: Reliability module, health module, strategy module, etc.

- In the second level, each module contains Apps that will have different purposes according to the scope of the specific decision-making process that they support. For instance, Apps will be found dealing with the hierarchy of assets, with the analysis of recurrent failures, with the design of the maintenance strategies, with the development of Condition-Based Maintenance (CBM) programs, with the assessment of the assets’ health, integrity and their life cycle cost, with the performance and analysis of the maintenance processes and activities, etc.

- Finally, in the third level, each application contains a data model. The data model serves to configure the databases where the relevant data for the Apps will be stored, with k-level scalability.

2. Factors Driving IAMP Market Growth

- The availability of the industrial IoT;

- New technologies (such as predictive maintenance analytics together with big data);

- Digital twin simulations.

2.1. The Availability of the “Internet of Things” (IoT) Technologies

- Device management: The platform should store a list of all connected devices with the corresponding operating status. In general, an IoT platform will have to manage thousands to millions of devices. To operate with low power consumption, you have to use light communication protocols.

- Data collection and storage: Storage of device data in the cloud is at a higher level in terms of data volume, variety and speed.

- Creation of virtual machines: The analysis (in real time, batch, predictive or interactive) of all the data from the sensors connected to the platform provides valuable information.

- Remote device configuration and control: Managing the configuration is essential to control the performance of the device.

- Reliability and data safety: The IoT platform must ensure reliability in the most demanding environments. The company’s most critical functions are at stake and the reliability of the platform has to be indisputable.

2.2. The Improvements in Big Data Management

- The company identified the data necessary to effectively analyze and manage critical assets, and

- The company specified the quality standards for the data. Data quality can be specified in terms of many attributes according to ISO 9000: 2015, including:

- ○

- Completeness (is all of the data to be collected, or only some of it);

- ○

- Accuracy (does the data accurately represent reality—particularly a concern when human data input is required);

- ○

- Timeliness (is the data available as and when required);

- ○

- Availability (is the data readily available to those using it);

- ○

- Consistency (are the same definitions and standards applied across the organization).

- Complex aggregation analysis: To process information obtained on different dates or in different locations;

- Multi-dimensional query and analysis: To analyze and extract asset data from different viewpoints;

- Log data analysis: To control the asset health during its operation;

- Time-window-based stream data analysis: To detect trends in operation;

- Complex event processing: To detect failures before they occur.

2.3. The Emerging Predictive Maintenance Analytics

- Baseline analytics is used to detect anomalies, and the data used is usually local to the asset itself when it operates under normal operating conditions.

- Diagnostic analytics provide very fast results and identify the root cause of the failure, so it requires a prior study of the different states of the failure.

- Prognostic analytics is generally used to calculate the remaining useful life of a component, requiring a multitude of input data and is not as fast as diagnostic analytics.

- Training a model for predictive analytics;

- Testing and validating the model with different data;

- Implementing the model in a real scenario.

2.4. Digital Twin Simulations

3. Key Managerial Areas to be Supported with the IAMPs

- Identify the requirements of all key stakeholders with respect to the provision of information.

- Identify the most critical assets and then select the information that must be taken into account that will lead to effective decision making. Finally, it is necessary to determine what data is needed to get this information. The necessary data could take many different forms, including:

- ○

- Data about the assets (themselves, current condition, current level of performance);

- ○

- Data relating to the activities that have been performed on the assets (operational activities, maintenance activities and modifications, upgrades or replacements);

- ○

- Data about the financial or other impacts if the assets underperform or fail to perform at all;

- ○

- Data relating to safety, environmental or other incidents;

- ○

- Data relating to expected future asset performance, costs and risks;

- ○

- Etc.

- Identifying the types of decisions that will have the greatest potential impact on the achievement of asset management (and organizational) objectives. The decisions can be made at many different organizational levels, including:

- ○

- Strategic Decisions—potentially those with the greatest potential business impact, capital investment and allocation of operating expenditure decisions. Moreover, those decisions for which objective data is most likely to be difficult to obtain and analyze.

- ○

- Management Decisions—such as to replace or upgrade an asset to meet specific business needs, about the timing of these major events, also those related to the allocation of working capital (such as for spare parts holdings), decisions relating to whether to insource or outsource particular activities.

- ○

- Operational Decisions—involved with short-term control of maintenance and operational activities, these are technical decisions relating to day-to-day operations.

4. Case Study. Analysis of an Industrial Vendor’s IAMP

5. A Methodology to Develop Proper Asset Data Models

6. Methodology Proof of Concept: Data Model for a Criticality Analysis App

- –

- It shows in Block 1 how a system is composed by one or more than one equipment units, which will be placed in specified functional locations and properly geo-referenced (data in this block), each one executing one or more functions.

- –

- In Block 2, for the Functional Description, each function may have different identified functional failures. Each function may have one or more functional failures and these failures will be caused by one or more maintainable items.

- –

- Block 3 depicts how when the functional failure occurs, the description of the effects of failure, history and frequency are recorded in a certain activity management system, and that data can be used later in Block 4.

- –

- In this particular example, the Block 4 AM decision-making analysis, refers only to the asset’s criticality analysis. For this kind of analysis, the contribution of each functional failure must be measured in terms of risk, which requires capturing the frequency of the failure on the one hand (deriving a Frequency Factor), and estimating the Severity of the failure on the other hand (deriving a Severity Factor). Frequency times severity results in a measure of failure risk, which must fit within the company risk objectives. Both parts have to be matched for each specific functional failure.

- –

- In Block 5, data for failures’ frequency and severity for a given equipment unit is transformed into a criticality value and then classified according to particular risk levels (company assets criticality levels: High, mid or low criticality). This makes easier the definition of actions, according to an existing Risk Strategy, to fulfil the company Risk Goals. In consequence, in Block 5, the decision-making process for each asset (equipment unit) is to determine the correspondent strategy to be applied to the asset in order to fulfill the company risk strategy, and also to make clear what is the priority for the execution of these asset strategies in a systematic way.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Birlasekaran, S.; Ledwich, G. Asset Management of Power Apparatus. In Engineering Asset Management; Mathew, J., Kennedy, J., Ma, L., Tan, A., Anderson, D., Eds.; Springer: London, UK, 2006. [Google Scholar] [CrossRef]

- Darvish Sarvestani, A.; Moazami Goodarzi, A.; Hadipour, A. Integrated asset management: A case study of technical and economic optimization of surface and well facilities. Pet. Sci. 2019, 16, 1221–1236. [Google Scholar] [CrossRef]

- Crespo, A.; Sola, A.; Moreu, P.; Gómez, J.F.; de la Fuente, A.; Guillén, A.; González-Prida, V. Criticality Analysis for improving maintenance, felling and pruning cycles in power lines. IFAC Pap. OnLine 2018, 51, 211–216. [Google Scholar] [CrossRef]

- Crespo Márquez, A.; Rosique, A.S.; Moreu de León, P.; Gómez Fernández, J.F.; Diego, A.G.; Fernández, E.C. Exploiting EAMS, GIS and Dispatching Systems Data for Criticality Analysis. In Value Based and Intelligent Asset Management; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Kolevski, G.; Gusev, M. Analysis of Cloud Solutions for Asset Management. In Conference: ICT Innovations 2010, Web Proceedings ISSN 1857-7288; Gusev, M., Ed.; Springer: Ohrid, Macedonian, 2010. [Google Scholar]

- Hamdaqa, M.; Tahvildari, L. Cloud Computing Uncovered: A Research Landscape. In Advances in Computers; Elsevier: Ontario, Canada, 2012. [Google Scholar] [CrossRef]

- Metcalfe, D.; Winter, S. Operational Risk Management Software Market Size and Forecast 2018–2038. 2018. Available online: https://research.verdantix.com/report/operational-risk-management-software-market-size-and-forecast-2018-2038 (accessed on 21 July 2020).

- Abualkibash, M.; Elleithy, K. Cloud Computing. The Future of IT industry. Int. J. Distrib. Parallel. Syst. 2012, 3, 1–12. [Google Scholar] [CrossRef]

- Maciaszek, L.A.; Skalniak, T.; Biziel, G. Architectural Principles for Service Cloud Applications. In Business Modeling and Software Design. BMSD 2014. Lecture Notes in Business Information Processing; Shishkov, B., Ed.; Springer: Berlin, Germany, 2020; p. 220. Available online: https://link.springer.com/chapter/10.1007/978-3-319-20052-1_1 (accessed on 21 July 2020).

- Kumar, S.; Tiwari, P.; Zymbler, M. Internet of Things is a revolutionary approach for future technology enhancement: A review. J. Big Data 2019, 6, 111. [Google Scholar] [CrossRef]

- Industrial Internet Consortium. Industrial Internet Reference Architecture. Tech. Rep. 2015. [Google Scholar] [CrossRef]

- Schiefelbein, U.H.; Soligo, D.; Maran, V.; de Oliveira, J.P.M.; Lima, J.C.D.; Machado, A. Internet of Things based on Situation-Awareness for Energy Efficiency. iSys Rev. Bras. Sist. Inf. (Braz. J. Inf. Syst.) 2019, 12, 28–53. [Google Scholar] [CrossRef]

- Xiao, Y.; Kalyanaraman, R.; Ylä-Jääski, A. Middleware for energy-awareness in mobile devices. In Proceedings of the 4th International ICST Conference on COMmunication System softWAre and middlewaRE-COMSWARE ‘09, Dublin, Ireland, 15–19 June 2009. [Google Scholar]

- Mineraud, J.; Mazhelis, O.; Su, X.; Tarkoma, S. A gap analysis of Internet-of-Things platforms. Comput. Commun. 2016, 89–90, 5–16. [Google Scholar] [CrossRef]

- Borgia, E. The Internet of Things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Perry, M. Evaluating and Choosing An Iot Platform; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2016. [Google Scholar]

- Hariri, R.H.; Fredericks, E.M.; Bowers, K.M. Uncertainty in big data analytics: Survey, opportunities, and challenges. J. Big Data 2019, 6, 44. [Google Scholar] [CrossRef]

- Crespo Márquez, A.; de la Fuente Carmona, A.; Antomarioni, S. A Process to Implement an Artificial Neural Network and Association Rules Techniques to Improve Asset Performance and Energy Efficiency. Energies 2019, 12, 3454. [Google Scholar] [CrossRef]

- Wilder-James, E. Breaking Down Data Silos. 2016. Available online: https://hbr.org/2016/12/breaking-down-data-silos (accessed on 12 December 2019).

- ISO/IEC JTC 1. Information Technology. 2015. Available online: http://www.iso.org/iso/big_data_report-jtc1.pdf (accessed on 14 October 2019).

- Lueth, K.L.; Patsioura, C.; Williams, Z.D.; Kermani, Z.Z. Industrial Analytics 2016/2017: The current state of data analytics usage in industrial companies. IoT Anal. 2016, pp. 1–50. Available online: https://digital-analytics-association.de/wp-content/uploads/2016/03/Industrial-Analytics-Report-2016-2017-vp-singlepage.pdf (accessed on 21 July 2020).

- Iot-analytics.com. Predictive Maintenance Report 2019–2024. 2019. Available online: https://iot-analytics.com/product/predictive-maintenance-report-2019-2024/ (accessed on 25 February 2020).

- Rodríguez, F.; Fleetwood, A.; Galarza, A.; Fontán, L. Predicting solar energy generation through artificial neural networks using weather forecasts for microgrid control. Renew. Energy 2018, 126, 855–864. [Google Scholar] [CrossRef]

- Vachtsevanos, G.; Lewis, F.; Roemer, M.; Hess, A.; Wu, B. Intelligent Fault Diagnosis and Prognosis for Engineering Systems. In Intelligent Fault Diagnosis and Prognosis for Engineering Systems; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Mosallam, A.; Medjaher, K.; Zerhouni, N. Data-driven prognostic method based on Bayesian approaches for direct remaining useful life prediction. J. Intell. Manuf. 2016, 27, 1037–1048. [Google Scholar] [CrossRef]

- Mosallam, A.; Medjaher, K.; Zerhouni, N. Component based data-driven prognostics for complex systems: Methodology and applications. In Proceedings of the 1st International Conference on Reliability Systems Engineering, ICRSE 2015, Beijing, China, 21–23 October 2015. [Google Scholar] [CrossRef]

- Jia, X.; Jin, C.; Buzza, M.; Di, Y.; Siegel, D.; Lee, J. A deviation based assessment methodology for multiple machine health patterns classification and fault detection. Mech. Syst. Signal Process. 2018, 99, 244–261. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin-the simulation aspect. In Mechatronic Futures: Challenges and Solutions for Mechatronic Systems and Their Designers; Springer: Berlin, Germany, 2016. [Google Scholar] [CrossRef]

- Roda, I.; Macchi, M. A framework to embed Asset Management in production companies. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 368–378. [Google Scholar] [CrossRef]

- Dunn, S. Asset Management Data and Decision Making—Implementing ISO 55000. 2019. Available online: https://www.assetivity.com.au/article/asset-management/asset-management-data-and-decision-making-implementing-iso-55000.html (accessed on 18 December 2019).

- Woodhouse, J. Asset Management Decision-Making. 2001. Available online: http://plant-maintenance.com/articles/AMdecisions.pdf (accessed on 14 June 2019).

- Woodhouse, J. Asset management: A science emerging. Int. J. COMADEM 2003, 6, 4–10. [Google Scholar]

- Available online: https://www.ge.com/digital/sites/default/files/download_assets/Predix-asset-performance-management-brochure.pdf (accessed on 14 July 2019).

- Guillén, A.J.; Crespo, A.; Gómez, J.F.; Sanz, M.D. A framework for effective management of condition based maintenance programs in the context of industrial development of E-Maintenance strategies. Comput. Ind. 2016, 82, 170–185. [Google Scholar] [CrossRef]

- Ciccozzi, F.; Malavolta, I.; Selic, B. Execution of UML models: A systematic review of research and practice. Softw. Syst. Model. 2019, 18, 2313–2360. [Google Scholar] [CrossRef]

| Sample Basic AM Process (Application) | Apps Big Modules in GE Predix | |||

|---|---|---|---|---|

| APM Health | APM Reliability | APM Strategy | APM Integrity | |

| Criticality Analysis for Assets Hierarchy | Asset Criticality Analysis: Uses default indenture level and severity factors. The User can select factors. | - | - | - |

| Root Cause Analysis | - | Root Cause Analysis: Based on the PROACT® RCA Methodology | - | - |

| PM and Inspection Plan Design | - | - | Reliability Centered Maintenance: Uses SAE Standard JA1012, “Evaluation Criteria for RCM Processes” | Risk Based Inspection: Uses the API 580/1 methods to derive risk and optimized inspection plan |

| PM and Inspection strategy Review/Management | - | - | Asset Strategy Management: Let’s you create a strategy to optimize equipment performance to achieve business goals. | Inspection Management: To manage inspection plans, document the condition of an asset on a mobile device, and track inspection recommendations |

| Predictive/Condition-Based Asset Management | - | Digital Twin blueprints and Predictive diagnostics: Leverages advanced predictive diagnostics, analyzes data and detects and diagnoses well in advance. | - | - |

| Asset Performance Analysis | - | Reliability Analysis: Collection of tools that apply reliability engineering principles. | - | - |

| Life Cycle Cost Analysis | - | - | Life Cycle Cost Analysis:It provides the ability to balance costs, plan budgets, collect performance data and build contingency plans | - |

| Spares Analysis | - | Reliability Analysis/Spares Analysis: Monte Carlo simulation is used to spare analysis. | - | - |

| Health Index | Asset Health Manager: A graphical summary of an asset’s health, based on information stored in various records, is presented. | - | - | - |

| Annual Frequency Failure | Classification | Management Definition | Frequency Factor |

|---|---|---|---|

| 2 ≤ f | Very High | Inadmissible failures | 2 |

| 1 ≤ f < 2 | High | Recurrent failures | 1.5 |

| 0.5 ≤ f < 1 | Medium | Acceptable failures | 1.2 |

| <0.5 | Low | Possible failures | 1 |

| Industrial Safety (30%) | Environmental (12%) | Quality Service (35%) | Availability (14%) | Maintenance Costs (5%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Catastrophic: Very serious effect with damage to the network or fatalities | 100 | Catastrophic: Non-recoverable effect | 100 | Catastrophic: Loss of continuity in electric service for more than 20,000 customers | 100 | Very High: Total loss of capacity of the line | 20 | Very High: Maint. Cost >30,000 € | 5 |

| High: High impact to the net or serious injury or severe damage to third parties (>300,000 M€) | 30 | High: Recoverable impact on vulnerable area | 12 | High: The same for 2000–20,000 customers impacted | 35 | High: Total loss of capacity of the line in grid or branch network with redundancy | 10 | High: >30,000 € Maint. Cost >6000 € | 4 |

| Medium: Average impact or damage to third parties (>50,000 €) | 18 | Medium: Outside impact in non-vulnerable area | 6 | Medium: The same for 200–2000 customers impacted | 12 | Medium: Partial loss of line capacity with possibility of remote manoeuvering | 5 | Medium: >6000 € Maint. Cost >1000 € | 3 |

| Slight | 1 | Slight | 1 | Slight | 1 | L Slight | 1 | Slight | 1 |

| Data Layers in the GIS | Content |

|---|---|

| Fire risk zone | Yes/No |

| Place of public interest | Yes/No |

| Special protection zone (animals) | Yes/No |

| Natural park | Yes/No |

| Vegetation fraction covered (%) | % |

| Railway crossing | Yes/No |

| Main road crossing | Yes/No |

| Populated zone | Yes/No |

| High frequency of persons area | Yes/No |

| Other network crossing AT, MT, BT, Phone | Yes/No |

| Criticality | Value Range |

|---|---|

| Critical | 91–200 |

| Semi-critical | 50–90 |

| Non-Critical | 1–49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crespo Marquez, A.; Gomez Fernandez, J.F.; Martínez-Galán Fernández, P.; Guillen Lopez, A. Maintenance Management through Intelligent Asset Management Platforms (IAMP). Emerging Factors, Key Impact Areas and Data Models. Energies 2020, 13, 3762. https://doi.org/10.3390/en13153762

Crespo Marquez A, Gomez Fernandez JF, Martínez-Galán Fernández P, Guillen Lopez A. Maintenance Management through Intelligent Asset Management Platforms (IAMP). Emerging Factors, Key Impact Areas and Data Models. Energies. 2020; 13(15):3762. https://doi.org/10.3390/en13153762

Chicago/Turabian StyleCrespo Marquez, Adolfo, Juan Francisco Gomez Fernandez, Pablo Martínez-Galán Fernández, and Antonio Guillen Lopez. 2020. "Maintenance Management through Intelligent Asset Management Platforms (IAMP). Emerging Factors, Key Impact Areas and Data Models" Energies 13, no. 15: 3762. https://doi.org/10.3390/en13153762

APA StyleCrespo Marquez, A., Gomez Fernandez, J. F., Martínez-Galán Fernández, P., & Guillen Lopez, A. (2020). Maintenance Management through Intelligent Asset Management Platforms (IAMP). Emerging Factors, Key Impact Areas and Data Models. Energies, 13(15), 3762. https://doi.org/10.3390/en13153762